The most popular abrasive material not only in households, but also in large enterprises is sandpaper.

Depending on the material being processed and the requirements for the surface, the appropriate modification is used in each specific case. Although, in itself, the canvas is not difficult to manufacture and contains only two main components, it is not always easy to understand the markings of sandpaper. This is due to the fact that there is no single standard even in the Russian Federation, not to mention the CIS and global manufacturers. Despite this, to make the right choice, you need to be able to decipher sandpaper symbols.

Currently, the widest range of abrasive components is used for the manufacture of grinding materials. In addition, there are several base options. Below we will consider the criteria by which you need to choose sandpaper for a particular type of work.

Sandpaper grit

Depending on the abrasive crumb fraction, base material and purpose, the entire range of produced abrasive cloth can be divided into several modifications.

Based on the grain size, the following types of sanding cloths are distinguished: fine-grained and coarse-grained. The table shows the grit values of the most commonly used sandpaper:

Initial grindingcorrection of minor surface defects

| GOST R 52381-05 | GOST 3647-80 | Grit size, microns | Scope of application |

| Coarse grain | |||

| P22 | 80-N | 800-1000 | Pre-cleaning |

| P24 | 63-N | 630-800 | |

| P36 | 50-N | 500-630 | |

| P40 | 40-N | 400-500 | Rough wood processing |

| P46 | 32-N | 315-400 | |

| P60 | 25-N | 250-315 | |

| P80 | 20-N | 200-250 | Initial grinding Correction of minor surface defects |

| P90 | 16-N | 160-200 | |

| P100 | 12-N | 125-160 | |

| P120 | 10-N | 100-125 | |

| P150 | 8-N | 80-100 | Treating hardwood before final sanding Sanding soft wood Removing old paint |

| P180 | 6-H | 63-80 | |

| Fine sandpaper | |||

| P240 | 5-H; M63 | 50-63 | Finish sanding of hard wood Intermediate grinding |

| P280 | 4-H; M50 | 40-50 | |

| P400 | M40; N-3 | 28-40 | Surface polishing Sanding for painting Wet grinding |

| P600 | M28; N-2 | 20-28 | |

| Р1000 | M20; N-1 | 14-20 | Sanding ceramics, plastics and metals Wet grinding |

| P1200 | M400 | 10-14 | Polishing, de-glossing |

| Р1500 | M10; N-0 | 7-10 | |

| P2000 | M7; N-01 | 5-7 | |

| Р2500 | M5; N-00 | 3-5 | |

As can be seen from the grain size table, the scope of application of sandpaper is quite wide:

- Carpentry and furniture industries;

- Mechanical engineering and industrial production;

- Manufacturing of non-standard equipment and instrumentation;

- Car repair and painting;

- Construction and finishing works.

This is far from a complete list, and the ways of using sandpaper in everyday life cannot be described at all due to its endless variety.

The most common are three forms of produced emery cloths:

As for the release form, the most common are sheet and roll. In addition, there are ready-made ring modifications for scraping and hand grinders, disk pads for electric drills and some other varieties.

Application

- Sandpaper for wood in carpentry is necessary when preparing the surface for painting or varnishing.

- In construction, sandpaper is used to clean out sagging on plaster and putty, and wood fibers before use. The sandpaper also helps get rid of paint smudges.

- Car repair: stripping old paint, preparing the surface for puttying, matting the gloss.

- In the production and repair of furniture and in many other industries.

How to choose?

When choosing, you should pay attention not only to the cost, but also to the characteristics of the product.

- Grain size of the material. The choice of fraction is made based on the purpose of the purchase: P22...P60 sandpaper is suitable for the primary preparation of wood. To prepare a wood or metal surface for painting, choose P240 or finer.

- Material is the basis. For long-term work, it is worth buying an abrasive on a fabric or combined basis. If manual leveling of surfaces is expected, paper will do.

- For manual labor, you can take a product of any format. For grinding machines and machines, it is more convenient to choose special wheels or strips that do not need to be cut and glued.

Marking of sandpaper depending on its purpose: table

Depending on the specifics of the work, coarse sandpaper is divided into several main groups:

| Marking | Types of jobs |

| P22; P24;P36 | Preparatory work: rust removal Elimination of large surface defects |

| 80-N; 63-N; 50-N | |

| P40; P46; P60 | Rough surface treatment |

| 40-N; 32-N; 25-N | |

| P80; P90; P100; P120 | Pre-grinding |

| 20-N; 16-N; 12-N; 10-N | |

| P150; P180 | Final sanding and finishing |

| 8-H; 6-H |

Fine-grained sandpaper is also marked according to the features of use:

| Marking | Types of jobs |

| P240; P280 | Sanding hardwood |

| 5-H; M63 | |

| P400; P600 | Polishing surface preparation for painting |

| M28; M40; 2-H; 3-H | |

| Р1000 | Grinding of ceramic surfaces, plastics and metals |

| M20; 1-H | |

| P1200; P1500; P2000; Р2500 | Polishing and deglazing |

| M14; M10; M7; M5; N-0;N-00; N-01 |

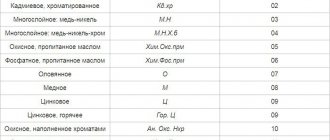

When purchasing sandpaper, you may find other markings on the back side. Each of them carries a certain meaning, for example, the type of abrasive powder, the method of its attachment, the characteristics of the adhesive mixture and the type of base and its mechanical properties. Let's look at the basic notation.

- The name “P” indicates the abrasive structure of the material;

- The letter “L” denotes the form of release, in this case – sheet;

- The numbers “1” and “2” indicate the purpose of the abrasive cloth: 1 – for grinding soft surfaces, 2 – metal and other hard and especially hard materials;

- Resistance to moisture is indicated by the symbols “L1”, “L2” or M;

- The designation “P” indicates that exposure to moisture and dampness is extremely undesirable.

In addition to these designations, special attention must be paid to the properties of the abrasive particles themselves.

Marking and base

To carry out most work, it is enough to know the grain size of the material. But there are still a lot of classification parameters that the material code contains. You can study them using the table below:

From all this, we recommend paying attention to the base of the skin, on which its durability and ease of use largely depend. The main options are paper and fabric base. The paper can be regular or moisture resistant and has high strength. The advantages are its cost, preservation of size during operation and the ability to apply the smallest particles. The disadvantage is low strength and wear resistance.

Polyester and cotton are most often used as the fabric base for sanding paper. To increase strength and resistance to moisture, the fabric is impregnated with polyester resin. The main advantages are tensile strength and elasticity. Fabrics are divided into several classes:

- J – Used for clean edge and profile sanding.

- X – for heavy work with a high degree of contamination.

- W and Y – have high strength and are used mainly in machine processing.

The main advantages of the fabric base are high strength, resistance to moisture and wear. Disadvantages - higher cost and likelihood of elongation during operation.

Among other types of sandpaper bases, it is worth noting a combined material - fabric glued to paper, as well as fiber - a dense and hard composition used for the production of fiber discs.

Types of abrasive

There are several most common materials that serve as raw materials for the manufacture of abrasive powder:

Pomegranate

. This abrasive is a natural mineral, therefore it is absolutely environmentally safe for humans. The natural structure of the particles allows this sandpaper to be used effectively for processing all types of wood.

Silicon carbide

characterized by high levels of hardness and strength. This type of sandpaper is used for grinding metals, fiberglass and other materials that are characterized by increased hardness.

Ceramic-based abrasive

used to form the surface and eliminate large defects during primary wood processing, polishing parquet, etc.

Aluminium oxide

It is quite fragile, so during the grinding process the crystals can crumble, forming new cutting edges instead of dull ones. This feature significantly extends the service life of the abrasive cloth.

There are other fillers, but they are quite rare and are used for special processing.

Considering the availability and low cost of sandpaper, we can say with confidence that no competition will threaten it in the near future. The versatility and ease of processing, as well as the variety of materials processed, make the abrasive cloth indispensable both in everyday life and in industrial conditions.

Manufacturing

The production of such a seemingly simple thing as a strip of paper with abrasive coating is a rather complex technological process and requires appropriate equipment and training of workers. At the first stage, the characteristics of the future sandpaper are printed on the base tape in such a way that they are repeated at a distance equal to the width of the tape.

Next, the tape is impregnated with components to make it waterproof. On the next unit, glue is applied to the surface of the base. Next, pre-sifted and calibrated abrasive chips are applied to the layer of binder material. The next stage is drying in an oven, where the adhesive mass, reacting to the temperature, is baked and firmly attaches the abrasive to the base. Next comes the application of the fixing layer and final drying.

Machine for cutting paper into rectangular sheets

The last operation is cutting the finished tape into rectangular sheets or sheets of other shapes for the manufacture of abrasive belts, gluing them, drying and packaging.

Documentation

Grinding and polishing materials on a paper-like carrier or wicker base are produced in light of the requirements of regulatory documents:

- GOST 6456-82 Sanding paper.

- GOST 13344-79 Waterproof fabric sanding paper.

- GOST 5009-82 Sanding paper and fabric sandpaper and other documents.

The rules for production, grain size, and application are described. The explanation of the marking (designation) of sandpaper is given.

Designation, name

To properly use abrasive material, you need to know about its properties and purpose. For this purpose, an inscription containing information about the abrasive is imprinted on the reverse side with indelible paintwork.

Designation according to GOST: L2E700×110S1G15A25-NMA GOST4, where

- Construction type of abrasive material:

- L – in sheets; for roll, there is no abbreviation.

It often happens that a seemingly insignificant thing turns out to be truly irreplaceable, and its scope of application is quite wide. Sandpaper is just one of these necessary things. It is also called sandpaper or sandpaper. It is the most popular abrasive, for which there is no alternative today. Every furniture maker, mechanic, sculptor, as well as car painter and any good owner needs it.

Release form

The finished product is available in several forms.

Available in the form of sheets or rolls. The leaf shape is characteristic of large fractions that are difficult to bend or roll. Fine-grain paper is available in roll form. In addition to these forms, there are also:

- abrasive mesh;

- abrasive wheels;

- sanding belts.

The form can be intended for installation in a specific mechanism for processing parts and have a specific appearance.

Types of sandpaper by manufacturing method

There are various methods for applying abrasive powder to the substrate. The most common of them are mechanical and electrostatic.

Cooper slag (abrasive powder)

With the mechanical application method, abrasive particles fall freely onto a base lubricated with glue, and excess powder is removed and can be reused. This method is often used to produce high-grit sandpaper.

Electrostatic method of applying abrasive powder

In the case of the electrostatic method, the abrasive particles and the base tape are electrified with opposite polarity. According to the laws of physics, unlike charges attract, and particles of abrasive powder stick to the base.

Sharpness of cycles

When working, especially with dense types of wood, the scraper becomes dull quite quickly. To sharpen it, use special bars of 20*60 millimeters, in which they are scraped and clamped in a vice. The file is passed alternately away from you and towards you, sharpening the scraper at the desired angle.

It is important to ensure the correct transverse profile of the cycle - the middle should smoothly rise above the edges by approximately half a millimeter.

It is also fashionable to sharpen a cycle using a whetstone - this method requires practiced skill, a steady hand and a good eye.