Marking of bolt strength class

For a long time in our country, all hardware was produced in accordance with GOST 22353-77, but today its rules are no longer relevant. All technical characteristics of bolts comply with GOST R 52644-2006. However, in the bins of grandfather's balconies, as well as in warehouses and workshops, bolts with the old markings are still found. And they are sometimes found on an industrial scale. Therefore, let's say a few words about the Soviet GOST and what the old markings meant.

It is represented in two parts: letters at the top and numbers at the bottom. The letters indicate the mark of the factory where the hardware was manufactured, for example, WT, Ch, L, OC, D and others. This is usually followed by numbers reflecting the temporary resistance of the hardware in MPa, divided by ten. Next are the letters again, by which we can determine the level of resistance of the fastener to aggressive environmental conditions. For example, HL would indicate that the bolt is designed for cold climates. The numbers below indicate the heat number.

Sometimes you can see an arrow on the bolts pointing in a counterclockwise direction. This means that you are holding hardware with a left-hand thread. If the thread is right-handed, then the designation is simply missing.

Characteristics of stainless steels

Austenitic steels contain 15-26% chromium and 5-25% nickel, which increase corrosion resistance and are virtually non-magnetic.

It is austenitic chromium-nickel steels that exhibit a particularly good combination of machinability, mechanical properties and corrosion resistance. This group of steels is most widely used in industry and in the production of fasteners: stainless bolts, stainless nuts, stainless studs, stainless screws, and stainless washers.

Steels of the austenitic group are designated by the initial letter “A” with an additional number, which indicates the chemical composition and applicability within this group:

Austenitic structure

| Steel group | Material number | Short designation | AISI number |

| A1 | 1.4305 | X 10 CrNiS 18-9 | AISI 303 |

| A2 | 1.4301 / 1.4303 | X 5 CrNi 18-10 / X 4 CrNi 18-12 | AISI 304 / AISI 305 |

| A3 | 1.4541 | X 6 CrNiTi 18-10 | AISI 321 |

| A4 | 1.4401 / 1.4404 | X 5 CrNiMo 18-10 / X 2 CrNiMo 18-10 | AISI 316 / AISI 316 L |

| A5 | 1.4571 | X 6 CrNiMoTi 17-12-2 | AISI 316 TI |

Steel A2 (AISI 304 = 1.4301 = 08Х18Н10) is a non-toxic, non-magnetic, non-hardening, corrosion-resistant steel. It is easy to weld and does not become brittle. May exhibit magnetic properties as a result of mechanical processing (washers and some types of screws). This is the most common group of stainless steels. The closest analogues are 08Х18Н10 GOST 5632, AISI 304 and AISI 304L (with reduced carbon content).

Fasteners and products made from A2 steel are suitable for use in general construction work (for example, when installing ventilated facades, stained glass structures made of aluminum), in the manufacture of fences, pumping equipment, instrument making from stainless steel. steel for oil and gas production, food, chemical industries, and shipbuilding. Retains strength properties when heated to 425°C, and at low temperatures down to -200°C.

Steel A4 (AISI 316 = 1.4401 = 10Х17Н13М2) - differs from steel A2 by adding 2-3% molybdenum. This significantly increases its ability to resist corrosion and acids. A4 steel has higher antimagnetic characteristics and is absolutely non-magnetic. The closest analogues are 10Х17Н13М12 GOST 5632, AISI 316 and AISI 316L (low carbon content).

Fasteners and rigging made from A4 steel are recommended for use in shipbuilding. Fasteners and products made from A4 steel are suitable for use in acidic and chlorine-containing environments (for example, swimming pools and salt water). Can be used at temperatures from -60 to 450°C.

Strength classes

All austenitic steels (from “A1” to “A5”) are divided into three strength classes, regardless of grade. Steels in the annealed state have the lowest strength (strength class 50).

Since austenitic steels are not hardened by hardening, they have the greatest strength in the cold-worked state (strength classes 70 and 80). The most widely used fasteners are A2-70 and A4-80 steels.

Modern marking of bolts by strength

The new GOST has changed little both in the arrangement of symbols and in their semantic meaning. At the top we can still see the maker's mark. Next comes the swim number.

The strength class of the hardware is indicated below according to the new GOST. Here you can also find the letter S, which says that we have a high-strength bolt with a hex head with an increased size. The designation of the class of resistance to harmful atmospheric influences also remains. It comes last.

INPO: Technical Library

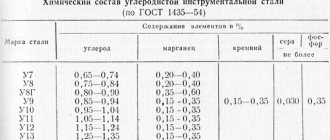

Chemical composition of stainless steel and compliance with standards

Stainless steels include a group of corrosion-resistant steels containing at least 10.5% chromium and low carbon content. As an example, here is a simple table of various alloys with iron.

| Cast iron | Fe + C > 2% |

| Carbon steel | Fe + C 5% |

| Stainless steel | Fe + C 10.5% |

In addition to Chromium as the “main stainless component,” stainless steel may contain Nickel, Molybdenum, Titanium, Niobium, Sulfur, Phosphorus and other alloying elements that determine the properties of steel.

Correspondence table of the main grades of stainless steels and chemical composition

Markings

If you are not a professional builder, you should not delve into the jungle of bolt classifications. It is important to know that, as already mentioned, the numbers on the head of the bolt indicate the strength class. Usually these are two numbers written with a dot, for example, 3.6 or 10.9.

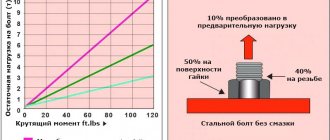

The first number indicates the load on the threaded connection that the hardware can withstand. More precisely, this is one hundredth of the nominal value of the tensile strength of the hardware. The measurement is carried out in MPa.

Example: if you see 8.8 on a bolt, this means that the tensile strength of the bolt will be 8×100 = 800 MPa.

The next figure indicates the ratio of the yield strength to the tensile strength multiplied by ten. From two numbers you can calculate the yield strength of the material. To do this, they are multiplied by each other, and then by another ten.

Example: we return to the same 8.8. 8×8 x 10 = 640 N/m.

It is important to understand that the maximum working load limit of a bolt is the yield strength. When calculating a bolt connection for a given load, use a coefficient of 0.5-0.6 from the yield strength. For example, if an M14 bolt of strength class 8.8 has a cross-sectional area of about one square centimeter and a body diameter of about 12 mm, then its tensile strength will be 8 tons, its yield strength will be 6.4 tons, and its design load will be 6.4× 0.5 = 3.2 t.

Stainless steel bolt markings

Among the markings on a bolt made of stainless steel, the marking of the steel itself, A2 or A4, comes first. Next comes the tensile strength, for example 50, 60, 70, etc. These numbers also indicate one tenth of the tensile strength of carbon steel, measured in MPa.

Compound

The mechanical, physical and technological features of A2 stainless steel are ensured by the optimal combination of alloying components. The composition of steel includes the following elements that affect the characteristics:

| Carbon, C | Silicon, Si | Sera, S | Phosphorus, P | Nickel, Ni | Manganese, Mn | Molybdenum, Mo | Chromium, Cr |

| 0,1-0,5 | 1,0 | 0,3 | 0,05 | 8-19 | 2,0 | Up to 5.0 | 15-20 |

The table shows the percentage of elements included in A2.

When replacing nickel with vanadium, an identical grade of steel is obtained, but characterized by increased strength and wear resistance. The main difference between the A2 steel grade and other austenitic grades of this category (A) is the increased copper (Cu) content, up to 4% (not indicated in the table)

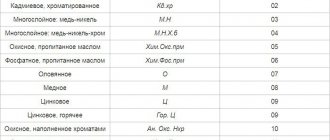

Nut strength markings

The same rules apply to nuts as to bolts. The marking itself is located on the side of the nut. It is supplied in abbreviated form, so the full designation must be looked at on the packaging.

First of all, there is the name of the product, then the accuracy class. But it, however, is not always indicated, since at the end of the description there is a state standard according to which this type of nut is manufactured, where all the necessary information is written down. The following is the type of thread: K - conical, T - trapezoidal, M - metric. The diameter of the nut in millimeters is also written here. Sometimes in this place they also give the thread pitch in millimeters, which is indicated only in cases where the thread is very small and the direction of the thread if it is left.

Next comes the strength class and coating value in microns, indicated as a number from one to thirteen. And finally, the state standard, which was already mentioned above.

Nuts have seven strength grades: 4, 5, 6, 8, 9, 10, 12. As with a bolt, the strength grade indicates one-hundredth of the tensile strength, which is the recommended value for evenly distributing pressure on the fastener.

But there are also differences from the markings of bolts: the indicated strength classes are only suitable for standard and high nuts. On the side of the low nut you will see other designations: 04 and 05. They say that this hardware is not intended for high loads.

Description of stainless steels A2 and A4. Characteristics, analogues, application for the manufacture of fasteners

A2 and A4 are abbreviated names for grades of stainless austenitic steels. Austenitic steel has a number of remarkable properties, which have ensured its very wide use in the national economy. Steels A2 and A4 are non-toxic and corrosion resistant. They are well subjected to mechanical and heat treatment, as well as welding. Fasteners made from A2 and A4 steels are practically non-magnetic, strong and durable. They retain their properties perfectly at high and low temperatures.

A2 steel has a domestic analogue - stainless steel grade 08Х18Н10 and a foreign analogue - grade AISI 304 (in the USA). Assembly units, parts and fasteners made of A2 steel are used in the oil, food, chemical and gas industries; in instrument making and shipbuilding; in construction during the installation of ventilated facades and stained glass structures, as well as in the manufacture of pumping equipment. Products made from A2 steel retain their strength properties over a wide temperature range: from low (-200 degrees Celsius) to high (+425 degrees Celsius).

A4 steel is similar in its characteristics to A2, but its scope of application has expanded significantly due to the addition of 2-3% molybdenum, which contributes to its higher resistance to corrosion in environments containing acids, salts and chlorine. Products made from A4 stainless steel retain their strength properties at low (up to -60 degrees Celsius) and high (up to +450 degrees Celsius) temperatures. These products are used: in the chemical industry, where they are exposed to aggressive environments; in shipbuilding (fastening elements and rigging products) for protection from the destructive effects of sea water; in swimming pools containing chlorinated water. Stainless steel A4, like A2, also has a domestic analogue - steel type 10Х17Н13М2 and a foreign analogue - AISI 316 (in the USA).

A2 steel and A4 steel are excellent for the manufacture of stainless fasteners of high accuracy class A, which are used to create strong and durable critical connections. Bolts and nuts of this class are made, for example, on computer numerical control (CNC) lathes. The difference in thread diameters, external for a bolt and internal for a nut, after finishing on a machine does not exceed 0.25...0.3 millimeters. However, the price of parts made from stainless steel will be significantly higher than those made from ordinary carbon steel. The strength class for bolts made of stainless austenitic steel grade A2 and steel grade A4 is 50, 70 or 80.

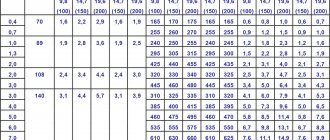

Calculation of loads for stainless steel bolts

Knowing the strength characteristics of austenitic alloys, it is not difficult to calculate the maximum load on bolts using the formula.

For example, an M12, A2-70 bolt is taken. Np0.2 = As x Rp0.2 = 84.3 x 450 = 37935 N

, Where:

As

– design cross-sectional area M12 (see GOST R ISO 3506 Table A.1.)

Rp0.2

– yield strength

To determine the calculated working load, the resulting value must be divided by at least 20: 37935 / 20 = 1896 kg, and for greater confidence in the safety of the bolt kit, it is better to divide by 30.

Strength class is the most important characteristic of stainless steel, prescribed in the national standard GOST R ISO 3506-1-2009, which should be taken into account when calculating the load on a bolted or stud joint.

Source: krepcom.ru