Wear-resistant steels, their grades and purpose

Steel is a compound of iron with carbon and other elements that can be forged or deformed. Steel is classified according to the composition of chemical elements, the manufacturing method and the amount of harmful impurities, the method of application and the microstructure.

One type of steel is wear-resistant steel. These are special alloys that are designed for use in extremely difficult conditions. They can withstand exceptional abrasive wear and the effects of sliding or impact.

Wear-resistant steels have increased hardness due to the use of manganese and other alloying elements in their composition. Steels with this composition are prone to intense hardening.

The more the element is exposed to superloads that cause stresses in the steel that are greater than its yield strength, the more intense the increase in its hardness and wear resistance occurs, with a generally significant viscosity.

Wear-resistant steels C500 are the best wear-resistant steels in the world

Steels and alloys are wear-resistant under conditions of abrasive wear (rolling friction, sliding friction). Parts such as ball and roller bearings, shafts, and parts of road and earth-moving machines operate under such conditions.

In order for a material to have increased wear resistance under such conditions, high hardness is required.

Along with high-carbon steels, white cast iron and hard alloys are used as wear-resistant materials. The latter have exceptionally high wear resistance.

A special group of wear-resistant steels consists of ball bearing steels having about 1% C and from 0.6 to 1.5% Cr: ShKh6 (0.6% C), ShKh9 (0.9% C), ShKh15 (1.5% C ) and etc.

Graphitized steel is also used as a wear-resistant alloy. This steel contains a high content of carbon (1.3...1.75%) and silicon (1.3...1.75). Due to this, part of the carbon in steel is released in the form of graphite.

Graphitized steels are used for the manufacture of dies, gauges, and shafts.

Wear-resistant materials under conditions of impact wear in an abrasive jet. Typical parts subject to such wear are workers of organic disintegrators (mills for crushing sand).

The most wear-resistant materials under conditions of impact abrasive wear are C500 steel. Wear-resistant armor C500 is widely used in the cement and mining industries. Useful properties: wear resistance, impact resistance, bullet resistance, abrasion resistance, explosion protection, ideal weldability, allow you to forget about HARDOX and steel 110g13, g13, 110g13l (cast version) forever.

Wear-resistant high-manganese steel grade G13 for work under wear conditions accompanied by high specific loads. G13 steel contains 1...1.4% carbon and 12...14% manganese, it has an austenitic structure and relatively low hardness (200...250 HB). G13 steel is widely used for the manufacture of such parts as ball mill bodies, rock crusher jaws, rail crosses, caterpillar tracks, dredge canopies, etc. The tendency to intense hardening is a characteristic feature of austenitic steels.

Wear-resistant, impact-resistant bullet-resistant steel S-500 exceeds 110g13 and HARDOX by 10 times in difficult wear conditions, accompanied by large specific and impact loads

Steels and alloys are wear-resistant under conditions of abrasive wear (rolling friction, sliding friction). Parts such as ball and roller bearings, shafts, and parts of road and earth-moving machines operate under such conditions.

In order for a material to have increased wear resistance under such conditions, high hardness is required.

Along with high-carbon steels, white cast iron and hard alloys are used as wear-resistant materials. The latter have exceptionally high wear resistance.

A special group of wear-resistant steels consists of ball bearing steels having about 1% C and from 0.6 to 1.5% Cr: ShKh6 (0.6% C), ShKh9 (0.9% C), ShKh15 (1.5% C ) and etc.

Graphitized steel is also used as a wear-resistant alloy. This steel contains a high content of carbon (1.3...1.75%) and silicon (1.3...1.75). Due to this, part of the carbon in steel is released in the form of graphite.

Graphitized steels are used for the manufacture of dies, gauges, and shafts.

Wear-resistant materials under conditions of impact wear in an abrasive jet. Typical parts subject to such wear are workers of organic disintegrators (mills for crushing sand).

The most wear-resistant materials under conditions of impact abrasive wear are C500 steel. Wear-resistant armor C500 is widely used in the cement and mining industries. Useful properties: wear resistance, impact resistance, bullet resistance, abrasion resistance, explosion protection, ideal weldability, allow you to forget about HARDOX and steel 110g13, g13, 110g13l (cast version) forever.

Wear-resistant high-manganese steel grade G13 for work under wear conditions accompanied by high specific loads. G13 steel contains 1...1.4% carbon and 12...14% manganese, it has an austenitic structure and relatively low hardness (200...250 HB). G13 steel is widely used for the manufacture of such parts as ball mill bodies, rock crusher jaws, rail crosses, caterpillar tracks, dredge canopies, etc. The tendency to intense hardening is a characteristic feature of austenitic steels.

Wear-resistant, impact-resistant bullet-resistant steel S-500 exceeds 110g13 and HARDOX by 10 times in difficult wear conditions, accompanied by large specific and impact loads

irontub.ru

Wear-resistant steel grades

In industry, cold-worked materials are widely used, for example, 110g13. Also used for mechanism parts is 110g13l grade, which contains from 1 to 1.4 percent carbon. High-manganese steel G13g13 is used.

As for foreign brands, preference is usually given to relatively wear-resistant materials Hardox, Raex, Fora, Xar.

As part of the substitution of imported materials, our country widely uses Russian armored steel type A3, which is more affordable, but at the same time superior to its analogues. In Russia, the 45X2NMFBA brand is also used.

Purpose of wear-resistant steels

Such materials are produced for units and equipment used in industrial areas related to sawmilling and mining, waste processing, soil cultivation and more.

These steels easily withstand impacts, abrasive friction and high pressure. They are used, for example, to make excavator buckets, scoops of earth-moving machines, jaws of stone crushers, caterpillar tracks and many other parts.

Similar steels are required for elements of such units. They are divided into three types:

ball bearings (rollers and bearing balls are made from them),

graphitized (pistons, crankshafts and other shaped castings are made from them),

high-manganese (track links and much more are made from these steels).

Source

Structural wear-resistant steels

The term “structural steels” refers to a number of alloys used in the manufacture of various components, parts, structures and mechanisms in mechanical engineering and the construction field. Structural steels are distinguished from other types by their particular strength.

Structural steels have several classifications. In particular, they can be divided according to the content of carbon and additives into carbon and alloyed; by processing methods (cemented and improved), by purpose - spring, bearing. A special category of such steels are wear-resistant alloys, developed for work in extremely difficult conditions, where there is high abrasive wear, wear as a result of sliding and impacts. These alloys are developed specifically for mechanisms and equipment operating in the mining and sawmilling industries, waste processing and scrap metal, in road construction, soil cultivation, etc.

Wear-resistant steels must have increased hardness. This is achieved in various ways. As a rule, to obtain this type of alloy, various alloying elements are used, in particular manganese. Among domestic alloys, such steel is high-manganese steel G13. It has from 1 to 1.4% carbon and from 12 to 14% manganese in its composition. Since this steel is austenitic, its characteristic feature is only resistance to intense hardening.

Ball bearing steels are designed to operate under conditions of increased abrasive wear resulting from sliding and rolling friction. These steels contain approximately 1% carbon and up to 1.5% chromium. Such alloys include domestic steels ШХ6, ШХ9, ШХ15.

Standing apart are high-strength wear-resistant alloy military steels of type A3 and steel produced by the SSAB Oxelosund AB concern, in particular, a line of alloys under the general name Hardox. Just like the above-described brands of ball bearing steels, Hardox steels have a high chromium content. For example, in the Hardox 500 brand it is from 1 to 1.5% depending on the thickness of the sheet. However, the carbon content of these alloys is much lower. Some grades of this brand include only 0.2% C. Carbon concentration affects such characteristics of steels as hardness and strength. Despite the fact that Hardox alloys are low-carbon alloys, they are nevertheless high-strength. For example, Hardox 450 steel has a hardness of 425-475 HB and a tensile strength of 1400 MPa. The manufacturer achieves this by using various innovative techniques, such as myroalloying, ladle purging with inert gases, and selecting feedstock to high standards. The concern's plants practice, in particular, the use of ore with low sulfur content. Comparative tests at the Uralvagonzavod of foreign and Russian steels as part of the import substitution program show that HARDOX is many times inferior to A3.

Laboratory tests for abrasion and wear do not allow HARDOX to be used for more than 3 months, while A3 is almost eternal.

In domestic practice, steel with a high carbon and silicon content - the so-called graphitized steel - is also used as a wear-resistant alloy. The amount of these two elements varies from 1.3 to 1.75%. Due to the presence of silicon, part of the carbon forms graphite. These alloys are used for smelting shafts, producing dies, gauges, and molds.

High-manganese steels like the G13 grade are inferior in hardness (this characteristic is approximately 200-250 HB), but are inexpensive options for wear-resistant steels. This alloy acquires maximum wear resistance after quenching at temperatures from 1000 to 1100 ° C and cooling in air. Such steel can be used to produce links for tractor tracks and crosspieces installed on railways.

The use of wear-resistant steels is very profitable and promising in any industry where parts, assemblies and other products made of steel alloys are subject to increased loads. Therefore, every day the demand for such steels is growing steadily and rapidly.

The term “structural steels” refers to a number of alloys used in the manufacture of various components, parts, structures and mechanisms in mechanical engineering and the construction field. Structural steels are distinguished from other types by their particular strength.

Structural steels have several classifications. In particular, they can be divided according to the content of carbon and additives into carbon and alloyed; by processing methods (cemented and improved), by purpose - spring, bearing. A special category of such steels are wear-resistant alloys, developed for work in extremely difficult conditions, where there is high abrasive wear, wear as a result of sliding and impacts. These alloys are developed specifically for mechanisms and equipment operating in the mining and sawmilling industries, waste processing and scrap metal, in road construction, soil cultivation, etc.

Wear-resistant steels must have increased hardness. This is achieved in various ways. As a rule, to obtain this type of alloy, various alloying elements are used, in particular manganese. Among domestic alloys, such steel is high-manganese steel G13. It has from 1 to 1.4% carbon and from 12 to 14% manganese in its composition. Since this steel is austenitic, its characteristic feature is only resistance to intense hardening.

Ball bearing steels are designed to operate under conditions of increased abrasive wear resulting from sliding and rolling friction. These steels contain approximately 1% carbon and up to 1.5% chromium. Such alloys include domestic steels ШХ6, ШХ9, ШХ15.

Standing apart are high-strength wear-resistant alloy military steels of type A3 and steel produced by the SSAB Oxelosund AB concern, in particular, a line of alloys under the general name Hardox. Just like the above-described brands of ball bearing steels, Hardox steels have a high chromium content. For example, in the Hardox 500 brand it is from 1 to 1.5% depending on the thickness of the sheet. However, the carbon content of these alloys is much lower. Some grades of this brand include only 0.2% C. Carbon concentration affects such characteristics of steels as hardness and strength. Despite the fact that Hardox alloys are low-carbon alloys, they are nevertheless high-strength. For example, Hardox 450 steel has a hardness of 425-475 HB and a tensile strength of 1400 MPa. The manufacturer achieves this by using various innovative techniques, such as myroalloying, ladle purging with inert gases, and selecting feedstock to high standards. The concern's plants practice, in particular, the use of ore with low sulfur content. Comparative tests at the Uralvagonzavod of foreign and Russian steels as part of the import substitution program show that HARDOX is many times inferior to A3.

Laboratory tests for abrasion and wear do not allow HARDOX to be used for more than 3 months, while A3 is almost eternal.

In domestic practice, steel with a high carbon and silicon content - the so-called graphitized steel - is also used as a wear-resistant alloy. The amount of these two elements varies from 1.3 to 1.75%. Due to the presence of silicon, part of the carbon forms graphite. These alloys are used for smelting shafts, producing dies, gauges, and molds.

High-manganese steels like the G13 grade are inferior in hardness (this characteristic is approximately 200-250 HB), but are inexpensive options for wear-resistant steels. This alloy acquires maximum wear resistance after quenching at temperatures from 1000 to 1100 ° C and cooling in air. Such steel can be used to produce links for tractor tracks and crosspieces installed on railways.

The use of wear-resistant steels is very profitable and promising in any industry where parts, assemblies and other products made of steel alloys are subject to increased loads. Therefore, every day the demand for such steels is growing steadily and rapidly.

irontub.ru

Wear-resistant steel

Wear-resistant steels include alloys intended for use in extreme conditions. Thanks to their special chemical composition, they withstand severe abrasive wear, exceptional mechanical and compressive loads, sliding and friction. There are many manufacturers and types of rolled products on the high-strength steel market, which can be difficult to understand even for professionals. From this article you will learn how to choose the right wear-resistant steel, and why in different industries it is simply necessary to use high-quality wear-resistant alloys.

Characteristics of wear-resistant steels

The main property of wear-resistant steels is increased hardness, which is ensured by the presence of manganese and other alloying elements in the composition. Moreover, the stronger the load on the element, the more wear-resistant and hard the part becomes, and the destruction of the surface and internal structure does not occur. With high strength values, the material remains plastic, does not crumble, and can be welded. When choosing a high-strength alloy, it is important to consider the conditions and intensity of operation of the part or assembly. Hardened rolled products have increased resistance to all types of wear.

Ball bearing steels. Marking, heat treatment.

For the manufacture of rolling elements and bearing rings of small sections, high-carbon chromium steel ShKh15 (0.95-1.0% C and 1.3-1.65% Cr) is usually used, and for large sections - chromium-manganese steel ShKh15SG (0.95-1.05% C, 0.9-1.2% Cr, 0.4 -0.65% Si and 1.3-1.65% Mn), calcined to great depth. Steels have high hardness, wear resistance and resistance to contact fatigue. Steels are subject to high requirements for the content of non-metallic inclusions, since they cause premature fatigue failure. Carbide heterogeneity is also unacceptable.

For the manufacture of rolling bearing parts operating under high dynamic loads, case-hardened steels 20Х2Н4А and 18ХГТ are used. After gas carburizing, high tempering, quenching and tempering, bearing parts made of steel 20Х2Н4А have 58-62 HRC on the surface and 35-45 HRC in the core.

Ш – index of this group of steels. X - indicates the presence of chromium in the steel. The following number shows the chromium content in tenths of a percent; in the indicated steels, 0.6% and 1.5%, respectively. Alloying elements included in the steel composition are also indicated. Carbon content more than 1%.

Ball bearing steels are high-carbon or low-carbon steels in a cemented state with high hardness. They are usually alloyed with chromium.

Characteristics of wear-resistant steels

The main property of wear-resistant steels is increased hardness, which is ensured by the presence of manganese and other alloying elements in the composition. Moreover, the stronger the load on the element, the more wear-resistant and hard the part becomes, and the destruction of the surface and internal structure does not occur. With high strength values, the material remains plastic, does not crumble, and can be welded. When choosing a high-strength alloy, it is important to consider the conditions and intensity of operation of the part or assembly. Hardened rolled products have increased resistance to all types of wear.

Areas of application of wear-resistant alloys

The use of high-strength steels increases the service life of equipment, machines and mechanisms, significantly reduces the costs of their repair and maintenance, and eliminates production downtime. Rolled metal is used in a variety of industries.

- Automotive

production Production of parts and assemblies subject to intense loads and operating under friction conditions - rollers and bearing balls, bushings, replaceable linings, piston rings, crankshafts and other shaped products, armored elements. - Road and construction equipment

Manufacturing of excavator buckets, cutting edges of equipment, visors of dredges, hydraulic hammers, leveling elements for asphalt paving machines. As a lining for equipment chutes, crushers, containers, drum blades, concrete mixers. - Heavy quarry and mining equipment

Manufacturing of cutting edges of equipment, bodies for dump trucks, transportation tanks and chutes, bunkers, lining of storage tanks and other elements of crushers, cutting tools. - Railway industry

Cladding of cars, as elements of railway tracks, links of caterpillar mechanisms, crosspieces, etc. - Agricultural machinery and equipment for logging

End mechanisms of a timber loader, reloader, elements of a squeezing press, plow equipment, equipment for transporting and storing silage. - Machine tool industry

As elements of production equipment subjected to severe loads and friction: shafts, assemblies, assemblies, parts. - Construction industry

Manufacturing of metal structures for various purposes, requiring special structural strength. For these purposes, structural grades are used.

Types and grades of wear-resistant steels

When studying the classification and selection of wear-resistant alloys, it is necessary to take into account that a number of brands of domestic manufacturers are designated by indices, and foreign markings do not contain information on the chemical composition.

Graphitized grades (U16 (EI336), 60G, 65G, 70G, 40Х, 40ХН, 45ХН, etc.)

— characterized by a high carbon content, the composition also includes chromium, nickel, and graphite. Rolled products are strengthened under dynamic loads and are difficult to process.

Ball bearing alloys GOST 801-78 (ШХ20, ШХ15)

– are a type of tool steel and have high strength and wear resistance, hardness and the required level of toughness.

High-manganese grades (G13L, 110G13L)

– in addition to manganese, the composition also includes iron, carbon, and chromium. They have the highest wear resistance, which is combined with low hardness and high strength. According to domestic standardization, alloys comply with GOST 977-88.

As you can see, the high quality and reliability of high-strength steels make their use justified in many industries and mechanical engineering. These alloys have firmly gained a position in the rolled metal market and are very popular.

Source

Types of wear-resistant metals

As already mentioned, there are many types of wear-resistant metals on the market, including:

- Ball bearing alloys are a type of tool steels that have high characteristics of strength, hardness, wear resistance, as well as the required level of toughness;

- Graphitized steel grades contain elements such as carbon, graphite, nickel and chromium; characterized by an increase in metal strength with increasing load, but is difficult to process;

- High-manganese grades of metal - contain elements such as manganese, chromium, carbon, iron; They are distinguished by the highest wear resistance, high strength and low hardness.

Ferrites

To reduce electrical losses, an increase in resistivity is used. Magnetic steel plays an important role in modern manufacturing. Magnetic materials—ferrites—have greater resistance. Ferrites are obtained from oxides using powder metallurgy. Such materials have ferromagnetic and dielectric properties, which allows them to be used where high and ultrahigh frequencies are used.

The cost of ferrite cores is lower than others due to production automation. Alloys can be divided into 4 groups:

Properties of stainless steels

Stainless steel contains 10 to 20% chromium, which makes the steel extremely resistant to corrosion (rusting). When steel contains more than 11% chromium, it is approximately 200 times more resistant to corrosion than steels that do not contain chromium. There are three groups of stainless steels:

- Austenitic steels with very high chromium content also contain small amounts of nickel and carbon. They are very often used for food processing and pipelines. They are prized in part because they are non-magnetic.

- Ferritic steels contain about 15% chromium, but only trace amounts of carbon and metal alloys such as molybdenum, aluminum or titanium. These steels are magnetic, very hard and strong, and can be further strengthened by cold working.

- Martensitic steels contain moderate amounts of chromium, nickel and carbon. They are magnetic and heat treatable. Martensitic steels are often used for cutting tools such as knives and surgical equipment.

Non-magnetic steels

Stainless steel grades and their characteristics

In electrical engineering, a material is sometimes required to be nonmagnetic and mechanically strong at the same time.

Instead of non-ferrous metals, cheaper non-magnetic austenitic steels are used for this purpose. Austenitic stainless steels (see Chapter XIX) or wear-resistant steels (see Chapter XX) are suitable as non-magnetic steels if their strength properties satisfy the specified requirements. However, steel often fails in terms of strength and technological properties, and austenitic stainless steels are too expensive as a material for heavy parts (for example, for non-magnetic banding rings in turbogenerators). In this case, steels alloyed with manganese, chromium, and aluminum with a relatively high carbon content and limited nickel content are used.

The austenitic structure is obtained as a result of hardening, and hardening is achieved by cold work hardening (if the strength in the hardened state is insufficient). The steel must have stable austenite, that is, the point must lie below so that deformation at room temperature does not cause the formation of martensite.

The composition of some industrial non-magnetic steels is given in table. 100.

Previously, steels with a high nickel content were used as non-magnetic steels. Currently, compositions have been found with a lower content of scarce nickel or even completely without nickel, where manganese acts as an austenite-forming agent. Manganese, as an austenite-forming agent, is two times weaker than nickel, so to obtain stable austenite, the carbon content is increased. If the nickel additive is completely abandoned, then an austenitic structure and non-magneticity can be obtained in a steel of the composition: This is a steel of the Gadf and Ice steel type with its inherent tendency to be strongly hardened during deformation and, therefore, difficult to process by pressure, cutting, etc. , which in this case is a disadvantage. The addition of aluminum to manganese austenitic steels greatly reduces their tendency to harden during deformation.

Table 100. (see scan) Composition of non-magnetic steels, %

This feature of alloying manganese austenite with aluminum is used in the most economical and fairly technologically advanced non-magnetic steel. The mechanical properties of this steel in the hardened state are as follows:

The tensile strength can be increased by cold hardening to 1500-1800 MPa while reducing ductility. All of the listed austenitic steels are not corrosion resistant; Their resistance to corrosion is higher than that of ordinary carbon steel. With the simultaneous requirement of non-magneticity and

Wear resistance is the property of a material to resist the wear process, which means the gradual destruction of the surface layers of the material by separating its particles under the influence of friction forces. Under the influence of these forces, repeated deformation of sections of the contact surface occurs, their strengthening and softening, heat release, structure changes, development of fatigue processes, oxidation, etc. Posted on ref.RF There are abrasive, oxidative, adhesive, fatigue and other types of wear.

High surface hardness is an extremely important condition for ensuring wear resistance under most types of wear. With abrasive, oxidative, and fatigue types of wear, the most wear-resistant steels are those with high initial surface hardness, the structure of which consists of particles of the hard carbide phase and a high-strength matrix that holds them.

Case-hardened low-carbon and medium-carbon steels, strengthened by nitriding or surface hardening, as well as white cast irons provide the necessary performance of friction units in which the material must be able to resist abrasion well by particles that are wear products or enter the lubricant from the outside.

Under conditions of impact wear in an abrasive jet (for example, the operation of basic working units of sand grinding mills), the most wear-resistant materials are hard alloys, the structure of which consists of tungsten, titanium and tantalum carbides bonded with cobalt, as well as high-carbon steels such as X12, X12M, Р18, Р6М5 with martensitic matrix and carbides.

Carbide alloys are used under the most severe operating conditions in the form of cast and surfacing materials. Οʜᴎ are alloys with a high content of carbon (up to 4%) and carbide-forming elements (Cr, W, Ti). It is worth saying that rods made of these alloys are used for surfacing, which are melted by an oxygen-acetylene flame or an electric arc and applied in a liquid state to the surface of the part. “Sormite” alloys are widely used

(1.7...3% C, 15...30% Cr, 2...5% Ni, 2...3% Si) with hardness up to 50 HRC and “stalinite”

(10% C, 20% Cr, 15% Mn, 3% Si) with a hardness of up to 65 HRC.

For work under conditions of wear, which is accompanied by large shock loads, high-manganese steel 110G13L (Hadfield steel) is widely used, containing 0.9...1.4% C, 11.5...15.0% Mn, 0.5...1.0 %Si.

Steel is poorly processed by cutting; therefore, parts are produced by casting or forging. After casting, the structure consists of austenite and excess manganese carbides in iron (FeMn)3C. When heated, carbides dissolve in austenite and after quenching in water at 1100°C, the steel has an austenitic structure and low hardness of 200..250 HB.

Under conditions of only abrasive wear, such steel turns out to be non-wear-resistant, but when the part is exposed to large impact loads, which cause stresses in the material above the yield point, the 110G13L steel undergoes intensive hardening and an increase in its hardness and wear resistance. In this case, the steel acquires high hardness up to 600 HB. Steel 110G13L is widely used for the manufacture of ball mill housings, railway crosspieces, caterpillar tracks, dredge canopies, etc.

Wear-resistant steels

Wear-resistant steels and alloys are necessary for the manufacture of machine parts and mechanisms operating under wear conditions: friction pairs, worm pairs, plain bearings, excavator buckets, railway switches, ship engine propellers, etc.

Wear

- the process of gradual damage to the surface of a part that works in constant or periodic contact under load with another part (or in contact with the working environment).

Wear resistance

- the property of a material to resist wear.

Wear

is expressed in weight loss, in changes in the shape, size and surface condition of the part.

The performance of parts under wear conditions depends on a number of external and internal factors. External factors include friction and operating conditions such as relative movement speed, load, temperature; to the internal ones - the structure of the material.

The following types of wear are distinguished: mechanical, corrosion-mechanical and electrical erosion (GOST 27674-88). Mechanical wear has a number of varieties - abrasive, adhesive, oxidative, erosive, hydroabrasive, etc. All types of mechanical wear can, in turn, be divided into two groups based on the object under the influence of which this process occurs: wear in friction pairs

and wear in

contact with the working environment.

In parts working in pairs under constant contact loads, friction occurs on the surface under operating conditions. In mechanical engineering structures and mechanisms, numerous parts operate under friction conditions: bushings, cams, worms, piston pins, friction discs, etc.

For the manufacture of friction pairs, steels are used that have been subjected to surface hardening - XTO (cementation, nitrocarburization, nitriding), and after hardening with high-frequency high frequency.

Case-hardening steels are divided according to the degree of core hardening. At the same hardness of the cemented layer, the performance of the parts increases as the hardness of the core increases.

The first group includes low-carbon steel grades steel 10, steel 15, steel 20: after carburization, the surface hardness is 55...63 HRC, and the core, due to low hardenability, has a ferrite-pearlite structure and is soft (250...350 HB). As a result, carbon steels are used for low-critical parts such as bushings, cams, sprockets, etc.

The second group includes low-carbon, low-alloy steels - chromium and manganese (15Х, 20Х, 10Г, 20Г). After carburization, quenching and low tempering, their surface hardness is 55...63 HRC, and the core is tempered martensite. Steels of this group have normal strength (s = 700...800 MPa). They are used to produce parts such as pins, tappets, discs, gears, piston pins, friction discs, cam shafts, plungers, etc.

For critical large-sized parts, case-hardened complex-alloyed low-carbon steels (12KhN3A, 20KhGNR, etc.) are used, which are characterized by good ductility and impact toughness. As alloying in steels becomes more complex, the tensile strength increases, the critical diameter increases, i.e., hardenability increases (Table 14.10).

For the production of parts that come into contact with the working environment during operation, there are a wide variety of materials: their choice depends on the type of these environments. For example, materials that are resistant to abrasive wear are necessary for the manufacture of parts that during operation come into contact with the ground or hard rock: drilling tools, augers, bunkers, parts of ore grinding units, parts of charging units of blast furnaces, etc.

Materials resistant to abrasive wear are high-carbon hypereutectoid steels (1.0...1.2% C) and carbide alloys.

Carbide alloys

belong to the alloying system Fe + 4%C + Cr + W + Ti + (Mn, Ni). Parts from them are made cast or in the form of overlays on the product by electric arc welding. Heat treatment is not applied to parts made of these alloys. The phase composition of carbide alloys includes martensite, 10...50% carbides of large (micron and millimeter) sizes, as well as austenite in some alloys. The amount of austenite is controlled by introducing nickel and manganese. The carbides in these alloys are high-modulus compounds Cr7C3, VC, TiC, WC. The hardness of the alloys is 61…63 HRC.

In the grades of these alloys (95Х7Г5С, 250Х38, 350Х15Г3Р1, 370Х7Г7С), as well as hypereutectoid steels, the percentage of carbon increased by 100 times is indicated (Table 14.11).

To work under conditions of abrasive wear, so-called hard alloys can be used, which are powder sintered material containing high-hard carbides: the main one is tungsten carbide (80...97%), and cobalt (3...12%) is used as a binder.

The marking of hard alloys includes letters indicating the type of carbide and cobalt (for those containing tungsten carbide) or the amount of other carbides and the amount of cobalt. Tungsten carbide WC is designated by the letter B, titanium carbide TiC by the letter T; two letters TT mean that the alloy contains both titanium carbides TiC and tantalum carbides TaC. Examples of markings and chemical composition of some hard alloys are given below:

Hard alloys are characterized by high wear resistance. They are used in the mining and oil refining industries, and are also widely used as tool material for the manufacture of cutting tools, die units, drawing units, etc.

Materials resistant to impact and abrasive wear

, are necessary for the production of parts operating under conditions of simultaneous impact loads and friction with abrasive particles (soil). Such working conditions are typical for the tracks of tracked vehicles, the teeth of excavator buckets, the fists of powerful stone crushers, and the crosspieces of railway rails.

The material of these parts must have both a high surface hardness to resist wear in contact with the ground, and a viscous core to resist shock loads. To the maximum extent, these requirements are met by Hatfield steel - a high-alloy steel of the Fe - C - Mn system. This is an austenitic steel: in the solid state it has an austenite structure that does not change during heat treatment.

This steel acquires wear resistance and resistance to impact loading not as a result of heat treatment, but during operation.

The main property of Hatfield steel is that manganese austenite is intensively hardened (hardened) under the influence of cold plastic deformation, especially strongly under impact loads. Under these conditions, the hardness of the surface layers of a part made of 110G13L steel increases approximately threefold due to work hardening, and the core of the part remains viscous, which is associated with the plasticity of the fcc austenite lattice. Thanks to this macrostructure of the part, resistance to both abrasive wear (surface) and impact loads (core) is ensured.

Steel grade 110G13L contains 0.9...1.4% C, 11.5...14% Mn, as well as Si, Ni, Cu, Cr (<1% each). The letter L in the marking means that products made from this steel have a cast macrostructure.

Chapter XXIV. MAGNETIC STEELS AND ALLOYS

Basic magnetic characteristics of metals

Characteristics of steel grade 65×13

Of all the metals, only three (iron, cobalt, nickel) have ferromagnetism, that is, the ability to significantly thicken magnetic field lines, which is characterized by magnetic permeability. The relative magnetic permeability of ferromagnetic metals reaches tens and hundreds of thousands of units; for the rest it is close to unity.

As is known, a substance whose relative magnetic permeability is slightly greater than unity is called paramagnetic, and less than unity is called diamagnetic.

Characteristics of wear-resistant steels

The main feature of this type of steel is its composition, which contains both manganese and other alloying elements, due to which the steel becomes hard enough to withstand almost any load. It is also important to understand that the higher the load on this type of steel, the higher its hardness and wear resistance become, which prevents the structure from becoming unusable or collapsing.

Moreover, in addition to strength indicators, this type of metal has fairly high ductility and good weldability if necessary. Hardened steel increases resistance to all types of wear. You should also pay attention to the conditions and intensity of use of the parts.

Wear-resistant HARDOX steel. Brands and their characteristics, applications and advantages

The manufacturer, SSAB Oxelosund AB, and its dealers position this product as “extremely resistant to all types of wear: friction and impact, sliding friction, deformation wear.” In terms of strength, Hardox steel is superior to other weldable steels, and in terms of impact strength it is comparable to conventional structural steels. Steel is easy to machine, bend and weld. Despite the high strength and toughness of HARDOX sheet steel, conventional shop processing methods can be used to produce the required part or structure. The combination of the absence of impurities and very precise thickness tolerances allows Hardox sheet steel to be bent. All Hardox sheet steel is suitable for gas cutting. The low content of alloying elements allows the use of welding steel sheets using all known methods. Acceptable machining operations include drilling, cylindrical countersinking, conical countersinking, threading and milling. In this case, welding of sheets, for example, Hardox 400 with a thickness of 20 mm, can be carried out without preheating, at room temperature.

Indeed, such a good characteristic makes you pay attention to the product.

Let’s take Hardox 550 for analysis. This grade of steel can be successfully used on mining equipment that operates in harsh conditions that cause overall increased wear of components and structures. Hardox 550 is a medium alloy structural steel. The digital index indicates the Brinell hardness of the steel sheet (HB). The well-balanced chemical composition of Hardox plus a well-developed hardening technology allows us to obtain a very high-quality product - wear-resistant steel with good impact toughness and high strength. The tensile strength of Hardox 550 after heat treatment is 1700 MPa, the yield strength (physical) is 1400 MPa (for comparison: the tensile strength of 30KhGSNA steel after complete quenching and tempering is 1750 MPa). It is the high yield strength that is most important for the use of steel and alloys in industry.

The introduction of alloying elements such as nickel, chromium, manganese and molybdenum helps to significantly increase the mechanical properties of Hardox steel after hardening, while its cost due to the insignificant volume of alloying additives (the most expensive are nickel and molybdenum, but their total content does not exceed 2%) not much more expensive than medium carbon structural steel. The composition is to some extent reminiscent of high-strength chromansil steels (for example, 30KhGSNA), used for the manufacture of components and frames for critical purposes in machines.

According to commercial representatives of SSAB Oxelosund AB dealers, the use of Hardox steel in the manufacture of excavator buckets makes it possible to extend the service life of the latter by more than four times compared to buckets made of structural alloy steel type 10HSND. This comparison is quite controversial, since, for example, in mining excavators the front wall with the cutting edge and the bottom of the bucket are made of 110G13L steel (casting). Such steel, after appropriate heat treatment, acquires high hardness without reducing ductility, is processed better than carbon steel, and has high wear resistance. To achieve the best cutting parameters, a complex shape of the cutting edge of the buckets is selected, i.e., it is necessary to manufacture elements of a complex configuration. The best manufacturing method here is, naturally, casting.

Hardox plate steel can be used for the manufacture of side walls of quarry excavators, welding of repair plates into the bottom and walls of dragline buckets, for the construction of chutes, receiving bunkers, etc.

Uralmash followed this path. Ural machine builders are planning to launch the production of dragline buckets using Hardox 400 steel. The standard ESH-20.90 bucket (capacity 20 m3) is a welded-cast structure made of cast manganese steel 75G13L and low-alloy steel 10HSND. In order to increase the capacity and durability of the bucket, Hardox 400 steel will be used instead of 10HSND steel. This will reduce the weight of the bucket and, therefore, increase its capacity to 22 m3, or by 10%, compared to the previous design. The end load of the boom (the mass of the loaded bucket) does not change. The development of a similar bucket design for the ESH-15.90 walking excavator is nearing completion, the capacity of which will be increased from 15 to 17 m3.

The production of excavator buckets from Hardox steel in the class of construction equipment is very promising. One of the first companies to receive the right to use the “Hardox In My Body” trademark on their buckets was KRANEKS. Now each KRANEKS bucket will have an individual sticker with an eight-digit identification number. Time will tell how much this will attract buyers to KRANEKS products.

Maximum element content in Hardox 550 steel, % C Si Mn PS Cr Ni Mo B 0.37 0.50 1.30 0.020 0.010 1.40 1.40 0.60 0.004

A three-section telescopic boom is made from Hardox steel on Motovilikha truck cranes (for example, KS-5579.22). Some domestic manufacturers have begun to produce blades for concrete mixing plants from Hardox R600 steel. CJSC Becema started producing dump trucks with bodies made of Hardox 400, and other machine-building plants also joined in.

The scope of application of sheet steel is extremely wide, and the use of Hardox steels will increase, especially since a well-organized advertising campaign is underway. At the same time, from January 2005, Severstal OJSC resumed the production of high-strength wear-resistant hot-rolled weldable steel grades 18KhGNMFR, 14KhG2SAFD, 16KhGN2FBR, 13KhG2NDF in thicknesses of 8.0...50.0 mm. These brands are analogues of the Swedish brands Hardox and Weldox and, with the right pricing policy, can displace the positions of Swedish opponents. https://os1.ru/artic...remsya-spokoyno

Welding materials

| Strength class (N/mm2) | JFE-HITEN | Shielded arc welding | Shielded arc welding | CO2 arc welding | Ar+CO2 arc welding | Electrogas welding | ||||

| JFE-Steel | KOBELCO | JFE-Steel | KOBELCO | JFE-Steel | KOBELCO | JFE-Steel | KOBELCO | KOBELCO | ||

| 590 | 590, 610 590S, 590SL 570U2, 590U2, 610U2 570E, 590E, 610E | KSA-86 | LB62 LB62U LB62UL | KB-110 x KW-101B KB-80C x KW-101B KF-300A x KW-101B KF-300A x KW-50C | MF38 x US40 | KC-60 | MG60 DW60 | KM-60 | MIX60B | DWS60G, DWS1LG |

| 690 | 690, 710, 690S 690M, 710M | — | LB106 | KB-80C x KW-102B | MF38 x US70 | — | MG70 | — | MGS70 | — |

| 780 | 780M, 780EX 780S, 780LE | — | LB116 LB80UL | — | PFH80AK x US80BN PFH80AK x US80LT | — | MG80 | — | MGS80 | — |

| 980 | 980S 980 | — | LB100B LB100J | — | PFH100A x US100A PFH100J x US100J | — | — | — | MGS100J | — |

JFE Company, Japan

JFE was the first company to produce and sell wear-resistant steel sheet in Japan in the mid-1950s, and since then, JFE-EVERHARD series wear-resistant sheet has been recognized as a reliable material for construction, mining, industrial and agricultural machinery. In addition, JFE Steel Co. has developed a qualitatively new ultra-resistant steel wear-resistant sheet EH-SP with hardness values above 500 Brinell, as well as high-viscosity grades EH360LE, EH400LE and EH500LE. Later, evolution in construction and technology led to the fact that industrial facilities and structures became larger, and their operating conditions became more aggressive. To ensure the technogenic safety of such objects, reliable high-strength materials are needed, which also have high weldability and toughness.

To meet the demand, JFE Steel has developed a series of steel sheets with unique characteristics under the brand name JFE-HITEN with a strength of 590-980 N/mm2.

This sheet is used for heavy machinery, tanks and storages, spherical gas tanks, pressure vessels, marine structures and shipbuilding, etc. JFE-HITEN is appreciated by our clients as a reliable material in all respects

In 2012, JFE, together with MITSUI and STAMI, signed the first contract for the supply of a various range of high-strength and wear-resistant steel.

In 2022, a retail warehouse for EVERHARD wear-resistant sheets opened in Yekaterinburg

In 2022, JFE Steel Corporation confirmed the rights of SMC Stami to distribute JFE products

EVERHARD is a registered trademark

Wear-resistant steel

Wear-resistant steels are characterized by high resistance to abrasion. This group includes ball bearing, high-manganese and other steels.

Wear-resistant steels are able to resist the wear process.

Wear-resistant steels can be very different in their mechanical properties and structure. There are contact and abrasive wear. Contact wear occurs when one surface rubs against another, accompanied by pressure or impact. Abrasive wear is the abrasion of a metal surface as a result of friction against it of solid particles moving in a stream of liquid or gas along this surface.

Wear-resistant steels have greater wear resistance. Steel gains wear resistance as a result of alloying it with manganese. The most common grade of steel is high-manganese steel G13 containing 1 0 - 1 3% carbon, 12 - 14% manganese and other elements. This wear-resistant and at the same time highly plastic steel is used for the manufacture of track links (tracks), bucket visors for excavators and dredgers, switches and crosspieces of rails, as well as other parts subject to impact and subject to intense wear.

Wear-resistant steels have greater wear resistance. Steel gains wear resistance as a result of alloying it with manganese.

Most wear-resistant steels have a martensitic base with evenly distributed carbide inclusions. For steels operating under conditions of high cyclic contact loads (ball bearing steel), a special role is played by the fine structure of martensite, the dispersion and uniformity of distribution of the carbide phase.

The use of wear-resistant steels for USP parts and proper heat treatment guarantee a long service life.

From the group of wear-resistant steels, we mention manganese steel (0 9 - 1% Cu, about 12 - 14% Mn), which, after quenching in water at 1000 - 1050 C, has a purely austenitic structure.

Cutting of stainless, heat-resistant, wear-resistant steels and alloys causes great difficulties.

Intensification of belt grinding modes of high-strength and wear-resistant steels usually does not cause the risk of grinding defects (burns, cracks, etc.), but leads to increased tool consumption. An analysis of the average cost per unit of production for belt grinding showed that the use of intensive cutting modes and, consequently, shortened service life of the belts is more economical than obtaining the maximum number of ground parts when the belt operates at weak modes. Belts that become dull during roughing operations can be additionally used during intermediate or finishing operations.

4.4. Wear-resistant steels.

A necessary condition for ensuring wear resistance for most types of wear is high surface hardness. When working under conditions of high pressure and shock, the greatest performance is achieved by austenitic steels with low initial hardness, but capable of forming high surface hardness under operating conditions due to intense strain hardening (hardening).

The greatest wear resistance during abrasive wear is possessed by materials whose structure consists of particles of a solid carbide phase and a high-strength matrix holding them. Such materials are usually used in the form of surfacing materials. They are alloys with a high content of carbon (up to 4%) and carbide-forming elements (Cr, W, Ti). Their structure can contain up to 50% special carbides, an increase in the number of which is accompanied by an increase in wear resistance. The structure of the matrix phase is regulated by the introduction of manganese or nickel. It can be martensitic, austenitic-martensitic and austenitic.

For parts operating without shock loads, alloys with a martensitic structure are used.

These include alloys such as U25Х38, У30Х23Г2С2Т (the numbers after the letter “U” indicate the carbon content in tenths of a percent). Parts operating under significant impact loads (excavator bucket teeth, jackhammer peaks, etc.) are made from alloys with an austenitic-martensitic (U37H7G7S) or austenitic (U11G13, U30G34) matrix. To ensure resistance to the fatigue type of wear to which rolling bearing parts are usually exposed, high-carbon chromium bearing steels are used, such as ShKh4, ShKh15, ShKh15GS and ShKh20GS. They contain approximately 1% carbon (GOST 801-78), the figure means the mass fraction of chromium in tenths of a percent.

Friction with high pressures and shock loading is typical for the operation of tracks of tracked vehicles, crosspieces of railway rails, excavator buckets and other parts. They are made from high-manganese austenitic steel 110G13L, containing 1.1% C and 13% Mn.

The high wear resistance of this steel is due to the ability of austenite to undergo strong strain hardening. Under impact conditions, the hardness of this steel increases from HB = 2000 MPa to HB = 6000 MPa.

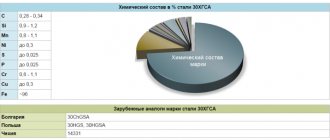

Steel is poorly processed by cutting, so parts are produced by casting. The correspondence of some domestic grades of alloy bearing steels with foreign analogues is presented in Table 4.5.

Table 4.5

Analogues of foreign bearing steels

| CIS countries (GOST) | Euronorms | USA (standards) | Japan (JIS) | China (GB) |

| ШХ4 | 100Cr2 (1.3501)* | 50100 | — | G20Cr2Ni4 |

| ШХ15 | 100Cr6 (1.3505)* | 52100 | SUJ2 | GCr15 |

| SHH15SG | 100CrMn6 (1.3520)* | A485 | SUJ3 | GCr15SiMn |

Note: * is a digital designation.

Control questions

1. What steel is advisable to use for the manufacture of excavator buckets?

2. What brands of wear-resistant steels do you know?

3. How is the high wear resistance of ShKh15 steel achieved?

4. What alloying elements increase the wear resistance of steels?

5. What steel can replace wear-resistant cast iron?

6. What foreign analogues of domestically produced bearing steels exist?

7. How does the wear resistance of steels alloyed with chromium change?

8. How does silicon affect the wear resistance of steels?

9. How does manganese affect the wear resistance of steels?

10. Under what operating conditions should steel grade 110G13L be used?

11. How does the wear resistance of steels alloyed with manganese change?

12. Why are 110G13L wear-resistant steels poorly welded?

13. What ensures resistance to fatigue wear in wear-resistant steels?

14. What is a necessary condition for ensuring wear resistance for most types of surface wear?

15. Why are wear-resistant steels grade 110G13L not subjected to cutting?

16. How to decipher the grade of wear-resistant steel U37Х7Г7С?

studfiles.net