Classic structural steel has high strength, resistance to cooling and overheating, and the absence of harmful impurities. However, these advantages can easily turn into disadvantages of the material when it comes to the manufacture of hardware. To solve this problem, engineers developed the so-called automatic steel (automatic steel).

The composition of this alloy additionally includes sulfur or phosphorus, as well as various additional elements - selenium, lead, tellurium and some others. This makes the material more brittle, making it much easier to work with on machines.

Automatic steels have special markings that make it possible to clearly distinguish the material from other alloys. But which steels are called automatic? What chemical and physical properties does free-cut steel have? How is this material labeled and in what areas of metallurgy is it most often used? In our article we will consider all these issues in detail.

What are the properties of automatic steel?

Automatic structural steels, unlike structural steels, have lower strength, but at the same time they have increased machinability. In metallurgy, they try to get rid of sulfur and phosphorus - additives that impair performance, while in the production of automatic alloys, on the contrary, their content is increased. For example, sulfur makes the product brittle and brittle, and phosphorus impairs strength and leads to cracks, but at the same time it speeds up the processing of a metal workpiece into a product of complex shape.

Materials Science

All metals known in nature belong to two groups - ferrous and non-ferrous metals. Ferrous metals include iron and its alloys (steel and cast iron).

In addition, ferrous metals include manganese, a silver-white metal; but in metallurgy and in everyday slang this element is rarely mentioned in the list of ferrous metals.

All other metals and alloys that do not contain iron or contain it in small quantities are classified as non-ferrous metals.

This classification is due to a number of reasons, primarily the chemical and mechanical properties of iron-containing metals and alloys with low corrosion resistance (except for some steels with specific additives) and magnetism.

Ferrous metals attract machine builders due to their good machinability, mechanical strength, and low price.

Non-ferrous metals have a number of unique properties - high electrical conductivity, resistance to corrosion, low specific gravity with high strength, and in some cases, high aesthetic and jewelry qualities.

Generally, non-ferrous metals are more expensive due to their relative rarity in nature, as well as the difficulty of isolating them from rocks.

Non-ferrous metals are most often classified into light, heavy and noble metals.

So, the basis of ferrous metals is iron.

However, this metal is practically never found in nature in its pure form due to its relatively low corrosion resistance, so iron in its pure form is not used in mechanical engineering, but alloys are used, the basis of which is compounds of iron and carbon - steels and cast irons. Steels are multicomponent alloys with a carbon content of up to 2.14%. Cast iron is an alloy of iron and carbon with a carbon content of more than 2.14%.

Steels and cast irons are very widely used in mechanical engineering. At the same time, minor additions of non-ferrous metals or non-metallic elements to steel or cast iron alloys make it possible to significantly change their chemical and mechanical properties depending on the needs of machine builders, while slightly affecting the cost of the resulting alloy.

***

Properties, classification and marking of steels

The classification of steels is based on their chemical composition, structure, purpose, machinability, and quality.

Depending on the chemical composition, carbon steels (GOST 380-94, GOST 1050-88) and alloy steels (GOST 4543-71, GOST 5632-72, GOST 14959-79) are distinguished.

By structure - hypoeutectoid, eutectoid, hypereutectoid, ferrite-pearlite, austenitic, martensitic.

By purpose - structural, mechanical engineering and instrumental.

Carbon steels, depending on their carbon content, can be:

- low-carbon, containing less than 0.25% carbon;

- medium-carbon, carbon content is 0.25...0.60%;

- high-carbon, in which the carbon concentration exceeds 0.60%.

Alloy steels are divided into:

- low alloy content of alloying elements up to 2.5%;

- medium alloyed, they contain from 2.5 to 10% alloying elements;

- highly alloyed, which contain over 10% alloying elements.

Structural steels are intended for the manufacture of construction and engineering products.

Tool steels are intended for the manufacture of cutting, measuring, stamping and other tools. These steels contain more than 0.65% carbon.

Steels with special physical properties: with certain magnetic characteristics (electrical steel) or with a low coefficient of linear expansion (superinvar).

Steels with special chemical properties: stainless, heat-resistant and heat-resistant steels.

The quality of steel depends on the content of harmful impurities: sulfur and phosphorus. Steels of ordinary quality contain up to 0.06% sulfur and up to 0.07% phosphorus; qualitative - up to 0.035% of sulfur and phosphorus each separately; high-quality – up to 0.025% sulfur and phosphorus; especially high quality - up to 0.025% phosphorus and up to 0.015% sulfur.

According to the degree of oxygen removal from steel, i.e. according to the degree of its deoxidation, there are:

- calm steel, i.e., completely deoxidized; such steels are designated by the letters “SP” at the end of the grade (sometimes the letters are omitted);

- boiling steels – slightly deoxidized; are marked with the letters “KP”;

- semi-quiet steels, occupying an intermediate position between the previous two; are designated by the letters "PS".

Ordinary quality steel is also divided into 3 groups based on supplies:

- Group A steel is supplied to consumers based on its mechanical properties (such steel may have a high sulfur or phosphorus content);

- steel group B – by chemical composition;

- Group B steel – with guaranteed mechanical properties and chemical composition.

***

Structural steels

Unalloyed structural steels of ordinary quality are designated according to GOST 380-94 with the letters “St” and a conventional grade number (from 0 to 6) depending on the chemical composition and mechanical properties. The higher the carbon content and strength properties of the steel, the higher its number. The letter “G” after the brand number indicates a high manganese content in the steel. For example:

St1KP2 – carbon steel of ordinary quality, grade number 1, boiling grade of the second category, supplied to consumers based on mechanical properties (group A);

VSt5G – carbon steel with a high manganese content, calm, grade number 5, first category with guaranteed mechanical properties and chemical composition (group B);

BSt0 – carbon steel of ordinary quality, grade number 0, group B, first category.

Table 1. carbon in steel:

| steel grade | carbon |

| St0 | |

| St1 | 0.06…0.12% |

| St2 | 0.09…0.15% |

| St3 | 0.14…0.22% |

| St4 | 0.18…0.27% |

| St5 | 0.28…0.37% |

| St6 | 0.38…0.49% |

Unalloyed structural quality steels

In accordance with GOST 1050-88, these steels are marked with two-digit numbers showing the average carbon content in hundredths of a percent: 05; 08; 10; 25; 40, etc. So steel with a carbon content of 0.07...0.14% is designated 10, steel with a carbon content of 0.42...0.50% is designated 45, etc.

In this case, for steels with a carbon content of less than 0.2% that have not been subjected to complete deoxidation, the letters “kp” (for boiling steel) and “ps” (for semi-quiet steel) are added to the designation. For mild steels, letters are not added at the end of their names. For example, 08KP, 10PS, 15, 18KP, 20, etc. The letter “G” in the steel grade indicates a high manganese content. For example: 14G, 18G, etc.

***

Steels with improved properties

High-quality steels with improved properties, used for the production of boilers and high-pressure vessels, are designated according to GOST 5520-79 by adding the letter “K” at the end of the name of the steel: 15K, 18K, 22K.

***

What additives are added to automatic alloy steels?

The alloy is enriched with alloying additives, which improve the flexibility of processing and reduce the mechanical characteristics of finished products. The main goal in increasing the sulfur and phosphorus content is to simplify metal processing and reduce the cost of servicing the machine and its consumables.

Depending on what properties the metal should have, various additives are added to alloy it. They allow you to speed up mass production and reduce the cost of finished products.

The alloy differs in the content of various components:

- Sulfur is introduced into the composition in manganese sulfide, due to which the strength of the alloy is reduced, chip cutting is improved and roughness is reduced.

- Phosphorus has a similar effect on metal, as does sulfur.

- Selenium further increases chip breakage without affecting the strength of the alloy.

- Lead allows you to reduce the cost of parts due to the fact that the cutting tool of the machine lasts longer and does not deteriorate as quickly as when processing more durable metals.

- Calcium facilitates the operation of the machine because the chips do not stick to the metal, and the cutting tool can last longer.

- Manganese does not affect the quality of the alloy and is used to introduce sulfur in the composition of manganese sulfide.

acceptance

3.1. General rules for acceptance of rental products are in accordance with GOST 7566.

3.2. Rods and coils are produced in batches. The batch must consist of rods and coils of the same size, the same heat, the same manufacturing method and heat treatment regime.

(Changed edition, Amendment No. 2).

3.3. Surface quality and dimensions are controlled on at least 10% of rods and coils. If unsatisfactory results are obtained, the entire batch is subjected to control. Surface quality control of hot-rolled steel subgroups

produced on all bars.

3.4. To check the quality of rolled products, the following are selected from the batch:

a) to determine the chemical composition of the melt - one sample from the melt-ladle in accordance with the requirements of GOST 7565;

b) to control the macrostructure by fracture or etching - two templates from different rods;

c) for tensile tests - two rods from different rods and coils;

d) to determine impact strength - two rods from different rods and coils;

e) to determine the depth of the decarbonized layer - three rods;

f) to test hardness - at least three rods;

g) to determine the grain size and hardenability - one rod from the melting ladle;

h) to control the microstructure - two rods, a coil.

(Changed edition, Amendment No. 3).

Features of physical processing of automatic steels

The alloy enriched with alloying additives is smelted at a temperature of 1300°C. After smelting, or diffuse annealing, all components are evenly distributed throughout the volume of the alloy. Exposure to high temperatures eliminates the fragility of finished metal fragments due to the high accumulation of phosphorus or sulfur in one area. Additionally, the characteristics are improved:

- Cementation - diffuse surface saturation of carbon, increasing wear resistance.

- Cyanidation - saturation with nitrogen and carbon at a temperature of 950°C.

- Quenching and tempering makes the alloy harder, more brittle and less tough.

Automatic steels. Composition, application:

Steels used in the manufacture of parts by cutting at machine-building plants must have:

• good cutting surface;

• brittle chips;

• good thermal conductivity;

• low strength (LS).

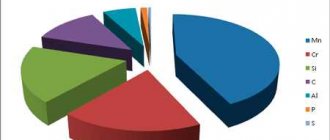

Such steels are called automatic steels. They are used on automated lines, where cutting tools and drills are changed without human intervention. The following elements are introduced into the composition of such steels: S, P, Si, Mn, Se, Te.

These elements improve cutting processing during complex alloying, while the consumption of tools, drills, and cutters is reduced (by 2–3 times).

Steels are marked with the letter “A” - automatic and with numbers indicating the carbon content (A20 - 0.2% C).

Spring steels. That. Marking:

Spring steel is steel intended for the manufacture of elastic elements (springs, springs, etc.). The operation of springs, springs and similar parts is characterized by the fact that they use only the elastic properties of steel. The large total amount of elastic deformation of a spring (spring, etc.) is determined by its design - the number and diameter of turns, the length of the spring. Since the occurrence of plastic deformation in springs is not allowed, the material of such products is not required to have high impact strength and high ductility. The main requirement is that the steel has a high elastic (yield) limit. This is achieved by hardening followed by tempering at a temperature in the region of 300-400 ° C. At this tempering temperature, the elasticity (yield) limit receives the highest value, and the fact that this temperature lies in the range of development of type I temper brittleness, due to the above-mentioned circumstance doesn't matter much.

General characteristics: spring steel, insensitive to flocking, prone to temper brittleness with Mn content ≥1%, not used for welded structures. Density at 20°C - 7.81x10³kg/m³. The normal elastic modulus at 20°C is 215 GPa. Specific heat capacity at 20-100°C - 490 J/(kg °C). Spring steel contains 0.5-0.75% carbon, up to 2.8% silicon, up to 1.7% nickel and 1.2% each of vanadium, tungsten, manganese and chromium.

They work in the area of elastic deformation of metal under the influence of cyclic loads. Therefore, they must have a high elastic limit, yield strength, endurance, if necessary, ductility and high resistance to brittle fracture.

Markings and main characteristics:

Spring steel grades:

| · 50ХГ | · 50HGA | · 50HGFA | · 50ХСА |

| · 50HFA | · 51HFA | · 55С2 | · 55С2А |

| · 55S2GF | · 55HGR | · 60G | · 60С2 |

| · 60С2А | · 60S2G | · 60С2Н2А | · 60С2ХА |

| · 60S2HFA | · 65 | · 65G | · 65GA |

| · 65S2VA | · 68A | · 68GA | · 70 |

| · 70G | · 70С2ХА | · 70С3А | · 75 |

| · 80 | · 85 |

Bearing steels. That. Marking:

Alloy steels used for the production of rolling bearings. Typically made from high carbon (1.00%) and low carbon (0.20%) steels. High carbon steels are used after induction surface hardening. Low-carbon steels are cemented to provide the necessary surface hardness while maintaining basic properties.

Bearing steel is used mainly for the manufacture of balls, rollers and bearing rings. During operation, these bearing elements are exposed to high alternating stresses. Each section of the working surface of the ball or roller and ring track experiences multiple loads distributed within a very small supporting surface.

Harmful impurities for ball bearing steel grades are phosphorus, copper and nickel. Phosphorus increases the tendency of steel to form a coarse-grained structure when heated, increases the brittleness of steel and reduces its bending strength.

The technology for producing bearing steel in oxygen converters is similar to the technology for smelting rail steel. To increase the efficiency of dephosphorization of high-carbon metal, smelting is carried out with intermediate downloading of mobile main slag containing 12–14% FeO, formed as a result of lime and fluorspar additives in the first 6–8 minutes of oxygen purging at a high tuyere height above the bath level. After downloading the first slag, a new one is added with additives of lime and fluorspar.

Marking: Bearing steels in accordance with GOST 801 - 78 are designated in the same way as alloy steels with the letter Ш at the beginning of the name. Bearing steel is produced in grades ШХ15, ШХ4, ШХ15СГ and ШХ20СГ with a diameter or thickness of up to 250 mm. Bearing steels are marked with the letters Ш (ball bearing), X (chromium) and numbers indicating the chromium content in tenths of a percent. The steels used are ShKh4, ShKh9, ShKh15, as well as ShKh15SG and ShKh20SG, additionally alloyed with silicon and manganese. The higher the content of alloying elements, the larger balls and rollers this steel can be used for.

The carbon content of bearing steels is about 1%. With an increase in the content of chromium and alloying elements, the depth of hardenability increases, i.e. the possibility of manufacturing larger parts from them increases. Supplied in accordance with GOST 801-78.

Marking examples:

ШХ6 - ball bearing steel containing 1% carbon and 0.6% chromium;

ШХ15СГ - ball bearing steel; containing 1% carbon, 1.5% chromium, silicon and manganese up to 1%.

studfiles.net

Advantages and disadvantages of metal

Automatic steel is characterized by:

- simplified and fast cutting;

- easy chip separation;

- high thermal conductivity

- low hardness;

- minimal wear of the cutting tool.

Increased machinability, easy chip release and low roughness can increase production productivity several times, reduce costs and increase profits. The disadvantages include the presence of sulfur and phosphorus, which reduce the viscosity and ductility of parts.

Manufacturing

The properties of automatic steels are determined by alloying impurities and their quantity, as well as subsequent processing.

Alloying

To obtain the required properties, the following alloying additives are introduced ( GOST 1414-75

regulates the chemical composition of automatic steels):

- Sulfur (0.08-0.2%) - the introduction of sulfur leads to the creation of manganese sulfides in the alloy, which contribute to improving chip breakage (sulfide dispersed inclusions disrupt the continuity of the alloy, as a result of which the chips break and do not wrap around the part and tool), obtaining low roughness of the machined surface, and also has a lubricating effect (the “dry lubrication” effect), reducing friction between the machined surface, chips and tool, which increases the durability of the cutting tool.

- Phosphorus (0.06-0.15%) - along with sulfur, improves cutting;

- Lead (0.15-0.30%) - increases tool life by 3 times and permissible cutting speed by 25-50%;

- Selenium (0.04-0.10%);

- Calcium - forms a calcium-containing layer several micrometers thick in the cutting zone, which plays the role of internal lubricant and prevents adhesion; in addition, the presence of calcium in steel leads, at certain cutting speeds, to the appearance of deposits on the surface of the processing tool, which prevent and compensate for wear;

- Tellurium;

- Bismuth - has the ability to lubricate the cutting zone;

- Nickel;

- Chromium;

- Manganese (0.7-1.7%).

The content of phosphorus and sulfur in free-cut steels must be strictly limited due to the negative properties they impart to the alloy.

Treatment

To improve the properties, free-flowing steel is additionally subjected to:

- diffusion annealing at a temperature of 1100–1150 °C, to eliminate segregation (heterogeneity of sulfur content by volume);

- cementation;

- cyanidation;

- hardening with high tempering.

Automatic steel is smelted both in open hearth furnaces and using the converter method.

To increase mechanical properties and improve cutting machinability, rolled automatic steel is supplied in cold-worked form.

What marking is applied to automatic steel?

Automatic steel must comply with GOST 1414-75. It is marked with a large letter A, judging by which you can understand what the steel is intended for. Additional additives that are included in the alloy are designated in the alloy by different letters. The numbers indicate carbon concentration, measured in hundredths of a percent.

Classification by alloy additives:

- A - sulfur steel;

- AC - lead added;

- E - selenium;

- C—calcium;

- G - manganese;

- X - chromium;

- N - nickel

Calibrated rolled structural steel with high machinability by cutting GOST 1414-75

Calibrated rolled steel GOST 1414-75 A12, free-cut steel is made by cold rolling or drawing from hot rolled steel (roll).

Unlike long hot-rolled steel, calibrated rolled free-cut steel has more accurate cross-sectional dimensions and metal surface quality. These qualities allow it to be used for processing on high-performance automatic lathes, as well as for cold stamping on cold heading equipment. High precision and surface quality make it possible to significantly reduce metal consumption during further processing. Calibrated rolled products GOST 1414-75 from structural steel with high machinability by cutting the use of automatic steel in the form of a circle, hexagon: in mechanical engineering, in the automotive industry. Rolled products calibrated GOST 1414. Steel grades and chemical composition. Steel groups

| steel grade | Content of chemical elements, % | |||||||

| C | Si | Mn | Cr | Pb | S | P | ||

| Carbon sulfur | A11 A12 A20 | no more than 0.10 0.15-0.35 0.15-0.35 0.15-0.35 | 0,80-1,20 0,70-1,10 0,70-1,00 | no more than 0.10 0.08-0.015 no more than 0.06 no more than 0.06 | ||||

| Sulfide-manganese lead containing | AC14 | 0,10-0,17 | no more than 0.12 | 1,0-1,30 | — | 0,15-0,30 | 0,15-0,30 | no more than 0.10 |

Mechanical properties of rolled products

| steel grade | Size, mm | Type of processing | Yield strength N/mm2(kgf/mm2) | Temporary tensile strength N/mm2 (kgf/mm2) | Relative extension, % | Relative narrowing, % | Hardness | |

| imprint diameter, mm, not less | NV, no more | |||||||

| A11 | all sizes | calibers | 309(40) | 490(50) | 10 | — | 4,2 | 207 |

| A12 | 30 or less | calibers carbon deposits. | — | 510(52) | 7 | — | 4,1 | 217 |

| A12 | over 30 | calibers carbon deposits. | — | 460(47) | 7 | — | 4,1 | 217 |

| A20 | all sizes | calibers carbon deposits. | — | 530(54) | 7 | — | 4,1 | 217 |

| A30 | all sizes | calibers carbon deposits. | — | 540(55) | 6 | — | 4,05 | 223 |

| A40G | all sizes | calibers annealed | — | 590(60) | 17 | — | 4,0 | 229 |

| AC14 | all sizes | calibers carbon deposits. | 390(40) | 490(50) | 10 | — | 4,20 | 207 |

Acceptable surface defects

| Surface quality group | Quality | Acceptable surface defects | The greatest depth of defects |

| A | h9 | Individual minor risks of mechanical origin | Established by agreement between the manufacturer and the consumer |

| h10 | maximum deviations | ||

| B | h10 | Individual small risks of mechanical origin, scale residues, fingerprints, rippling, shallow stripping, traces of abrasive cleaning | Limit deviations |

| h11 | |||

| h12 | |||

| IN | h10 | Isolated small risks of mechanical origin, scale residues, fingerprints, rippling, shallow stripping, traces of abrasive stripping, individual small rolled out and loosened bubbles and dirt (hairs) | Limit deviations |

| h11 | |||

| IN | h12 | Isolated small risks of mechanical origin, scale residues, fingerprints, rippling, shallow stripping, traces of abrasive stripping, individual small rolled out and loosened bubbles and dirt (hairs) | Limit deviations for quality h12 |

| Limit deviations for quality h11 |

Calibration (calibrated rolled products) is used for the manufacture of critical parts in the automotive and mechanical engineering industries.

Calibrated rolled products have the highest possible dimensional accuracy and high technical characteristics of surface quality; rolled products are produced in sizes from 4 to 16 mm - in coils, in sizes from 5 to 65 mm - in rods from steel grades A12 (carbon, sulfur).

Due to the increased sulfur content in the range of 0.08-0.20%, the machinability of rolled products by cutting is improved. Temporary tensile strength depending on steel grades from 460 to 510 N/sq.mm

How to buy calibrated rolled steel GOST 1414-75 st.A 12 at low prices:

- fill out the simple “Place an order” form at the top of the page;

- call on the phone +7;

- send your application by email;

Terms of sale:

- Sales of metal products wholesale and retail;

- Cashless payment by transferring funds from a bank account;

- Possibility of deferred payments;

- Free consultations from our specialists;

- We provide packaging services according to customer requirements;

- We are ready to produce products of any complexity to order according to customer drawings.

Delivery terms:

- Products are delivered from the warehouse based on availability;

- If necessary, we can provide a storage service;

- We are ready to provide a discount on delivery according to the terms of partnership programs of transport companies;

- Possibility of self-pickup of goods from warehouses.

- All products are certified and released after technological control;

- Hardware, fasteners, ropes, mesh, wire, electrodes and other metal products comply with GOST and TU;

- Possibility of returning goods in accordance with the legislation of the Russian Federation;

Delivery within the Russian Federation: Moscow, St. Petersburg, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Yekaterinburg, Ivanovo, Izhevsk, Yoshkar-Ola, Kazan, Kaluga, Kirov, Kostroma, Krasnodar, Kurgan, Kursk, Lipetsk, Omsk, Orenburg, Penza, Perm, Pskov, Rostov-on-Don, Ryazan, Samara, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Stavropol, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk, Ufa, Chelyabinsk, Yaroslavl, etc.

The information presented on this website contains a catalog of reference information on more than 3,000 types of metal products, is for informational purposes only, and can be used in various areas of enterprise activity.

The main brands in the production of automatic steels

The grade of metal determines the scope of application. Sulfur grades are used in production:

- A11 - bolts, nuts, chains, forks for clutches in cars;

- A12 - axles, screws, bolts, nuts and products of complex shapes;

- A20 - small parts of complex shape;

- A30 - hardware and parts that are subject to precision processing.

From brands containing various additives the following are produced:

- A35E - matrices and bandages;

- AS19KhGN - gear transmission mechanisms;

- AS35G2 - oil pump rollers;

- AC40X - car axle rings.

Literature

- Rivlin Yu. I., Korotkov M. A., Chernobylsky V. N. Metals and their substitutes. - M.: Metallurgy, 1973. - 440 p.

- Lakhtin Yu. M. Fundamentals of metallurgy. - M.: Metallurgy, 1988. - 320 p.

- Anuriev V.I. Handbook of mechanical engineering designer: in 3 volumes. T. 1. - 9th ed., revised. and additional / ed. I. N. Zhestkova. - M.: Mashinostroenie, 2006. - 928 p. — ISBN 5-217-03343-6 (Vol. 1)

- Degarmo, E. Paul; Black, J T.; Kohser, Ronald A. (2003), Materials and Processes in Manufacturing (9th ed.), Wiley, ISBN 0-471-65653-4.