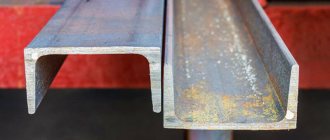

A channel is a very popular product made of metal today. Its main distinguishing property is its U-shaped cross-section. The thickness of the finished product can be from 0.4 to 1.5 cm, and the height of the walls can be 5-40 cm.

Thin flange products are manufactured by processing flexible strip using special profile mills. Channels made from non-ferrous metals are obtained after processing the workpiece by pressing and extrusion, and steel channels are obtained using the technology of hot rolling of a metal billet on section mills.

Load calculation algorithm

- We find out the full value of the load on the profile included in the design and increase it by multiplying it by the reliability factor for the loads (we find it in the standards);

- We multiply the resulting product by the channel pitch;

- We determine the maximum bending moment - information on the channel is in the GOST tables. We calculate: Mmax (bending moment) in KiloNewtons per meter is equal to the product of the design load by the square of the length of the channel. Clarification: 1 kNm is equal to 102 kgcm.

The moment of resistance of the product - Wtr, is found by the following calculations: Mmax is multiplied by the coefficients for operating conditions and divided by the coefficient taking into account plastic deformations - 1.12. We compare the obtained result with the provisions in GOST and find the parameters of the desired profile.

Important!

According to the channel number, you always need to select a little more than what was calculated.

Types of loads and channels

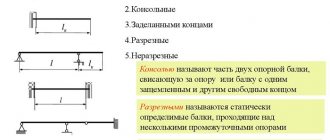

View A.

"Canopy over the entrance." This type includes beams with rigid embeddings. The load is usually applied evenly. These could be canopies over entrances. Welding is used for their manufacture. They are made of two channels attached to the wall, and the space is filled with reinforced concrete.

View B.

“Interfloor slabs” Rigidly fixed single-span beams, the load on which is distributed evenly. Usually these are floor beams between floors.

Species C.

"Hinged balcony support." The beams have two supports with a cantilever, the load is distributed evenly between them, but they extend beyond the outer walls. This is necessary to create support for the balcony slabs.

View D.

"Under two jumpers." These are single-span hinged-supported beams on which two concentrated forces act. Usually these are lintels on which another pair of floor beams rests.

Species E.

"Under one jumper." These are single-span hinged-supported beams where one force is concentrated. Usually these are lintels on which one beam of another floor rests.

After it has been clarified what type of channel this channel belongs to and where the main load will go, a calculation formula is selected.

Preliminary Considerations

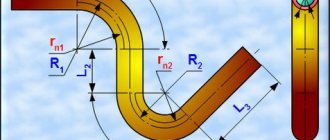

The calculator provides calculations of beams for various schemes of their fastening and load. The load of beams can be distributed (“q” in diagrams 3,4,5,9,15, etc.) or concentrated (“P” in diagrams 1,2,6,7,8, etc.)

Read also: Homemade band saws for wood drawings

The fastening of beams can be: a) cantilever with rigid termination of one of the ends (for example, schemes 1,2,3 and others); b) “sealing - sealing”, when both ends of the beam are rigidly clamped (sealed), schemes 6,7,8,9; c) “hinge - hinge” (diagrams 12,13,14,15 and others), with the left hinge being fixed and the right hinge being movable; d) “sealing - hinge”, (diagrams 9,10,11 etc.)

Rigid embedding of the beam prevents the beam from turning and moving in any direction. A fixed hinge allows only rotation of the beam at the point of attachment in the vertical plane. The movable hinge allows the beam to rotate at the point of attachment in a vertical plane and move along its own axis.

An approximate method for calculating the load on a channel

To make the calculation you need to do the following:

-First, determine the total load that will act on the beam - and multiply it by the standard safety factor for loads.

-Multiply the result obtained by the pitch of the beams (in this case this applies to channels).

Next, you need to calculate the maximum bending moment.

All data for the channel is taken according to GOST.

The formula is as follows: the bending moment Mmax will be equal to the design load multiplied by the length of the channel squared. The unit of measurement is kiloNewtons per meter. (1 kNm = 102 kgcm)

Then proceed to calculate the required moment of resistance of the beam.

The formula is as follows: the moment of resistance Wtr will be equal to Mmax, which is multiplied by the operating conditions coefficients and divided by 1.12 (this is a coefficient for taking into account plastic deformations).

Thus we obtain the required section. But at the same time, you need to remember that the channel number must be greater than the required section moment.

Maximum permissible deflection: the most important characteristic of a channel

When choosing a structural material and approving it for use in construction, various calculation data are used: minimum moment of resistance, bending moment, normal stress, etc.

However, the most important characteristic is the maximum permissible deflection. It is calculated as follows: the coefficient 5/384 is multiplied by the fraction. The numerator of the fraction contains the product of the design load and ¼ of the length of the channel span. The denominator is the product of the moment of inertia and the longitudinal elasticity index of the material from which the channel is made (its modulus).

The results obtained are a comprehensive calculation that allows you to find out whether the channel is really suitable for use in a particular part of the structure.

Conventions in channel markings - how to understand them?

And since the main purpose of the channel is to withstand loads, from its markings it is first necessary to find out the parameters that will allow this load to be calculated, namely, the composition of the steel, its strength, rolling quality, and so on.

What can you learn from the labeling?

For example, before us is a package of hot-rolled channels, on which it is written: 30P-V GOST 8240-97/St3sp4-1 GOST 535-88

This means that we have a 30P channel - that is, with parallel edges and a section height of 30 cm. The letter B indicates the usual rolling accuracy B, made of steel St3, fourth category, first group.

The same channel, but only made of steel 09G2S with increased rolling precision will receive the designation 30P-B GOST 8240-97/345 GOST 19281-89

, in which 345 will mean the strength of steel corresponding to grade 09G2S.

But in the marking A 300x80x6 B GOST 8278-83/2-St3sp GOST 11474-76

the letter A will indicate high accuracy of profiling of a steel blank (strips) from the second category of steel St3sp, from which a bent equal-flange channel with dimensions of 300x80x6 is made (where 300 mm is the height of the section of the product, 80 mm is the width of the shelves, and 6 mm is the thickness of the shelves and walls)

What load can channel 10 withstand?

The channel is considered the most common rolled metal product. This is a metal blank in the form of a beam, which has the shape of the letter “P”. The main useful functions of the channel include increasing the stability and rigidity of various structures, which allows the latter to withstand high loads.

The product is manufactured by hot deformation of metal on a rolling mill without the subsequent use of additional heat treatment. All norms for the production of 10P channel are specified in the norms of the GOST 8240-97 standard.

Channel 10 technical specifications

Each GOST standard specifies the technical characteristics of a 10P channel depending on the type and method of its manufacture. But the main ones include the width and length of the workpiece.

The standard length of channel 10 varies from 4m to 12m, but there are also non-standard sizes with a length of 13m. In this case, metal rolling companies produce the product to order. After the length of the rolled product, its marking is indicated - the index “P”, which means the presence of parallel edges in the metal product. The width of the channel between the shelves indicates its number in the assortment.

When producing the product, ordinary steel grades PS 3 or SP 3 are used, low-alloy steel - 09g2s, which increases the strength and reliability of the workpiece, since the steel contains a manganese alloy. You can usually distinguish a hot-rolled billet from a cold-rolled one by its appearance: a hot-rolled channel has a slightly rounded outer corner. The weight of one meter of the product is 8.59 kg.

What load can a 10 channel channel withstand?

Thanks to its technical characteristics and design, the product is able to withstand axial loads and is very resistant to bending loads. The small thickness of the channel serves, as a rule, for the construction of floors on a small shoulder and the creation of crossover structures of medium length.

Channels are used to make supports for high-voltage power lines, cranes, oil rigs and other structures. Also, such samples often find application in machine tool building, mechanical engineering and carriage building.

The wide spread of 10P channel in industrial production has been facilitated by its high strength and reliability characteristics, as well as its affordable price.

Channels come in different sizes and therefore for each type of work it is necessary to select special rolled metal. And for this you need to know what load you can count on it. The channel load is calculated based on what type of beam it is and where the load goes. It is more convenient to make the calculation by presenting a diagram of the beam.

Choosing a channel from the point of view of economic feasibility

The cost of a channel is calculated based on data on weight and cost per ton:

| Characteristics / Name | Channel 12P | Channel 140x60x5 |

| Weight of 1 meter, kg | 10,7 | 9,77 |

| Weight of a channel 6 meters long, kg | 64,2 | 58,6 |

| Price per ton* | 97790 rub. | 87490 rub. |

| Price for 1 piece of channel | 6278 rub. | 5127 rub. |

* Price as of December 2022, see the current prices on the date of purchase in the online store in the Rolled Metal - Channel section.

It can be noted that from the conditions for calculating the strength of a channel working in bending, a more economical solution would be to use a bent channel in comparison with a hot-rolled one.

Moment of resistance of a channel when designing floors

When designing floors and load-bearing metal structures, one strength calculation of the load on the channel is not enough. To ensure the reliability of the designed structure, it is also necessary to calculate the rigidity of the channel. The deflection in this case should not exceed the permissible value. This profile check is mandatory when designing floors for residential and other premises. For example, let's take the same beam as before. The distributed load acting on it is 50 kgf/m or 500 N/m. The moment of inertia of the 10P channel has the value Ix = 175 cm4. When checking a beam for rigidity, its relative deflection is determined using the formula:

- f/L = M∙L/(10∙E∙Ix)≤[f/L], where

M – bending moment, N∙m L = 1000 cm – rod length E = 2.1∙105 MPa – modulus of elasticity of steel Ix = 175 cm4 – moment of inertia of the channel section

The moment of resistance of the channel, the bending moment is equal to: M = q∙L2/8 = 500∙102/8 = 6250 N∙m.

Then the relative deflection of the 10P channel will be: f/L = 6250∙1000/(10∙2.1∙105∙175) = 0.017 = 1/59

If we compare it with the permissible values regarding deflection according to SNiPs, then this channel cannot be used for interfloor ceilings, since the permissible value there is 1/200. Therefore, despite ensuring the strength of this design, it is necessary to select a larger channel profile and check it for rigidity.

Channel available in warehouse in Moscow

A channel is a rolled product that has a U-shaped cross section.

Depending on the production technology, channels can be hot-rolled or bent. The dimensions and shape of general-purpose hot-rolled channels are regulated by GOST 8240-97. The width of the rolled product, according to the specified regulatory document, can be from 32 to 115 mm, and the height from 50 to 400 mm.

The designation of the profile number encodes the height of the channel in centimeters (number) and the series or type of profile (letter).

The dimensions of the bent channel are regulated by the GOST 8278-83 standard. In accordance with this document, the profile height can range from 25 to 410 mm, the channel thickness can range from 2 to 8 mm, and the width can range from 26 to 160 mm.

At APEX METAL you can purchase the most popular channel sizes made from steel grades St3 and 09G2S:

- series P with parallel edges - profile sizes 5P - 30P;

- U series with sloped edges - profile sizes 6.5U - 30U;

- bent channel with dimensions from 50x40x3 to 250x125x6.

For the height and width of the flange, width and wall thickness according to GOST 8240-97, see the page - How to correctly decipher the symbol of a channel.

Hot rolled steel channel: standards, range, characteristics

The range of these products is determined by GOST 8240-89. The profile size is characterized by a number that is equal (approximately) to the height of the wall, taken in centimeters. In accordance with the standard, the following products are produced:

- With a slope of the inner edges of the shelves. The marking contains the letter “U” after the number. The standard provides for the production of products with a wall height of 50-400 mm, a shelf width of 32-115 mm, a wall thickness of 4.4-8.0 mm, and a shelf thickness of 7.0-13.5 mm. If the designation contains the letter “a” between the profile number and the letter “U,” this means that the product has an increased width and thickness of the shelves. The main area of application of this type of channel is construction. Due to some thickening in the inner corners, the profile has increased strength characteristics. Such metal products are used in frame construction, for the installation of floors, the construction of trusses, stairs, small architectural forms, and metal structures for various purposes.

- With parallel inner edges of shelves. The marking indicates the letter “P” after the number. The index “a” indicates the presence of reinforced shelves. In accordance with the standard, the wall height of products is in the range of 50-400 mm, shelf width - 32-115 mm, wall thickness - 4.4-8.0 mm, shelf thickness - 7.0-13.5 mm. This type of channel has areas of use similar to products with sloped internal edges of shelves. A profile with parallel internal edges is effective in cases where the interface with other parts of the structure occurs along the internal surface of the product.

Table of geometric characteristics of hot-rolled channel

| Channel number | Profile height, cm | Shelf width, mm | Wall thickness, mm | Shelf thickness, mm | Weight 1 m, kg |

| With a slope of the internal edges of the shelves | |||||

| 5U | 5 | 32 | 4,4 | 7,0 | 4,84 |

| 6.5U | 6,5 | 36 | 4,4 | 7,2 | 5,9 |

| 8U | 8 | 40 | 4,5 | 7,4 | 7,05 |

| 10U | 10 | 46 | 4,5 | 7,6 | 8,59 |

| 12U | 12 | 52 | 4,8 | 7,8 | 10,4 |

| 14U | 14 | 58 | 4,9 | 8,1 | 12,3 |

| 16U | 16 | 64 | 5,0 | 8,4 | 14,2 |

| 16аУ | 16 | 68 | 5,0 | 9,0 | 15,3 |

| 18U | 18 | 70 | 5,1 | 8,7 | 16,3 |

| 18аУ | 18 | 74 | 5,1 | 9,3 | 17,4 |

| 20U | 20 | 76 | 5,2 | 9,0 | 18,4 |

| 22U | 22 | 82 | 5,4 | 9,5 | 21,0 |

| 24U | 24 | 90 | 5,6 | 10,0 | 24,0 |

| 27U | 27 | 95 | 6,0 | 10,5 | 27,7 |

| 30U | 30 | 100 | 6,5 | 11,0 | 31,8 |

| 33U | 33 | 105 | 7,0 | 11,7 | 36,5 |

| 36U | 36 | 110 | 7,5 | 12,6 | 41,9 |

| 40U | 40 | 115 | 8,0 | 13,5 | 48,3 |

| With parallel edges of shelves | |||||

| 5P | 5 | 32 | 4,4 | 7,0 | 4,84 |

| 6.5P | 6,5 | 36 | 4,4 | 7,2 | 5,9 |

| 8P | 8 | 40 | 4,5 | 7,4 | 7,5 |

| 10P | 10 | 46 | 4,5 | 7,6 | 8,59 |

| 12P | 12 | 52 | 4,8 | 7,8 | 10,4 |

| 14P | 14 | 58 | 4,9 | 8,1 | 12,3 |

| 16P | 16 | 64 | 5,0 | 8,4 | 14,2 |

| 16aP | 16 | 68 | 5,0 | 9,0 | 15,3 |

| 18P | 18 | 70 | 5,1 | 8,7 | 16,3 |

| 18aP | 18 | 74 | 5,1 | 9,3 | 17,4 |

| 20P | 20 | 76 | 5,2 | 9,0 | 18,4 |

| 22P | 22 | 82 | 5,4 | 9,5 | 21,0 |

| 24P | 24 | 90 | 5,6 | 10,0 | 24,0 |

| 27P | 27 | 95 | 6,0 | 10,5 | 27,7 |

| 30P | 30 | 100 | 6,5 | 11,0 | 31,8 |

| 33P | 33 | 105 | 7,0 | 11,7 | 36,5 |

| 36P | 36 | 110 | 7,5 | 12,6 | 41,9 |

| 40P | 40 | 115 | 8,0 | 13,5 | 48,3 |

Calculation of the table weight of the channel is carried out using the average value of the density of various steel grades - 7.85 g/cm3.

How much can a channel weigh?

| Channel number | Weight of 1 meter in kg | Meters per ton |

| 5 | 4,84 | 206,6 |

| 6,5 | 5,9 | 169,5 |

| 8 | 7,05 | 141,8 |

| 10 | 8,59 | 116,4 |

| 12 | 10,4 | 96,2 |

| 14 | 12,3 | 81,3 |

| 16 | 14,2 | 70,4 |

| 18 | 16,3 | 61,3 |

| 20 | 18,4 | 54,3 |

| 22 | 21 | 47,6 |

| 24 | 24 | 41,7 |

| 30 | 31,8 | 31,4 |

Bent steel channel: GOST, assortment, technical characteristics

The starting material for the production of bent profiles is hot- or cold-rolled steel strip. The manufacturing process takes place on profile bending units. A bent metal profile can be distinguished from a hot-rolled one by its rounded outer corners and the same thickness of the wall and shelves, which does not exceed 8 mm. Bending eliminates some surface defects. Unlike hot-rolled metal products, which are produced only as equal flanges, bent metal products are produced both as equal and unequal flanges. The range of equal flange products is determined by GOST 8278-83, unequal flange products - by GOST 8281-80. Their range is much wider than the list of hot-rolled U-shaped products. The height of the wall of the equal-flange profile is 25-410 mm, the width of the shelf is 26-65 mm, the wall thickness is 2-8 mm.

Due to the strength, which is inferior to the similar characteristics of hot-rolled metal products, various brands of bent channel are used as additional reinforcing elements in metal structures, during finishing work, and reconstruction of dilapidated buildings, in which the low mass of metal plays a decisive role.

How to install a channel correctly un-altra.ru

Channel is a type of shaped steel, often used for installation of floors. A ceiling is a load-bearing structure located inside a building and dividing it into several levels: floors, attics, attics.

It absorbs loads from the elements of the floor itself, equipment, furniture, people, with their subsequent transfer to walls or columns, which depends on the architecture of the building. Floors can be slab or beam.

The second option is often used in low-rise private construction; the function of a beam can be performed by a steel channel.

How to properly install a channel when installing a floor?

The U-shaped profile is used to create basement, interfloor and attic floors. When installing the channel, consider the following points:

- the channel is installed on a shelf, that is, the cross-section has the shape of the letter “C” and not “P”. This is due to the fact that the moment of resistance of the section in this case is higher than when installing rolled products with the letter “P”;

- correct installation of the channel in structures implies the placement of the letters “C” from the middle of the floor in opposite directions, since the center of gravity of this profile product is located outside the section of its wall. The position of the center of gravity depends on the modification of the channel. This installation scheme compensates for shear stresses.

Difference from other I-beams

The column-type I-beam has some differences from any other variations of this product. The main difference lies in the fact that the wall thickness of the columns is much higher than that of other models.

Thanks to this, we can say with confidence that the strength and rigidity of this product is much higher. In addition, this significantly expands the scope of its use. However, there is also some disadvantage here.

As the thickness of the walls increases, the mass of one column also increases.

For example, an I-beam with a cross section of 30 cm and marked “B” will weigh about 33 kg. But if we take the same section for a column type, then its mass will be about 87 kg (twice as much).

One of the distinctive features lies in the fact that the beam faces can be located at different angles.

This means that it can be changed for each application, which will further increase the strength and rigidity of the structure on an individual basis.

One of the main differences and advantages of this type of beam is a well-calculated interface. This allows the beams to cope well not only with static loads, but also with dynamic ones.

This type of load can arise due to a variety of factors.

This feature has led to the fact that column I-beams have been successfully used in areas where there is increased seismic activity.

Methods for securing a channel when installing floors

- The interfloor floor beam is hinged and supported and experiences a uniformly distributed load.

- A canopy made of two channels with reinforced concrete filler - cantilever beams with rigid embedding, loaded evenly distributed.

- The floor beam extended beyond the wall is hinged and supported with a uniform load.

- A lintel designed to support one or two floor beams is hinged and supported with one or two concentrated loads.

- A canopy made of two profiles with a steel sheet between them and with an installed wall - cantilever beams with a concentrated load.

The reliability of the building structure largely depends on the correct choice of the channel number, the pitch between the beams and the method of fastening.

What is stronger, channel or I-beam

Channels and I-beams are the most reliable types of long products used for tying foundations, strengthening walls, and installing floors in building structures.

An I-beam is a wall with perpendicular flanges of the same length (it is sometimes called an “H-profile” due to its external resemblance to a letter). A channel is a profile in the form of a wall with two shelves, externally resembling the letter “P”.

Channel or I-beam

It should be borne in mind that the comparison is only reasonable for beams and channels with the same wall height and profile thickness. There is no point in comparing, for example, beam No. 14B1 and channel 24P.

Numbers, letters and GOSTs

According to the production method, the channel can be bent or hot-rolled. It is easy to distinguish them even for a non-specialist - a hot-rolled channel has a clearly defined edge, while a bent channel it will be somewhat rounded. Other features of various types of channel are determined by their markings.

In particular, the letters A, B and C in relation to batches of hot-rolled channels will indicate that the rolling was carried out with high (A), increased (B) or normal accuracy (C).

The channel number indicates the height of its section, expressed in centimeters.

The width of the profile corresponds to the width of the shelf and can range from 32 to 115 mm. The marking of a channel, for example 10P, reflects its height and type of profile. The height of the channel section is generally the main parameter in its marking. The channel number is its height in centimeters, and the letters adjacent to it indicate that the channel cross-section can be:

1) with a slope of edges (series U and C), where U is the slope, and C or Sb are special series. 2) with parallel edges (P, E and L series), where E means economical series, and L means light. Letters C (for example - 18С, 20С, etc.

), can be found in products intended for the automotive industry or for the construction of railway cars (GOST 5267.1-90). Sometimes there are also exotic types of channels.

For example, GOST 21026-75 determines the parameters of channels with a bent flange (they are used in the production of trolleys for mines and mines).

The most popular channel sizes

The most popular among consumers are channels with numbers from 8 to 20. Their geometric parameters in categories P (that is, with parallel edges) and series Y (with a slope of internal edges) are the same, the difference is observed only in the radii of curvature and the angles of inclination of the shelves.

Channel 8

It is mainly used to strengthen structures inside domestic and industrial buildings. In its production, semi-quiet (3PS) and mild (3SP) carbon steels are used, which are characterized by excellent weldability.

Channel 10

widely used in mechanical engineering, machine tool manufacturing and other areas of industry. It is also successfully used in the construction of bridges, walls and load-bearing supports in the construction of industrial buildings.

Channel 12

is very similar to the “eight” channel, but has higher strength characteristics and load-bearing capacity, which makes it possible to reduce the metal consumption of structures erected with its participation.

Channel 14

- one of the most popular types of channels. used in building structures for rigid reinforcement of load-bearing parts, giving metal structures special strength and rigidity. Channel 14 comes in standard and increased accuracy.

Channel 20 acts as a load-bearing element when reinforcing bridges, when reinforcing floors (including complex ones) of multi-storey buildings, and in roof purlins.

Due to its high performance qualities, the “twenty” is often used in structures with high loads - both dynamic and static.

There are also non-standard applications of channels. A perforated (that is, “holey”) channel allows, for example, the installation of metal structures without welding, which significantly reduces installation time.

For perforation, channels with high shelf heights and wide distances between them are best suited.

Such products are designated by the letters ШП - “Perforated Channel” and are most often used in the construction of temporary structures (for example, scaffolding) or warehouse racks.

Areas of application of channels

Since the channel is very durable, it is widely used in construction and industry. In the production of cars and car bodies, a special-purpose channel made to order is used. During construction, it is used for the construction of load-bearing structures, frames, ramps, stands, where the use of conventional reinforcement will not be enough.

It is often used as a load-bearing part in spans and ceilings in building elements that have a large mass or are subject to large mechanical loads. Also, with the help of a channel, load-bearing walls are strengthened and door and window openings are reinforced with them.