When constructing a reinforcement cage for concrete structures, the rods must be tied together. For knitting, wire is used, which is twisted with a special hook. A hook for tying reinforcement is sold at any hardware store. However, an easy-to-use tool can be made independently using available materials.

What is a hook for tying reinforcement

A large number of fittings connected using a cooking apparatus are most often subject to corrosion, which leads to a loss of structural quality. It is recommended to connect frame parts made of reinforcing bars using a knitting method, which can ensure the strength and stability of the structure.

In this case, the knitting wire is tightened using a reinforcing hook. The device is a comfortable handle that holds a metal hook in the form of a rod with a curved tip. This configuration of the handheld device helps to grip the wire during tying.

A crochet hook allows you to reduce the labor intensity of work on forming a reinforcement frame. The frame is used in the construction of foundations, columns, walls, ceilings or fences. Knitting should not take a lot of effort and time, so as not to increase the delivery time of the project and correctly distribute working time on the construction site.

Methods for connecting reinforcement

There are several methods for connecting reinforcing bars to form a stable frame. Builders use four main methods of fastening:

- welding using a machine;

- knitting using wire;

- laying overlapping reinforcement;

- connection of rods with steel couplings.

Most often, when constructing buildings and structures, the first two methods are used: welding and knitting with wire material.

Fastening the reinforcement cage using a welding machine is effective, but not always justified.

The disadvantages of using welding include:

- the need for professional skills, which leads to an increase in the cost of the construction project;

- lack of strength at welded joints;

- some types of reinforcement cannot be connected by welding, for example, fiberglass or class A-400 rods;

- the likelihood of damage to reinforcement joints during concrete compaction using a vibrator.

In such cases, it is rational to use a crochet hook. Advantages of forming a reinforcement cage:

- the use of a crochet hook speeds up the work;

- in case of shortcomings and deviations, errors are easy to correct;

- the broken wire material can not be removed by applying an additional layer;

- The reinforcement is fastened directly in the formwork;

- low cost of work.

Disadvantages include instability and unsteadiness of the reinforcement frame when moving. When transferring the structure into the formwork, the reinforcement may sag and lose tension at the attachment points.

Types of hooks

The structure and method of application of hooks can vary significantly. Among the varieties of devices for fastening reinforcement, three main types can be distinguished.

Simple hooks

A primitive product that consists of a rod ending with a hook at the end. The design allows for easy gripping of the wire loop. The tool rod has a curved shape, which, in combination with a bearing in the handle, provides the device with a high rotation speed.

Manual rotation of the device at a sufficient speed allows you to tighten the wire tightly. The simple hook design is suitable for small jobs in home construction. The advantages of such a tool:

- low market value;

- ease of operation;

- ease of use in hard-to-reach places.

Disadvantages include the inconvenience of use on large-scale construction projects.

Screw hooks

The semi-automatic tool tightens the wire by rotating the hook-shaped tip. The device has a different design from a simple tool, but at the same time makes the work of the master easier. During the knitting process, the rotational movement is ensured by the translational force of the tool, which is transmitted using a worm gear.

A screw hook for tying reinforcement provides high speed of work, but the cost of the device is slightly higher than a primitive tool. A device for knitting reinforcement is called differently - reversible. This tool has some advantages:

- long operation;

- ease of use;

- significant speed of knitting.

Purchasing tools makes sense for large volumes of work on a construction site.

Tying gun

The hook design is characterized by high performance, so it is mainly used on large construction sites. The device of the tool is automated and operates when connected to the network or with batteries.

The principle of operation of the gun is to dock with the tying element and press the release button. In a few seconds, the wire is wound and tightened into a strong knot with uniform tension.

To work with such a tool, wire with certain parameters and rigidity characteristics is used, otherwise the device will break.

The choice of the type of tool for the fastening procedure depends on the characteristics of the installation of the reinforcement and the purpose of using the gun. It is used for both metal and fiberglass reinforcement, for which annealed steel wire, plastic clamps or plastic fasteners are used.

Forming a reinforcement frame using a gun involves a lot of wire consumption. There are pistols powered by central electricity and batteries. The time spent connecting one node is 1 second.

At the same time, pistols have some disadvantages in operation:

- the need for an electrical outlet to operate the tool or to charge the battery;

- high cost of the device;

- The wire for knitting must be of the same diameter.

How to knit the frame?

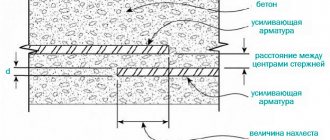

When reinforcing a small volume of concrete, builders simply place the reinforcement in the formwork and then fill it with mortar. However, if large concrete products are to be reinforced, for example, a monolithic (slab) or massive strip foundation, then a frame is required. The reinforcement must be distributed evenly throughout the entire volume of concrete in order to reliably perform its function of increasing the strength of the structure. In these cases, a complex frame is made from metal rods.

crochet hook

The first option is the simplest and most accessible. If necessary, you can buy it in a specialized store for a hundred rubles or even cheaper. Moreover, it can be made by hand if the suitable material is available - we will return to this later. The downside is low performance. A novice knitter, with a sufficient supply of wire, will be able to produce 6-10 knitting per minute.

Screw hook

The screw hook is the next step in the development of the tool for knitting reinforcement. Outwardly, it looks a little like a regular one, but thanks to it, the knitting speed will increase, and the worker will get tired much less. If, when working with a regular hook, a specialist must twist the ends of the wire and manually twist them, then a screw hook is much more convenient.

Loop the loop and ends, then gently but firmly pull towards you. The plastic handle will be fixed in the hand, and the hook itself will begin to spin quickly, securely tightening the loop. Such a tool costs from 600 to 1000 rubles, depending on the manufacturer and store. It will be an excellent choice if you need to perform work once on a relatively large object. The knitting speed will increase, however, the wire will still have to be cut and bent by hand.

DIY hook for tying reinforcement

When building a country cottage or country house, you can make a hook for tying reinforcement yourself from scrap materials.

Electrode hook

To produce the tool you will need:

- welding electrode with a diameter of 3-4 mm;

- a handle from a construction trowel or a piece of small diameter rubber hose.

The hook is useful for small jobs. With this type of hook, thin wire is used for tying, since using this tool involves manual labor, which can quickly tire your hand.

For tying foundation reinforcement, it is better to use a hook with a more massive structure.

The electrode device is made in stages:

- A piece is cut from the hose and a handle is made to fit the size of the rod.

- The rod and handle are connected using epoxy resin.

- The working part of the future hook is bent at 90°, departing from the handle by about 6 cm.

- In this case, a tip measuring 2 cm is deformed into the shape of an arc.

After all the manipulations, the hook for tying the wire is sharpened with a file.

Rebar hook

A hook with a rod made of reinforcement can withstand a fairly large load. To make the tool you will need:

- reinforcing rod with a diameter of 6-8 mm;

- hex washers or nuts that are installed on the rod as clamps;

- a handle from an old tool: a screwdriver or a paint roller.

The fittings are inserted into the handle and secured with a washer or nut. The rod must be bent as in the case of making a hook from an electrode. In this case, the tip of the reinforcing rod is ground off and twisted into a loop.

It must be remembered that the handle must have a hole larger than the cross-section of the rod. This is necessary so that the handle rotates freely around the reinforcing bar.

The process of making a crochet hook from reinforcement is not complicated. At the same time, the design is durable, which will allow you to use the tool for a long time.

Hook using a screwdriver

A simple way to make a semi-automatic tool for tying reinforcement. To do this, use a metal rod or a large nail with the head torn off. The sharp tip of the rod is bent to the shape of a hook. The other side is inserted into the screwdriver hole and secured. Thus, knitting occurs due to the operation of the electric motor of the construction tool, which greatly simplifies and speeds up the process.

Tying reinforcement with a knitting gun: pros and cons

The first thing any novice developer who decides to assemble a reinforcement cage thinks about is how to knit it. Some people use homemade or purchased hooks for this.

Others prefer to use pliers. Still others believe that only purchasing a special cordless gun for tying reinforcement will solve the problem.

As the practice of our users shows, in most cases, a battery-powered knitting gun is too expensive for regular construction. In addition to the high price (branded models cost $1,000 - $2,000), a knitting gun can sometimes be difficult to tighten the wire. Moreover, you will have to buy special wire on spools for the equipment (not cheap). An attempt to “outsmart” the mechanism and, after the branded wire runs out, wind an ordinary one on a reel, will lead to equipment failure.

Mitriy FORUMHOUSE user

I don’t recommend even trying to wind a simple wire bought at the nearest market instead of branded wire. Verified. A couple of such “charged” coils, and dirty, poorly annealed wire will break the knitting gun. The designers have provided protection from self-made consumables. In addition to the breakdown of an expensive “toy”, after such a trick you are automatically void of the warranty.

Despite the high price of an automatic knitting gun, there are enthusiasts on the portal who either buy it or rent it.

Sergey960FORUMHOUSE user

I liked working with this equipment. One knitting gun replaces several people. Batteries charge quickly. Just have time to change the coils. Of the minuses, I’ll note - yes, it’s expensive. Both the gun and the coils cost money. I heard that you can’t get into everything with a pistol, especially in narrow places, but for large volumes and for professional use I think that this is a justified purchase.

TitovchaninFORUMHOUSE user

My hard workers and I enjoyed working with a knitting gun, but it is an expensive pleasure.

Another disadvantage of a knitting gun, especially in relation to our construction conditions, is the possibility of its breakdown due to the “crooked” hands of workers or the banal theft of an expensive tool.

Most often, the cordless gun is used to knit the reinforcement of slab foundations when installing horizontally laid reinforcement in a mesh.

The experience of a portal participant with the nickname Sinyavinsky is interesting. The user rented a pistol and was completely disappointed in it. According to the participant, the gun has poor control over the tension of the wire. The wire gets tangled or wound in the wrong place. As a result, Sinyavinsky abandoned the use of a knitting gun and hired “reinforcement workers” who tied the frame with hooks.

Conclusion: with all the advantages of a knitting gun, its purchase or rental requires careful calculation to determine whether it is economically justified. Therefore, most people prefer the method that has been proven over the years - crocheting reinforcement.

Tagan1FORUMHOUSE user

My workers knit reinforcement cages with a regular crochet hook with a rotating wooden handle. The price of the device is 150 rubles. And all sorts of automatic mechanisms, including reversible hooks and the use of a screwdriver, are just pampering. Professionals use hooks.

About the pros and cons of using the so-called for tying reinforcement. semi-automatic devices - hooks with reverse and battery-powered "Shuras" with a hook clamped in the cartridge, we will tell you in the second part of the article. Now let’s describe in more detail the process of making a homemade hook and tell you how to knit reinforcement correctly.

Knitting technology

There are several types of knitting:

- double;

- corner;

- double row;

- cross;

- "dead node"

The knitting process does not depend on the type of hook used, whether it is a homemade device or a factory-made tool. Before using manual and semi-automatic devices, it is necessary to cut the wire for knitting.

Typically, pieces about 30-40 cm long are cut, the size of the wire generally depends on the diameter of the reinforcing bar.

Before carrying out work, it is recommended to cut several samples of wire material for test twisting. Next, following the instructions, knit the reinforcement cage.

- Fold a piece of wire in half and wrap it around the knot that requires tying.

- Insert the hook into the resulting loop, hook the opposite end of the wire and begin rotating with the twisting tool.

- The first few revolutions are made quite quickly. At the last stage, the pace must be slowed down and the fastening carefully tightened.

- Pull the tool out of the loop and check the strength of the knot.

To check the reliability of fastening, you need to move the reinforcing mesh. The frame rods must be firmly and motionlessly positioned relative to each other.

The process of tying wire using a screw hook looks almost the same, taking into account the nuances of the tool’s design. The wire for the bundle is folded in half and installed at the location where the reinforcement is attached. Then the ends of the wire are bent and placed on the hook.

The action of a screw tool does not involve making circular turns with a brush. To operate, you need to pull the handle towards you, and the displacement leads to rotation of the rod. The handle is released and the action is repeated, the number of which depends on the required rigidity.

Tying a dead knot

A tie, which is called a “dead knot,” is used for structures consisting of reinforcement, rods and clamps.

This type of reinforcement frame is usually used in the construction of beams and columns.

The unit securely and firmly fixes the reinforcing bar into the corner of the clamp. Knitting is done in this way:

- A piece of wire about 20-40 cm long is bent in half.

- Pass the loop forward under the bottom of the reinforcement rod on the left side of the clamp. In this case, leave the ends of the wire approximately 2-4 cm long for twisting the knot.

- Place the wire over the clamp, bending it under the bottom of the reinforcing bar.

- The crochet hook is inserted into the loop and the free end of the wire material is grabbed.

- Pull the hook towards you, making several turns. Do this until the wire is completely clamped.

The binding is checked by loosening the clamp by hand. If the clamp gives in, it means that the knot is made incorrectly, or the wire is not fully tightened. When performing reinforcement of complex structural elements, a combined combination of nodes is used. First, a “dead knot” is performed, and then two simple ones are mounted crosswise.

Work specifics

Externally, the instrument is a fairly compact device that weighs a little more than 4 kg.

The main components of the pistol are:

- Case with mechanism.

- Cutting mechanism.

- Handle with start button.

- Wire feed mechanism.

- Working part.

- Electric drive device

- Reel holder.

- Wire cassette.

Expert opinion

Torsunov Pavel Maksimovich

The specific operation of the knitting device is quite simple: wire is fed from a reel, a loop is formed at the intersection of the reinforcing bars, tightened, and then the wire is automatically cut off.

Wire selection

According to standards, when tying reinforcement, baked steel wire is used. In this case, the cross-section of the wire is selected relative to the parameters of the reinforcing bars, which is prescribed in the building codes.

The following requirements must be met:

- for reinforcement with a cross-section of up to 12 mm, 1.2 mm wire is used;

- with a cross section of 16-18 mm, 1.6 mm wire is used;

- with a cross section of more than 18 mm, 2.0 mm wire is used.

The choice of material for knitting affects the strength of the rod frame and the speed of work.

Top best models

Firecore, 12 V, 1500 mAh

- Plus: high binding speed.

- Cons : none found.

Grost RT 308 C

- Plus: easy knitting of reinforcement.

- Cons: none found.

Egor: “Before using a new coil from the components, I sand it down. After this, the feed goes smoothly, the reel does not bite.”

Firecore, 12 V, 3000 mAh

- Plus: 2 batteries included.

- Cons: Not found.

Recommendations for mating

Having selected the wire of the required diameter and prepared the tool for knitting, it is recommended to follow the tips:

- to fix the immobility of perpendicular rods during knitting, you can use boards, clamping the ends of the rods with them;

- after knitting, it is necessary to check the strength of the nodes, since when pouring concrete using a concrete pump, shifts and displacements of the frame may occur;

- Corner rods need stronger reinforcement, so the wire assemblies at the corners are made and checked especially carefully.

You can check the strength of a frame made of reinforcement using the mechanical influence of a person’s weight.

Knitting the reinforcement frame is necessary when forming monolithic reinforced concrete building elements. Since the number of knots when attaching rods is quite large, it becomes necessary to choose the optimal method of twisting the wire. For this, a special hook is used, the design of which may vary. Moreover, each knitting tool has its own advantages that will be useful in certain areas of construction.

In conclusion

Knitting reinforcement is, although not the easiest task, but, in principle, quite doable even by the most inexperienced craftsman. You just need to stock up on the necessary tools, choose the appropriate knitting method and get to work. Of course, using plastic clamps is the easiest and cheapest way, and a special gun for tying is even faster, but it will be very expensive, which is why many still use a special hook: although it takes longer to work, it is not difficult with some skill, and in the end strong connections are obtained.

The article was written for the site.

Tags:Construction fasteners