Sometimes the question arises of how to solder without a soldering iron, because soldering is the most common way to connect small parts at home. But what to do when you urgently need to connect wires, and the soldering iron is broken.

A soldering iron is a convenient and simple tool. You can use it to connect small products at home.

A soldering iron is a simple and convenient tool. Probably everyone knows how to join metals using it. But how to solder without a soldering iron when there is no electricity is a question that should be considered in more detail.

Tinning without a soldering iron

Tinning is the preliminary application of a thin layer of solder to the surface of the parts to be joined. It is produced to improve electrical contact and improve soldering quality.

Tinning can be done without a soldering iron. To do this, you need to prepare a small metal trough. In terms of size, a metal lid of a can, for example, from instant coffee, is best suited. Small pieces of POS60 tin-lead solder (pure tin is even better) and rosin are placed in the lid.

Soldering with foil.

If you need to solder wires, then first remove the insulation from their ends at a distance of approximately 20-30 mm. The container with solder and rosin is heated until the solder melts. As a heater, you can use an electric stove, a candle, a fire, or any open flame source. The bare end of the wire is immersed in molten rosin so that the flux covers the entire surface. Then the treated section of the wire is placed in molten solder for 2-3 s. After removing the wire from the melt, with a quick movement of your hand, using a rag, remove excess solder. A thin, uniform layer of tin should remain on the surface of the wire.

If you need to tin a section of a flat part, then finely planed solder and a small piece of rosin are poured onto its surface. The heating flame is brought from below the part, under the soldering area. After melting, the solder is rubbed over the surface with a steel rod. Excess mass is removed with a rag. When tinning a steel part, rosin is not used. The soldering area is carefully treated with soldering acid. The tinning process itself is similar.

Electronics for everyone

When solder paste was delivered to the only normal store in the city, almost to order, I was first in line for it. I have long wanted to completely switch to SMD, as the laziest technology - too lazy to drill holes and there was a soldering station LINKO 850, a Chinese clone I don’t know what (Well, judging by the style of writing the logo, they mow everything under HAKKO =) A kind of Adibas =) approx. DI HALT), so far used only for dismantling. Picking out mosfets from motherboards is a nice thing to do. The paste I had was BAKU BK-30G

(I have the same mud. It’s a nasty thing, but it’s fun to solder with. Note: DI HALT)

We develop the board as usual.

Wiring Tips for SMD Mounting

- Two sites are nearby - never merge them! On the contrary, stretch it and connect it with a thin conductor, so they will not stick together (which makes the board look sloppy) and will allow you to visually check the presence of a line between them (there are simply two resistors next to each other, or there is a conductor there).

- Don't chase the size! Make the pads slightly larger than the component, and leave enough space between them. If you are limited in size, take a larger case, or make a double-sided board. At first I suffered from this kind of bullshit. While there is enough resolution - I placed it as close to each other as possible, now there are a bunch of small boards with 1206 components stuck in a checkerboard pattern - the board and conductors behind them are not visible.

After which we etch as usual, but there are problems with tinning: I tin with rose alloy, followed by removing the excess layer with a hot rubber scraper (right in the same pan/jar where the board was tinned) - I get flat conductors with an almost mirror-like shine

If you don’t have one, you can use the following hint - we wind a braid on a low-power soldering iron to remove the solder, tin it, and run it along the tracks previously coated with flux. If you can’t do this and tin with a sting, leave as thin a layer of tin as possible on the contact pads. On flat traces, parts are practically “glued” to the solder paste, but they are less easily installed on a convex tin layer. It’s okay if it’s still a resistor - it will still be pulled into place by the surface tension of the solder (the main thing is to keep the air pressure to a minimum so as not to blow it away).

But mikruh (for example, the well-known FT232RL) on a convex surface is oh so difficult to install evenly, everything tends to fall into the hole between the tracks, and if it does, the air flow, even at a low degree, will blow it into that very hole, after which the solder will dirty the legs , and contacts, turning the terminals into a monolith , and the flux will almost completely evaporate in a minute, after which it will be almost impossible to move it normally without first coating the terminals with some kind of rosin gel.

In short, as a result, we should get a board with FLAT contact pads (the flux is weak, it sticks to pink copper and rose alloy with a bang, but not so much to dirty copper).

After which, having thoroughly stirred the paste, carefully, avoiding air bubbles, we draw the semi-liquid paste (This paste, by the way, tends to dry out, even when tightly closed. You can soak it by adding alcohol to it, approx. DI HALT) into a regular insulin syringe, we put it on and break off (as it is convenient for anyone, I first broke off the needle, leaving a centimeter, then spat and broke off at the root) the needle.

Now, having washed it thoroughly and dried it even more thoroughly (: the board, we put a little bit of paste on each area. You can look at the photo how much exactly, but after two or three times you will understand, after which we press the crumbs with tweezers.

Installation Tips

- We install tall and large components last. First capacitors 0603, then resistors 1206, high LEDs, and then mikruhi.

- Each size has its own tweezers. (or is this already bourgeoisie?) usually two are enough - small change and mikrukh. You can’t pick up the same 2313 with small tweezers, and with large ones you can’t fit the resistors as carefully as with small ones - your hands are shaking or something. (And one was always enough for me. Note: DI HALT)

Now, heating the board with a hairdryer, you can observe how the paste, having first boiled with flux and dried, begins to turn into molten metal, which will reliably weld the parts to the board (the paste, by the way, decreases very much in volume. Where there was a huge snot, a small drop remains Note: DI HALT)

Due to the fact that the temperature of my station fluctuates a little, I had to learn how to determine the degree of roasting by...smell ^_^ When the flux heats up to operating temperature, it starts to smell like something similar to vanilla ;-), and when it starts to smell like burnt hair, that means Again, I turned the temperature knob with my elbow and I have to go and buy 5 LEDs to replace the fried ones. (I prefer to fry at a hair dryer outlet temperature of about 290 degrees. The board will have 10 degrees less, just right. And the air flow will be at a minimum. Note DI HALT).

Soldering wires without using a soldering iron

The question of how to solder copper wires with a cross-section of up to 0.75 mm² without a soldering iron is easily resolved. The tinned ends of the wires are twisted together. The soldering area is heated until the solder layer melts. As a heater, you need to use a source of narrowly directed flame: a candle, a lighter, matches. The solder applied to the surface during tinning should be enough to solder the wires.

If you need to solder a wire to the middle of another wire, then its end should be wrapped around the connection point (2-3 turns) or clasped around this area, bending the wire 180º. The soldering itself is done in the same way as connecting the ends of the wires.

It is recommended to solder aluminum cookware with special solder made from tin and lead.

When soldering larger wires, the mass of tin in the tinned layer may not be enough for a reliable connection. In this case, finely grated solder should be poured on top of the twisted area and heated until it melts and fills the gaps in the twist. This way you can solder copper wires with a diameter of up to 2 mm without a soldering iron.

Sometimes it is necessary to solder a wire to a flat surface. To do this, the end of the wire and a section of the surface of the part (case) are pre-tinned. The wire is pressed against the plane of the part, and finely sawn solder is poured on top of the soldering area. By heating the parts from below, the tin melts.

Foil as a soldering method

The soldering method using foil is characterized by practicality. Typically, it only takes 5 minutes to restore the connection. Foil can be used as solder, which is unwound over the entire area and heated to a high temperature. Due to this, the plasticity of the material increases significantly; after cooling, it hardens.

Foil can be used in a variety of cases. An example is damage to the board or wire connection. Among the features of the work carried out, we note the following points:

- Standard contact preparation is carried out.

- The ends are twisted to form a joint. Due to this, the reliability of the connection is significantly increased.

- The required amount of foil is cut off, the junction is wrapped in several skeins.

After this, uniform heating is carried out using a hair dryer or other heat source. When exposed to heat, the surface of the foil quickly becomes soft and plastic; after heating stops, it quickly cools and hardens, providing the required degree of sealing and strength.

In conclusion, we note that without a soldering iron it is almost impossible to carry out jewelry work, as well as soldering circuit boards. This is due to the lack of possibility of directed heat exposure. However, in some cases a soldering iron and other tools are not required.

Features of soldering in the groove

Soldering of wires with a diameter of up to 3 mm can be done without a soldering iron using a groove. This groove is made of aluminum foil about 0.8 mm thick. Soldering is done in the following order. At the ends of the connected wires, the insulation is removed to a length of about 30 mm. The bare ends are twisted together or laid parallel.

The foil is cut in the form of a short strip with a width equal to the width of the connection area, and is bent in the form of a groove, covering the joined wires. Crushed solder and rosin are evenly poured into the groove. One end of the foil is tightly wrapped around the area to be joined so that the solder does not spill out. When working, pliers with thin noses are used. The area covered with foil is heated with a candle, lighter, etc. until the solder melts. After the mass hardens, the foil is removed.

If necessary, excess solder is removed with emery cloth or a file.

Varieties

The modern market offers products from the brands ALPHA, HERAEUS, Felder, etc. All soldering pastes are classified according to the following criteria:

- according to the composition of the solder - halogen-free or halogen-containing;

- if necessary, additional washing;

- by type of solder - lead-free or lead-based;

- according to temperature indicators - high, medium, low temperature.

If the composition is not washed off, it contains rosin. In such a situation, special solvents must be used to wash the elements.

It is also necessary to take into account that an increase in the level of solderability of elements is accompanied by a decrease in the reliability of fixation. For example, compositions containing halogen are highly technological, but their reliability is low.

Soldering utensils or containers

The device of a homemade soldering iron.

Very often there is a need to solder a small hole in a pan or bucket. If the hole is no more than 6-7 mm, soldering can be done without a soldering iron. To do this, it is enough to use POS60 solder. The area around the hole must be carefully sanded inside the container so that the hole is given a conical shape (with an expansion into the container). This area is then treated with hydrochloric or soldering acid. A small thin plate is placed at the bottom of the hole to prevent solder leakage. From inside the container, crushed solder and rosin are poured into the hole. The container is placed on a source of directed fire. Molten solder seals the hole.

Read also: Sharpener for saw chains

If you need to solder aluminum cookware, you should prepare special solder in advance. You can use one of the recipes: tin and zinc in a ratio of 4:1; tin and bismuth in a ratio of 30:1 or tin and aluminum in a ratio of 99:1. Such alloys can only be prepared at high temperatures by stirring the melt.

Main conclusions

Soldering SMD LEDs is not very difficult, but requires care and caution. You should remember the danger of overheating of the elements, which will result in their failure. It is necessary to ensure compliance with the following conditions:

- use a low-power soldering iron with a heating temperature no higher than 260°;

- use high-quality flux (experts recommend a special composition for soldering aluminum);

- limit the contact time of LEDs with the soldering iron tip.

In addition, you must remember to maintain polarity and monitor the condition of the current-carrying paths. Please share your options for soldering SMD LEDs in the comments.

Soldering using paste

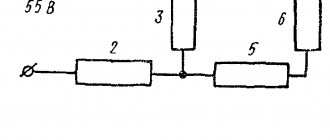

Necessary tools for a soldering iron made from a paper clip: 1 – autogenous lighter, 2 – metal paper clip, 3 – pliers, 4 – slotted (flat) screwdriver.

You can solder a wire or radio component without a soldering iron using solder paste. This pasta is prepared with your own hands. To obtain the “tinol” paste, 32 ml of concentrated hydrochloric acid is poured into an enamel container and mixed with 12 ml of water. 8.1 g of zinc is added to the liquid, and after its dissolution - 7.8 g of tin. After the end of the chemical reaction, the water is evaporated until a paste-like composition is formed. Further operations should be carried out in porcelain dishes. 7.4 g of lead and 14.8 g of tin are added to the paste in the form of powder, as well as 10 ml of glycerin, 7.5 g of dry ammonia, 29.6 g of zinc in the form of dust and 9.4 g of rosin. The added substances are preheated and mixed in the form of powder.

Soldering a wire or part is done in the following order:

- The soldering area is cleaned.

- The paste is spread on it using a brush.

- The soldering area is heated on the flame of an alcohol lamp or candle until the paste melts.

When soldering small radio components or thin copper wire, you can use a slightly different composition: 7.4 g of lead powder, 738 g of zinc dust, 14 ml of glycerin, 4 g of rosin, 14.8 g of tin in powder form. The paste-like state is achieved mainly in two ways: by mixing with glycerin or with a solution of 10 g of rosin in 10 ml of diethyl ether.

Making at home

Sometimes ready-made solder paste is not available, so it is useful to learn about how to make it. For this purpose, it is necessary to prepare soldering fat and a solder rod made of lead and tin. If the first material is not available, it can be replaced with Vaseline LTI-120.

The solder must be crushed using a needle file or a special drill attachment. The finished crumb should consist of small particles. It is put into a container into which Vaseline is added in a 1:1 ratio and a small amount of flux.

All components of the homemade paste are thoroughly mixed and heated in a water bath. The finished composition can be stored in a large syringe. With the help of it, a paste-like substance will be applied to the boards.

To increase the efficiency of the solder mass, you can add a little ammonium chloride to it. In the finished mixture, the concentration of this ingredient should not exceed 5-10%. You can replace ammonium with aniline hydrochloride. Substances must be stored in sealed containers and away from pets and children.

Homemade soldering iron

In places where there is no electricity, you can use a homemade analogue of a soldering iron. To do this, you need to find a copper rod (wire) with a diameter of 4-5 mm and a length of about 10 cm. One end of the rod is ground off in the form of a screwdriver, and the other is fixed in a wooden handle. This round shaped handle can be easily cut from a tree branch. Such a basic soldering iron is heated from an open flame. The soldering process itself is not much different from soldering with an electric soldering iron. You just need to adapt a heat-resistant stand into which the device is installed when heated. Installation should be done quickly - with one movement of the hand. Solder and rosin should be in a flat container. The soldering of wires or other parts is carried out in close proximity to the heating source.

Some tips on how to use a homemade soldering iron

In general, soldering is the joining of two metals using another molten metal. This metal, called solder, must fill the space between the parts and adhere to the surface of the materials being joined.

The most commonly used solder is a tin-lead alloy with varying tin content; Moreover, the more tin in the alloy, the lower its melting point. Thus, the common solder brand POS40 (tin content 40%) melts at a temperature of 230ºC, and POS60 (60% tin) - at 180ºC. The melting point of a tin-lead alloy with the introduction of bismuth (POSV33 solder) has an even lower melting point - 130ºС. When soldering aluminum, special alloys with a melting point of more than 400ºC are required. Standard tin-lead solders are sold in the form of rods or wires with a diameter of up to 2 mm.

Soldering cannot be carried out without cleaning the parts in the joint area from the oxide film. To do this, it is necessary to use flux, i.e. a substance that prevents the formation of an oxide film during soldering. When joining copper parts, rosin is usually used as a flux. Cleaning the surface of workpieces can be done using soldering acid or other acids (for example, phosphoric acid in relation to aluminum soldering). If it is necessary to solder steel products or galvanized parts, then rosin will not help; soldering acid should be used. Modern solder wire of the POS type has rosin inside it, which ensures soldering of copper without additional flux. To connect steel and nichrome elements, a flux made according to the “folk recipe” - aspirin - is sometimes used.

The generalized mechanism for soldering metals is as follows. The connected parts are pressed tightly against each other. Solder and flux are introduced into the soldering area. The soldering area must be heated to a temperature sufficient to melt the solder and flow into the gap between the metals. Before hardening, it is necessary to ensure that the melt is in the gap. Usually the whole process is easily done with a soldering iron, but parts can be soldered without it. To do this, the most important thing is to find an alternative heater that does not use electricity.

Application benefits

Solder pastes are used not only in everyday life, but also in industry. Such widespread distribution of this material is explained by its following advantages:

If there is no opportunity or desire to make the mixture yourself, you can purchase a ready-made version. But you need to remember that high-quality solder paste costs about 10 US dollars per 50 g. Cheaper options are of poor quality and may not only not provide sufficient fixation reliability, but also lead to additional problems during subsequent use of the electronic product. To avoid problems, it is better to buy such materials in certified stores or directly from manufacturers.

Source

Necessary tool

If you need to solder a wire or something else without a soldering iron, you need to prepare the following tool:

- pliers with thin noses;

- pliers;

- knife;

- scissors;

- sandpaper;

- file;

- needle file;

- brush.

An alcohol lamp or dry alcohol lamp should be used as a fire source.

The question of how to solder without a soldering iron seems absurd only at first glance. Such soldering can be done in very simple ways, or it can be done efficiently using solder paste.

A soldering iron is a very convenient tool that allows you to quickly and reliably connect a wide variety of metal parts and mount electronic components on a printed circuit board. Its absence or power outage at the most inopportune moment significantly complicates installation. But we know how to solder an electrical wire without a soldering iron, and we hasten to share this information with all interested readers.

Read also: Diagnostics of the generator voltage regulator

Welding pencil

This is an affordable tool that is sold in almost all specialized stores. It helps to make high-quality soldering without using a traditional soldering iron. The pencil can be stored in the house for an unlimited time; it is suitable for soldering various metals.

Instructions for using the pencil are included in the package. It's extremely easy to use:

- one end of the pencil must be heated in any convenient way;

- hold the molten end on the desired area;

- wait until the molten material cools down.

The result is a solder joint that can withstand temperatures up to 180 degrees. On average, one pencil is enough to carry out 30 rations.

How to tin parts without using a soldering iron

Before joining metal parts, a procedure such as tinning is usually required. It allows you to significantly improve the quality of soldering and significantly improve contact. To tin surfaces, you need a soldering iron, but if you have certain skills, you can do without it. You just need to follow these simple steps:

- In a small metal container we place scraps of tin or lead solder, as well as several small particles of rosin.

- Remove the insulating layer from the wires.

- Heat the container until the tin or lead completely melts. For this purpose, you can use a household electric stove or even a small fire flame.

- Dip the wire into rosin and then into molten solder. Just 2-3 seconds is enough.

- Using a rag prepared in advance, we quickly remove excess solder, not allowing it to harden.

When working with metal parts, rosin and small solder shavings are placed directly on their surface. After this, we warm up the part well at the processing site and use a steel rod to grind the tin.

Headphone repair

Not everyone these days has a soldering iron at home, which cannot be said about headphones, and the latter tend to often fail. In order to correct the situation, you will need a working connector from other headphones with a wire or an AUX cable, as well as an ordinary lighter, knife and tape. How to fix headphones without a soldering iron:

- First, cut the AUX cable about five centimeters from its beginning.

- Remove the braid.

- Clean off the nylon and varnish that covers the wires.

- Cut the headphone wire about three centimeters from the beginning (it can be higher), since the wires in the headphones break not much above the connection point.

- Twist the three AUX wires together with the headphone wires.

- Insulate each twist separately. Scotch tape will help with this.

- Tape all the twists together in several layers.

The headphone repair process is complete. After all, you should check them for functionality. All this takes about fifteen minutes, but it can be done faster, depending on your skill. This example clearly shows that it is not necessary to use a soldering iron to connect two wires.

Originally posted 2018-07-04 08:09:40.

Connecting wires without a soldering iron

Thin wires from a garland or any electronics can be easily connected to each other without using a soldering iron. For this purpose you will need:

- tin the ends of the wires;

- twist them together at the place of tinning and, accordingly, connection;

- heat the desired area using a lighter or matches until the solder melts; you can also use a lit candle.

This method allows you to firmly connect the wires to a microcircuit or any other electronic part.

We do the same thing if we need to solder one wire to the middle of another. In this case, the tinned end is simply bent in the form of a hook and put on the desired area.

To solder thick wires after the tinning procedure, you will need to additionally treat the surface with crushed solder. This will provide increased connection reliability.

How to solder SMD components

Installation of LED elements is technologically significantly different from connecting a lamp. Soldering SMD LEDs requires some experience and skill. If there are none, it is recommended to first practice on some unnecessary pieces of wire. This will help you master the art of soldering and keep your LEDs in working order. Before starting work, you should inspect the surface of the board. If it is coated with varnish or a layer of silicone, the current-carrying paths to which the LEDs will be soldered should be freed from them.

The specificity of installing SMD LEDs is the absence of conventional long leads. The elements are installed on the board and soldered to the tracks, for which there are small areas on the sides of the LED device housings. The work requires accuracy and attention. It is important to remember the danger of heating, reducing the time the soldering iron touches SMD parts as much as possible. If there is no appropriate tool, a copper wire about 1 mm thick is wound around the tip of a regular soldering iron. One end of this winding serves as a sting, the heating temperature of which is significantly lower than that of the main element. Let's look at the procedure in more detail:

Connect the wire to the board

If you need to solder a wire to the board, you will need to perform the following steps:

- we tin the section of the part to which the conductor will be attached;

- we tinning the wire itself;

- press the wire firmly and pour crushed solder on top;

- heat the surface until the tin and lead melt.

Soldering in a groove: a reliable connection method

To facilitate the process of soldering wires, you can use a pre-prepared foil groove. The connection is made in the following sequence:

- the wires connected to each other are lowered into the gutter;

- sprinkle small particles of solder and rosin on top;

- roll the foil tightly to prevent tin from spilling out;

- We heat the gutter using the same lighter or candle.

This method allows you to do without tinning the wires and connect them together as reliably as possible.

We repair dishes without a soldering iron

Various containers and other kitchen utensils can be repaired using so-called pencils, which are sold in specialized stores or markets. If such a device is not available, we suggest doing the following:

- We treat the damaged area with sandpaper.

- We remove traces of rust and also perform additional treatment with hydrochloric acid.

- Place a wide plate on the outside of the container by hand. This is needed to prevent solder leakage.

- From the inside, pour crushed tin and rosin onto the damaged area.

- Place the container on the fire and wait for the solder to melt.

Solder paste: we quickly connect parts

Another way to connect wires or metal parts without a soldering iron is to use a special paste consisting of the following ingredients:

- hydrochloric acid – 32 ml;

- tin – 7.8 g;

- zinc – 8.1 g;

- water – 12 ml.

First, we dilute hydrochloric acid in water, and then successively pour zinc and tin into it. Then we add additional components:

- glycerin – 10 ml;

- lead powder – 7.4 g;

- tin – 14.8 g;

- zinc dust – 29.6 g;

- rosin - 9.4 grams.

All ingredients are preheated and mixed together after melting.

The resulting paste-like composition should be spread on the area to be joined. After this, heating is carried out using a candle or lighter until this kind of solder completely melts. The paste connects even thick wires quite reliably, but you will have to tinker with its preparation. It is very important to comply with all the above proportions in order to achieve the desired result.

Modern technologies simplify our life: you can even use technology such as soldering wires without a soldering iron. It appeared recently, but has already become indispensable: its use is often easier than working with a real device.

Soldering is one of the types of joining metal parts, applied to unloaded products. Connects non-ferrous metals of small sizes, connection in another way, which is impossible. Used in electrical engineering to work with low- and medium-current wires. The soldering method involves connecting metal surfaces by applying a low-melting metal that has a high coefficient of adhesion to the surfaces being connected and good conductivity.

The tool itself - the soldering iron - determines the method of applying the connecting substance. But there are methods that explain how to solder a wire without a soldering iron in extreme conditions where there is no electricity.

Solder paste and its properties

Initially, such compositions were used only in SMT technologies. Now their area of use has increased. Solder paste for SMD contains the following ingredients:

- Powdered solder. Most often, alloys based on silver, lead or tin are selected. Lead-free pastes are the most common.

- Degreasing solder.

- Connecting elements. They make it easier to fix elements on the surface of the boards. The larger the board size, the more viscous the soldering paste should be.

- Auxiliary ingredients and activators.

It is possible to achieve high-quality soldering only in a situation where all conditions and shelf life of the solder mass have been met. Most of the ingredients in such formulations have a shelf life of no more than six months. They should be stored at a temperature of +2…+10°C. The room should not be too cold or hot. The air humidity level should not exceed 80%. Before using the composition, it must be warmed to room temperature and only then open the jar or remove the substance from the syringe. In some cases, it takes about 5-6 hours to warm up.

It is also necessary to take into account that over time the solder mixture loses its properties. It is necessary to select materials for soldering with tin or other materials taking into account the following requirements:

- preventing the formation of balls and splashing;

- high adhesive ability;

- resistance to spreading during initial heating;

- no residual flux;

- maximum shelf life.

In addition, solder paste materials must be easy to dispense and suitable for screen printing.

Materials for soldering wires without a soldering iron

The difference between the methods is the shape and temperature of the solder applied. In this case, the shape of the material with which you can solder the wire without a soldering iron becomes decisive. This is solder, which can come in various forms:

- the familiar composition of rosin, tin or a tin-lead mixture in ingots;

- the same solder, rolled into thin foil, 0.5-0.7 mm wide;

- paste, where solder is a mixture made from powders and an acid solution of various metals and rosin;

Read also: What kind of steel can be hardened

Since it has become possible to solder a contact without a soldering iron, various forms of material have appeared, the use of which allows the use of a primitive heating source: the open fire of a lighter, an alcohol lamp or an ordinary candle.

The use of materials in different states still has its differences, for example, the choice of technology for how to solder a wire without a soldering iron into a headphone differs from the one that can be used when soldering dishes. And the method of restoring the board will be different from how to solder a garland without a soldering iron.

Recommendations

When deciding to solder a section of wire using the direct heat method - without tools - it is important to consider the type of components used. For work, standard tin-lead wire and rosin, special foil or paste can be used. The last 2 options are very convenient when heating with a lighter, candle flame, or burner. At the same time, you don’t have to add rosin as a flux - it’s already in the composition.

If you use an improvised tip that imitates the tip of a soldering iron, you need to heat it 2-5 mm from the end. This way the desired temperature will be reached faster. You will have to hold such a tool manually. It is worth stocking up on the necessary rags or a piece of denim or cloth material, which will allow you not to get burned when in contact with heated metal.

Using the tinning method when soldering

To answer the question of how to solder wires without a soldering iron, let's start with the tinning method. In the same way, you can connect parts with ordinary soldering material, having previously made shavings from it.

The method is that on a metal plate, it can be a tin lid or thick foil, pieces of rosin and tin or lead-tin solder POS60, previously crushed, are placed and held over the open flame of a candle, burner or lighter (it is more practical to use a turbo lighter) .

The ends of the connected wires, previously cleared of insulation, are lowered into the liquid phase. If the first method of how to connect wires without a soldering iron is not suitable in any case, consider the next one.

Foil soldering method

How to solder a wire without a soldering iron at home in 5 minutes. The above methods, although not complicated, still require careful handling and precision of movements when heating. Foil is solder rolled in the form of a thin strip; this is a very convenient form, since it will not spread over an excess area and will not leak with an excess dosage - this is physically impossible.

There are no restrictions on the types, location and sizes of contacts for this method; it is equally convenient to solder a wire to a board without a soldering iron, or to connect the contacts of two twisted wires.

We prepare the contacts: remove the insulation and clean it from residues. Then we connect the ends of the wire using the twisting method, cut off the required piece of foil, remove the adhesive tape and wrap it around the wire. Heat evenly using a candle or lighter.

Features of soldering garlands without a soldering iron

The difference between ordinary wires and how to solder a garland without a soldering iron is in preparation: when working with a garland, you need to find the place where the wire is disconnected. There could be three reasons:

- Most often, contact breaks occur in the control unit, which is due to the small coupling area due to thin wires.

- Gusts can occur along the entire length of the garland.

- Parallel connection of lamps; when one of them burns out, the entire circuit opens.

We carry out work only after disconnecting the garland from the network!”

The detached contacts are clearly visible, in two other cases: a broken wire or a damaged light bulb, the search is carried out using a tester: we measure each half separately, on the one from which a break is detected, it is divided in half again and so on until damage or a non-working element is found.

After finding the break point, you need to decide how to solder the garland wire without a soldering iron. It is in this case that it is most convenient to use the solderless method due to the small diameter of the wire. The most suitable here is the use of paste and heat-shrink tubing. The following is all according to the scheme:

- cut the wire at the break point;

- strip the wires;

- We put on the tube in advance and move it to the side (before soldering is completed);

- we twist and apply the paste, but do not come into contact with the edges of the insulation;

- heat evenly with the flame of a candle or lighter until the solder reaches the desired consistency;

- Place an insulating tube over the cooled area and also heat it.

If a problem arises, how to solder headphones without a soldering iron, solve it using the same method as repairing a garland.

Another great way to solder without a soldering iron is with a candle and copper wire. The design can be seen in the photo.

Features of soldering wires to a board without a soldering iron

The board is a multi-component structure made of dissimilar materials that differ in melting and fire resistance, so the use of open fire close to is excluded.”

This complicates the problem of how to solder a wire to a board without a soldering iron. For this method we need a source of high temperature, but without an open flame. Solder can be used in any form that is available: foil, paste, ingot.

In this method, you can do without the soldering iron itself, but you will have to find a replacement for it. This requires three components:

- A sting, which can be used as a metal object with a melting point above 350 ºC (paper clip, sharpened copper wire, nail, etc.);

- A handle or holder that ensures safe operation, it can also be a strip of natural non-melting fabric (denim, cotton, cotton wool) or pliers;

- A source of fire, which can be used as a turbo lighter, a candle, or, at home, a gas stove burner;

- All types of materials are used as solder.

Precautionary measures

Soldering without special tools at home is a dangerous task that requires precautions.

It is imperative to take care of insulation if live wires are to be connected. You cannot carry out work touching them with bare hands.

If possible, ensure that devices are disconnected from the mains or other power source.

When using hot soldering methods at home using an open flame, the list of precautions will be as follows.

- Do not leave a flame source unattended.

- Prepare and place fire extinguishing equipment in the freely accessible area.

- Do not light a fire near flammable objects, pressure cylinders, including aerosol substances.

- It is better to protect your hair with a hat or bandana. Choose clothes from non-flammable materials that fit tightly to the body.

- Wear fire-resistant gloves while performing work. Choose shoes with heat-resistant soles.

- Avoid the presence of children, people with disabilities, and animals nearby.

- Ensure the drainage of accumulated combustion products from the premises.

By following these guidelines, you can safely perform hot soldering using an open flame.