When connecting steel rods, reinforcing a strip foundation, many people have a natural question: how to correctly overlap the reinforcement, and what its length should be. After all, the correct assembly of a metal load-bearing frame will prevent deformation and destruction of a monolithic concrete structure from the loads acting on it and increase its trouble-free service life. What are the technical features of making butt joints, we will consider in this article.

Types of lap reinforcement connections

According to the requirements of SNiP, the concrete foundation must have at least two continuous, unbroken reinforcement contours. This condition can be met in practice by joining the reinforcing rods with an overlap. In this case, connections at joints can be of several types:

- Lap without welding

- Welded and mechanical connections.

The first connection option is widely used in private housing construction due to its ease of execution, availability and low cost of materials. In this case, the common reinforcement class A400 AIII is used. The joining of overlapping reinforcing bars without the use of welding can be carried out both with and without the use of tying wire. The second option is most often used in industrial housing construction.

According to building codes and regulations, the connection of overlapping reinforcement during tying and welding requires the use of rods with a diameter of up to 40 mm. The American Cement Institute ACI allows the use of rods with a maximum cross-section of 36mm. For reinforcing rods whose diameter exceeds the specified values, the use of overlap joints is not recommended due to the lack of experimental data.

According to construction regulations, it is prohibited to overlap reinforcement when knitting and welding in areas of maximum load concentration and places of maximum stress on metal rods.

Types of fittings

Requirements for reinforcement for constructing a reinforced concrete foundation are regulated by GOST 10922-2012. The standard defines the grade, section diameter, permissible loads and other characteristics of reinforcing steel applicable to specific construction conditions. Design organizations calculate the loads on the foundation, draw up optimal reinforcement layout diagrams, and calculate its parameters and requirements. Reinforcement design is an indispensable condition for the foundations of high-rise buildings, public buildings, and production workshops.

For small buildings, reinforcement technology allows you to assign sections and fastening methods based on the parameters of a specific construction project and its location. This approach is due to the fact that the foundation strip, as a rule, takes insignificant loads.

In private low-rise housing construction, it is possible to use average standards and general principles of reinforcement.

Layout of foundation reinforcement involves dividing the rods into three main groups according to their spatial location in the reinforced frame structure:

- Working rods. Lay out along the foundation strip.

- Transverse horizontal rods.

- Reinforcement located vertically.

Transverse rods are usually called clamps.

In private low-rise buildings, you can be guided by the minimum permissible section sizes:

- The diameter of the working reinforcement is calculated from the ratio of its cross-sectional area to the total cross-sectional area of the house foundation as 1:1000, or 0.1%.

- When the length of the foundation strip is up to 3 m, the permissible diameter of the reinforcement is 10 mm.

- For tape over 3 m, the minimum diameter is 12 mm.

- The maximum diameter of the rods cannot exceed 40 mm.

- The diameter of horizontal connections (clamps) is at least ¼ of the diameter of the working reinforcement.

- Vertical bars for buried foundation strips must have a minimum diameter of 8 mm.

When constructing buildings made of stone or brick, it is recommended to lay reinforcement with an addition of 10-20% by weight to the calculated norms - for additional confidence in the correctness of the calculations.

Joining overlapping reinforcing bars by welding

For country house construction, welding overlapping reinforcement is considered an expensive pleasure, due to the high cost of metal rods of the A400C or A500C brand. They belong to the weldable class. Which significantly increases the cost of materials. It is unacceptable to use rods without the “C” index, for example: the common class A400 AIII, since when heated the metal significantly loses its strength and corrosion resistance.

However, if you decide to use weldable class rods (A400C, A500C, B500C), their connections should be welded with electrodes of 4...5 mm diameter. The length of the weld seam and the overlap itself depends on the class of reinforcement used.

| Overlapping weld length | |

| Reinforcing bar class | The length of the overlap weld in the diameters of the reinforcement being connected |

| А400С | 8 ᴓ |

| А500С | 10 ᴓ |

| В500С | 10 ᴓ |

Based on the data presented, it can be seen that when using steel rods of class B400C for knitting, the amount of overlap, and therefore the weld, will be 10 diameters of the reinforcement being welded. If ᴓ12 mm rods are taken for the load-bearing frame of the foundation, then the length of the seam will be 120 mm, which, in fact, will correspond to GOST 14098 and 10922.

According to American codes, reinforcing bar crosses cannot be welded. Effective loads on the base can cause possible ruptures of both the rods themselves and their connections.

Knots and twists - diagrams

Techniques for tying rods vary and depend on the type of knot and the angle of access. As a rule, when tying by hand:

- The areas connecting the horizontal reinforcement to each other are tied with diagonal double loops, with 2-3 turns of the ends until there are no backlashes.

- The connection nodes of vertical and horizontal reinforcement are fixed with cross-shaped or mutually diagonal loops. The ends are scrolled at least 3, but no more than 5 times.

Overlapping reinforcement connection when knitting

In cases of using common rods of the A400 AIII brand, in order to transfer the calculated forces from one rod to another, a connection method without welding is used. In this case, the places where the reinforcement overlaps are connected with a special wire. This method has its own characteristics and special requirements are placed on it.

Reinforcement overlap options

In accordance with the current SNiP, non-welding connection of rods during the installation of a reinforced concrete frame can be made using one of the following options:

- Overlay of profile rods with straight ends;

- Overlap of a reinforcing profile with a straight end with welding or installation throughout the entire bypass of transversely located rods;

- With curved ends in the form of hooks, loops and claws.

Such connections can be used to knit profiled reinforcement with a diameter of up to 40 millimeters, although the American standard ACI-318-05 allows the use of rods with a diameter of no more than 36 mm.

The use of bars with a smooth profile requires the use of lap joint options either by welding transverse reinforcement or using bars with hooks and tabs.

Knitting methods

The tool and knitting technology depend on the number of joints and the experience of the worker. It’s easier to tie a few knots with pliers or a crochet hook; in other cases, it’s worth considering the options of renting or purchasing an automatic and semi-automatic tool.

Crochet

When grabbing loops of wire with any type of hook, there are a number of general rules to follow, including:

- Cutting pieces of wire taking into account the cross-section of the reinforcement itself and the method of connection. For complex loops and thick rods, pieces up to 30-40 cm long will be required, when tying rods with a standard section and conventional grips - 15-20. You should check the length that is comfortable for you in advance.

- Fold the piece in half and wrap it around the rods at least once.

- Hooking and crocheting the free ends of the wire, holding if necessary.

- A quick turn around the former and a slow turn around the latter.

- Mandatory connection reliability check.

Important! The reliability of the knot is checked not by tensioning the knitting wire itself, but by applying pressure to the connecting rods. When tightened correctly, the frame and individual rods will not move.

From the video you will learn how to quickly and correctly crochet reinforcement:

Simple knot

When choosing this option:

- a piece of wire 15-20 cm long is bent in half, bent into a loop at the end and tucked under the reinforcement;

- after this, the hook grabs the end and makes one turn;

- then the loop is tightened and crocheted to the end.

Note! The method is valued for its simplicity and reliability, but requires control of the free ends of the wire at the first scrolling step.

"Dead Knot"

This strapping method is chosen when assembling frames with a large number of clamps, typical for beams, columns and protrusions. The advantages of connecting rods with a “dead knot” include reliability, the disadvantages are the relatively high wire consumption (up to 40 cm compared to the usual 15-20) and complexity; the method requires a certain skill and practice.

With this tying, step by step:

- pieces of wire 20-40 cm long are folded in half;

- the wire is directed in a loop forward, under the bottom of the rods, to the left of the clamp or curved section - about 3-4 cm should remain at the edges;

- In the same loop, the wire is wound to the top of the clamp and bent under the bottom of the rods;

- the hook is inserted into the loop, catches the free ends and turns several times, until the wire breaks or is completely pinched.

With a pistol

When using this tool, it is important to check in advance that the reinforcement scheme is correct; the knots fixed with a gun are almost impossible to untie.

The action scheme is simple - a gun loaded with wire is directed to the docking unit and the trigger is pulled. All actions take no more than 1-2 seconds.

After passing through all open areas, individual hard-to-reach knots can be tied using another tool.

Screwdriver

The main attention is paid to the choice of the screwdriver itself; ideally, at the initial stages, this tool operates at slightly higher speeds, and at the end of tightening - at lower speeds. An ordinary nail bent at a right angle is used as a nozzle ; other knitting rules do not change.

With pincers

The advantage of this method is that it saves wire: the wire is not cut into pieces, but is wound into small balls held with the non-working hand. The scheme of action is simple - one end is pushed under the rods, the other is grabbed by pincers. After connecting both ends in the jaws, the pliers are turned 1-2 times, and the excess is bitten off.

On a note. The speed of knitting when using pliers depends on professional skills, but in general this method is better suited for connecting a small number of knots (otherwise your hands will simply get tired).

Basic requirements for making overlap joints

When performing overlapping reinforcement joints, there are rules defined by construction documentation. They define the following parameters:

- The size of the rod lining;

- Features of the location of the connections themselves in the body of the concreted structure;

- The location of adjacent bypasses relative to each other.

Taking these rules into account allows you to create reliable reinforced concrete structures and increase the period of their trouble-free operation. Now about everything in more detail.

Where to place reinforcement overlap joints when knitting

SNiP does not allow the location of overlapping reinforcement ties in areas of the greatest load on them. It is not recommended to place joints in places where steel rods experience maximum stress. It is best to place all connecting rod connections in unloaded areas of reinforced concrete, where the structure is not under stress. When pouring a strip foundation, the bypass ends of the reinforcement are placed in places with minimal torque and minimal bending moment.

If it is not technologically possible to fulfill these conditions, the length of the overlap of the reinforcing rods is taken at the rate of 90 diameters of the joined rods.

What is the amount of overlap of reinforcement when knitting?

Since the overlap of the reinforcement is determined by the technical documentation, the length of the joint connections is clearly indicated there. In this case, the values can vary not only from the diameter of the rods used, but also from such indicators as:

- Nature of the load;

- Concrete grade;

- Reinforcing steel class;

- Connection points;

- Purpose of reinforced concrete products (horizontal slabs, beams or vertical columns, pylons and monolithic walls).

Splicing reinforcing bars when performing overlaps

In general, the length of the overlap of reinforcement bars during tying is determined by the influence of the forces arising in the rods, the perceived adhesion forces with concrete acting along the entire length of the joint, and the forces that provide resistance in the anchoring of the reinforcing bars.

The fundamental criterion when determining the length of the reinforcement overlap during tying is its diameter.

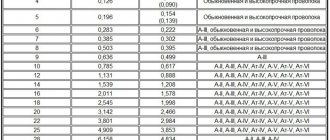

For the convenience of calculating the overlap of reinforcing bars when knitting the load-bearing frame of a monolithic foundation, we suggest using a table with the indicated diameter values and their overlap. Almost all values are reduced to 30 times the diameter of the rods used.

| The amount of reinforcement inlet in diameters | ||

| Diameter of reinforcing steel A400, mm | Overlap amount | |

| in diameters | in mm | |

| 10 | 30 | 300 mm |

| 12 | 31,6 | 380 mm |

| 16 | 30 | 480 mm |

| 18 | 32,2 | 580 mm |

| 22 | 30,9 | 680 mm |

| 25 | 30,4 | 760 mm |

| 28 | 30,7 | 860 mm |

| 32 | 30 | 960 mm |

| 36 | 30,3 | 1090 mm |

Depending on the loads and purpose of the reinforced concrete products, the length of the lap joints of the steel rods changes upward:

| Inlet of reinforcement depending on the purpose of reinforced concrete products | ||

| Type of load | Purpose of concrete products | |

| Horizontal use, in diameters | Vertical use, in diameters | |

| In compressed concrete | 33.8 ᴓ | 48.3 ᴓ |

| In stretched concrete | 47.3 ᴓ | 67.6 ᴓ |

Depending on the grade of concrete and the nature of the load used for pouring the monolithic foundation strip and other reinforced concrete elements, the minimum recommended values for the bypass of reinforcement during the binding process will be as follows:

| For compressed concrete | ||||

| Diameter of reinforcing steel A400 used in compressed concrete, mm | Length of overlap of reinforcing bars for concrete grades (concrete strength class), in mm | |||

| M250 (B20) | M350 (B25) | M400 (B30) | M450 (B35) | |

| 10 | 355 | 305 | 280 | 250 |

| 12 | 430 | 365 | 335 | 295 |

| 16 | 570 | 490 | 445 | 395 |

| 18 | 640 | 550 | 500 | 445 |

| 22 | 785 | 670 | 560 | 545 |

| 25 | 890 | 765 | 695 | 615 |

| 28 | 995 | 855 | 780 | 690 |

| 32 | 1140 | 975 | 890 | 790 |

| 36 | 1420 | 1220 | 1155 | 985 |

| For stretched concrete | ||||

| Diameter of reinforcing steel A400 used in tensile concrete, mm | Length of overlap of reinforcing bars for concrete grades (concrete strength class), in mm | |||

| M250 (B20) | M350 (B25) | M400 (B30) | M450 (B35) | |

| 10 | 475 | 410 | 370 | 330 |

| 12 | 570 | 490 | 445 | 395 |

| 16 | 760 | 650 | 595 | 525 |

| 18 | 855 | 730 | 745 | 590 |

| 22 | 1045 | 895 | 895 | 275 |

| 25 | 1185 | 1015 | 930 | 820 |

| 28 | 1325 | 1140 | 1040 | 920 |

| 32 | 1515 | 1300 | 1185 | 1050 |

| 36 | 1895 | 1625 | 1485 | 1315 |

How to position reinforcement bypasses relative to each other

To increase the strength of the foundation's load-bearing frame, it is very important to correctly position the reinforcement overlaps relative to each other in both planes of the concrete body. SNiP and ACI recommend spacing connections so that there are no more than 50% bypasses in one section. In this case, the spacing distance, as defined in regulatory documents, must be at least 130% of the length of the connecting connection of the rods.

Mutual arrangement of reinforcement bypasses in the concrete body

If the centers of overlap of the knitted reinforcement are within the specified value, then it is considered that the connection of the rods is located in the same section.

According to ACI 318-05 standards, the relative position of the connecting connections must be at a distance of at least 61 centimeters. If the distance is not maintained, then the likelihood of deformation of the concrete monolithic base from the loads exerted on it during the construction of the building and its subsequent operation increases.

Knitting materials and their selection

To connect and fix the rods, the following are used:

- Burnt or galvanized wire with a diameter in the range of 1.2-1.4 mm (thinner grades break, thicker grades are more difficult to twist).

An exception is made for frames made of rods with a cross-section of 16-18 mm, tied with wire 1.6 mm thick (10% of the diameter of the reinforcement itself). When the thickness of the rods is more than 18 mm, which is generally rare, it is easier to double the binding wire. - Screw couplings holding reinforcement with a cross-section over 25 mm.

- Plastic clamps that securely fix the frame under small and medium dynamic loads and are optimal for knitting composite types of reinforcement.

- Clips made of durable plastic , perpendicularly fastening the rods of composite reinforcement.

- Reinforcement clamps are embedded polymer elements that provide sufficient thickness of the concrete layer and hold the rods in the desired position.

Reference. Soft but strong wire is recognized as a universal connecting material. To speed up the work, it is cut into pieces 25-30 cm long or inserted into guns in special coils.

The average wire consumption for reinforcement of 1 m3 is 75 linear meters; when working with an automatic gun or lack of skills, this value increases. Plastic clamps, for all their advantages, are considered less reliable under high dynamic loads and require special attention when pouring a large mass of mortar or compacting concrete with deep vibrators.

Reinforcement of foundation corners

Reinforcement of corners requires adherence to technology.

Corner connections of the foundation are divided into 2 types: corners of the building and adjoining walls. Corner reinforcement can be done using several technologies:

- "Paw." “Paws” are made at the ends of the working rods. They are made at right angles in the shape of a poker. The minimum length of the foot is 35 rod diameters. After connecting the curved part with the perpendicular section, a structure is obtained in which the outer rods are connected to the outer ones, and the inner ones are also connected to the outer ones.

- L-shaped clamps. Instead of paws, L-shaped parts with a length of 50 working rod diameters are used.

Reinforcement of a strip foundation with a “Paw”

- U-shaped elements. To connect, two products with a length of 50 times the diameter of the main rod are required. Each clamp is connected to parallel rods and an external perpendicular one.

- Obtuse angles. The outer rod is bent at the desired angle and reinforced with additionally tied rods. The internal element is connected to the external one.

Scheme of reinforcement of obtuse corners

In corners and abutments, foundations take the greatest loads. The simple option of knitting right angles is unacceptable because it does not provide adequate structural strength. Video on corner reinforcement: