GOST 15527-2004

INTERSTATE STANDARD

COPPER-ZINC ALLOYS (BRASS), PRESSURE TREATABLE

Stamps

INTERSTATE COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION Minsk

Preface

1 DEVELOPED by the Russian Federation, Interstate Technical Committee for Standardization MTK 106 “Tsvetmetprokat”

2 INTRODUCED by Gosstandart of Russia

ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Minutes No. 17 of April 1, 2004, by correspondence)

The following voted for adoption:

| State name | Name of the national standardization body |

| Azerbaijan | Azstandard |

| Armenia | Armgosstandard |

| Belarus | State Standard of the Republic of Belarus |

| Kazakhstan | Gosstandart of the Republic of Kazakhstan |

| Republic of Kyrgyzstan | Kyrgyzstandard |

| The Republic of Moldova | Moldovastandard |

| Russian Federation | Gosstandart of Russia |

| The Republic of Tajikistan | Tajikstandard |

| Turkmenistan | Main State Service "Turkmenstandartlary" |

| Uzbekistan | Uzstandard |

| Ukraine | Gospotrebstandart of Ukraine |

3 By Order of the Federal Agency for Technical Regulation and Metrology dated October 25, 2004 No. 42-st, the interstate standard GOST 15527-2004 was put into effect directly as a national standard of the Russian Federation on July 1, 2005.

4 INSTEAD GOST 15527-70

GOST 15527-2004

INTERSTATE STANDARD

COPPER-ZINC ALLOYS (BRASS), PRESSURE TREATABLE

Stamps

Pressure treated copper zinc alloys (brasses). Grades

Date of introduction 2005-07-01

GOST 15527-2004

INTERSTATE STANDARD

COPPER-ZINC ALLOYS (BRASS), PRESSURE TREATABLE

Stamps

Official publication

INTERSTATE COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION

Minsk

Preface

1 DEVELOPED by the Russian Federation, Interstate Technical Committee for Standardization MTK 106 “Tsvetmetprokat”

2 INTRODUCED by Gosstandart of Russia

ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Minutes No. 17 of April 1, 2004, by correspondence)

The following voted for adoption:

| State name | Name of the national standardization body |

| Azerbaijan | Azstandard |

| Armenia | Armgosstandard |

| Belarus | State Standard of the Republic of Belarus |

| Kazakhstan | Gosstandart of the Republic of Kazakhstan |

| Republic of Kyrgyzstan | Kyrgyzstandard |

| The Republic of Moldova | Moldovastandard |

| Russian Federation | Gosstandart of Russia |

| The Republic of Tajikistan | T ajikstandard |

| Turkmenistan | Main State Service "Turkmenstandartlary" |

| Uzbekistan | Uzstandard |

| Ukraine | Gospotrebstandart of Ukraine |

3 By Order of the Federal Agency for Technical Regulation and Metrology dated October 25, 2004 No. 42-st, the interstate standard GOST 15527-2004 was put into effect directly as a national standard of the Russian Federation on July 1, 2005.

4 INSTEAD GOST 15527-70

© IPC Standards Publishing House, 2004

This standard cannot be fully or partially reproduced, replicated or distributed as an official publication without permission from the Federal Agency for Technical Regulation and Metrology

to GOST 15527—2004 Copper-zinc (brass) alloys processed by pressure. Stamps

| In which place | Printed | To be |

| Item 2.1, Table- | ||

| 3. Column “Mass dollars, %, Pb lead- | ||

| "nets." For brand LO 60-1 | 0,03 | 0,3 |

(IUS No. 6 2005)

2a Normative references

GOST 1652.1-77 (ISO 1554-76) Copper-zinc alloys. Methods for determining copper

GOST 1652.2-77 (ISO 4749-84) Copper-zinc alloys. Lead determination methods

GOST 1652.3-77 (ISO 1812-76, ISO 4748-84) Copper-zinc alloys. Methods for determining iron

GOST 1652.4-77 Copper-zinc alloys. Methods for determining manganese

GOST 1652.5-77 (ISO 4751-84) Copper-zinc alloys. Tin determination methods

GOST 1652.6-77 Copper-zinc alloys. Methods for determining antimony

GOST 1652.7-77 Copper-zinc alloys. Methods for determining bismuth

GOST 1652.8-77 Copper-zinc alloys. Arsenic determination methods

GOST 1652.9-77 (ISO 7266-84) Copper-zinc alloys. Methods for determining sulfur

GOST 1652.10-77 Copper-zinc alloys. Methods for determining aluminum

GOST 1652.11-77 Copper-zinc alloys. Methods for determining nickel

GOST 1652.12-77 Copper-zinc alloys. Methods for determining silicon

GOST 1652.13-77 Copper-zinc alloys. Phosphorus determination methods

GOST 9716.1-79 Copper-zinc alloys. Method of spectral analysis using metal standard samples with photographic recording of the spectrum

GOST 9716.2-79 Copper-zinc alloys. Method of spectral analysis using metal standard samples with photoelectric recording of the spectrum

GOST 9716.3-79 Copper-zinc alloys. Method of spectral analysis of oxide samples with photographic recording of the spectrum

GOST 24978-91 (ISO 4740-85) Copper-zinc alloys. Methods for determining zinc

GOST 25086-87 Non-ferrous metals and their alloys. General requirements for analysis methods

ST SEV 543-77 Numbers. Recording and rounding rules

(Introduced additionally, Amendment No. 1).

Mechanical characteristics

Due to the presence of lead in the composition of LS59-1 brass, when processing products made from it by cutting, small chips are formed, which allows such processing to be performed at high speeds. A distinctive feature of the alloy in question is that lead constitutes a separate phase in its internal structure. This makes such a material highly susceptible to plastic deformation. Meanwhile, if we compare LS59-1 brass with two-component alloys, it is significantly inferior to them in its ductility, so it is better to process such material by cutting.

The range of products made from LS59-1 brass includes:

- rods with different cross-section profiles;

- sheet material – strips, sheets, plates;

- wire;

- profile rolled products;

- pipe products.

Main characteristics of L59-1 brass

Brass of the LS59-1 brand is distinguished by good anti-friction characteristics, which allows the use of such material for the manufacture of products operated in conditions of high friction. From this alloy, in particular, sliding bearings are produced, used to complete various mechanisms and machines. In addition, the abrasion resistance that LS59-1 is characterized by allows this brass to be used for the manufacture of guides for machine tools for various purposes.

Technological properties of alloy L59-1

Since brass of this brand has a multiphase structure, products made from it are characterized by increased fragility. Parts made from LS59-1, on which surface cuts are made, cannot be used as load-bearing elements, since they can break under significant pressure. In addition, the increased fragility of this brass leads to the fact that when exposed to shock loads, the surface of products made of this material can become covered with cracks, which does not allow them to be processed using such a technological operation as forging.

Types of brass

It is customary to distinguish single-phase brass or so-called alpha-type brass, containing up to 30-35% zinc, and two-phase varieties of alpha-beta type with a higher (up to 47-50%) content of the main alloying component than in single-phase brasses. Single-phase brasses are more ductile; with increasing additives, the strength of the brass increases, but its ductility significantly decreases.

Two-phase brass alloys are significantly less ductile than single-phase ones. This change in properties due to a change in composition is explained by the fact that with an increase in the number of alloying additives, the structure of the alloy invariably changes. Moreover, the strength of two-phase brass varieties is significantly higher than that of single-phase ones. Dual-phase brass alloys may contain up to 6% lead as an additional alloying additive.

Brass alloys with a relatively low zinc content of up to 10% are usually called tombacs, and with a zinc content of 10-20% - semi-tompacs.

Chemical composition of brass

Brass is close in chemical composition to bronze, and both brass and bronze are based on copper. A significant difference is that the main alloying component in brass alloys is zinc, the content of which can reach 45%.

Let's take a closer look at the properties of the main components of brass.

Zn (zinc) element of the periodic table, atomic number 30. The element belongs to the secondary subgroup 2 of group IV of the IV period. The metal is transitional; it is characterized by the appearance of electrons in d- and f-orbitals in atoms. The metal has a light blue tint, which darkens in air, becoming covered with an oxide film.

Cu is the main component of the alloy. The element belongs to group 11 of the IV period of the Mendeleev periodic system and has atomic number 29. The metal, like zinc, is transitional. The metal has a beautiful yellowish-golden color. When an oxide film forms, copper acquires a reddish tint.

As discussed above, brass can have a structure that consists of an alpha phase or an alpha-beta phase.

As alloying components, brass may include:

- Mn to increase the strength of alloys, including anti-corrosion. In addition to Mn, additional introduction of Al, Sn, and Fe enhances the strength and anti-corrosion characteristics of the metal.

- Sn to improve salt water resistance. Such brass alloys have acquired a “secret” name - marine brass and are widely used in areas of contact with sea water.

- Ni gives the joint high strength characteristics and also increases anti-corrosion properties.

- Pb is used if the brass part will be cut. This element makes the metal more malleable during machining. Brass alloyed with lead is called automatic brass.

- Si is necessary to enhance the antifriction characteristics of the alloy, which makes it possible to safely use it along with bronze in some technological units, bearings, etc. But it is worth noting that silicon significantly reduces the hardness and strength of brass products.

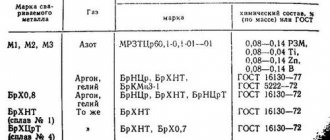

The table below shows the chemical compositions of some brands of brass alloys. The table shows that all brands have different compositions; the copper content in some brands can reach 91%.

Properties of brass depending on the percentage of components, heating temperature

When the percentage of solid solution components changes or additional alloying elements are introduced, the properties of the resulting metal also change.

Let's try to trace how the properties of the metal change when the Zn content changes:

- When the zinc content is less than or equal to 30%, the hardness and elasticity of the metal increase.

- With a further increase in zinc content, the elasticity begins to decrease due to the compaction of the alpha solution. At the same time, hardness increases.

- But when the zinc content reaches 45%, the hardness also drops.

Due to its elasticity, brass can be easily processed under pressure. This especially applies to single-phase alloys. The temperature regime for changing shape should not fall within the range of 300-700°C; this is the “fragile zone” of the metal. Alpha-beta varieties exhibit increased ductility when heating temperature increases above 700°C.

Thus, the content of chemical elements in a metal directly affects its technological parameters and properties. Alpha-brass alloys are characterized by increased ductility, alpha-beta varieties are durable and strong, but they are not suitable for deformation processing. The brass alloy has increased resistance to corrosion and sea water due to the addition of alloying components, which allows its use in areas of constant exposure to aggressive environments.

What is

This is one of the most recognizable materials on the planet. Like bronze, brass is not a metal, but an alloy.

It can be two- or multi-component. The base component of the alloy is the main non-ferrous metal of the planet, copper:

- In the first case, it is supplemented with zinc (up to 44%). This pair accounts for the bulk of the mass in the alloy.

- In multicomponent compositions, tin, lead, nickel, iron, manganese, and other alloys are added to zinc.

Zinc improves consumer properties, simultaneously reducing the price of the final product.

Brass is not a metal. Like bronze, it is a conglomerate of several components.

Rolled brass

Rods

Produced in accordance with GOST 2060-90.

Round, hexagonal or square brass rods are produced in coils of unmeasured and measured lengths.

According to manufacturing accuracy, rods are divided into rods:

- normal accuracy;

- high;

- elevated.

Based on the state of copper, they are divided into hard, semi-hard and soft.

There are also special conditions for the release of copper lashes. So, this material happens:

- with cut ends (anti-magnetic, automatic);

- increased ductility in a soft state;

- increased plasticity in a semi-solid state;

- increased plasticity in the solid state;

- normal plasticity in the pressed state.

Wire

Produced according to GOST 1066-90.

The material , in accordance with GOST 15527, is brass L80, L68, L63 and LS59-1.

Brass wire is produced only to normal precision. Depending on the condition of the metal, the wire can be hard, semi-hard or soft.

Ribbon

Produced in accordance with GOST 2208-91.

The material is brass grades L90, L85, L68, L63, L80, LS59-1, LMts58-2 (GOST 15527).

Brass tape is produced in spring-hard, soft, semi-hard, extra-hard and hard states.

According to the manufacturing accuracy, the tapes are divided into materials:

- normal accuracy both in width and thickness;

- increased accuracy in width, but normal in thickness;

- increased accuracy in thickness, but normal in width.

Based on their design, the tapes are divided into the following types:

- antimagnetic;

- by crescent shape - increased accuracy;

- with normalized extrusion depth;

- bend tested.

Pipes

Produced according to GOST 494-90.

Based on material, brass pipes are divided (GOST 15527) into:

- drawn pressed and cold rolled (L63, L68);

- pressed (L60, LS5-1, LZhM259-1-1, L63).

According to the length of the outlet, brass pipes can be of measured and unmeasured lengths (1...6 m) and in coils (more than 10 m).

According to the manufacturing accuracy, pipes are divided into products of normal, increased and high precision.

Depending on the condition of the metal, pipes are produced: soft, quarter-hard, semi-hard, semi-hard with increased ductility and soft with increased ductility.

According to special conditions, brass pipes are divided into products of increased accuracy in curvature, simply increased accuracy and anti-magnetic.

Depending on the brand of brass alloy, pipes are produced in semi-hard or soft form.