NATIONAL STANDARDS

STEEL IS QUALITY AND HIGH QUALITY

Sections and shaped steel, calibrated steel

Part 1

Moscow IPK PUBLISHING HOUSE OF STANDARDS 2004

INTERSTATE STANDARD

| ROLLED ALLODED STRUCTURAL STEEL Specifications Structural alloy steel bars. Specifications | GOST 4543-71 |

Date of introduction 01/01/73

This standard applies to hot-rolled and forged steel with a diameter or thickness of up to 250 mm, calibrated and with a special surface finish made of alloy structural steel, used in a heat-treated state.

In terms of chemical composition standards, the standard applies to all other types of rolled products, ingots, forgings and stampings.

(Changed edition, Amendment No. 2, 5).

CLASSIFICATION

1.1. Depending on the chemical composition and properties, structural steel is divided into categories:

quality;

high quality - A;

especially high quality - Sh.

Notes:

1. Particularly high-quality steel includes electroslag remelted steel.

2. (Deleted, Amendment No. 2).

1.2. Depending on the main alloying elements, steel is divided into groups: chromium, manganese, chromium-manganese, chromium-silicon, chromium-molybdenum and chromium-molybdenum-vanadium, chromium-vanadium, nickel-molybdenum, chromium-nickel and chromium-nickel with boron, chromium-silicon-manganese and chromium-silicon-manganese-nickel, chromium-manganese-nickel and chromium-manganese-nickel with titanium and boron, chromium-nickel-molybdenum, chromium-nickel-molybdenum-vanadium and chromium-nickel-vanadium , chrome-aluminum and chrome-aluminum with molybdenum, chrome-manganese-nickel with molybdenum and titanium.

(Changed edition, Amendment No. 4).

1.3. By type of processing, rolled products are divided into:

hot-rolled and forged (including with a turned or peeled surface);

calibrated;

with special surface finishing.

1.4. Depending on the quality of the surface, hot-rolled and forged steel is produced in groups: 1, 2, 3.

1.5. Depending on the condition of the material, rolled products are produced:

without heat treatment;

heat treated - TO;

cold-worked - N (for rolled products calibrated and with special surface finishing).

1.3 — 1.5 (Changed edition, Amendment No. 5)

.

Steel grade 20X

| Grade: 20Х (substitutes: 15Х, 20ХН, 12ХН2, 18ХГТ) Class: Structural alloy steel Type of supply: long products, including shaped steel: GOST 4543-71, GOST 2590-2006, GOST 2591-2006, GOST 10702-78, GOST 2879-2006. Calibrated rod GOST 8559-75, GOST 8560-78, GOST 7417-75, GOST 1051-73. Polished rod and silver GOST 14955-77. Thick sheet GOST 1577-93, GOST 19903-74. Strip GOST 82-70, GOST 103-2006. Forgings and forged blanks GOST 1133-71, GOST 8479-70. Pipes GOST 8731-74, GOST 8732-78, GOST 8733-74, GOST 8734-75, GOST 13663-86. Use in industry: bushings, gears, cages, sleeves, disks, plungers, levers and other cemented parts that require high surface hardness with low core strength, parts operating under friction wear conditions. |

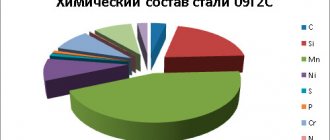

| Chemical composition in % of steel 20Х | ||

| C | 0,17 — 0,23 | |

| Si | 0,17 — 0,37 | |

| Mn | 0,5 — 0,8 | |

| Ni | up to 0.3 | |

| S | up to 0.035 | |

| P | up to 0.035 | |

| Cr | 0,7 — 1 | |

| Cu | up to 0.3 | |

| Fe | ~97 | |

| Foreign analogues of steel grade 20Х | |

| USA | 5117, 5120, 5120H, G51170, G51200, H51200 |

| Germany | 20Cr4, 20CrS4 |

| Japan | SCr420, SCr420H |

| England | 207 |

| European Union | 20Cr4 |

| Bulgaria | 20Ch |

| Hungary | BC2 |

| Poland | 20H |

| Additional information and properties |

| Specific gravity: 7830 kg/m3 Heat treatment: Normalization Hardness of material: HB 10 -1 = 179 MPa Critical point temperature: Ac1 = 750, Ac3(Acm) = 825, Ar3(Arcm) = 755, Ar1 = 665, Mn = 390 Temperature forging, °C: beginning 1260, end 750. Workpieces with a cross-section of up to 200 mm are cooled in air, 201-700 mm are subjected to low-temperature annealing. Cutting machinability: in the hot-rolled state at HB 131 and σв =460 MPa, K υ solid. spl=1.3 and Kυ b.st=1.7 Weldability of the material: no restrictions except for chemically and thermally treated parts. Welding methods: RDS, KTS without restrictions. Flock sensitivity: low sensitivity. Tendency to temper brittleness: not prone. |

| Mechanical properties of steel 20Х | ||||||||

| GOST | Delivery condition, heat treatment mode | Section, mm | σ0.2 (MPa) | σв (MPa) | δ5 (%) | ψ % | KCU (kJ/m2) | NV , no more |

| GOST 4543-71 | Bar. Quenching 880 °C, water or oil; hardening 770-820 °C, water or oil; holiday 180 °C, air or oil | 15 | 640 | 780 | 11 | 40 | 59 | |

| GOST 10702-78 | Cold-worked steel, calibrated and calibrated with special finishing without heat treatment | 590 | 5 | 45 | 207 | |||

| Bar. Cementation 920-950 °C, air; hardening 800 °C, oil; holiday 190 °C, air | 60 | 390 | 640 | 13 | 40 | 49 | 250 (surfaces 55-63) | |

| Mechanical properties of forgings made of steel 20Х | ||||||||

| Heat treatment | Section, mm | KP | σ0.2 (MPa) | σв (MPa) | δ5 (%) | ψ % | KCU (kJ/m2) | NV , no more |

| Normalization | up to 100 100-300 300-500 | 195 | 195 | 390 | 26 23 20 | 55 50 45 | 59 54 49 | 111-156 |

| up to 100 100-300 | 215 | 215 | 430 | 24 20 | 53 48 | 54 49 | 123-167 | |

| up to 100 | 245 | 245 | 470 | 22 | 48 | 49 | 143-179 | |

| Hardening. Vacation | 100-300 | 245 | 245 | 470 | 19 | 42 | 39 | 143-179 |

| up to 100 100-300 | 275 | 275 | 530 | 20 17 | 40 38 | 44 34 | 156-197 | |

| 100-300 100-300 | 315 345 | 315 345 | 570 590 | 14 17 | 35 40 | 34 54 | 167-207 174-217 | |

| Mechanical properties of 20X steel depending on tempering temperature | ||||||

| Temperature, °C | σ0.2 (MPa) | σв (MPa) | δ5 (%) | ψ % | KCU (kJ/m2) | |

| Rod with a diameter of 25 mm. Hardening 900 °C, oil | ||||||

| 200 300 400 500 600 | 650 690 690 670 610 | 880 880 850 780 730 | 18 16 18 20 20 | 58 65 70 71 70 | 118 147 176 196 225 | |

| Mechanical properties of 20X steel at elevated temperatures | |||||

| Test temperature, °C | σ0.2 (MPa) | σв (MPa) | δ5 (%) | ψ % | KCU (kJ/m2) |

| A sample with a diameter of 6 mm and a length of 30 mm is forged and normalized. Deformation speed 16 mm/min. Strain rate 0.009 1/s | |||||

| 700 800 900 1000 1100 1200 | 120 63 51 33 21 14 | 150 93 84 51 33 25 | 48 56 64 78 98 | 89 74 88 97 100 | |

| Endurance limit of steel 20Х | ||

| σ-1, MPA | n | Heat treatment |

| 107 | σ 4001/10000=137 MPa, σ 4001/100000=88 MPa, σ 5001/10000=59 MPa | |

| 235 | Normalization. σ0.2=295-395 MPa, σв=450-590 MPa, HB=143-179 | |

| 395 | Hardening. High holiday. σ0.2=490 MPa, σв=690 MPa, HB=217-235 | |

| 412 | Cementation. Hardening. Low vacation. σ0.2=790 MPa, σв=930 MPa, HRC=57-63 | |

| Impact strength of steel 20Х KCU , (J/cm2) | ||||

| Т= +20 °С | Т= -20 °С | Т= -40 °С | Т= -60 °С | Heat treatment |

| 280-586 | 280-289 | 277-287 | 261-274 | Rod with a diameter of 115 mm. Hardening. Vacation |

| Hardenability of steel 20Х (GOST 4543-71) | ||||||||||

| Distance from the end, mm | Note | |||||||||

| 1,5 | 3 | 4,5 | 6 | 7,5 | 9 | 10,5 | 12 | 13,5 | 18 | Hardening 860 °C |

| 38,5-49 | 34-46,5 | 29-44 | 24,5-40 | 22-35,5 | 32,5 | 30 | 28,5 | 27 | 24,5 | Hardness for hardenability strips, HRC |

| Amount of martensite, % | Critical hardness, HRCе | Critical diameter in water | Critical diameter in oil |

| 50 90 | 32-36 38-42 | 26-48 12-28 | 8-24 3-9 |

| Physical properties of steel 20Х | ||||||

| T (Grad) | E 10-5 (MPa) | a 10 6 (1/Deg) | l (W/(m deg)) | r (kg/m3) | C (J/(kg deg)) | R 10 9 (Ohm m) |

| 20 | 2.16 | 42 | 7830 | |||

| 100 | 2.13 | 10.5 | 42 | 7810 | 496 | |

| 200 | 1.98 | 11.6 | 41 | 7780 | 508 | |

| 300 | 1.93 | 12.4 | 40 | 525 | ||

| 400 | 1.81 | 13.1 | 38 | 7710 | 537 | |

| 500 | 1.71 | 13.6 | 36 | 567 | ||

| 600 | 1.65 | 14 | 33 | 7640 | 588 | |

| 700 | 1.43 | 32 | 626 | |||

| 800 | 1.33 | 31 | 706 | |||

Interpretation of the 20X grade: a simple designation says that this is structural steel with 0.20% carbon and a high chromium content, but since there is no number after X, this indicates that there is less than 1.5% chromium.

The use of 20X steel and heat treatment of products: dies and templates of various types are made from case-hardened steels, and in the case of the manufacture of tools of long length and complex configuration, steels 15X, 20X, 15ХG are used, hardened after carburization in oil.

When manufacturing a measuring tool that is not subject to grinding, after rough machining it is necessary to carry out improvement (hardening with high tempering). The improved tool produces a clean surface during machining and significantly reduces deformation during hardening.

The tool, made from low-carbon steel, is carburized. The cementation depth, depending on the thickness of the tool, ranges from 0.4 to 0.6 mm for small tools and up to 1.2-1.3 for large ones.

Heating for hardening is carried out both in chamber furnaces and in salt and lead baths. Tools of complex configurations made of high-carbon and alloy steels, when heated in baths, are heated by immersing them twice or three times in molten salt. Cool in hot oil or molten salt, which significantly reduces the degree of deformation.

Reduction of leads is achieved by hardening only the working surfaces of the calibers.

The measuring tool is tempered within 120-200°. The purpose of tempering is to relieve internal stresses that arise during hardening. These stresses are one of the reasons for the appearance of cracks during grinding, and are also the main reason for spontaneous changes in the size of gauges during storage (natural aging). The phenomenon of natural aging is associated with a very stressed state of the structure of hardened steel.

The tetragonal martensite that appears as a result of quenching, which has a distorted lattice, is unstable and tends to transform into a more stable form of cubic martensite. This transition entails a change in the volume of the atomic lattice, and consequently, deformation of the measuring instrument. At room temperature this transition occurs very slowly, over several months and even years, and at elevated temperatures over several hours or tens of minutes. In factory practice, the tempering of a measuring instrument is usually carried out in two stages: first, low-temperature tempering is carried out after hardening within 150-180° for 1-2 hours, then artificial aging after grinding by heating at a temperature of 120-160° for 2-5 hour.

For aging tools made of carbon steel, a lower temperature limit is used, and for alloy steel, an upper limit is used. The best aging environment is an oil bath. Prolonged heating in an electric oven at 150° causes a tarnished color to appear.

In some factories, to maintain dimensions, the measuring tool is subjected to cold treatment.

The hardness of the measuring tool should be within the range Rc = 56-64.

When heat treating threaded rings, the practice of hardening a test ring is justified. Before the end of turning a batch of rings, one ring is submitted for hardening and the degree of deformation determines the allowance for finishing the entire batch. It is important that the entire test ring hardening regime, such as the temperature of the heating and cooling medium and the holding time, is recorded and repeated without any changes for the entire batch.

Plug gauges made from alloy and high-carbon steel that have lost their size can be restored by tempering them in an oil bath at a temperature of 210-230°. The diameter increases due to the decomposition of retained austenite.

Ring gauges, both smooth and threaded, are restored using the so-called landing method in the following sequence: 1) the ring is clamped in a device; 2) the ring with the device is heated in a lead bath in such a way that only the surface layer of the outer diameter is heated (the time can be determined experimentally); 3) the ring and the device are cooled.

This method is greatly simplified when the ring is heated with high frequency currents. The surface of the outer diameter is heated in a ring inductor of a high-frequency installation and care is taken that a tarnish color higher than yellow does not appear on the working part.

2a. ASSORTMENT

2a.1. The range of rolled products must comply with the requirements of GOST 2591, GOST 2590, GOST 2879, GOST 103, GOST 1133, GOST 7417, GOST 8559, GOST 8560, GOST 14955 and other regulatory and technical documentation.

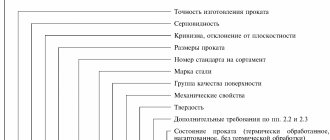

Examples of symbols

Hot-rolled, square, with a square side of 46 mm, normal rolling accuracy B according to GOST 2591, made of steel grade 18ХГТ, surface quality group 2, heat-treated:

The same, round, 80 mm in diameter, normal rolling accuracy B according to GOST 2590, made of steel grade 18Х2Н4МА, surface quality group 1, mechanical properties option 2, heat-treated TO:

The same strip, 20 mm thick, 75 mm wide according to GOST 103, made of steel grade 25KhGT, surface quality group 3, mechanical properties option 1, without heat treatment:

Calibrated rolled products, round, 15 mm in diameter, with maximum deviations according to h11 in accordance with GOST 7417, made of steel grade 40ХН2МА, surface quality group B in accordance with GOST 1051, with control of mechanical properties M, cold-worked N:

Rolled products with special surface finishing, round, diameter 8.5 mm, with maximum deviations according to h9 and surface quality of group B according to GOST 14955, made of steel grade 12ХН3А, with normalized hardenability P, heat-treated TO:

(Changed edition, Amendment No. 5).

Alloy steels. Classifications of alloy steels

Elements specially introduced into steel in certain concentrations in order to change its structure and properties are called alloying elements , and steels are called alloyed .

In structural steels, alloying is carried out in order to improve mechanical properties (strength, ductility). In addition, the physical, chemical, and operational properties change.

Alloying elements increase the cost of steel, so their use must be strictly justified.

Alloy steel has valuable properties that carbon steel does not have, and does not have its disadvantages. The use of alloy steel increases the durability of products, saves metal, increases productivity, simplifies design, and therefore becomes crucial in advanced technology.

For example, steel 11Х11Н2В2МФ

C = 0.11%, C r = 11%, Ni = 2%, W = 2%, Mo and V = 1% rest Fe.

— alloyed, low-carbon, high-alloyed, high-quality, quiet, structural, deformable, chromium-nickel-molybdenum, seven-component.

nitrogen (N) – A aluminum (Al) – Yu beryllium (Be) – L boron (B) – P vanadium (V) – F bismuth (Bi) – Vi tungsten (W) – B gallium (Ga) – Glyridium ( Ir) - I cadmium (Cd) - Kd cobalt (Co) - K silicon (Si) - C magnesium (Mg) - W manganese (Mn) - G lead (Pb) - AC copper (Cu) - D molybdenum (Mo) — M nickel (Ni) — N niobium (Nb) — B selenium (Se) — E titanium (Ti) — T carbon (C) — U phosphorus (P) — P chromium (Cr) — X zirconium (Zr) — C

Additional Information

| English name | |

| Put into effect | 01.01.1973 |

| In return | GOST 4543-61 |

| Substitute | GOST 4543-2016 |

| In return in part | GOST 1050-60 regarding grades 15G, 20G, 25G, 30G, 35G, 40G, 45G, 50G |

| Substituting in part | GOST 1050-2013 regarding steel grades 15G, 20G, 25G, 30G, 35G, 40G, 45G, 50G, 10G2, 30G2, 35G2, 40G2, 45G2, 50G2 |

| Expiration date | 30.09.2017 |

| Publication date | 07/01/2008 reissue with amendment. 1 |

Alloy steels. Classifications of alloy steels

Elements specially introduced into steel in certain concentrations in order to change its structure and properties are called alloying elements , and steels are called alloyed .

In structural steels, alloying is carried out in order to improve mechanical properties (strength, ductility). In addition, the physical, chemical, and operational properties change.

Alloying elements increase the cost of steel, so their use must be strictly justified.

Alloy steel has valuable properties that carbon steel does not have, and does not have its disadvantages. The use of alloy steel increases the durability of products, saves metal, increases productivity, simplifies design, and therefore becomes crucial in advanced technology.

For example, steel 11Х11Н2В2МФ

C = 0.11%, C r = 11%, Ni = 2%, W = 2%, Mo and V = 1% rest Fe.

— alloyed, low-carbon, high-alloyed, high-quality, quiet, structural, deformable, chromium-nickel-molybdenum, seven-component.

nitrogen (N) – A aluminum (Al) – Yu beryllium (Be) – L boron (B) – P vanadium (V) – F bismuth (Bi) – Vi tungsten (W) – B gallium (Ga) – Glyridium ( Ir) - I cadmium (Cd) - Kd cobalt (Co) - K silicon (Si) - C magnesium (Mg) - W manganese (Mn) - G lead (Pb) - AC copper (Cu) - D molybdenum (Mo) — M nickel (Ni) — N niobium (Nb) — B selenium (Se) — E titanium (Ti) — T carbon (C) — U phosphorus (P) — P chromium (Cr) — X zirconium (Zr) — C

Casting alloy steels.

In accordance with GOST 977-88, they are designated according to the same rules as carbon cast steels.

Also, at the end of the names of casting steels the letter L is given, for example, 15L, 20G1FL, 35 KhGL, etc.

For the manufacture of castings, low-alloy, medium-alloy and high-alloy steels are used.

But alloy steels have poor casting properties.

8. By composition: nickel, chromium, chromium-nickel, chromium-nickel-molybdenum and so on (a sign is the presence of certain alloying elements).

9. By the number of alloying elements:

— three-component (iron, carbon, alloying element);

- four-component (iron, carbon, two alloying elements) and so on.

Combinations of letters and numbers give characteristics of alloy steel. If there are two numbers in front of the brand, they indicate the average carbon content in hundredths of a percent. One number in front of the mark indicates the average carbon content in tenths of a percent. If there is no number in front of the brand, this means that it contains either 1% carbon or higher than 1%. The numbers behind the letters indicate the average content of this element as a percentage; if there is no number behind the letter, then the content of this element is about 1% (no more than 1.5%). The letter A at the end of the grade, both in carbon and alloy steel, denotes high-quality steel, i.e. steel containing less sulfur and phosphorus.

This marking system covers most existing alloy steels. The exception is certain groups of steels, which are additionally designated by a specific letter:

R - high-speed,

E – magnetic,

Ш – ball bearings,

E – electrical.

An example of steel grade decoding

Other GOSTs

GOST R 52927-2008 Rolled products for shipbuilding from normal, increased and high strength steel. Technical specifications GOST R 52927-2015 Rolled products for shipbuilding from normal, increased and high strength steel. Technical specifications GOST 7566-81 Rolled products and products for further processing. Rules for acceptance, marking, packaging, transportation and storage GOST 10702-78 Rolled products from high-quality structural carbon and alloy steel for cold extrusion and upsetting. Technical specifications GOST 1414-75 Rolled products from structural steel with high machinability. Technical specifications GOST R 51394-99 Rolled products from corrosion-resistant steel for surgical implants. Technical specifications GOST 31622-2012 Rolled products made of corrosion-resistant steel for surgical implants. Technical specifications GOST 1051-73 Calibrated rolled products. General technical conditions GOST 8560-78 Calibrated hexagonal rolled products. Assortment GOST 23570-79 Rolled carbon steel weldable for building metal structures. Technical specifications GOST 19281-89 Rolled products from high-strength steel. General technical conditions GOST R 55374-2012 Rolled products from structural alloy steel for bridge construction. General technical conditions GOST 14959-79 Rolled products from spring carbon and alloy steel. Technical specifications GOST R 56299-2014 Rolled bearing steel. Specifications