STATE STANDARD OF THE USSR UNION

STEEL SHEETS WITH RHOMBIC AND LENTIC CORRUPTIONS

TECHNICAL CONDITIONS

GOST 8568-77

PUBLISHING HOUSE OF STANDARDS

Moscow

STATE STANDARD OF THE USSR UNION

| STEEL SHEETS WITH RHOMBIC AND LENTIC CORRUPTIONS Specifications Corrugated steel rnombic and lentilform steel. Technical requirements | GOST 8568-77 |

Date of introduction 01/01/78

This standard applies to hot-rolled steel sheets with one-sided rhombic and lenticular corrugation for general purposes.

Changed edition. Change No. 4 .

Features and properties of rolled corrugated sheets

The indispensability of this rolled product is due to its attractive performance characteristics and a large selection of assortments.

This material reveals the manufacturing technology of corrugated sheets, the method of applying corrugations and the consequence of this in the form of improved technical characteristics. For example, a very important factor is the appearance of anti-slip properties. Today, there are a number of regulatory documents (primarily GOSTs) according to which the product is produced and its quality is monitored. There are, for example, standards regarding the size of the riffles and their pattern.

Among the advantages of the material, there are a number of advantages that make it preferable compared to existing analogues. Among them we name ease of processing, corrosion resistance, durability, resistance to deformation, etc.

More detailed information on products can be found here: Corrugated sheet

Rolled metal is a product that does not lose its popularity and demand even in times of crisis. It is indispensable in modern construction due to its wide range of products and high performance characteristics.

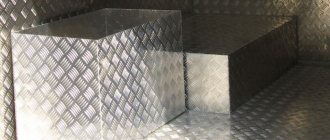

Among hundreds of rolled metal products, the most important is corrugated sheet - this is a rectangular product made of steel on a smooth base. By pressing and molding, a certain geometric pattern is formed on the upper part - riffles. The height of the formed convexities ranges from 0.5 mm. The position of the pattern on the sheet is formed from each other at a distance of up to 200 to 350 mm. Geometric patterns include rhombuses, squares, stripes, and strokes. Depending on the capabilities of the enterprise, it is possible to produce custom-made corrugated sheets with a specific pattern on it.

This type of rolled metal is supplied in rolls and sheets. The technical characteristics and external characteristics of the product directly depend on the steel alloy or iron and rolling technology.

The key feature of corrugated sheets is the presence of riffles. These convex irregularities create an anti-slip surface, making movement on such metal flooring safe both in large industrial facilities and in small domestic areas (flights of stairs).

Production of corrugated sheets

How are ripples made on the surface? To sell this type of rolled metal, it is necessary to use the hot deformation method, which includes 3 production stages:

- Carbon steel is heated in hot rolling machines and rolled.

- Using rollers, smooth sheets are pushed through the press, and then the product comes out of the machine: on one side the workpiece is smooth, on the other there is a grooved pattern of a given shape and size.

- Corrugated sheets are cooled and certified.

To sell these products, different grades of stainless steel are used, as well as alloys of iron and other alloyed metals. To achieve maximum product protection against corrosion, some corrugated sheets undergo a galvanizing procedure. An additional protective layer reduces to zero the oxidation of metals under the influence of moisture, salts, acids and alkalis.

The most popular sheet is corrugated stainless steel with galvanized coating.

The peculiarity of corrugated sheets is the presence of a pattern, which can be of two types:

- lentil ornament (quintet, duet, regular);

- rhombic pattern.

Regardless of the shape of the pattern, the sheets have identical anti-slip properties.

TECHNICAL REQUIREMENTS

2.1. Sheets and rolls are manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Sheets and rolls are made from carbon steel of ordinary quality, grades St0, St1, St2 and StZ (boiling, calm and semi-quiet) with a chemical composition in accordance with GOST 380. By agreement between the manufacturer and the consumer, it is allowed to produce rolled sheets without rationing the content of chromium, nickel, and copper.

2.1, 2.2. (Changed edition, Amendment No. 4).

2.3. At the request of the consumer, it is possible to produce sheets from steel of other grades. (Changed edition, Amendment No. 3).

2.4. Sheets rolled on sheet rolling mills are cut on four sides.

2.5. Sheets and coils rolled on a continuous rolling mill may be supplied with rolled longitudinal edges. The notches on the edges should not extend the sheet beyond the nominal dimensions in width.

2.4, 2.5. (Changed edition, Amendment No. 1).

2.6. The surface of the sheets should be free of rolled and ingot films, indentations, scale shells, rolled bubbles, cracks and dirt. There should be no delamination on the edges of the sheets.

2.7. Ripples, scale, rust, prints, and individual films are allowed on the surface of the sheets, the depth of which does not exceed the maximum deviations in thickness.

Technical characteristics: dimensions of corrugations, sheets and weight of rolled products

Corrugated sheets can differ from each other not only in the type of alloy, but also in the thickness of the sheet: from 2.5 - 12 mm. The height of the riffles can also vary from 3 to 6 mm.

The width of the corrugated sheet can be 600-2200 mm, and the length from 1400 to 8000 mm. In this case, the height of the riffles should not exceed 30% of the total thickness of the product.

At the same time, riffles, like sheets in general, also have the following parameters according to GOST. The width for a rectangular pattern is 5 (±0.15) mm, for an oval pattern the width is 3.6-6 (±0.15) mm. If the corrugated sheet has a thickness of more than 5 mm, then the height of the corrugations will be at least 1 mm.

In corrugated sheets with a lenticular pattern, the length of the corrugation can be 24 mm and the radius of curvature 30 mm. The distance between adjacent riffles must comply with established GOST standards and be within 20.25 and 30 mm.

Corrugated sheets, where a rhombic pattern is chosen as a geometric pattern, have more flexible requirements and tolerances for the placement of figures on the surface of rolled metal. Diamonds, where the aspect ratio is 25-30/60-70, are the most common, but it is also possible to produce riffles in other sizes.

When choosing a building material, special attention is paid to the weight of the product. For 1 sq.m. corrugated sheet accounts for:

- with a rectangular pattern 21-99.3 kg;

- with oval ornament 20.1-96.8 kg.

Characteristics of Corrugated Steel Sheet

For the manufacture of these metal products, carbon steels of ordinary quality St0, St1, St2, St3 are used in large quantities. The characteristics of the original rolled products used for steel corrugated sheets comply with GOST 19903-2015. If there are high requirements for decorative characteristics and corrosion resistance, more expensive stainless steel grades are used.

The height of the corrugation is 0.1-0.3 of the thickness of the main sheet, but should not be less than 0.5 mm. Diamond corrugation on steel sheets has diagonals (25-30) x (60-70) mm. The arrangement of the riffles is determined by the customer. The distance between the “lentils” is 20, 25, 30 mm.

The table shows the theoretical approximate mass of a square meter and a corrugated sheet measuring 1.5x6.0 m, calculated using the following parameters:

- specific gravity – 7.85 g/cm3;

- corrugation height – 0.2 of the nominal thickness of the original sheet;

- sizes and distances between grooves are average values.

Corrugated Steel Sheet Weight Table

| Thickness of corrugated sheet, mm | Sheet size (width, m x length, m) | Weight 1 m2, kg | Sheet weight, kg |

| Corrugated sheet "lentil" | |||

| 3,0 | 1.5x6.0 | 24,15 | 217 |

| 4,0 | 1.5x6.0 | 32,2 | 290 |

| 5,0 | 1.5x6.0 | 40,5 | 365 |

| 6,0 | 1.5x6.0 | 48,5 | 437 |

| 8,0 | 1.5x6.0 | 64,9 | 584 |

| Corrugated sheet "rhombus" | |||

| 3,0 | 1.5x6.0 | ||

| 4,0 | 1.5x6.0 | 33,5 | 302 |

| 5,0 | 1.5x6.0 | 41,8 | 376 |

| 6,0 | 1.5x6.0 | 50,1 | 450 |

| 8,0 | 1.5x6.0 | 66,8 | 600 |

Advantages of steel sheet with relief pattern:

- aesthetic appearance;

- good anti-slip characteristics;

- ease of installation due to good weldability;

- environmental friendliness;

- explosion and fire safety;

- resistance to biological factors;

- long operational period.

Application of rolled metal

The main industry requiring corrugated sheets is the construction industry. This rental is the basis for the construction of staircase structures, in particular on open street areas, thresholds and ramps at the entrance to the premises. It is the main material for flooring in tire shops. Corrugated sheets are used to reinforce floors or construct wall partitions. Can be used to construct observation platforms, pedestrian crossings and ventilation systems.

Corrugated sheets are used in the agricultural industry, in particular for the improvement of farms. It is convenient to store grain, hay and other mixtures in containers made of corrugated sheets.

The scope of application of corrugated sheets directly depends on the thickness of the product. For the construction of small buildings and civil objects, sheets less than 3 mm are used. In large industrial enterprises, corrugated sheets with a thickness of more than 3 mm are used.

The building material has gained popularity in many areas and areas of human activity. This was achieved due to a number of unique properties of the material:

- Stainless steel does not respond to salts and moisture, which makes the material resistant to corrosion;

- high breathability due to through-type riffles;

- resistance to deformation, physical and mechanical damage;

- anti-slip surface;

- aesthetic appeal of building materials;

- ease of processing: the ability to cut and weld sheets;

- service life over 35 years.

Requirements for the quality of rolled products, marking of sheets

In order not to get confused in the assortment on the market and to choose the appropriate type of rental, you should know how to read the markings correctly and what each letter on it means. How to understand what is meant by the name “diamond sheet V-K-PU-4.0x1500x6000 BStZsp GOST 8568-77”. At the beginning of each designation there is the name of the product and the type of pattern, then its parameters (thickness, width and length), after which the marking indicates the steel grade and its certification for compliance with GOST requirements.

Regardless of what marking the corrugated sheet has, it must meet the general requirements for product quality. The width of the product must correspond to that indicated on the marking, and the error can be up to +25 mm. All sheets put on sale must be sanded on all sides, completely free of nicks. The surface of the product on the smooth side should not have bubbles or obvious contamination of the metal. The sheet on the riffle side should have a clear pattern, where the step size of one riffle to the other will be identical.

Products in which technical defects in the form of rolled film or edge delamination were found are defective and are not available for sale.

Source: cvet-metall.com

ASSORTMENT

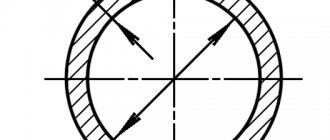

1.1. The shape, dimensions, maximum deviations and weight of 1 m² of sheet with rhombic and lentil corrugation must correspond to those indicated in the drawing. 1, 2 and in the table.

Changed edition. Change No. 2 .

1.1a. Rolled sheets by thickness are produced:

- high accuracy - A,

- normal accuracy - V.

Changed edition. Change No. 4 .

Crap. 1

Crap. 2

| Sheet base thickness s, mm | Maximum deviations in sheet thickness at width, mm | Width of ribbed base b, mm | Angle at the top of the riffle φ, degrees | Ribbon length l, mm | Radius of curvature of grooves R, mm | Location of corrugations on the plane of the sheet φ1, deg | Weight of 1 m² sheet, kg | Limit deviations by mass, % | |||||||||

| from 600 to 1000 | St. 1000 to 1500 | St. 1500 to 2000 | St. 2000 to 2200 | ||||||||||||||

| normal accuracy | high accuracy | normal accuracy | high accuracy | normal accuracy | high accuracy | normal accuracy | high accuracy | ||||||||||

| Nom. | Prev. off | Nom. | Prev. off | ||||||||||||||

| Diamond knurling | |||||||||||||||||

| 2,5 | ±0,25 | ±0,18 | ±0,25 | ±0,18 | — | — | — | — | 5,0 | ±0,15 | 28 | ±2 | — | — | — | 21,0 | ±10 |

| 3,0 | ±0,23 | ±0,23 | 25,1 | ±10 | |||||||||||||

| 4,0 | +0,3 | ±0,30 | +0,3 | ±0,3 | +0,3 | ±0,3 | +0,3 | ±0,3 | 33,5 | ±8 | |||||||

| -0,7 | -0,7 | -0,7 | -0,7 | ||||||||||||||

| 5,0 | +0,3 | ±0,35 | +0,3 | ±0,35 | +0,3 | ±0,35 | +0,3 | ±0,35 | 41,8 | ±6 | |||||||

| -0,7 | -0,7 | -0,7 | -0,7 | ||||||||||||||

| 6,0 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | 50,1 | ±9 | |||||||

| -0,8 | -0,6 | -0,8 | -0,6 | -0,8 | -0,6 | -0,8 | -0,6 | ||||||||||

| 8,0 | +0,4 | +0,3 | +0,4 | +0,3 | +0,4 | +0,3 | +0,4 | +0,3 | 66,6 | ±5 | |||||||

| -0,8 | -0,8 | -0,8 | -0,8 | -0,9 | -0,8 | -0,9 | -0,8 | ||||||||||

| 10,0 | +0,5 | +0,4 | +0,6 | +0,4 | +0,6 | +0,5 | +0,6 | +0,5 | 83,0 | ±3 | |||||||

| -1,0 | -0,7 | -1,0 | -0,7 | -1,0 | -0,9 | -1,0 | -0,9 | ||||||||||

| 12,0 | +0,6 | +0,5 | +0,7 | +0,6 | +0,7 | +0,6 | +0,7 | +0,6 | 99,3 | ±3 | |||||||

| -1,1 | -1,1 | -1,1 | -1,0 | -1,1 | -1,0 | -1,1 | -1,0 | ||||||||||

| Lentil corrugation | |||||||||||||||||

| 2,5 | 0,25 | ±0,18 | ±0,25 | ±0,18 | — | — | — | — | 3,6 | ±0,15 | 45 | ±1 | 24 | 30 | 45 | 20,1 | ±10 |

| 3,0 | 0,25 | ±0,23 | ±0,25 | ±0,23 | 4,0 | 24,2 | ±10 | ||||||||||

| 4,0 | +0,3 | ±0,3 | +0,3 | ±0,3 | +0,3 | ±0,3 | +0,3 | ±0,3 | 4,0 | 32,2 | ±8 | ||||||

| -0,7 | -0,7 | -0,7 | -0,7 | ||||||||||||||

| 5,0 | +0,3 | ±0,35 | +0,3 | ±0,35 | +0,3 | ±0,35 | +0,3 | ±0,35 | 5,0 | 40,5 | ±6 | ||||||

| -0,7 | -0,7 | -0,7 | -0,7 | ||||||||||||||

| 6,0 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | +0,4 | 5,0 | 48,5 | ±5 | ||||||

| -0,8 | -0,6 | -0,8 | -0,6 | -0,8 | -0,6 | -0,8 | -0,6 | ||||||||||

| 8,0 | +0,4 | +0,3 | +0,4 | +0,3 | +0,4 | +0,3 | +0,4 | +0,3 | 6,0 | 64,9 | ±5 | ||||||

| -0,8 | -0,8 | -0,8 | -0,8 | -0,9 | -0,8 | -0,9 | -0,8 | ||||||||||

| 10,0 | +0,5 | +0,4 | +0,6 | +0,4 | +0,6 | +0,5 | +0,6 | +0,5 | 6,0 | 80,9 | ±3 | ||||||

| -1,0 | -0,7 | -1,0 | -0,7 | -1,0 | -0,9 | -1,0 | -0,9 | ||||||||||

| 12,0 | +0,6 | +0,5 | +0,7 | +0,6 | +0,7 | +0,6 | +0,7 | +0,6 | 6,0 | 96,8 | ±3 | ||||||

| -1,1 | -1,1 | -1,1 | -1,0 | -1,1 | -1,0 | -1,1 | -1,0 | ||||||||||

Notes:

1. The thickness of sheets with one-sided rhombic and lentil corrugation is determined by the thickness of the base of the sheet s in millimeters.

2 For sheets rolled in sheet rolling mills, in the middle part of the sheet width, a base thickness of 0.2 mm above the plus limit deviation is allowed.

3. The width of the base of the grooves b, the angle at the top of the grooves φ, the diagonals of the rhombus t1 + t2, the angle of location of the grooves on the plane of the sheet φ1, the distance between the grooves t, the length of the grooves l, the radius of curvature of the grooves R on finished sheets are not controlled and are given for calculations when tool making.

4. The weight of 1 m² of sheet is determined by the nominal dimensions of the sheets, the height of the corrugations equal to 0.2 sheet thickness, the small diagonal of the diamond equal to 27.5 mm, the larger diagonal of the diamond equal to 65 mm. Steel density 7.85 g/cm³.

Changed edition. Change 2, 3, 4. Amendment. IUS 2-2003. Amendment. IUS 2-2005

1.2. Corrugated steel is produced in sheets and rolls with one-sided rhombic or lenticular corrugation.

Changed edition. Change 3.

1.3. The height of the corrugations on the sheets should be 0.1 - 0.3 of the thickness of the base of the sheet, but not less than 0.5 mm. At the consumer's request, sheets with a base thickness of 5 mm or more must have a ribbed height of at least 1.0 mm.

Changed edition. Change 2 .

1.4. Sheets with rhombic corrugation are manufactured with diamond diagonals (25-30) × (60-70) mm. The configuration of the corrugations and the location of the large diagonals of the diamond along or across the sheet are set by the manufacturer.

At the request of the consumer, it is allowed to produce a sheet with a different ratio of the diagonals of the rhombus.

Changed edition. Change 2, 3 .

1.5. Lentil corrugated sheets are manufactured with a distance between corrugations of 20, 25 and 30 mm.

1.6. Sheets are manufactured in widths from 600 to 2200 mm and lengths from 1400 to 8000 mm with a gradation of 50 mm.

1.7. At the request of the consumer, it is possible to produce sheets of other sizes.

Changed edition. Change 3 .

1.8. Sheets are produced according to sizes:

- indicating dimensions for thickness in accordance with the dimensions indicated in the table, and for width and length within the limits specified in clause 1.6 - form I;

- with indication of thickness dimensions within the limits specified in the table, without indication of width and length dimensions - form II;

- indicating dimensions that are multiples in width and length of the dimensions specified by the consumer within the limits established in clause 1.6 - form III;

- indicating the measured dimensions within the limits specified in clause 1.6 - form IV.

Changed edition. Change 1 .

1.9. Maximum deviations in the length and width of sheets are in accordance with GOST 19903-74.

- At the request of the consumer, sheets and rolls are manufactured with maximum deviations:

- +20 mm - in width for rolled products over 1000 mm with uncut edges;

- +15 mm - in length for sheets over 2000 to 6000 mm and over with a thickness of 4.0 and 5.0 mm;

- +25 mm - with a thickness of 6.0; 8.0; 10.0 and 12.0 mm.

Changed edition. Change 3, 4 .

1.10. Deviations from flatness - according to GOST 19903 improved flatness.

Changed edition. Change 14 .

1.11.(Excluded. Amendment 1.)

1.12. Requirements for steel produced in rolls, as well as the width of the rolls, are in accordance with GOST 19903.

EXAMPLES OF CONDITIONAL NOTATIONS

Hot rolled sheet of steel grade St3sp according to GOST 380 with one-sided rhombic corrugation, size 3.0 × 1000 × 2000 mm, normal thickness accuracy, improved flatness with rolled edge:

Rhombus sheet V-K-PU-3.0 × 1000 × 2000 St3sp GOST 8568-77

The same, with lentil one-sided corrugation:

Lentil leaf V-K-PU-3.0 × 1000 × 2000 St3sp GOST 8568-77

Hot-rolled steel grade St3sp according to GOST 380 with one-sided rhombic corrugation, size 3.0 × 1000 mm, high precision, with rolled edge:

Roll rhombus A-K-3.0 × 1000 St3sp GOST 8568-77

The same, with lentil one-sided corrugation:

Lentil roll A-K-3.0 × 1000 St3sp GOST 8568-77

Changed edition. Change 4 .