STATE STANDARD OF THE USSR UNION

ROLLED HIGH STRENGTH STEEL

GENERAL TECHNICAL CONDITIONS

GOST 19281-89

USSR STATE COMMITTEE FOR PRODUCT QUALITY MANAGEMENT AND STANDARDS Moscow

STATE STANDARD OF THE USSR UNION

| ROLLED STEEL OF HIGH STRENGTH General technical specifications Rolled steel with increased strength. General specifications | GOST 19281-89 |

Valid from 01/01/91

until 01/01/96

This standard applies to thick-plate, wide-band universal, shaped, long-rolled and bent sections made of high-strength steel used for welded, riveted or bolted structures and used in products, mainly without additional heat treatment.

In terms of chemical composition standards, the standard also applies to thin sheets, ingots, slabs, blooms, forgings and stampings.

ASSORTMENT

1.1. Rolled products are manufactured in strength classes 265, 295, 315, 325, 345, 355, 375, 390 and 440.

1.2. In terms of shape, size and maximum deviations, rolled products must comply with the requirements of GOST 8509 - for angular equal-flange, GOST 8510 - angular unequal-flange, GOST 8239 - I-beams, GOST 19425 - for I-beams and special channels, GOST 26020 - for I-beams with parallel flange edges, GOST 8240 - for channels, GOST 19903 - for sheets, GOST 103 - for strip and GOST 82 - for broadband universal rolled products, GOST 7511, GOST 8278, GOST 8281, GOST 8282, GOST 8283, GOST 9234, GOST 10551, GOST 13229, GOST 14635, GOST 19771, GOST 19772, GOST 25577 - for bent profiles, GOST 2590 - for round, GOST 2591 - for square rolled products; GOST 21026 - for channels with a bent flange.

(Changed edition, Amendment No. 1).

1.3. The degree of accuracy of rolled products in terms of dimensions, flatness, curvature, within the limits provided for by the standards for the product range, is indicated by the consumer in the order. If there are no requirements in the order, the manufacturing accuracy is determined by the manufacturer.

1.4. Examples of symbols are given in Appendix 1.

Areas of application

Areas of application:

- Manufacturing of parts that are subject to heavy loads - metal corners, channels, axles, beams.

- Assembly of vehicles, industrial equipment, construction of metal structures. Due to their resistance to different temperatures, the structures can be used in different climatic conditions.

- Application in the chemical industry. The material is resistant to chemicals.

- Manufacturing of poles, fences, frames for public benches, gazebos, swings, children's slides, horizontal bars.

- Production of heating equipment, steam boilers, machines for agricultural activities.

To use the material in other areas of industry, various alloying components are added to its composition.

TECHNICAL REQUIREMENTS

2.1. Characteristics of the basic version

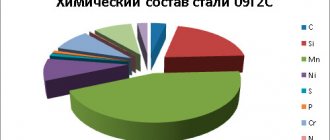

2.1.1. The basic chemical composition for each strength class is given in Appendix 2.

The mass fraction of phosphorus in steel should be no more than 0.035%, sulfur - no more than 0.040%.

The mass fraction of nitrogen in steel is no more than 0.012%, arsenic is no more than 0.08%. When smelting steel from Kerch ores, the mass fraction of arsenic is no more than 0.15%, while the mass fraction of phosphorus is no more than 0.030%.

The list of steel grades recommended for various strength classes and thicknesses of shaped and long products is given in Appendix 3, for sheet products - in Appendix 4.

2.1.2. Rolled products are produced in a hot-rolled, heat-treated state or after controlled rolling in accordance with the order. In the absence of an indication, the manufacturing method is determined by the manufacturer.

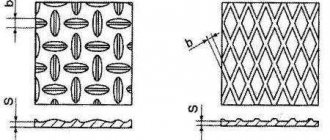

2.1.3. The surface, requirements for the edges and ends of rolled products must comply with: sheets - GOST 14637, sections and shapes - GOST 535.

(Changed edition, Amendment No. 1).

2.1.4. Delaminations in sheets are not allowed.

2.1.5. Mechanical tensile properties, as well as bending test conditions, must comply with the requirements of Table 1 for shaped and rolled products. 1, sheet and wide universal rolled products and bent profiles - table. 2.

It is permissible not to carry out bending tests on shaped and sheet metal up to 20 mm thick at the manufacturer. In this case, compliance with the established standards by the manufacturer must be guaranteed.

Table 1

Mechanical properties of long and shaped steel

| Strength class | Thickness of rolled products supplied according to this strength class, mm, no more | Yield strength st, N/mm2 (kgf/mm2) | Tensile strength sв, N/mm2 (kgf/mm2) | Relative elongation d5, % | Bend until the sides are parallel (A - thickness of the sample, |

| no less | |||||

| 205 | 100 | 265(27) | 430(44) | 21 | d = 2a |

| 295 | 100 | 295(30) | 430(44) | ||

| 325 | 60 | 325(33) | 450(46) | ||

| 345 | 20 | 345(35) | 480(49) | ||

| 375 | 10 | 375(38) | 510(52) | ||

| 390 | 20 | 390(40) | 530(54) | 18 | |

Note. When ordering strength class 295 from steel parks 09G2, 09G2D, thickness up to 20 mm, the yield strength must be at least 305 N/mm2, and the tensile strength must be at least 440 N/mm2.

table 2

Mechanical properties of sheet, strip, broadband universal rolled products and roll-formed profiles

| Strength class | Thickness of rolled products supplied according to this strength class, mm, no more | Yield strength st, N/mm2 (kgf/mm2) | Tensile strength sв, N/mm2 (kgf/mm2) | Relative elongation d5, % | Bend until the sides are parallel (A - thickness of the sample, |

| no less | |||||

| 265 | 160 | 205(27) | 430(41) | 21 | d = 2a |

| 295 | 100 | 295(30) | 130(44) | ||

| 315 | 60 | 315(32) | 450(46) | ||

| 325 | 60 | 325(33) | 450(46) | ||

| 345 | 32 | 345(35) | 490(50) | ||

| 355 | 20 | 355(36) | 490(50) | ||

| 375 | 50 | 375(38) | 510(52) | 20 | |

| 390 | 50 | 390(40) | 510(52) | 19 | |

| 410 | 32 | 440(45) | 590(60) | ||

Note. When ordering strength class 265 from steel grade 16GS, the tensile strength must be at least 450 N/mm2; when ordering strength class 295 from steel grade 09G2, 09G2D, thickness up to 20 mm, the yield strength must be at least 305 N/mm2, and the tensile strength must be at least 440 N/mm2; when ordering strength class 315 from steel grade 12GS, the relative elongation must be at least 26%; when ordering strength class 325 from steel grade 09G2S with a thickness of St. 10 to 20 mm, the temporary resistance must be at least 470 N/mm2; when ordering strength class 345 from steel grades 17 GS and 17G1S, the relative elongation must be at least 23%.

When ordering strength class 345 from steel grade 10KhNDP, the tensile strength must be at least 470 N/mm2, and the relative elongation must be at least 20%.

(Changed edition, Amendment No. 1).

Table 3

Chemical composition of low-alloy steel grades

| steel grade | Degree of deoxidation | Mass fraction of elements, % | |||||||

| carbon | silicon | manganese | chromium | nickel | copper | vanadium | other elements | ||

| 09G2 | No more than 0.12 | 0,17…0,37 | 1,4…1,8 | No more than 0.30 | No more than 0.30 | No more than 0.30 | — | — | |

| 09G2D | No more than 0.12 | 0,17…0,37 | 1,4…1,8 | No more than 0.30 | No more than 0.30 | 0,15…0,30 | — | — | |

| 12GS | 0,09…0,15 | 0,5…0,8 | 0,8…1,2 | No more than 0.30 | No more than 0.30 | No more than 0.30 | — | — | |

| 16GS | 0,12…0,18 | 0,4…0,7 | 0,9…1,2 | No more than 0.30 | No more than 0.30 | No more than 0.30 | — | — | |

| 14G2 | Sp | 0,12…0,18 | 0,17…0,37 | 1,2…1,6 | No more than 0.30 | No more than 0.30 | No more than 0.30 | — | — |

| 17GS | 0,14…0,20 | 0,4…0,6 | 1,0…1,4 | No more than 0.30 | No more than 0.30 | No more than 0.30 | — | — | |

| 09G2S | No more than 0.12 | 0,5…0,8 | 1,3…1,7 | No more than 0.30 | No more than 0.30 | No more than 0.30 | — | — | |

| 09G2SD | No more than 0.12 | 0,5…0,8 | 1,3…1,7 | No more than 0.30 | No more than 0.30 | 0,15…0,30 | — | — | |

| 14ХГС | 0,11…0,16 | 0,4…0,7 | 0,9…1,3 | 0,5…0,8 | No more than 0.30 | No more than 0.30 | — | — | |

| 15HSND | 0,12…0,18 | 0,4…0,7 | 0,4…0,7 | 0,6…0,9 | 0,3…0,6 | 0,2…0,4 | — | — | |

| 10KhNDP | No more than 0.12 | 0,17…0,37 | 0,3…0,6 | 0,5…0,8 | 0,3…0,6 | 0,3…0,5 | — | phosphorus 0.07…0.12 aluminum 0.08…0.15 | |

| 17G1S | 0,15…0,20 | 0,4…0,6 | 1,15…1,6 | No more than 0.30 | No more than 0.30 | No more than 0.30 | |||

| 10G2S1 | Sp | No more than 0.12 | 0,8…1,1 | 1,3…1,65 | No more than 0.30 | No more than 0.30 | No more than 0.30 | — | — |

| 10G2S1D | No more than 0.12 | 0,8…1,1 | 1,3…1,65 | No more than 0.30 | No more than 0.30 | 0,15…0,30 | — | — | |

| 15GF | 0,12…0,18 | 0,17…0,37 | 0,9…1,2 | No more than 0.30 | No more than 0.30 | No more than 0.30 | 0,05…0,12 | — | |

| 15GFD | 0,12…0,18 | 0,17…0,37 | 0,9…1,2 | No more than 0.30 | No more than 0.30 | 0,15…0,30 | 0,05…0,12 | — | |

| 10G2B | No more than 0.12 | 0,17…0,37 | 1,2…1,6 | No more than 0.30 | No more than 0.30 | No more than 0.30 | — | Niobium 0.02…0.05 | |

| 10G2BD | No more than 0.12 | 0,17…0,37 | 1,2…1,6 | No more than 0.30 | No more than 0.30 | 0,15…0,30 | — | Niobium 0.02…0.05 | |

| 10HSND | No more than 0.12 | 0,8…1,1 | 0,5…0,8 | 0,6…0,9 | 0,5…0,8 | 0,4…0,6 | — | — | |

| 15G2SF | 0,12…0,18 | 0,4…0,7 | 1,3…1,7 | No more than 0.30 | No more than 0.30 | No more than 0.30 | 0,05…0,10 | — | |

| 15G2SFD | Si | 0,12…0,18 | 0,4…0,7 | 1,3…1.7 | No more than 0.30 | No more than 0.30 | 0,15…0,30 | 0,05…0,10 | — |

| 14G2AF | 0,12…0,18 | 0,3…0,6 | 1,2…1,6 | No more than 0.40 | No more than 0.30 | No more than 0.30 | 0,07…0,12 | Nitrogen 0.015…0.025 | |

| 12G2B | 0,10…0,16 | 0,17…0,37 | 1,30…1,65 | No more than 0.30 | No more than 0.30 | No more than 0.30 | — | Niobium 0.02…0.04 | |

| 16G2AF | 0,12…0,18 | Up to 0.17 | 1,3…1,7 | No more than 0.40 | No more than 0.30 | No more than 0.30 | 0,08…0,14 | Nitrogen 0.015…0.025 | |

| 15G2AFD | Ps | 0,12…0,18 | 1,2…1,6 | No more than 0.30 | No more than 0.30 | 0,2…0,4 | 0,08…0,15 | Nitrogen 0.015…0.030 | |

| 14G2AFD | Sp | 0,14…0,20 | 1,2…1,6 | No more than 0.40 | No more than 0.30 | 0,15…0,30 | 0,07…0,12 | Nitrogen 0.015…0.025 | |

| 16G2AFD | 0,14…0,20 | 0,3…0,6 | 1,3…1,7 | No more than 0.40 | No more than 0.30 | 0,15…0,30 | 0,08…0,14 | Nitrogen 0.015…0.025 | |

| 18G2AF | Ps | 0,14…0,22 | No more than 0.17 | 1,3…1,7 | No more than 0.30 | No more than 0.30 | No more than 0.30 | 0,08…0,15 | Nitrogen 0.015…0.030 |

| 18G2AFD | 0,14…0,22 | No more than 0.17 | 1,3…1,7 | No more than 0.30 | No more than 0.30 | 0,15…0,30 | 0,08…0,15 | Nitrogen 0.015…0.030 | |

Notes:

1. The mass fraction of nitrogen in steels not alloyed with nitrogen should not exceed 0.008%. A nitrogen mass fraction of up to 0.010% is allowed, while rolled products, regardless of category, must meet the requirements of Table. 6 and 7 in terms of impact strength standards after mechanical aging.

2. The addition of aluminum and titanium is allowed based on the mass fraction in rolled aluminum - no more than 0.05%, titanium - no more than 0.03%.

3. Mass fractions of phosphorus, sulfur and arsenic in steel must comply with clause 2.1.1.

(Changed edition, Amendment No. 1).

2.2. Performance characteristics installed at the customer's request

2.2.1. Rolled products with regulated chemical composition.

The chemical composition of the melting analysis of the ladle sample must comply with the standards given in table. 3. In finished rolled products, permissible deviations in the mass fraction of elements from the standards given in table. 3, must correspond to table. 4.

Note. For rolled products intended for welded structures and structures for critical purposes, the steel grade and weldability requirements are specified in the order.

Table 4

| Name of elements | Permissible deviations in the mass fraction of elements, % | Name of elements | Permissible deviations in the mass fraction of elements, % |

| Carbon | +0,02 | Sulfur Phosphorus | +0,005 |

| Manganese | +0,1 | Nitrogen | |

| Vanadium | +0,02 -0,01 | ||

| Silicon | |||

| Chromium Nickel Copper | ±0,005 | Niobium | +0,010 -0,005 |

Note. In rolled steel grade 10KhNDP, deviations in the mass fraction of phosphorus +0.03%, aluminum, % are allowed.

(Amendment, IUS 8-2004).

2.2.2. Rolled products with a mass fraction of phosphorus limited to no more than 0.030%, sulfur - no more than 0.035%.

2.2.3. Rental products with weldability guarantee

The weldability of steel is ensured by its manufacturing technology and chemical composition.

(Changed edition, Amendment No. 1).

2.2.4. Rolled products with a standardized carbon equivalent Se should be: no more than 0.49 for steel of strength class 390, no more than 0.51 for steel of strength class 140.

2.2.5. Rolled products of strength classes 265, 295, 315 (thickness over 20 mm), 325 (thickness over 10 mm), 345, 355, 375, 390 and 440 with increased resistance to atmospheric corrosion. In this case, the mass fraction of copper in steel should be 0.15-0.30%, the letter D is added to the designation of the strength class (for example, 265D, 295D).

Note. Rolled steel grade 09G2D, strength class 295, can be produced with a thickness of up to 20 mm.

(Changed edition, Amendment No. 1).

2.2.6. Rolled strength classes 315 and 345 using normalization or controlled rolling, strength classes 390, 440 using thermal hardening or controlled rolling.

2.2.7. Rolled products for HL-designed products using heat treatment or controlled rolling specified in the order.

2.2.8. Rolled products of strength classes 390 and 440 with an upper limit of tensile strength limited to values not more than 180 N/mm2 exceeding those indicated in the table. 1 and 2.

2.2.9. Rolled products with standardized impact strength.

Depending on the requirements for impact bending tests, rolled products are manufactured according to the categories indicated in Table. 5. Impact strength standards are given in table. 6 and 7.

2.2.10. Rolled with descaling.

2.2.11. Rolled with deburring and without crushing ends.

2.2.12. Rolled products with ultrasonic continuity testing.

The continuity class of sheets is established by agreement between the manufacturer and the consumer in accordance with GOST 22727. Inspection of edge zones is carried out at the request of the consumer.

(Changed edition, Amendment No. 1).

2.2.13. Rolled products with a regulated upper yield strength.

2.3. Marking and packaging of rolled products - in accordance with GOST 7566.

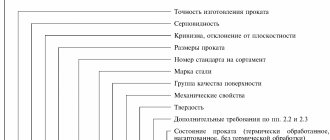

What does the transcript look like?

Knowing the labeling makes it possible to directly understand what exactly is offered by the manufacturer and what features the product has. From a technical point of view, the marking 09g2s means the following:

- 09 - exact proportion of carbon in the total alloy;

- G2 - presence of manganese and its fluctuation in the total volume - 2%;

- C—presence of silicon, the proportion of which does not exceed 1%.

However, one should not think that the composition of steel includes only those elements that are indicated in the marking.

In addition to manganese and silicon, the overall composition is supplemented by sulfur, nitrogen, nickel, copper and phosphorus. However, the share of additional components rarely exceeds 1%, so they are not mentioned in the labeling.

Also, decoding concerns not only doping, but also other criteria. For example, the following should be included here:

- Structure and changes after the hardening process;

- Main purpose;

- Manufacturing method;

- Chem. composition of the material.

As a result, there are analogues for these indicators on the domestic market. You can often hear that 09g2s is steel 345. However, the second indicator is intended for builders and does not mean the chemical composition, but the fluidity indicator, which corresponds to the steel standard.

CONTROL METHODS

4.1. Sampling to determine the chemical composition is carried out according to GOST 7565.

4.2. Chemical analysis of steel is carried out according to GOST 22536.0 - GOST 22536.12, GOST 27809, GOST 12346, GOST 12347, GOST 12348, GOST 12350, GOST 12351, GOST 12352, GOST 12355, GOST 12356, GOST 12357, GOST 1 2358, GOST 12359, GOST 12361, GOST 12364, GOST 18895 or other methods that provide the necessary accuracy of analysis.

In case of disagreement in quality assessment, the assessment is carried out using the methods established in the standard.

(Changed edition, Amendment No. 1).

4.3. Carbon equivalent (Ce) is calculated using the formula

where C, Mn, Si, Cr, Ni, Cu, V, P are the mass fractions of carbon, manganese, silicon, chromium, nickel, copper, vanadium and phosphorus.

4.4. Control of surface quality and dimensions of rolled sheets according to GOST 14637, long products - according to GOST 535.

4.5. Delamination of rolled products during cutting is controlled by inspection of the edges and ends without the use of magnifying devices.

If necessary, the quality of the metal on the edges of sheets and universal strips is checked by removing chips: in this case, bifurcation of the chips serves as a sign of discontinuity of the metal.

4.5.1. Ultrasonic testing of the continuity of rolled sheets is carried out in accordance with GOST 22727.

4.6. Sampling and production of samples for mechanical and technological tests are carried out in accordance with GOST 7564. Samples are cut lengthwise from shaped rolled products and universal strips, and across the rolling direction from sheet metal. When testing for impact bending on samples with a sharp notch, samples are taken along the rolling direction.

For rolled products with a diameter or side of a square greater than those indicated in the table. 1 and 7, it is allowed to determine the mechanical properties on samples cut from blanks, forged or rolled to the dimensions regulated by Table. 1 and 7. The standards of mechanical properties in this case must correspond to table. 1 and 7.

(Changed edition, Amendment No. 1).

4.7. From each rod, sheet, universal strip, roll selected for control, one sample is taken for tensile and bending tests, and two samples for each temperature are taken to determine impact strength. The quality of bent profiles is controlled by the workpiece.

4.8. Tensile testing of rolled products is carried out on samples of five times the length in accordance with GOST 1497.

(Changed edition, Amendment No. 1).

4.9. The bending test is carried out according to GOST 14019.

4.10. Determination of the impact strength of rolled products with a nominal thickness of up to 10 mm inclusive is carried out on samples of type 1, 2 or 3, and for categories 8 and 9 - types 11, 12, 13 according to GOST 9454. For rolled products with a thickness of more than 10 mm, the impact strength is determined on samples of type 1, and for categories 8 and 9 - type 11 according to GOST 9454.

The impact strength of shaped and strip products with a thickness of 3-4 mm, sheet products with a thickness of less than 5 mm can be determined on samples with a width equal to the thickness of the product.

(Changed edition, Amendment No. 1).

4.11. Impact strength after mechanical aging is determined according to GOST 7268 on samples with a U-type concentrator. The thickness of the samples must correspond to those adopted in clause 4.10.

4.12. When testing samples with a concentrator of type U, a reduction in impact strength on one sample by 15% is allowed; when testing samples with a concentrator of type V, a reduction in impact strength on one sample is allowed by 30%; in this case, the average value of the test results must not be lower than the standards in Table. 6 and 7.

4.13. When the manufacturer uses statistical and other non-destructive methods for monitoring mechanical properties in accordance with regulatory and technical documentation, the manufacturer may not carry out control of mechanical properties according to the methodology provided for by this standard. The manufacturer guarantees compliance of manufactured products with the requirements of this standard. In case of disagreement in quality assessment and during periodic product quality checks, control methods provided for in this standard are used.

ACCEPTANCE RULES

3.1. Rules for acceptance of rolled products according to GOST 7566 with additions. Rentals are accepted in batches. The batch must consist of rolled products of the same strength class, the same thickness thickness, the same steel heat treatment mode, and the same basic chemical composition. The mass of the batch should not exceed 350 tons. A batch of rolled steel with a regulated chemical composition and cast into ingots should also consist of one melting ladle; in a batch of rolled steel cast on continuous casting machines (CCMs), the difference in the mass fraction of carbon in the steel should not exceed 0.04%, and in the mass fraction of manganese - 0.15% according to ladle analysis. Each batch of rental products is accompanied by a quality document containing: a trademark or the name and trademark of the manufacturer; consumer name; Order number; date of issue of the quality document; wagon or vehicle number; name of the product, dimensions, number of pieces, their total weight and, in the case of delivery based on delivery (theoretical) weight, the TM mark; strength class; actual chemical composition; rolling accuracy; mechanical properties; type of flatness for the sheet; nature of the edge for the sheet; surface quality group for long products; type of heat treatment (if rolled products are supplied in a heat-treated state); NTD number; stamp of the technical control department. For rental products accepted with characteristics established by the consumer in accordance with clause 2.2, the quality document additionally indicates test results for the ordered parameters. For rolled products accepted with a regulated chemical composition, the quality document indicates the steel grade, chemical composition and heat number, batch number if the heat is divided into batches. For rolled products with a guarantee of weldability, an additional designation is indicated - St. (Changed edition, Amendment No. 1).

3.2. To check the quality of rolled products, two rods or two sheets, two strips, one roll are selected from each batch.

3.3. If unsatisfactory test results are obtained for at least one indicator, repeated tests are carried out in accordance with GOST 7566.

EXAMPLES OF SYMBOLS

Hot-rolled shaped products, standard rolling precision (B), I-beam number 30 according to GOST 8239-89, strength class 345:

Hot-rolled shaped steel with increased rolling precision (B), channel number 20 with parallel flange edges (P) according to GOST 8240-89, strength class 315:

Hot-rolled shaped products, standard rolling accuracy (B), angular unequal flange, dimensions 63´40´4 mm according to GOST 8510-86, strength class 345:

Hot-rolled bars, square, normal rolling accuracy (B) with a square side of 50 mm according to GOST 2591-88, strength class 315:

Long products, hot-rolled, round, normal rolling accuracy (B) with a diameter of 40 mm according to GOST 2590-88, first group 1, ninth category, strength class 345:

Rolled sheets, normalized, with increased rolling precision (A), high flatness (PV), with a cut edge (O) measuring 8´1100´5000 mm according to GOST 19903-74, strength class 390, made of grade 10HSND steel:

Hot rolled sheets, normal rolling accuracy (B), normal flatness (PN) with uncut edge (NO) size 16´1200´6000 mm according to GOST 19903-74 strength class 325 from steel grade 16GS, with a guarantee of weldability, category 12:

(Changed edition, Amendment No. 1).

BASIC CHEMICAL COMPOSITION OF STEEL

Table 8

| Strength class | Basic chemical composition, mass fraction, % | Additional alloying | |||

| 265, 295 | From up to 0.14 | Al up to 0.03 | |||

| Si » 0.5 | Ti » 0.03 | ||||

| Mn » 1.6 | |||||

| 315 | From up to 0.18 | Al up to 0.03 | |||

| Si » 0.7 | Ti » 0.03 | ||||

| Mn » 1.6 | |||||

| 325 | From to 0.20 | Al up to 0.03 | |||

| Si » 0.9 | Ti » 0.05 | ||||

| Mn » 1.6 | V » 0.10 | ||||

| 345, 355, 375 | From up to 0.22 | Al up to 0.03 | |||

| Si » 0.9 | Ti » 0.05 | ||||

| Mn » 1.6 | V » 0.10 | ||||

| Nb » 0.02 | |||||

| N » 0.03 | |||||

| 375, 390 | From up to 0.22 | Al up to 0.03 | |||

| Si » 1.1 | Ti » 0.05 | ||||

| Mn » 1.8 | V » 0.10 | ||||

| Nb » 0.03 | |||||

| N » 0.03 | |||||

| 440 | From up to 0.22 | Al up to 0.03 | |||

| Si » 1.1 | Ti » 0.05 | ||||

| Mn » 1.8 | V » 0.15 | ||||

| Nb » 0.05 | |||||

| N » 0.03 |

Note. To ensure the required level of properties, steel is treated with liquid synthetic slag, degassed, blown with argon, modified with calcium and rare earth elements based on the introduction of no more than 0.02% calcium and 0.05% rare earth elements into the metal.

Manufacturing

The basis for the manufacture of the material is cast iron. It goes through a long optimization process, during which the amount of carbon in the composition increases and the basic properties of the metal improve. To achieve certain technical characteristics, additional alloying additives are added.

Manufacturing technologies:

- Open-hearth method. An industrial furnace is loaded with scrap, cast iron, charge, and additional components. A pile of metal is melted using a torch of burning fuel. Once the scrap is melted, alloying components are added to the bath. When carrying out the procedure, special open-hearth furnaces are used, which can smelt up to 900 tons of metal at a time.

- Electrothermal method. During production, an industrial electric furnace is used, with which you can accurately set the heating mode and control the metal production process. The main advantage of the technology is the ability to obtain metal with the lowest content of harmful impurities (phosphorus, sulfur). Thanks to the ability to set very high heating temperatures, it is possible to obtain specialized types of steel with unique technical characteristics.

- Converter. Molten cast iron is poured into the melting apparatus and purged with oxygen. The impurities contained in the cast iron begin to oxidize. Oxidation releases a large amount of heat, which increases the overall temperature to 1600 °C.

GRADES OF STEEL LOCKED, STRIP AND FIGURED STEEL

Table 9

| Strength class | Thickness of rolled products supplied according to this strength class, mm | Steel grades that provide a given strength class at different rolled thicknesses | Grades that provide this strength class during hardening treatment |

| 265 | Up to 20 From 20 » 100 incl. | St3sp 09G2S | — |

| 295 | Up to 20 St. 20 » 32 incl. » 32 » 100 » | 09G2 09G2S, 09G2 10G2S1 | St3sp* |

| 325 | Up to 20 incl. » 32 » St. 10 to 60 » | 09G2S 14G2, 15GF, 15HSND 10G2S1 | St3sp* |

| 345 | Up to 10 incl. From 10 » 20 » | 09G2S, 10G2S1, 10ХНДП, 15ХСНД, 15GF | 09G2*, St3sp* St3sp* |

| 375 | Up to 10 incl. | 15GF, 10G2B | — |

| 390 | Up to 15 incl. » 20 » | 10HSND 15G2SF | — |

* Regulated or controlled rolling, or accelerated cooling.

Analogs

Using low-alloy steels grade 09g2s, like other Russian-made metals containing carbon and manganese, it is possible to produce various types of rolled products and pipe products.

Class. Low-alloy structural steel for welded structures.

Some foreign analogues: 9MnSi5, 09G2S, 9SiMn16.

The offered metal meets both the requirements of GOST and international standards. Before shipment, each batch of goods undergoes a thorough check for defects, as well as compliance with the declared chemical composition. We are ready to provide all the necessary documents for rafting.

Material 09G2S - exact and closest foreign analogues

Bulgaria

Hungary

Germany

China

Romania

Japan

| BDS | MSZ | DIN, WNR | G.B. | STAS | JIS |

| 09G2S | VH2 |

| 9MnSi5 |

Steel 09G2S - domestic analogues

| Rolled metal grade | Substitute |

| 09G2S | 09G2, 09G2DT, 09G2T, 10G2S |