Corrugated stainless steel pipes, annealed and unannealed, first appeared in Japan in the 80s of the 20th century. This was due to the need to create earthquake-resistant pipelines for various purposes that can withstand loads from strong earthquakes. In addition to very high resistance to destructive loads, corrugated pipes have proven to be a reliable, practical, simple and easy-to-install material for cold and hot water, gas and heating pipelines. Many users are interested in the differences between annealed and unannealed corrugated stainless steel pipes. The article presented here will be devoted to this topic.

Why is corrugation a good option for heating?

Stainless steel corrugation began to be used for heating systems not so long ago, but has already gained popularity due to its unique technical and operational characteristics.

Advantages and disadvantages:

The advantages can be safely attributed to:

- wide range of operating temperatures. Corrugated pipes can be operated with coolant temperatures in the range -50ºС to +110ºС without loss of their original properties;

- resistance to strong pressure surges within the network. Stainless steel products have a large margin of safety in terms of pressure, as they can withstand up to 50 bar. In heating systems at a maximum circulating temperature of +110ºС, the pressure level usually does not exceed 15 Bar;

- high elasticity. Pipes are easily bent without the use of special tools. They can be given any shape (bending radius is 30 - 150 mm depending on the diameter of the pipes), which allows you to assemble the wiring with a minimum number of fittings, thus reducing the overall cost of the heating system;

- unusually high resistance to corrosion. The corrugated pipe does not collapse under the influence of moisture, its internal walls are not subject to the formation of limescale deposits that reduce the throughput of pipelines;

- durability. The service life of corrugated stainless steel pipes is practically unlimited; the service life of the heating system can only be affected by a violation of the integrity of the fittings, the service life of which does not exceed 30 years;

- smooth inner surface of the walls. Corrugated pipes have a smooth surface on the inside, creating minimal resistance to the movement of the coolant and ensuring noiselessness;

- maintainability. If necessary, you can easily replace only a section of a corrugated pipe or a device that has failed;

- the ability to compensate for linear expansion due to the corrugated structure, which is especially important when installing a “warm floor”;

- frost resistance. Stainless steel corrugation is not afraid of defrosting; if water freezes in it, the pipe simply expands, and in the future it can be warmed up with a blowtorch.

Like any other product, flexible heating pipes have some disadvantages:

- low impact resistance. When installing sections of the heating system in places where there is a risk of mechanical damage, it is recommended to protect the corrugated stainless steel pipe with a metal or polymer box;

- difficult care. Cleaning corrugated pipes from dust is somewhat more difficult than pipes with a smooth surface. When cleaning, you will have to use a brush, and it is best to immediately cover the corrugated structures with a protective casing or screen;

- specific appearance. Many people do not consider the corrugated surface of products to be aesthetically pleasing enough, but if you use a hidden installation method, then this drawback becomes insignificant;

- impossibility of concreting inside the wall. To connect to heating devices, special fittings are used, to which free access must be provided for inspection and maintenance;

- high electrical conductivity, so a grounding device and installation of dielectric gaskets are necessary.

Copper pipes

Copper pipes are available in two versions: annealed and unannealed. The latter variety is produced by processing ore into ingots of almost 100% frequency. During the pipe rolling process, the material significantly loses its elasticity, but at the same time gains strength. The internal structure of the metal remains at the same level.

Annealed pipe is produced using a similar technology, but the final stage of processing involves exposure to high temperatures. After complete cooling, the material begins to exhibit the required properties.

Annealed copper pipe

The differences between annealed and unannealed copper pipe are only in operational characteristics. Both types are used when creating a heating system, water supply channel and air conditioner. Copper has important properties - thermal conductivity, bactericidal properties, corrosion resistance, which makes the material optimal for the manufacture of household pipes.

In modern production of annealed and unannealed pipes, polymer coating technology is used, which is aimed at reducing heat loss. This is important for products that will subsequently become part of the hot water supply and heating system. In addition, condensation does not form on the surface.

Copper products are characterized by smooth internal walls, so the formation of scale and clogging of the diameter is practically impossible throughout the entire period of use. Copper pipes can withstand high temperatures well, so even thin walls can withstand sufficient loads.

Annealed pipes have improved technical characteristics; a special composition is used for manufacturing. The result is a product that becomes resistant to UV radiation and chemical attack. Also, an annealed copper pipe does not deform when the liquid in it freezes.

The main difference between annealed and unannealed copper pipes is flexibility and the ability to create any shape. Accordingly, the scope of application is significantly expanded.

Features of installing a warm water floor made of corrugated steel pipe

Due to the very high coefficient of thermal conductivity, corrugated stainless steel pipe can be laid with a large pitch between turns. The concrete is qualitatively heated to a distance of up to 10 cm on each side of the corrugation. This means that the optimal distance between the loops is 20 cm, but even when the pipes are located at a distance of up to 35 cm, effective floor heating can be achieved. This result is obtained due to the peculiarities of heat distribution by the corrugated surface.

Laid steel corrugation

Important! It is recommended to install a warm water floor from a corrugated pipe according to the principle of one coil per circuit (minimum connections).

Approximate diagram of a warm water floor The main advantage of stainless steel corrugation is its elasticity; it can be easily bent to any desired shape without the use of special tools. This means that it is possible to install a heated floor from a corrugated steel pipe yourself. The clearance of the corrugation at the bend does not change.

Important! It is recommended to lay corrugated steel pipe over the entire area of the room with the same spacing.

Alternatives

In addition to stainless steel, plastic or cast iron (products with a ribbed surface) are used to make corrugated pipes. Plastic products are not the best option for heating, where the operating temperature of the coolant can reach +110ºС, since they can function normally only at temperatures up to +85ºС and a pressure in the system of no more than 20 atmospheres.

Cast iron finned pipes are characterized by high resistance to thermal loads, but they are gradually falling out of mass use due to their high weight, low impact resistance and complex installation process.

Calculation of copper pipes

When arranging a pipeline from copper pipes, it is necessary to calculate their number in advance.

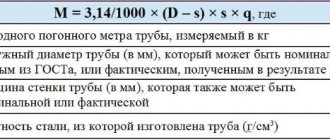

To calculate the total weight of a copper pipe, you must use the following formula:

Where L is pipe length (m),

p – copper density,

n – constant equal to 3.14,

b – pipe wall thickness,

d – outer diameter (m).

When laying a pipeline using copper products, you must also think about thermal insulation - high thermal conductivity always goes hand in hand with large heat losses. To insulate copper pipes, it is best to use ready-made casings - you will have to spend too much other materials.

To calculate the lateral surface area of the pipeline, you must use the following formula:

Where r is the outer radius of the pipe,

The diameter of pipes is often indicated in inches, and to convert into conventional units of measurement you have to use special tables that indicate all the necessary parameters.

In addition to calculating the indicators described above, you also need to know the maximum permissible pressure in the system, for which the following expression is used:

Where s is the maximum stress that the pipe can withstand during long-term operation,

Positive and negative sides

The reason for the attractiveness of stainless corrugated pipelines is their many advantages:

- the pipe material is not subject to corrosion;

- judging by the technical characteristics, the product can easily withstand changes in temperature and pressure, water hammer and does not collapse when the coolant freezes;

- the pipe easily bends by hand without disturbing the patency, so some of the traditionally used fittings (bends) are no longer needed;

- installation couldn't be easier. No other type of material is assembled as simply and quickly as corrugation for heating pipes;

- smooth inner surface: due to this, the frictional resistance of the fluid flow is reduced to a minimum, the flow area will not “overgrow”;

- according to the manufacturer, the service life of the corrugated pipe when operated within the operating characteristics is unlimited;

- the weight is almost the same as that of some polymer pipes.

Note. This is not to say that flexible corrugated stainless steel pipes last forever. The service life of a heating or water supply system depends on the quality and reliability of the connections - fittings. However, if problems arise, these elements can be easily replaced with new ones.

Advantages and disadvantages of copper pipes

Copper products have many positive qualities. Heat-treated pipes withstand moisture and any temperature changes perfectly. If we talk about thick-walled copper pipes, they are also capable of withstanding very high pressures.

In modern production processes, a polymer layer can be applied to copper pipes to reduce the level of heat loss - and this is very important in heating systems and hot water supply. In addition, the presence of the coating prevents moisture from condensing on the surface of the pipes.

The inner surface of copper pipes is quite smooth, so it is almost not prone to deposits. This quality allows you to fully use copper pipes throughout the entire period of operation. It is also worth noting that such pipes (even the thinnest ones) can withstand high temperatures perfectly without the slightest damage.

During annealing, the pipe is treated with an inert composition, which makes the pipes resistant to ultraviolet radiation and most aggressive chemicals. Annealed pipes can work without problems even after the water in them freezes.

Copper pipes also have disadvantages, but they are few: firstly, it is worth noting the very high cost of such products, which makes their use impractical in some areas. Secondly, installing copper pipes can be quite problematic for an inexperienced person. In addition, thin-walled products have their own drawback - insufficient strength.

How are corrugated pipes made from stainless steel?

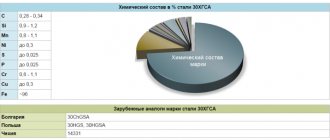

The technical conditions for the manufacture of corrugated pipes regulate the use of AISI 304 stainless steel.

It is produced using the following technology:

- the stainless steel sheet enters the forming machine, where it takes on a cylindrical shape;

- the edges of the cylinder are welded together by laser, plasma or induction current;

- the strength of the weld is checked by eddy currents;

- then the workpiece undergoes calibration, during which the product acquires a characteristic wavy structure;

- When leaving the calibrating machine, cutting to the required length is carried out.

Such a pipe can already be used for installation, but it is less durable and ductile. To increase these indicators, products are subjected to heat treatment (firing) at a temperature of +600ºС, followed by a period of forced cooling (tempering).

Visually, the products are no different, but after firing they become stronger and more flexible, which means that when bent, creases will not form on them, as on unmolded corrugation.

Copper pipe production

There are two types of copper pipes:

- Unannealed products produced using standard manufacturing techniques.

- Annealed products undergoing additional heat treatment.

The basic raw material required for the production of pipes is ore, which is first processed into blister copper. Such copper is subsequently purged with oxygen, which eliminates most of the impurities found in the ore - the purity of the finished ingots can exceed 99%.

Refined ingots, in turn, are the starting material used to produce unannealed pipes. During rolling and stamping, the material loses its ductility, but in return acquires good strength. Unannealed copper pipe can withstand loads up to 350-450 MPa, and the ultimate elongation can reach up to 6%.

The next processing step to create annealed pipes is heat treatment. The pipes are heated to a temperature of about 700 degrees, and then gradually cool down. Finished pipes have slightly lower strength compared to those that have not been annealed, but the main difference between an annealed copper pipe and an unannealed one is elasticity - annealed pipes can stretch by about 1.5 times.

Features of corrugated stainless steel unannealed pipe

We will continue the topic of what are the differences between stainless steel corrugated annealed and unannealed pipes by considering the second type of these products. Structurally, unannealed pipes differ only in the shell material. Steel that has not undergone heat treatment is more rigid. Pipes of this type require a larger bending radius, which creates inconvenience when working with them in cramped conditions. They cannot be used for rolling joints because the unannealed corrugated casing has insufficient ductility.

If you make a mistake when bending unannealed pipes, then after alignment, visible traces of previous bends will remain on the corrugation. Therefore, such work requires special care.

As for marking, unannealed pipes are indicated by the following symbols:

- GF at Lavita;

- A at Kofulso;

- TN at Hydrosta.

Let us remind you that there are no external differences between the two types of pipes, but they exist for products designed for different installation conditions and main intended purposes. We must also remember that, other things being equal, the cost of a meter of unannealed corrugated pipes is approximately 10% lower than that of annealed products.

Copper pipe production

There are two types of copper pipes:

- Unannealed products produced using standard manufacturing techniques.

- Annealed products undergoing additional heat treatment.

The basic raw material required for the production of pipes is ore, which is first processed into blister copper. Such copper is subsequently purged with oxygen, which eliminates most of the impurities found in the ore - the purity of the finished ingots can exceed 99%.

Refined ingots, in turn, are the starting material used to produce unannealed pipes. During rolling and stamping, the material loses its ductility, but in return acquires good strength. Unannealed copper pipe can withstand loads up to 350-450 MPa, and the ultimate elongation can reach up to 6%.

The next processing step to create annealed pipes is heat treatment. The pipes are heated to a temperature of about 700 degrees, and then gradually cool down. Finished pipes have slightly lower strength compared to those that have not been annealed, but the main difference between an annealed copper pipe and an unannealed one is elasticity - annealed pipes can stretch by about 1.5 times.

Read more about the disadvantages

Like any normal material, stainless corrugation has a number of disadvantages, the most significant of which is its high price. Because of this, it cannot be called accessible to a wide range of users. In current times, when the incomes of citizens of post-Soviet countries leave much to be desired, this is a big minus. Although everyone understands that you should pay the appropriate money for reliability and durability.

The second drawback is its unpresentable appearance. Not everyone will like the heating system shown in the photo above, and it may not fit harmoniously into every interior. But it is worth noting that recently corrugated heating pipes with polymer coatings of different colors have appeared. This improved the situation somewhat, but there is a nuance here: the recesses in the pipe eventually fill with dust, which is not so easy to remove.

The conclusion suggests itself that our corrugations have no equal when using a closed installation method, but this is not entirely true. Due to detachable connections using polymer seals, it is not recommended to embed the entire system into the floor or walls; only a pipe can be used, without fittings. This causes some inconvenience when installing radiator heating, but it is hardly possible to find the best material for installing heated floors.

There is one more point. Despite the ideal smoothness of the inner surface, the corrugated stainless steel pipe has many stiffeners that provide additional resistance to fluid flow. Any specialist knowledgeable in hydraulics will say that these ribs should be considered as a set of local resistances located at a certain pitch.

As a result, the structure of the water flow is far from ideal (laminar); rather, the flow is turbulent throughout the entire length of the pipe. This means that, theoretically, a corrugated pipe has a higher hydraulic resistance than any polymer pipe, where the surface is just as smooth, but without ribs.

Since there are no supporting theoretical calculations, let’s turn to practice. According to homeowners' reviews, the stainless corrugated heating pipe did not require the installation of a high-pressure circulation pump, although the system was designed to use polymer pipes. It can be concluded that corrugation is unsuitable for gravitational systems with natural coolant circulation, but there is no practical confirmation of this. Accordingly, we will not make recommendations based on unverified data.

And one last thing. As a thin-walled metal product, stainless corrugation can suffer over time from Foucault eddy currents where it intersects with the home's electrical networks. It is better not to take risks and prevent electrochemical corrosion by taking appropriate measures during installation, as discussed below.

Manufacturers and what to look for when purchasing

The bulk of stainless steel corrugations are produced in South Korea by the following companies:

- Lavita is a manufacturer of corrugated stainless steel pipes for heating in the mid-market price segment. There are complaints about the strength characteristics of the walls: when installing fittings, there is a danger of damaging the stainless steel, which subsequently causes leaks. However, this drawback is most likely the result of illiterate installation.

- Corrugated stainless steel pipes for heating from this company are considered the best among similar products. It’s true that their price is several times higher than the cost of corrugations from the previous manufacturer. These models are connected with fittings equipped with thicker O-rings, which provides a more reliable connection.

- Hydrost products are comparable in price to pipes from Lavito, but these products often have factory defects. Leaks at fitting installation sites occur on average in 7% of systems assembled from these pipes.

- Quite high-quality products, but their cost is considered unreasonably high.

When purchasing a corrugated product, you should visually inspect its surface for damage, creases and deformations. The distance between the ridges should be the same size along the entire length of the pipe.

It is also necessary to familiarize yourself with the certificate of conformity, which will confirm the quality and allow you to avoid buying handicraft fakes.

Additional selection criteria depend on the type of corrugation:

- numbered length. The pipe must have a complete set of fittings;

- arbitrary length. It is necessary to check the quality of the cutting line. The edges should be smooth and free of burrs.

Installation subtleties

Sometimes the flexibility of corrugated pipes for heating or water supply turns from an advantage into a disadvantage, which must be remembered in the following situations:

- In difficult places in the system, do not repeatedly bend the corrugated part. During operation, this place will be a weak link, since bending loads will exceed permissible values.

Heat exchangers for heating a private house (in a brick oven) Source ytimg.com

- If there are children in the house, it is worth considering how to secure the system. Children's imagination can easily turn a flexible part into a convenient support or crossbar. Sooner or later, fatigue will accumulate in the material with all the ensuing (in every sense) consequences.

Installation of corrugated stainless steel pipes for heating includes the following operations:

- A piece of the required size is cut from the bay, for which a grinder or pipe cutter is used. If necessary, the cut site is cleared of burrs.

- The pipes are connected using fittings. In this case, you must ensure that the diameters match and the union nut is tightly tightened.

- If necessary, the pipeline is fixed to the wall using brackets.

- Lastly, water is supplied to make sure the joint is tight.

A pipe cutter allows you to obtain a cut without deforming the pipe Source rothenberger-russia.ru

Corrugated stainless steel pipe, annealed and unannealed: the difference

It is impossible to find differences between unannealed and annealed corrugated stainless steel pipes by their appearance. The pipe shell is made of AISI 304 and AISI 201 stainless steel or their analogues, which also have no external differences. Both types of pipes are fully compatible with each other, as well as with pipelines made of other materials. In terms of price-quality ratio, the products of manufacturers from South Korea appear in the most favorable light:

- Hydrosta;

- Lavita;

- Kofulso.

In 2014, a domestic manufacturer of such products entered the market under the Neptun IWS brand. Corrugated pipes from Meibes (Germany) are also on sale, but their cost is several times higher than that of South Korean products. All other things being equal, the price of annealed pipes is higher than that of unannealed pipes. However, this is not the main and not the only difference between an annealed stainless steel pipe and an unannealed one.

Characteristics of annealed and unannealed pipes

Copper pipes are produced using technologies that are regulated by relevant regulatory documents. To find a suitable material, you need to have an understanding of the classification of copper pipes and know the difference between an annealed copper pipe and an unannealed one.

According to standards, copper pipes are:

The standard also classifies pipes into cold-woven, drawn and pressed. There is another difference between annealed and unannealed copper pipes: annealed pipes are supplied to the market in coils, but unannealed pipes are deformed when bent, so they are produced in the form of straight sections.

Certain requirements are imposed not only on the pipe production technology itself, but also on the quality of the resulting products. In this case, there are no differences between annealed and unannealed stainless pipes - they must be intact and sealed, without any external or internal defects.

Annealed pipes operate in a very wide temperature range - from +250 to -200 degrees. They can also withstand high pressure - as a rule, irreversible deformation occurs at a pressure of 200 atmospheres. Annealing allows pipes to withstand elongation of up to 60%.

The estimated service life of copper pipes can be up to 100 years.

What product shortcomings should we not forget?

- The downside is the high price - this is a controversial issue, since the material itself is not cheap, plus a unique manufacturing technology. The low price of such a thing should alert you, most likely it is a fake. When making a purchase, check the integrity of the packaging - there are markings on it, there are no inscriptions on the pipe.

- Another feature manifests itself during operation and saddens housewives: dust accumulates in the depressions of the pipe, which is difficult to wash out.

- The products are afraid of external mechanical damage; special screens will provide protection.

- The disadvantages of the connections include the fact that the fittings require regular maintenance.

- If part of the heating system is located in an open room, additional insulation is required to avoid heat loss.

- Twisting is not allowed.

- There is a possibility of corrosion caused by electrochemical processes (grounding saves).

Advantages and disadvantages of copper pipes

Copper products have many positive qualities. Heat-treated pipes withstand moisture and any temperature changes perfectly. If we talk about thick-walled copper pipes, they are also capable of withstanding very high pressures.

In modern production processes, a polymer layer can be applied to copper pipes to reduce the level of heat loss - and this is very important in heating systems and hot water supply. In addition, the presence of the coating prevents moisture from condensing on the surface of the pipes.

The inner surface of copper pipes is quite smooth, so it is almost not prone to deposits. This quality allows you to fully use copper pipes throughout the entire period of operation. It is also worth noting that such pipes (even the thinnest ones) can withstand high temperatures perfectly without the slightest damage.

During annealing, the pipe is treated with an inert composition, which makes the pipes resistant to ultraviolet radiation and most aggressive chemicals. Annealed pipes can work without problems even after the water in them freezes.

Copper pipes also have disadvantages, but they are few: firstly, it is worth noting the very high cost of such products, which makes their use impractical in some areas. Secondly, installing copper pipes can be quite problematic for an inexperienced person. In addition, thin-walled products have their own drawback - insufficient strength.

Which corrugation is better?

Lavita is a manufacturer of corrugated stainless steel pipes for heating in the mid-market price segment. However, this product has complaints from consumers regarding the strength characteristics of the walls: when installing fittings, there is a danger of damaging the stainless steel, which subsequently causes leaks. However, this drawback is most likely the result of illiterate installation.

Hydrosta's products are comparable in price to pipes from Lavita, but often have factory defects. Leaks at fitting installation sites occur on average in 7% of systems assembled from these pipes.

The products of the Meibes company are quite high quality, but their cost is considered unreasonably high.

Corrugated stainless steel pipes for heating Kofulso are considered the best among similar products. It’s true that their price is several times higher than the cost of corrugations from the previous manufacturer. These models are connected with fittings equipped with thicker O-rings, which provides a more reliable connection.

Product marking

Annealed corrugated stainless steel pipes are designated by the index HF, unannealed – GF. Next, the nominal diameter is indicated, for example, D 40 mm, or simply with numbers. It differs from the exact dimensions. The inscription unannealed or gf 15a, or 20a means a coefficient between the outer and inner diameters that is close to the average. The exact parameters should be checked with the manufacturer.

Thus, the marking of an annealed d15 steel pipe from Hydrosta has an internal diameter of 14.1 mm and an external diameter of 18.1. This corresponds to connectors: fittings, couplings and other 1/2 inch. It is better to immediately buy connecting parts from the same manufacturer. This is a guarantee of reliable fastening.

Supplier companies sell corrugation in small wholesale or retail in meters. You can buy any quantity. If you need an annealed pipe of 8 meters, there is no need to purchase a whole coil. All you need to do is place an order, indicating the desired length.

Recommendations for selection

The first confusion that awaits you when choosing is that the stainless heating pipe is not marked. All information about the manufacturer and technical parameters of the product is printed on the packaging of the coil. That is, with a certain dexterity, it costs nothing for an unscrupulous seller to pack a not very high-quality product from the Middle Kingdom into the packaging of the famous South Korean brand KOFULSO or LAVITA. There are two options here: trust the sales representative or purchase the material from places recommended by friends who have already purchased and installed the system some time ago.

As for the recommended brands, at the moment the most popular are the mentioned “Koreans” KOFULSO and LAVITA, which have been tested in operation and have proven themselves to be good. Moreover, LAVITA products are somewhat cheaper, but the quality is slightly worse. There are also a number of German brands, but their stainless steel corrugation is unreasonably expensive. Well, you shouldn’t pay attention to unknown companies whose products are surprisingly cheap. Surely such pipes do not have the required wall thickness.

Calculation of copper pipes

When arranging a pipeline from copper pipes, it is necessary to calculate their number in advance.

To calculate the total weight of a copper pipe, you must use the following formula:

Where L is pipe length (m),

p – copper density,

n – constant equal to 3.14,

b – pipe wall thickness,

d – outer diameter (m).

When laying a pipeline using copper products, you must also think about thermal insulation - high thermal conductivity always goes hand in hand with large heat losses. To insulate copper pipes, it is best to use ready-made casings - you will have to spend too much other materials.

To calculate the lateral surface area of the pipeline, you must use the following formula:

Where r is the outer radius of the pipe,

The diameter of pipes is often indicated in inches, and to convert into conventional units of measurement you have to use special tables that indicate all the necessary parameters.

In addition to calculating the indicators described above, you also need to know the maximum permissible pressure in the system, for which the following expression is used:

Where s is the maximum stress that the pipe can withstand during long-term operation,

b – pipe wall thickness,

d is the outer diameter of the pipe.

Installation of stainless corrugated pipe for heating

In addition to very good performance characteristics, this material is attractive for the quick and easy assembly of pipelines. All you need is fittings and a wrench. Connections to all heating devices are made using them. Select the required type (angle, tee, cross, etc.) and start connecting:

- Use a pipe cutter to cut a piece to the required length. The cut must be strictly perpendicular to the pipe. The edges are smooth without burrs or irregularities.

- Check that the fitting is complete and fold it. Insert the cut piece into it and tighten the nut. If necessary, tighten it a little with a wrench. That's the whole installation.

Complete set of fittings for stainless steel corrugated pipes

Dimensions and approximate prices

Corrugated pipes in diameters of 15, 20, 25 and 32 mm are produced for the distribution of radiator heating systems and “warm floors”.

Price per 1 running meter different for all manufacturers. For example, an annealed corrugated pipe made of Kofulso stainless steel is sold at the price:

- DN 15 mm - 172 rubles;

- DN 20 mm - 320 rub.;

- DN 25 mm - 399 RUR;

- DN 32 mm - 766 rub.

Briefly about the main thing

Corrugated steel pipe is an advanced engineering communication that combines usually incompatible properties: strength and flexibility. The material is convenient to install and operate in different types of systems; it lasts for decades and remains resistant to chemical corrosion all this time. The property is especially valuable for the use of water supply and sewer systems.

Corrugated material has gained popularity due to its ability to withstand heavy loads, as well as quick installation and a reduction in the number of connection points. Such capabilities simplify the creation of complex configuration systems, which is especially important for plumbing or heating in a private home.

Price

Prices depend on the country where they are produced, the company, the diameter, whether the products are annealed or not, as well as the presence of a polypropylene coating. When using a small piece of pipe for connecting to a heating boiler or connecting radiators, you should opt for the budget option, and if you are a wholesale buyer and require at least a whole coil, then do not be lazy to look at the price lists of different companies. Sometimes you can get discounts.

Let's compare the prices of two well-known brands in this industry (per meter):

- Flexor Group of Companies (official distributor of Hydrosta). The minimum prices in rubles for annealed, unannealed and polypropylene-coated pipes are listed, respectively.

- HF20 – from 185.80, from 153.14 (with discount), from 240.96;

- HF25 – from 243.14, from 270.72, from 308.46;

- HF32 – from 464.50, from 524.01.

- “Lavita” (only annealed corrugation is presented), cost in rubles:

- HF20 – from 222;

- HF25 – from 277.50;

- HF30 – from 516.15.

The prices given are not a public offer and may vary.

The pipe and its components must be from the same company.

Advantages of using stainless steel corrugation in heating systems

Corrugated stainless steel pipes have features that set them apart from other types of heating pipes:

- They bend in all directions (a large bending radius even helps to build a radiator or heated towel rail from corrugated material). This property of the product allows it to be used in rooms of different configurations, eliminating the need to purchase rotating corners as in products made of plastic and metal.

- They are not afraid of negative temperatures (if your heating system is frozen, the integrity of the pipe will not be compromised, and you can thaw it using any available methods).

- They have high strength (withstand pressure over 200 atmospheres).

- Do not react to atmospheric influences (do not rust).

- They have good heat dissipation.

- Suitable for laying heated floors and laying in the wall.

- Withstands temperatures up to 150 degrees.

- Not exposed to fungus.

- They have a low roughness coefficient, which maintains high throughput without the use of additional equipment.

- They are not afraid of rodents.

- Easy to install, require a minimum of connecting elements, cut with a pipe cutter.

- Convenient to transport.

- Can be dismantled without difficulty.

Subject to operating rules, manufacturers set a minimum service life of 20 years.

Application

Unannealed copper pipes are distinguished, first of all, by their serious strength, which determines their scope of application - this material is successfully used in the automotive industry, various cooling and hydraulic systems. In addition, such pipes are well suited for arranging water pipelines that transport hot water heated to 100 degrees - such systems are found both among private consumers and at industrial facilities.

When installing hot water supply networks, it is best to connect individual sections of copper pipes to each other using detachable connections. The fact is that solder has a low melting point, and hot water during system operation can break the tightness of the pipeline. In other situations, copper pipes can be connected in any available way - soldering, welding or using fittings.

Annealed pipes also have a fairly wide range of applications. Thin-walled copper products are often a profitable option, because in this case it is possible to maintain performance characteristics with smaller dimensions and weight.

Pipes with a diameter of up to 10 mm are most often used to install heat exchangers in ventilation and heating systems, and high efficiency is achieved through optimal energy distribution. For plumbing systems, products are often used whose diameter varies from 10 to 25 mm.

Copper pipes can also be used in sewer systems, but then their thickness must be at least 40 mm - with a smaller diameter, the pipes will not be able to guarantee high-quality drainage of wastewater, even taking into account the high throughput. In addition, thick pipes are also used in heating systems. The use of thin-walled copper pipes with good heat resistance allows you to save on heating without reducing the efficiency of the system.

Conclusion

Annealed and unannealed copper pipe is a good material with excellent performance characteristics. An extensive range of copper pipes allows you to select the optimal material for solving a specific task.

Connection methods

To connect stainless steel corrugated pipes, a brass compression fitting with a silicone or rubber O-ring is used. The end of the pipe is inserted into it until it stops and tightened with a ring.

When switching from a smooth steel pipe to a corrugated one, the fitting is first attached to the smooth pipe, and then a stainless corrugated pipe is inserted into it.

Flexible radiator connection

A manual rolling machine is used to make flexible hoses for radiators and heaters.

First, a piece of pipe of the required length is cut with a pipe cutter or grinder, and the cut line is carefully cleaned. The pipe is then inserted into the protruding flaring machine onto two corrugated rings to allow the protruding edge to be flared using a hammer. Next, a union nut with a rubber gasket is put on this end of the pipe. Attaching the union nut to the other end is done in the same way.

Installation features

The connection of corrugated annealed and unannealed pipes does not require special equipment.

For installation you will need:

- connecting parts;

- pipe cutter;

- sealing material: tow or fum tape, special gaskets.

The connection itself is very simple, you can trust the child, the main thing is that he has enough strength:

- A piece of the required length is cut.

- A fitting is inserted into it.

- The seal is installed.

- The union nut is tightened.

You can connect the segment to the necessary devices or bends.