The development of technology has caused computers and other advanced technical means to be increasingly used in people's daily lives, as well as in industry. For example, in modern industrial enterprises you can increasingly find a CNC milling machine, which is controlled not by the operator’s hands, but using special computer programs and corresponding electronic devices.

CNC milling machine

Thanks to such a control system, the operation of the machine is greatly facilitated, and the human factor is eliminated from the process of manufacturing parts, which can have a negative impact on their quality and processing accuracy.

Operating principle of milling machines

Milling equipment allows you to carry out various technological operations: cutting, drilling, calculating the distances between holes that need to be performed, as well as a number of others. The materials that can be processed on such equipment can be:

- wood;

- ferrous and non-ferrous metals;

- ceramics;

- polymer materials;

- natural and artificial stone.

The workpieces are fixed on the work table, and their processing is carried out by a rotating cutter, which cuts the material.

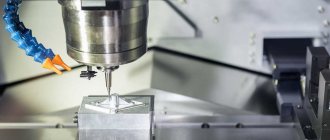

CNC machine processes a metal workpiece

Milling machines equipped with CNC are available in various designs.

Console type:

- models with wide versatility;

- horizontal type;

- vertical type.

Non-cantilever design:

- vertical;

- horizontal.

The most popular and, accordingly, widespread are console-type CNC milling machines. The workpiece being processed is fixed to the console, and it is this working body that makes movements in relation to the cutting tool. The spindle of such a machine does not move; it is rigidly fixed in one position.

Processing on non-cantilever type milling machines is carried out due to the fact that both the work table, which moves in two directions, and the spindle, which can change its position in the vertical plane, as well as in all other directions, can move in them.

Main components of a CNC milling machine

The CNC milling group machine automatically performs operations, information about which is previously recorded on one of the media. The programs that control its operation can be of several types.

- Positional, which involves fixing the coordinates of the end points along which the workpiece is processed. Such programs are used to control drilling and boring machines.

- Contour, controlling the trajectory of workpiece processing. They are used to control cylindrical grinding machines.

- Combined, which combine the capabilities of contour and positional programs. Such programs control machines belonging to the multi-purpose category.

- Multi-circuit. With their help, you can control all the functionality of the machine; they are the most complex type of software. With the help of such programs, control of large-format equipment is ensured.

Milling machines equipped with CNC have a number of significant advantages:

- allow you to increase processing productivity by 2–3 times;

- make it possible to produce parts with high precision;

- minimize the amount of manual labor, which allows reducing the number of service personnel;

- reduce the time required to prepare workpieces;

- minimize processing time for parts.

CNC classification

The following software is used to control the operation of the machine:

- Positional - working parts move to points with specific coordinates. They differ in the accuracy of stopping at a given point.

- Contour rectangular (collinear) - moving elements move in a straight line. The speed is determined by the specified cutting modes, in turn for each coordinate axis. Making curved surfaces is not possible.

- Contour (continuous) - elements move in space along a predefined path, shape and end points. Volumetric parts of complex configuration are created.

- Adaptive (self-adjusting) - the work process automatically adjusts to speed, cutting force, and feed. The motor and feed drive automatically protected It is distinguished by high-quality processing and increased reliability.

Contour and adaptive controls are based on 4 and 5 coordinate systems, providing a complex trajectory of movement of moving elements. Processing is carried out along at least 2 axes simultaneously.

Conversion of a 3-axis machine into a 4- or 5-axis machine occurs by installing an additional rotary surface. At the same time, the work area is reduced.

Types of equipment

Milling group machines equipped with CNC, depending on what material is processed on them, are divided into the following categories:

- for metal work;

- for processing wood blanks;

- milling and engraving group.

A large category of equipment in this group consists of machines that process parts made of various metals:

- desktop milling machines equipped with CNC;

- processing centers with high functionality;

- machines of a wide-universal type;

- turning and milling category;

- drilling and milling group.

Milling machines, controlled using special programs, can also be used to equip a home workshop, as they are easy to operate and make it possible to produce metal parts made with high accuracy of their geometric parameters.

CNC milling machine at work

Enterprises that produce furniture, as well as construction companies, use CNC-equipped milling machines to process wood blanks. These machines process wood products, as well as blanks made of polymers, aluminum alloys, plywood and chipboard.

A CNC machine, which can perform engraving operations, is used for processing products made of metal, natural and artificial stone, concrete and a number of other materials. It is used to make decorative stone columns, figurines, and other products that perform a purely decorative function. Such machines for metal and a number of other materials are most often used for the production of various advertising structures.

Based on the principle of operation and their performance, milling machines equipped with CNC can be of the following categories:

- characterized by small dimensions and low productivity - mini machines;

- desktop type;

- vertical milling type;

- widescreen.

The machines that are used to equip a home workshop cannot be called professional; they are mainly used for a useful hobby. Such CNC-equipped milling machines are inexpensive, so they are often equipped in workshops of various educational institutions: schools, technical colleges, universities, etc.

Desktop equipment has a number of significant advantages:

- low cost;

- exceptional mobility;

- ease of operation and design.

Such machines, despite their compactness, are capable of performing various technological operations on metal and other materials: milling, drilling, boring.

Vertical milling machines are used to process large workpieces. They use drills, cylindrical, end, shaped and end cutters as working tools. With the help of such equipment, which is mainly equipped with large production enterprises, it is possible to process both horizontal and vertical surfaces.

Large-format CNC-equipped milling machines live up to their name: they have a special working head that can be rotated in any direction. Due to their versatility, such machines are most often used to equip non-standard equipment workshops and tool areas.

Large Format CNC Router

Machine overview

Before deciding which milling machine to choose to equip a home workshop or manufacturing plant, it is important to familiarize yourself with the characteristics of the equipment that is offered on the modern market. Today, the most popular are milling machines produced in the following countries:

- Germany;

- Italy;

- Austria;

- China;

- North Korea;

- Malaysia;

- USA;

- Taiwan;

- Czech Republic;

- Türkiye.

Five-axis milling machine

The most famous companies that produce and sell CNC milling machines are:

- GCC Jaguar;

- Redwood;

- RuStan;

- JCC;

- Hyundai Wia;

- Kami;

- Zenitech.

Some of the fastest machines, which also feature a wide variety of settings and additional functions, are models of the GCC Jaguar brand.

JCC is distinguished by its wide variety of machines for processing parts made of metal and other materials. The catalog of this manufacturer presents CNC machines for the following purposes:

- universal type, designed for engraving and milling work;

- for processing wood and metal products;

- piercing machines of electroerosive type;

- equipment for milling and turning group.

Advanced software products that control the machines of this brand allow you to use their full potential.

CNC vertical milling machine MA655

CNC-equipped milling machines of the RuStan brand are primarily equipment of a highly versatile type, with which you can perform a wide range of technological operations. What makes the models of this brand different is that when purchasing them you can take advantage of a variety of discount programs, as well as the possibility of warranty and post-warranty service.

Truly unique are the CNC milling machines produced under the Redwood brand. They are capable of processing parts in 2d and 3d format. The implementation of 3D technology assumes that, according to a given program, a volumetric part is obtained from a workpiece that fully corresponds to the given geometric parameters.

The main principle of the work of specialists involved in the production of milling equipment of the Kami brand is the production of high-quality products. Using machines of this brand, you can process not only metal, but also parts made of stone, wood, plastic and even glass.

Hyundai Wia specializes in the production of CNC machines that produce products for the aerospace and automotive industries. The programs that are used to control them require minimal human intervention and greatly simplify the use of such equipment.

Milling machine from the German manufacturer Zenitech

The catalog of the well-known manufacturer Zenitech is dominated by professional CNC milling equipment designed for processing metal and wood parts.

CNC milling equipment of the Invest Adam brand is widely represented on the modern market. The main advantages of the models, which are distinguished by their compactness and versatility, are:

- high processing accuracy;

- efficiency and productivity;

- control programs can be played repeatedly;

- the design is highly reliable;

- communication with the computer that controls the operation of the equipment is carried out via a regular USB port.

To equip a home workshop and a large manufacturing enterprise, you can use a CNC milling machine produced by the German company BZT. The machines of this brand are distinguished by high stability, reliable fixation of workpieces, accuracy and efficiency of processing. It is also convenient that the machines of this brand can run on almost any software.

The cost of a CNC milling machine is influenced by the following parameters:

- complexity of equipment design and its type;

- type of production for which the equipment is intended;

- country of origin and brand;

- functionality of the machine.

The simplest design is available on desktop CNC machines, which are much cheaper than more functional equipment. To save on purchasing a milling machine, choose equipment from domestic manufacturers. On average, the cost of desktop CNC milling equipment is about $4,000. This price can vary depending on a number of factors: dimensions of the machine and work table, engine power, weight of the equipment and its functionality.

The cost of equipment for a CNC vertical milling group varies from $7,000 to $25,000. The price of a specific equipment model depends on its power, the number of spindle revolutions and processing accuracy.

Domestic machine GF2171

Large-format CNC-equipped milling machines are the most expensive in their category, as they allow a wide range of technological operations. The high cost of such equipment is compensated by the fact that it can be operated in a fairly intensive mode. The list of operations that can be performed using equipment of this category is impressive:

- cutting blanks;

- milling of various types of surfaces;

- polishing operations;

- drilling;

- boring operations.

Control

A control program (CP) containing the following types of information is loaded into the software:

- geometric - dimensions of the part and the processing tool, their location relative to each other on the table (the coordinate movements of the table are determined by the workpiece);

- technological - material, hardness, surface cleanliness of the part, selected modes, sequence of tool replacement.

Options for entering information:

- hand typing by the operator on the console;

- via the remote control without using numeric data.

Popular systems are "SIMENS" Germany, "GE FANUK Automation" USA-Japan, from domestic "Balt-Systems" St. Petersburg. U.P. are produced in various classes for simple and complex machines. Pay attention to the compatibility of hardware and software.

How to choose the right milling machine

You should choose a CNC-equipped milling machine not based on an advertising video, but based on the functionality of such equipment and its technical characteristics. In these situations it is necessary to be guided by the following criteria:

- the type of machine that is needed to perform certain tasks;

- advantages and disadvantages of certain models;

- desktop dimensions;

- the presence in the design of a T-shaped groove, which facilitates more convenient fastening of the workpiece;

- voltage required to operate a CNC machine;

- functionality;

- category: desktop, mini or professional;

- warranty provided by the manufacturer.

And, of course, you can also watch a video from the manufacturer for the selected equipment, which will give you the opportunity to understand what characteristics it has. You should not choose a CNC machine that can perform functions that you will never need.

Machine characteristics

The characteristics of such machines directly depend on the characteristics of the spindle, the speed of movement and the size of the table. Spindle speed is the range of rotation speed of its head. Drive power is the rated power of the air turbine, electric motor or piston motor that drives the spindle.

The number of cutters that the tool magazine supports is also an important criterion, as it gives the machine a certain versatility. On simple machines, only one tool can be operated at a time.

Motion options for milling machines include:

- number of axles;

- maximum movement along the X axis;

- maximum movement along the Y axis;

- maximum movement along the Z axis.

As for the size of the table, its length is measured parallel to the main axis of movement. The width of the table is measured perpendicular to the main axis of movement.