The jointer and jointer have long been one of the most popular carpentry tools, and they have not lost their relevance today. Many specialized specialists are interested in the question of how to sharpen jointer knives, since a fully prepared tool for work allows you to achieve better quality of work. The first thing to do is to remove the knife and chipbreaker, which must be unscrewed before work. Used tools need to be cleaned of contaminants, such as tar, which is best removed with gasoline.

To sharpen planing and jointing type knives, it is better to use specialized devices. The procedure is also carried out manually; in addition, the device for sharpening jointer knives can be assembled independently. When working, you need to follow a number of rules, you can use several technologies. Regardless of which sharpening option you use, you need to follow the instructions as closely as possible. Otherwise, you can achieve poor-quality work of the tool, the functions of which the carpenter will not be able to use 100%. If you are thinking about how to sharpen jointer knives at home, then use regular sharpening stones, although choosing a professional sharpening machine with a cooling function is ideal.

Sharpening machine for planing knives

Owners of planing machines and electric planers periodically face the problem of sharpening cutting edges. A well-sharpened tool will ensure clean wood processing even at non-ideal angles and speeds. The easiest way is to sharpen knives and knife heads with your own hands using specialized equipment.

Knife sharpening is necessary

sharpening a planer knife

Planer knives require timely care because:

- blunt surfaces process wood poorly;

- when processing soft rocks with dull knives, the surface becomes covered with lint and unevenness;

- worn edges crumble;

- During planing with blunt edges, the engine and power units are overloaded.

Attempts to sharpen blades with your own hands using diamond stones, as a rule, give short-term results. Due to poor quality of editing, the blades have to be sharpened soon. Therefore, professional carpenters use only mechanical sharpening.

Types and designs of machines

The machines on the market are distinguished by the knife feeding mechanism:

The machine for sharpening planing knives with manual feed consists of:

- grounds;

- abrasive stone;

- carriages for fixing the knife.

During processing, the cutter moves forward with the help of a handle. Transverse movement of the cutter is ensured by a flywheel.

Automatic machines differ in size and range of options. Mechanisms for industrial use are installed on a powerful cast-iron frame. The carriage is equipped with a support. You can set the speed of movement of the blade and the thickness of the metal layer being removed. Industrial machines allow you to simultaneously sharpen several planer blades without changing settings.

| Corvette K-470 | WTG-163 | GA-630 | GA-850 | ZX-1000 | |

| Maximum length of knives, mm | 630 | 630 | 640 | 850 | 1000 |

| Abrasive disc diameter, mm | 100 | 150 | 125 | 125 | |

| Sharpening angle, degrees | 35…55 | up to 30 | 35…45 | 35…45 | Up to 30 |

| Engine power, W | 550 | 550 | 850 | 850 | 1500 |

| Dimensions, cm | 90 x 48 x 42 | 100 x 60 x 65 | 100 x 54 x 120 | 120 x 54 x 120 | 190 x 56 x 150 |

| Weight, kg | 75 | 60 | 112 | 125 | 250 |

| Add. intelligence | Equipped with an asynchronous motor, wet sharpening possible | Processes cutters, circular saws | Wet sharpening possible | Can sharpen up to 4 blades, wet method | A wet method is provided, a cup-type grinding disc is controlled via a remote control |

Table 1. Characteristics of some models of machines for sharpening planing knives

Compact automatic machines for home and small workshops are designed to process one cutter in one go. They also provide speed control and automatic tool feeding.

Before starting work on any sharpening equipment, you should make sure that the frame is securely fastened. Machine vibration impairs the quality of sharpening and can lead to injury to the operator.

Basic rules for using manual feed equipment

machine for sharpening planing knives Corvette-470

Such machines are used for one-time work and for sharpening small batches of blades with your own hands, since the processing process is quite long.

- Before starting work, you need to make sure that the grinding surface is clean, without stains or streaks.

- The movement of the carriage should be smooth, without jerks or jolts. It is forbidden to stop it when the cutter approaches the sharpener.

- The faster the carriage moves, the lower the quality of sharpening. The optimal speed of movement is 5 - 6 m/minute.

- For proper sharpening, the range of motion of the carriage is important. During a pass in each direction, it should move 10 - 13 cm further than the end of the knife. This ensures optimal contact between the cutter and the sharpener, which must be broken before moving in the opposite direction.

Basic rules for working on automatic machines

- Planing knives can be sharpened dry or wet. In the second case, the blade is constantly washed with a stream of water. The wet method is gentler on the blade and more effective;

- Before processing begins, it is necessary to set the following parameters: sharpening angle, amplitude of carriage movement. The amplitude should be 15 cm greater than the length of the knife;

- The blades are carefully fixed in the mobile carriage with your own hands.

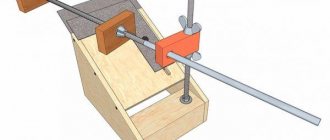

Homemade machine for sharpening planing knives

machine for sharpening planing knives Kraton-630

The design, made at home with your own hands, allows you to quickly and efficiently sharpen knives to one set angle. This will change the factory angle, so all blades will need to be re-sharpened. The quality of planing will not deteriorate, but may even improve.

To make a device for sharpening straight blades of planing, jointing and thicknessing machines with your own hands, you need:

- metal corner No. 50;

- round pipe with a diameter of no more than 50 mm;

- electric motor from a washing machine;

- powerful spring;

- bolt with nut;

- plastic handle (knob);

- Bulgarian;

- welding machine.

Making a machine with your own hands.

- Cut a corner about 50 cm long.

- We bend two pieces of pipe so that we get a stable stand for the corner, and weld the legs. The corner should be positioned vertically towards the master.

- At the left end, behind the corner, we attach an electric motor. It is placed on two points: a rigid axis and a powerful spring; The spring is tightened and released using the adjusting screw, moving the motor closer or further from the angle guide.

- We put an abrasive wheel on the electric motor shaft.

- The engine is started by a switch located on the frame in a convenient location.

- We feed the tool using homemade vise from a piece of pipe 25 cm long, a pressure plate, a bolt with a nut and a knob. We clamp the knife in a vice and move it along the guide, holding it by the knob.

Video review of this machine model:

stanokgid.ru

Description of sharpening knives for woodworking machines

Sharpening knives for woodworking machines is a mandatory process that can be done with your own hands using special tools. Sharpening is the restoration of the previous cutting capabilities of hacksaws, scissor shafts, planers, jointers and other devices for wood processing.

Photos of sharpened knives

- To sharpen the blade shaft of a planer or jointer, you will need the appropriate device;

- The sharpening work is done by hand;

- Craftsmen learned to assemble sharpening devices;

- When restoring hacksaws, jointing devices, sharpening knife shafts, be sure to follow several recommendations and strictly follow the technology;

- If the teeth of hacksaws and knife shafts are sharpened incorrectly, the quality of wood processing with tools will significantly deteriorate;

- Sharpening stones are a good alternative for a sharpening machine. But if you have the opportunity to assemble it yourself or purchase a sharpening machine, be sure to take advantage of it.

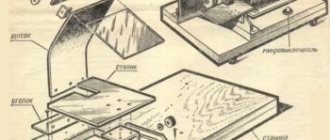

Diagram of the device for sharpening knives of woodworking machines

If you need to sharpen knives for a woodworking machine, you should start with the required preparation steps. It is not so important what parameters the knife shaft or cutting sheets of hacksaws have 13 mm, 20 mm or all 200 mm, they will definitely need sharpening.

Some people prefer to send dull shafts to special workshops, where they can easily restore the previous sharpness of a 200 mm knife or a small lathe cutter. But both ordering sharpening and buying new knife shafts is a financially expensive matter.

Preparation for sharpening begins with familiarization with the available means of restoring the surfaces of cutting tools and some recommendations.

- To keep jointers, planers, and hacksaws in working order, assemble or purchase an appropriate sharpening device.

- The simplest, budget option is a whetstone. But the quality of processing directly depends on your skills in working with stone. If there are none, it is extremely difficult to achieve the required level of sharpening. Plus, stones are not able to cope with all types of cutting tools that are equipped with modern woodworking machines.

- Choose a machine that can sharpen at low speeds, as this has a positive effect on the quality of the finish.

- The recommended equipment for a sharpening machine is a water cooling system.

- Carefully study the equipment of household woodworking machines. Often there is already a sharpening stone, which is optimally suited for processing the knives used.

- If the stone is not included in the package, it will have to be purchased separately, leveled with a special device, and smoothed. This is the only way you can sharpen the knife shafts of jointing machines efficiently.

- The machines have a function for setting the angle of inclination, adjustable with a special screw. By turning the screw and changing the position of the sharpening device, you can correctly fix the tool relative to the stone.

- The next preparatory stage is the holder into which the knife shaft is installed.

- If you are a beginner, it is not recommended to start your first job with 200 mm knives. Start literally with 13-15 mm, and gradually you will learn to process 200 mm and even 2 mm. To do this you need to accumulate certain experience.

- The length of the knife is not a fundamental parameter, since the knife in the holder can move to the distance you require.

- Make sure to hold the shaft firmly in place. Otherwise, you will get a significant distortion, due to which the quality of woodworking will suffer.

- Study the operating manual of the purchased sharpening machine in detail. If this is a DIY tool, you will have to rely on drawings and available information on the Internet about a specific sharpening device project.

Sharpening

In order for the sharpening of knives for a woodworking machine to give a positive result, you can resume working with the equipment at the same level of quality, you need to adhere to a few fairly simple rules.

- The sharpener holder can move left and right relative to the stone to sharpen knives.

- Do not allow the blade to end up over the edge.

- Immediately fix the holder at a distance of 12 mm from the edge of the grinding wheel.

- When sharpening knives of 200 mm or smaller variations, make sure that the water cooling function is activated on the machine.

- The cooling system requires constant monitoring. The tank usually has a small volume, so water needs to be added periodically. If it runs out and the sharpening process continues without cooling, you risk ruining a rather expensive knife.

- As the knives are processed, water from the cooling system may accumulate on the floor. Since sharpening machines are electrical devices, ensure that water is drained away from your feet and wear rubber shoes. In any case, standing in a puddle of water while working with an electric machine is always dangerous. Follow safety regulations.

- Keep the whetstone clean. It gets dirty quite quickly with active use.

- The grinding wheels of machines are cleaned using a special device. The machines should be equipped with this cleaning bar, but if it is not included in the set, then you will have to purchase it separately.

- Each subsequent sharpening, according to the operating rules, is performed only on the condition that the stone is cleaned. Therefore, after each sharpening, arm yourself with a cleaning bar and treat the machine with it.

- On average, sharpening using a special machine takes about 10-20 minutes. It all depends on the type and size of the tool, which became dull as a result of woodworking operations.

- After sharpening the tools of woodworking machines, do not rush to return them to their place and continue working. After processing on the machine, the tool needs to be fine-tuned.

- Finishing consists of applying a special paste to the surface of the cutting element. Proceed according to the instructions provided by the manufacturer of the finishing paste on the packaging. Different pastes may differ slightly in application methods.

If you did everything correctly, then the knife should be perfectly smooth, sharply sharpened, and free of any irregularities or burrs. Don't worry when the result doesn't meet your expectations the first time. This takes some time and a little experience. That’s why you should start with simple and inexpensive knives that you don’t mind ruining.

Article rating - material rating: 5.00 out of 5 Loading…

tvoistanok.ru

Sharpening angle of knives for planing machines

Any owner of planing equipment has had to deal with sharpening the corresponding knives. If you have a special machine at your disposal, then this will not be difficult to do. Another option would be to contact a specialized workshop. You can also sharpen such cutting tools yourself.

Why is timely and correct sharpening necessary?

Planing knives, like other cutting tools, require maintenance for certain reasons:

- with a blunt blade of planing knives, the wood will be processed very poorly;

- when working with soft types of wood, pile and various irregularities will form on the surface;

- the worn edge will crumble;

- When planing with blunt tools, the machine motor overloads

Even if you decide to sharpen it yourself using diamond stones, the effect of such work will be very insignificant. You'll have to resharpen them soon. For these reasons, people who plan professionally choose only automatic or mechanical sharpening.

Preparing the workplace and equipment, installing the screw that controls the angle

To sharpen knives, you will need a special sharpener, but you must use modern variations of it with a low speed, which have water-type cooling. The Tormek T7 with a special Tormek SVH holder is most suitable for these purposes. A smooth and clean sharpening stone will help you complete this process efficiently. In the future, a practical example will be considered based on a set of Tormek equipment.

When sharpening, you need to install a screw with which you can change the sharpening angle, but first you need to prepare the workspace by fulfilling certain conditions:

- We install the Tormek SG250 sharpening stone, leveling it using a special tool Tormek TT-50. The device comes complete with T7.

- It is necessary to smooth the sharpening stone using a cleaning and leveling stone.

- We remove the standard stop and install a specialized stop.

- We screw in the screw itself, which can later be used to adjust the angle of the chair being sharpened.

- We install a special holder for the blade.

It is recommended to sharpen cutting tools whose width is more than 12 millimeters. And the length of the knife no longer matters. In addition, you can rearrange long knives. Correct installation of the blade in the holder is of great importance, because sharpening with large distortions is possible. Correctly this process is performed as follows: install the back of the knife all the way and clamp it with special holders.

Estimating and setting the required inclination angle

By analyzing the characteristics of the marks left by the sharpening stone, it is possible to correctly assess the angle of inclination by selecting the desired proportions. Then a holder with a knife is installed on the fixed stop. Adjustment is carried out using the stop screws; you need to lower the holder until it touches the stone. Using the angle adjustment screws, select the required parameter in relation to the stone. When rotating manually, the marks on the painted blade determine the need to adjust the angle of the holder. And if necessary, such adjustments are very easy to make.

Operating angle range 30-45 degrees. Its exact degree is determined by the specific type of tree. A 1985 handbook written by Karl Fronius states that quality will depend not only on the angle, but also on the blade's reach and head diameter. The classic parameter is considered to be 40 degrees. When choosing a specific number, do not forget that the cutters are designed according to a standard backing. If you increase the angle, there is a risk of the butt rubbing against the workpiece. And if you reduce it, the cutting edge will become weaker and thinner.

Solving the problem of choosing the right angle

There are two ways to solve the problem of setting the required angle of inclination:

- Using a double-headed backing based on the principle of double-layer blades. We make the main back at an angle of 40 degrees, and the very top of the knife - about 20 degrees. This will significantly extend its service life, and the knife will also have good shock resistance.

- Check the sharpening pattern and modes.

Some rules and features of sharpening

Having set the angle of inclination to the desired position, you can begin the sharpening process itself. You can record the amount of metal being removed; two sliders with a scale and 0.1 mm division are designed for this purpose. The sharpening specialist will be able to adjust this parameter quite accurately. Do not forget to securely fix it with special clamps after each filing to prevent vibrations during sharpening.

The sharpening process itself is carried out by changing the position of the holder in relation to the sharpening stone. It is important to ensure that the knife does not go beyond the extreme point of the stone. It is advisable to stop the holder 10 mm from the edge. Separate stops are provided as a braking element, by moving which the desired stroke is set. The decisive factor here will be the experience of the person who sharpens the planing knives. During the process itself, water is formed, which accumulates and collects on the blade. Then it flows onto the body itself and onto the floor. A lot of water is wasted, so don’t forget to constantly add it to the special section. And the spill itself can be reduced by placing some kind of pad under the leg, 6 mm high.

Another nuisance during sharpening will be the constant clogging of the sharpening stone, which affects the duration of this work. It is best to periodically clean it with the SP-650 bar provided for this purpose. When working with soft metal, sharpening will go much faster and the stone will have to be cleaned less often, because such material is removed in fairly massive sections.

After half an hour of work, you get an even chamfer with a stable burr. All that remains is to polish it using a leather wheel and polishing paste. First of all, you will need to complete the plane of the knife, and only then the chamfer itself.

Features of working with a manual machine

Manual machines are used only in cases where it is necessary to sharpen not too many knives. Otherwise it would have taken a lot of time. But if you need to sharpen several knives, then this method will be quite acceptable, but you must adhere to the following rules:

- you need to check the surface of the stone, because the use of such machines is only possible with clean sharpening tools;

- try to make sure that the carriage with the attached knife is brought in quite smoothly, without any sharp jolts;

- the speed of movement of the carriage should not exceed 6m/min, high speed may damage the blade;

- During one pass, the carriage must advance a distance that is 15 cm greater than the length of the knife.

Features of working with an automatic machine

- the wet method is more suitable for sharpening planing knives, because the blade is constantly cooled;

- at the preparation stage, you already need to set all the parameters, including the angle of inclination and the distance of movement of the carriage;

- the most important factor is the installation of knives on the carriage;

- the process should be carried out quite smoothly, without sudden twitching

DIY sharpening machine

If desired, it is possible to assemble the sharpening machine yourself. You will need the following items: table, faceplate, vacuum cleaner, motor and machine cover. The faceplate will become the main and most expensive component. It is advisable to choose American or German manufacturers. Then an engine with a power of 1.5 kW is selected; even supported options are suitable. For example, you can purchase motors from washing machines.

The motor must be installed under the tabletop, and the faceplate must be secured to the moving element. Don't forget to consider the on and off buttons. You need to put a casing on the faceplate, cutting off one side, from which sharpening will be done. You will also need to make a cutout at the bottom of the tabletop for a vacuum cleaner. This machine is also suitable for working with other cutting surfaces.

Sharpening knives in specialized workshops

If you are unable to organize the correct sharpening of planing knives or it becomes difficult to set the desired level of inclination, then contacting a workshop will be an excellent solution to the problem. This method has the following advantages.

- Expensive and high quality equipment is used. The straightness of the cutting edge will be much better than when processing it yourself.

- Modern cooling systems are used that will prevent the cutting surface from overheating and collapsing.

- Additional materials and special technologies are used to refine the knife, which affects the functionality and service life of such knives.

- In a workshop environment, it is possible to obtain the most even edge due to the absence of overheating and weight differences. In practice, the result should be an ideal instrument.

What you need to know about sharpening jointer knives

Published: 11/23/2015

The jointer and jointer have long been one of the most popular carpentry tools, and they have not lost their relevance today. Many specialized specialists are interested in the question of how to sharpen jointer knives, since a fully prepared tool for work allows you to achieve better quality of work. The first thing to do is to remove the knife and chipbreaker, which must be unscrewed before work. Used tools need to be cleaned of contaminants, such as tar, which is best removed with gasoline.

To sharpen planing and jointing type knives, it is better to use specialized devices. The procedure is also carried out manually; in addition, the device for sharpening jointer knives can be assembled independently. When working, you need to follow a number of rules, you can use several technologies. Regardless of which sharpening option you use, you need to follow the instructions as closely as possible. Otherwise, you can achieve poor-quality work of the tool, the functions of which the carpenter will not be able to use 100%. If you are thinking about how to sharpen jointer knives at home, then use regular sharpening stones, although choosing a professional sharpening machine with a cooling function is ideal.

Preparing to sharpen knives

Sharpening jointer knives can be done more efficiently if you choose a device with low speeds and high quality. If you want to use a whetstone, you must first level it. After straightening the device, the stone must be smoothed with a block.

Now set the appropriate angle of inclination, this is done by rotating the screw securing the blade. Next, you need to use the holder that is included in the standard equipment of the machine, where the jointing knife is fixed. Work should begin with knives no wider than 13 mm. The length is not important, since the holder holds the tool in a comfortable position.

To secure the knife well, hold it in the selected position and tighten the screws tightly.

To control the sharpening angle of the jointer knives, a marker is used to mark the chamfer of the knife. To understand the accuracy of the adjustment, you can turn the stone manually.

Tool sharpening

Sharpening jointer blades is a simple process, you just need to move the holder from side to side relative to the whetstone. Try not to let the blade go beyond the edges of the stone. Fix the holder 12 mm from the end of the circle. When carrying out work, it is necessary to establish a supply of water cooling. Be prepared to regularly replenish the fluid in the tank and not allow the tank to dry out. To ensure safe work, you need to ensure that moisture does not flow onto the floor under your feet.

Sharpening jointing knives is a rather lengthy procedure. Periodically check the cleanliness of the whetstone, as it can quickly become dirty. To clean it, you need to use a special bar as soon as contamination is detected. By the way, the choice of stone largely depends on the type of instrument. A planer can include knives of varying hardness types, so choose your whetstone carefully.

Typically, jointer knives are sharpened for 20 minutes, after which finishing needs to be done. This procedure is carried out using a special paste. Polishing is carried out so that the blade does not have the slightest roughness or burrs, otherwise the work with such a knife will not be complete. Check the effectiveness of sharpening by cutting a piece of paper with it. If the cut is made carefully, then the knife is completely ready for use.

Other materials for sharpening tools: * Sharpening a hacksaw for wood. * Sharpening a chisel with your own hands.

drevologia.ru

Sharpening process and operating rules

Scheme of a machine for sharpening knives.

The holder moves to the right and left, movements are made relative to the sharpening stone. The blade should not be allowed to go beyond the edge. It is best to immediately install the holder 12 mm from the edge of the working circle. If sharpening is carried out, water cooling must be supplied. You will have to add water to the tank, you need to make sure that it does not run out. It is necessary to ensure that water does not accumulate on the floor near your feet. This is done for security reasons.

When performing work, you must ensure that the stone remains clean at all times, as it gets dirty quite quickly. A special whetstone is used for cleaning; it is recommended to carry out this procedure frequently, since only clean stones can be used for sharpening. The choice of stone itself depends on what kind of knives are used. Today, manufacturers produce jointing knives from soft or hard tool steel, so working conditions will vary.

Sharpening takes approximately 20 minutes, then fine-tuning is done. A special paste is used for this. After polishing, there should be no burrs left on the surface, otherwise the jointing knife will not be ready for use. The test is simple to carry out; a finished knife with excellent sharpening should easily and evenly cut a sheet of paper while hanging, leaving a neat cut.