Home / Electrodes

Back

Reading time: 2 min

1

636

Zeller is a brand of electrodes that is in demand among professional welders due to its worthy characteristics. When purchasing these electrodes, preference is mainly given to Zeller 855.

The versatility of these electrodes lies in the fact that with them you can cook any type of cast iron, and even alloys, without preheating the metals before the work process.

This article will help you understand the characteristics, methods of application and features of electrodes for working with Zeller 855 cast iron, and will also tell you which of them make this brand unique.

- General information

- Indicators

- Methods of application

- Conclusion

General information

Zeller 855 - electrodes intended for welding and surfacing work on cast iron (any type: malleable, viscous, nodular graphite).

These models can be used for welding both with pure cast iron and for welding cast iron with various steels, without preheating the working material.

During repair work, Zeller rods 855 reveal their full potential, since with them you can easily “bring back to life” cast iron parts of varying complexity: from gearbox housings to crankshafts.

Electrode Specialization

Different models of electrodes of this brand have the ability to satisfy the need for their use for various materials. They are also used for surfacing, which improves the quality of the product.

| Materials to be welded and surfacing | product name |

| High carbon steel | Zeller 655 |

| Cast iron | Zeller 855 |

| Bronze | Zeller 340N |

| Copper | Zeller 390 |

| Aluminum and compounds based on it | Zeller 480 |

| Stainless steel | Zeller 6809 LC |

| For surfacing to protect against mechanical damage due to impacts | Zeller D600 |

| For welding to improve wear resistance | Zeller Turbular 700 |

Zeller 855 electrodes are the most famous and popular because they are designed for connecting cast iron products, which many other electrodes cannot do.

Due to the fact that each type of electrode has a narrow focus, this is taken into account in their production technology and results in high-quality connections. The seams formed are straight, even, without roughness. The roller is formed beautiful and finely scaly. The use of electrodes is justified by both professionals and amateurs.

Indicators

As a result of working with Zeller electrodes, you will get: straight, uncracked, high-strength, precise seams without roughness with a fine-scaled, elegant bead.

We also get a high degree of surfacing and economical consumption. The Zeller 855 core makes them highly conductive, because it consists of bimetallic wire.

If welding work is carried out on very dirty or corroded surfaces, then you don’t have to worry about these products - the welding spirit will burn steadily.

Thanks to the coating of this brand, pores do not form in the weld pool. High ductility of the deposited metal is ensured by the high nickel content in the rods.

Electrodes from a defunct manufacturer * ZELLER *

Hello, gentlemen, I want to tell you not about welding, but about sorrowful matters around welding.

Prologue.

Then I came across ZELLER electrodes on the Internet. Judging by the advertising, the electrodes are simply super: a wide selection, European quality, made in Vaterland, which to the Russian ear sounds no less attractive than the rustle of green bills. I think it might jump from ESAB to ZELLER. I started looking for information on them. This is where all the fun began. I had to retrain from a welder to a detective.

Part one.

So, how do you distinguish good welding materials from all the rest? Any brand, whether Esab, Lincoln, and all the others (with the exception of Kastolin, but that’s why they are Kastolin), provide information on the chemical composition of the deposited metal and its physical properties. I tried to find something similar on the Internet about ZELLER electrodes and did not find it (or rather, I found it, but more on that later). Everywhere the same phrase: “specially developed chemical composition of the deposited metal” and that’s it. Suspicious. Moreover, this phrase appears like a copy in all available sources.

I decided that since the company is European, German, there should be some kind of official website in the .com or .de domain. Google and Yandex had not yet managed to ban me, so I used these search engines. So, let's type ZELLER.com

— we are looking, but we don’t find anything similar to manufacturers of welding materials. Type ZELLER.de

- again, neither Google nor Yandex knows such a manufacturer of European welding materials. Don’t despair, fortunately we still find the official ZELLER website through the links. All links lead to zellerwelding.com.

Hurray, we found them! But the joy turned out to be premature.

It’s strange, the site is in the .com domain, but it’s in Russian, only in Russian! There are no English or German versions. A bit strange for a European company. Let's look at their contacts:

only in Russia and the CIS, the telephone number is a regular federal one. How so?? Is this a German company??

We go to the main page of the site. We see that the company is positioning itself in Dusseldorf. True, there is neither a street nor a house. Let's start searching on the Internet:

There is no address with a street and a house. Düsseldorf and that's it, write to your grandfather in the village. It doesn't happen like that. No matter how many times I’ve been to various websites of normal European companies, there are always clear, specific addresses and phone numbers/faxes. And here it is empty.

Well, just out of curiosity I went to Wikipedia. She knows nothing about such a manufacturer as ZELLER.

He knows about others, but not a word about this.

From my little investigation I draw the following conclusions:

1. ZELLER is a Russian company and has nothing in common with Germany. They do not have their own production.

2. The official ZELLER website is located in the .com domain in order to create the appearance of non-Russian origin.

3. The design of the packaging of the electrodes with inscriptions in German, indicating that they were made in Germany, is a banal disguise to create the appearance of German origin.

4. The story about Dusseldorf was invented from beginning to end.

End of the first part. To be continued.

I want to hear feedback and opinions, gentlemen. I'll go play the violin and smoke a pipe.

Post edited by svarnoi69: 04 August 2022 20:20

zeller welding (Germany, Dusseldorf)

Where to buy Zeller electrodes

The production of the company “ZELLER WELDING” is located in the German city of Dusseldorf. The company was founded in 1963, and today occupies one of the leading positions in the market for the development and manufacture of welding electrodes.

Electrodes of the ZELLER WELDING brand are manufactured by the CARBO WELD plant. If you go to the plant’s website and switch to Russian, you will go to ZELLER WELDING. For the Russian market, materials are manufactured as ZELLER, in Europe they are manufactured as CARBO, for Turkey and the USA, other brands, in fact there are a lot of them there. For Europe, several brands are used. But they are all manufactured by the CARBO WELD plant.

The main task is to produce high-quality materials that meet the standards and norms of GOST. The accumulated experience and the use of innovative technologies allows us to fully satisfy customer requirements.

Products are supplied to more than 70 countries around the world. The company has a developed distribution network. Buyers can find official representatives located in Russia on the website.

The company “ZELLER WELDING” is located at:

- Germany, Dusseldorf.

- Telephone -.

- Website – https://zellerwelding.com/.

Range:

- Electrodes for protection against abrasive wear (ZELLER): 75WC.

- L63.

- L65.

- Tubular 700.

- T-590 (for direct current).

- 750Mn.

- 880AS.

- 470.

- 745.

- 663.

- 320.

- 6808AC.

- 655.

- 501VB.

- 800.

Where to buy Zeller electrodes

ZELLER D600 - electrode for surfacing (59 HRC) (Video)

Universal economical electrode ZELLER D600 for surfacing surfaces that are resistant to strong impact loads, high pressure and aggressive wear.

Application area:

The ZELLER D600 electrode is designed for surfacing a wear-resistant layer on parts made of steel, cast steel, manganese steel, subject to strong impacts, high pressure and abrasive wear.

Purpose: Ideal for repair and restoration of parts of tunneling shields (restoration of the radial edge, the front side of the rotor, surfacing of cutters, balls and bucket teeth), working surfaces of earthmoving and transport machines (teeth and cutting parts of buckets of excavators and bulldozers), for wearing parts of stone processing machines installations (screens, augers, hammers, crushers).

Welding characteristics:

Electrode ZELLER D600, with basic coating. Stable welding arc, smooth, uniform seam without undercuts. The deposited metal has high hardness, strength and crack resistance. Stable surfacing characteristics are maintained when the electrode is in a vertical position. Possibility of multi-layer surfacing, up to 10 layers, without cracking of the seam.

The coefficient of metal transition into the seam is 120%.

Subsequent processing is only possible by grinding.

The hardness of the deposited metal is 59 HRC.

| Hardness, HRC | Hardness, HV | Weld metal | Wear rate,% |

| 59 | 700 | FeCrSi | 2,2 |

| D x L (mm) | Z.2x350 | 4.0x450 | 5.0x450 | 6.0x450 |

| Current strength, A | 90-120 | 110-160 | 150-200 | 180-250 |

| Packing, kr | 5 | 6 | 6 | 6 |

Electrode for surfacing surfaces resistant to strong shock loads Zeller D600 (Video):

specg.ru

How to use?

The use case for Zeller 855 largely depends on the type of welding work. We will tell you how to use these electrodes when repairing cracks. For other work, the recommendations are similar, but may have minor differences.

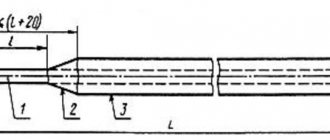

First you need to cut the crack. A U-shaped cut to the full depth of the metal is recommended. This way the penetration will be deep and the internal stress will be distributed evenly. Also, the U-shaped groove literally burns out excess moisture and oil from the welding area.

Where can there be oil or moisture in the welding area? The fact is that cast iron is a porous material. It is able to absorb liquids, even if it is not visually noticeable. And liquids absorbed into the metal structure negatively affect the welding process. The likelihood of pores and cracks forming in the welded joint increases. For cutting, you can use electrodes from Zeller brand 880AS. They are great for such purposes. If you use a mechanical method for cutting edges, excess liquids will simply spread over the surface of the edges and can cause defects.

After cutting, clean the edges using a sander. Do not leave any sharp edges. Drill out the crack at both ends. This is also necessary to reduce welding stress.

Welding should be done with short beads. Professionals recommend forming a seam with a slight offset to the side relative to the center. In this case, each new section of the connection must be welded in a checkerboard pattern. That is, boil the short roll on the right, then the short roll on the left a little higher. Then again a short roller on the right, etc.

If you ignore this recommendation, the crack may increase in size and spread. Cook on a short arc. Move the electrode slowly, the vibrations should be insignificant. Monitor the heating temperature of the metal when welding; it should not exceed 80 degrees.

After welding, the joints need to be forged to relieve the part of excess stress. Take a rounded hammer and, using light, precise movements, hit the welding area several times. Forging is necessary when welding cast iron because after welding there is always residual stress in the seam.

Other types of electrodes

The zeller 655 electrode has high welding properties. Its intended purpose is welding and surfacing of various steels that are difficult to weld, have increased strength and heterogeneity. Indicators such as high tensile strength and corrosion resistance allow these electrodes to be used in the installation and repair of various mechanisms and machines.

The advantages include easy separation of slag, minimal metal spattering, and a weld with no corrosion or cracks. A special feature of the use of these electrodes is the ability to weld not homogeneous metals, but those with different compositions.