Welding is the heating of an electrode and metal for the purpose of joining. Welding non-consumable electrodes are an important element and are needed for automatic and manual welding. The materials for joining are non-ferrous alloys and steel. To create seams, you need a wire, which is a filler wire, changes its structure and melts during discharge. The shielding gas that is used in the process is necessary in order to create conditions for protecting the area where welding takes place from harmful fumes and removing them. This also affects the quality of the work performed.

Characteristics of non-consumable electrodes

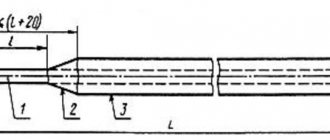

Non-consumable tungsten electrodes have a diameter of 2-6 mm. Their tips have the shape of a long cone for constant uninterrupted current and in the shape of a sphere for replaceable power. Sharpening is done manually or on special machines that have a guide for installing the rod. Can be used with alternating and direct current, with direct or reverse polarity. For alternating current, a prerequisite is the use of a stabilizer that compensates and equalizes the electric current. Welding is performed in one of the types of shielding gases - helium, argon or nitrogen.

Varieties and purpose

When welding, the following types of non-consumable electrode coating are most often used:

- coal-based;

- pure graphite;

- made of tungsten.

Regardless of the coating of electrodes for manual arc welding, they all belong to the same category, but are intended for very specific purposes.

Coal

Thus, carbon consumables are used when carrying out air-arc cutting, and are also in demand when eliminating defects on the surface of workpieces.

Welding with non-consumable rods with a carbon coating is carried out in modes with currents of no more than 500-600 Amps, which is enough to connect not very massive steel structures, as well as correct surface defects of cast products.

At the same time, welding with their help can be organized both with filler material supplied to the formation zone of the future weld, and without it.

Graphite

Pure graphite electrodes are most often used when working with non-ferrous metals (aluminum or copper), as well as their alloys. This type of welded material, in contrast to coal samples, is more economical and beneficial in practice.

In addition, such non-melting rods have a number of advantages, namely: resistance to high temperatures, less wear and simple preparation for work (cutting).

Graphite rods are especially widespread when welding wires and other copper products.

Tungsten

Tungsten non-consumable electrodes of non-consumable type belong to the category of the most popular consumable material in production and in domestic conditions.

With their help, it is possible to process various types of metals, including aluminum, in a protective environment of argon or other gases.

They are made in the form of a long coated rod with a diameter of 1 to 4 millimeters and are very refractory. The melting point of such an electrode is much higher than the same indicator for the working arc, as a result of which it has universal properties and can be used even for welding stainless steel that is difficult to process.

Tungsten non-consumable electrodes can be made with the addition of thorium, lanthanum oxide (lanthanated) or yttrium. Each brand is designed for a specific type of welding.

Differences from consumable electrodes

The disadvantage and difference is that the electrode melts during operation. It not only covers the seams with its alloys, but also decreases in size in comparison with the non-melting one. This results in the welder having to replace the electrode to work.

Application of non-consumable electrodes:

- working with workpieces whose parts consist of non-ferrous alloys;

- reliable connection of sheet materials;

- joining large sizes of non-ferrous metal in large sheets;

- methods of transferring coating from one metal to another;

- welding of metal containers for many types of industry.

Thanks to the technology of non-consumable electrodes, it is possible to weld structures made of metals with a large percentage of silicon and titanium.

Pros and cons of the method

The advantages of this welding method have always been considered:

- ease of operation and low price of equipment for the welding process;

- the ability to weld a large number of types of metals with a wide range of choice of electrode material;

- ability to perform welding work in hard-to-reach places;

- Suitable for welding in any spatial position.

Among the disadvantages it is worth highlighting:

Types of welding

Types of welding of non-consumable electrodes:

- Manual welding with non-consumable electrode.

- Automated.

Advantages of use:

- welding of different types of materials;

- the seams do not require grinding or descaling;

- cracks and deformations do not occur;

- You can weld any alloys and metals; there are no prohibited ones;

- when the seam is formed, the melt can be 0-100%;

- The polarity of the connection does not matter;

- the shielding gas system has good resistance to a number of arcs;

- the chemical composition can be changed using filler wire;

- fast execution;

- high-quality connection;

- Little labor involved in installation or welding.

Advantages and disadvantages

Refractory rods often cause controversy among beginners and experts. This is because there are equal amounts of both pros and cons.

- Deformation of the material is excluded.

- High quality and service life of the seam.

- Minimum time for the process and required skills.

Disadvantages of non-melting models:

- Shielding gas easily spreads beyond the welding zone, which does not allow working in open areas.

- Preliminary preparation of the material is necessary to avoid defects.

- Parts outside the welding area must be cleaned.

Some may agree with us and say that the described disadvantages of refractory electrodes are not so significant.

Welding Features

Welding with a non-consumable electrode, which is refractory in composition and has a high temperature for melting, which is much higher than the level. To select the type of electrode, the chemical composition and thickness of the metal are studied and then selected.

Types of consumables for welding:

- Tungsten. Welding with a non-consumable electrode in shielding gases is needed for reliable, strong seams in industry and everyday life. The electrodes have a core with a diameter of 1-4 mm and a protective coating for connecting different metals to each other. Tungsten has a higher temperature than the arc, which wears out less and loses its abilities due to this. Argon is used as gas.

- Graphite. There are conductors with carbon-graphite, the most durable type, which is resistant to high temperatures and electric current. They are used only in industry for welding cables from aluminum and copper using special equipment. Electrodes are used to connect parts made of steel with a low carbon composition and to hide defects in cast iron. To work with copper wires, graphite rods are used.

- Coal. In workpieces with thick walls, defects are removed; they are not often used. When welding with a non-consumable electrode, a current of up to 600 A is used and is usually used only for industrial purposes. They conduct electricity well due to the copper layer in their coating and are used not only for welding, but also for soldering and cutting. These electricity levels are enough to heat and melt structural and low-alloy steel. The electrodes contain coke, which provides strength. Diameter and length from 1.5 mm to large sizes. Carbon and graphite electrodes are not in demand; they are rarely used.

Welding steel with a non-consumable electrode allows you to carefully, almost invisibly, without gross defects, obtain a beautiful seam and connect large sheets of metal into one whole. Sheet metal is used in mechanical engineering, construction for shelters and fencing of temporary structures, and military industry. A big plus is the ability to combine and connect sheets that are made of different metals and alloys, while the risks of getting dents or deformations are minimal. Welding with a non-consumable electrode according to GOST always complies with it. When using a welding machine, you must follow the rules and use a protective mask for your eyes and face.

Graphite

Graphite electrodes have electrical conductivity higher than that of carbon consumables. This allows welding to be carried out at high current values. Another advantage is their high resistance to oxidation at high temperatures, which reduces their consumption during connection work. Graphite electrodes are widely used in metallurgical enterprises.

The advantages of graphite electrodes include: a short period of time required for their heating, resistance to cracks, and lack of sticking to the surface of products when heated. To form a stable arc, a small current value is sufficient.

Graphite rods are more practical than carbon rods. Working with them is convenient, and the resulting connection is strong and durable.

Tungsten welding using an inverter

To work with tungsten electrodes, a universal source of electrical energy is used - an inverter. Less common are the use of welding rectifiers (for direct current only) and transformers (for alternating electricity). The inverter is in demand, due to its practicality, for working with two types of welding voltage.

Approximate cost of inverters for welding on Yandex.market

Inverter welding equipment

For this type of welding you need:

- welding inverter;

- burner;

- argon;

- non-consumable electrode;

- filler wire;

- oscillator;

- personal protective equipment (mask, gloves for argon arc welding, overalls).

Scheme of argon arc welding

A welding torch is used to rigidly fix the tungsten electrodes in the required position. It supplies current and evenly distributes the supply of argon around the weld pool.

Shielding gas is used primarily to displace air from the welding area and to remove its contact with the working rod. Argon or helium also ensures the passage of current and heat transfer through the arc. The choice of specific gas type depends on the material being welded.

An important condition for a high-quality final seam is the initial preparation of the edges of the part.

Welding technique

For manual welding using an inverter, the following rules must be followed:

- Welding occurs from right to left.

- For products with small thickness, the burner is positioned at an angle of 60°.

- For thick parts, the burner is placed at an angle of 90°.

- The method of guiding the filler wire depends on the thickness of the metal being welded.

The most important condition for a high-quality weld is a stable arc. This can be achieved using direct current with straight polarity. Sharpening the non-melting rod is also important. During the sharpening process, it is necessary to ensure that the electrode does not overheat, in which case the rod becomes brittle during welding.

The filler wire is not inserted into the center of the arc, but slightly to the side with a reciprocating movement, if the metal thickness is up to 10 mm. To weld metals with greater thickness, the wire is moved in translational and transverse movements.

Classification of electrodes for welding high-alloy steels according to GOST 9466-75 and GOST 10052-75

Table 11. Designation structure

| E | 2 | 00 | 5 | P | 2 | 0 | |

| Resistance to intergranular corrosion | |||||||

| Heat resistance | |||||||

| Ferrite phase content | |||||||

| Type of coverage | |||||||

| Position of seams during welding | |||||||

| Polarity, transformer open circuit voltage | |||||||

Table 12. Resistance to intergranular corrosion

| Resistance against intergranular corrosion according to GOST 6032-89 | |

| Index | Method |

| 0 | — |

| 1 | A |

| 2 | AM—AMU |

| 3 | B |

| 4 | V and VU |

| 5 | D |

Table 13. Heat resistance

| Index | Maximum operating temperature, °C, according to: | |

| heat resistance | heat resistance | |

| 0 | — | — |

| 1 | Up to 500 | Up to 600 |

| 2 | 510—550 | 610—650 |

| 3 | 560—600 | 660—700 |

| 4 | 610—650 | 710—750 |

| 5 | 660—700 | 760—800 |

| 6 | 710—750 | 810—900 |

| 7 | 760—800 | 910—1000 |

| 8 | 810—850 | 1010—1100 |

| 9 | Over 850 | Over 1100 |

Table 14. Ferrite phase content

| Content of ferrite phase in deposited metal | |

| Index | % |

| 0 | — |

| 1 | 0,5—4,0 |

| 2 | 2,0—4,0 |

| 3 | 2,0—5,5 |

| 4 | 2,0—8,0 |

| 5 | 2,0—10,0 |

| 6 | 4,0—10,0 |

| 7 | 5,0—15,0 |

| 8 | 10,0—20,0 |

Table 15. Type of coating

| Index | Type of coverage |

| A | Sour |

| B | Basic |

| C | Cellulose |

| R | Rutile |

| AC, RB, etc. | Mixed |

| P | Others |

Table 16. Position of seams during welding

| Index | Position of seams during welding |

| 1 | All |

| 2 | Everything except vertical from top to bottom |

| 3 | Bottom, horizontal on a vertical plane and vertical from bottom to top |

| 4 | Bottom and Bottom |

Table 17. Polarity, transformer open circuit voltage

| Index | DC polarity | UXX transformer, V |

| 0 | Reverse (+) | — |

| 1 | Any (+/–) | 50 |

| 2 | Direct (–) | 50 |

| 3 | Reverse (+) | 50 |

| 4 | Any (+/–) | 70 |

| 5 | Direct (–) | 70 |

| 6 | Reverse (+) | 70 |

| 7 | Any (+/–) | 90 |

| 8 | Direct (–) | 90 |

| 9 | Reverse (+) | 90 |

Classification

To simplify the work of welders, all tungsten electrodes are classified - color marking is used for this. It complies with the international standard DIN EN 26848, which means that no matter in which country they were produced, the welder will know what current to weld and what parts they are suitable for. The color of a tungsten electrode indicates its main characteristics - rod size, chemical composition, type of suitable current. The following colors are used for marking: green, gray, red, blue, gold, white, dark blue.

Each color has a corresponding alphanumeric expression:

- the first index indicates W - indicates that the base metal is tungsten;

- the second symbol indicates the element used as an impurity (additives of other metals make it possible to obtain the required current conductivity, the necessary fusibility and arcing characteristics);

- the first number indicates the proportion of alloy per 1000 parts of tungsten (the number 30 indicates that the impurity concentration is 3%);

- the second number indicates the length (20 indicates that the stubble is 200 mm long).

Explanation of markings, scope of application of different brands

Let's take a closer look at the purpose of a tungsten electrode with one or another marking.

- WP (green) – The green color of a tungsten electrode indicates that it is made of pure tungsten (no other metal impurities). They are intended for welding workpieces made of aluminum, magnesium and their alloys; the welding process occurs using alternating current.

- WC (gray) – the presence of the “C” index indicates the presence of cerium impurities in the composition. This is a universal type that is suitable for welding workpieces using both direct and alternating current.

- WT (red) - red tungsten electrodes contain thorium dioxide. These tungsten electrodes have high strength and can be used for DC welding of various metals. They mainly weld steel, non-ferrous metals, carbon-containing alloys, and stainless steel. A special feature of products with thorium additive is the presence of slight radioactivity (thorium is a radioactive element), so work with them must be carried out strictly according to safety rules.

- WY (dark blue) - this electrode color indicates the possibility of using materials such as titanium, copper, low- and high-alloy steels for DC welding. Used for welding particularly critical structures and parts with complex shapes.

- WZ (white) – welding with a white tungsten electrode is performed using alternating current. The rods contain zirconium oxide and are suitable for working with copper and aluminum workpieces.

- WL (blue, golden) – the rods contain lanthanum, these tungsten electrodes are the same in purpose, the color indicates the different lanthanum content; in blue electrodes – 1.5% impurities, in golden-colored products – 2%; W-variety is suitable for DC/AC.

Equipment for manual arc welding

The equipment required for manual arc welding consists of:

- from a power source, which can be either portable or stationary, depending on the type of work performed by the welder;

- from a cable with an electrical holder in which an electrode coated with a special coating is fixed;

- from a reverse grounding cable to connect the workpiece being welded to the power source.

Also, do not forget about additional equipment, such as: a protective mask, welder’s gloves, various devices for removing slag and other things necessary for the convenience of the specialist.