Purpose and GOST

Products are produced for connecting steel parts:

- installation of pipes and gas pipelines in the absence of pressure;

- assembling structures using fillet welds.

ANO-21 is used in shipbuilding, housing and communal services, repair shops, dachas and private homes. Rods with a diameter of 2.5 and 3 mm are often used.

Products are manufactured in compliance with GOST 9467-75 and coated on the outside with a rutile coating. It stabilizes the arc, reduces the rate of spattering of hot metal, prevents the occurrence of oxidation processes, and protects the seam from oxygen penetration.

At the junction of the parts, a smooth roller is formed that does not contain pores. Approximately 1.5 kg of rods are consumed per hour. This is a high figure.

ANO-21 welding electrodes are used when connecting steel products and parts made of other metals. The rods are easily excited and maintain an arc, are powered by a 220 V electrical network, and form an easily removable slag coating. This corresponds to GOST 380-2005 or 1050-88.

Welding is carried out with direct and reverse current. ANO-21 guarantee the quality of work.

Welding with an inverter machine

A characteristic feature of any type of inverter is the constant performance and stability of the welding current, which guarantee the quality of the resulting seam and the formation of alternating voltage that forms the welding arc. The connection of the surfaces to be welded is carried out by the melting method.

The qualitative indicators of the reliability of the unit are due to its design feature. Each device, regardless of type, consists of the following elements:

- frequency converter;

- control systems (center);

- transformer;

- power rectifier;

- network filter.

All of them form the general circuit of the inverter, and the main tool for welding is the electrode.

Explanation of markings

The symbols that are part of the full name of the product - E46-ANO-21-d-UD E 430/3/- R 11, have the following meanings:

- E46 – product type;

- ANO – brand;

- D – diameter;

- U – intended for carbon steels;

- D – thick protective coating;

- 43 – level of seam rupture;

- 0 – elongation 18%;

- 3 – viscosity;

- R – rutile coating;

- 1 – welding position – any;

- 1 – alternating current.

The rods were developed by scientists from the Electric Welding Institute.

Letter designations:

- A – Academy;

- N – Sciences;

- O – coated;

- 21 – model.

The data will help beginners choose electrode products.

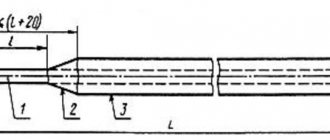

An example of decoding electrode symbols.

UONI 13/55 and LB – 52U

Consumables UONI 13/55 and LB-52U are essentially, in the context of our article, not absolutely complete, but analogues, since in addition to their general applicability for welding carbon and low-alloy steels, they have similar welding characteristics due to the similarity of the coating material related to the main coating. Some differences occur due to differences in production technology between Russian and Japanese manufacturers.

Welding characteristics

Features of electrodes:

- product diameter – 1-5 mm;

- coating – rutile;

- metal spattering – does not exceed 4%;

- hourly consumption – 1.65 kg.

The arc remains smooth throughout the welding process.

The seam material can withstand:

- tensile strength – not less than 460 MPa;

- elongation – 18%;

- viscosity – 80 J/cm²;

- connection bend angle – 150°.

We recommend reading: How to use TsL-11 electrodes

Other parameters are also important.

Chemical composition of the seam

Even for a person without work experience, the connection point between the parts is strong. Molten and solidified metal contains the elements presented in the table.

| Name | Quantity in % |

| Carbon (C) | 0,1 |

| Silicon (Si) | 0,3 |

| Magnesium (Mn) | 0,5-0,8 |

| Sulfur (S) | 0,04 |

| Phosphorus (P) | 0,045 |

The above list complies with state standards and must be observed in the production of electrodes at all factories. In practice, the composition of the seam is slightly different when welding with rods from different manufacturers.

Smooth weld seam.

Physical properties

Rutile coating consists of titanium dioxide and other substances: silica, calcium carbonate, ferromanganese. The mixture allows you to cook wet and corroded parts. You can make connections at non-rotating joints, which are often found on pipelines.

Products with a diameter of 2, 3, 4 and 2.5 mm are easy to ignite and burn evenly, the molten material hardly splashes.

The Sv-08 wire (the electrodes are made from) contains additives that can increase the surface tension in the weld pool. This allows vertical and ceiling seams to be made without leaking metal.

The maximum permissible moisture content in the coating is 0.9%. For larger values, the rods are calcined for 30-40 minutes. The temperature is 120°C. In the future, electrodes are used for welding non-ferrous and ferrous metals, incl. and aluminum.

When purchasing, you should choose dry products. You shouldn’t settle for cheap products; it’s better to buy more expensive products from popular manufacturers.

When welding with an ANO-21 electrode, there is almost no spatter.

Welding modes

These indicators depend on the thickness of the electrode. The parameters are indicated in the table indicating the spatial location of the seam.

| Diameter (mm) | Length(cm) | Quantity (1 kg) | Current (A) | ||

| Lower | Vertical | Ceiling | |||

| 2 | 30 | 95 | 60-100 | 70-80 | 80-100 |

| 2,5 | 30 | 58 | 70-120 | 70-100 | 90-110 |

| 3 | 35 | 40 | 100-150 | 90-110 | 110-140 |

| 4 | – | – | 160-190 | 150-170 | 150-180 |

| 5 | – | – | 170-220 | 150-190 | 120-160 |

It is not recommended to weld workpieces thicker than 5 mm and pipe joints with subsequent injection of pressure.

Basics of choosing electrodes for welding

The main feature of any coated electrode is its coating. Each electrode coating has its own chemical composition, which largely determines the purpose of the electrode. Electrodes are available with basic, rutile and acidic coatings.

- Basic coated electrodes are used for DC welding. They have somewhat more difficult ignition than rutile electrodes, and are also more sensitive to moisture.

- Rutile-coated electrodes provide easy arc ignition, which is why they are popular among welding beginners.

- Acid-coated electrodes are used for inverter welding. However, due to the special composition of the electrode coating, it is recommended to cook with acid electrodes in a well-ventilated area.

In manual arc welding, coated piece electrodes are used. Below is the rating of electrodes in 2022, according to users.

Dimensions and packaging

After release, the finished products are placed in moisture-proof film and a cardboard box. Packages of 1 or 5 kg are available for sale.

| Rod Diameter (mm) | Length(cm) | Weight 1 pc. (G) | Quantity per 1 kg |

| 1,6 | 25 | – | – |

| 2,0 | 25 | – | – |

| 2,5 | 30 | 17,0 | 58-59 |

| 3,0 | 30 or 35 | 26,5 | 38 |

| 4,0 | 45 | 53,0 | 18-19 |

| 5,0 | 45 | 84,5 | 12 |

| 6,0 | 45 | 135,0 | 7 |

We recommend reading Features and main advantages of using E46 electrodes

Small packages are convenient for home use.

Consumption rate

When connecting parts in small volumes, a competent calculation of the required number of electrodes and the diameter of the rod will ensure the continuous activity of the master and eliminate unjustified monetary costs.

This requires parameters that are inserted into tables developed by scientists from the Montazhspetsstroy Research Institute and other organizations. Detailed information about the types of welding is presented in document VSN 452-84.

In practice, the consumption is 1.65 kg for every hour of operation.

How to find out what kind of electrodes are and what they are intended for

All the necessary information about the use of electrodes and the properties of the deposited metal, as well as about calcination, is available on the packaging. From the name of the electrodes alone, it often becomes clear what metal they are intended for welding.

And if you look at the alphanumeric marking of the electrodes, you can see:

- Type of electrode coating: basic or rutile;

- Where and for what welding are electrodes used;

- Mechanical properties of electrodes;

- Type of current and its polarity;

- Spatial position during welding.

Let's take an example of the most popular brand of electrodes that most welders use.

Pros and cons of using

Positive aspects of the rods:

- accessibility for all users;

- fast ignition and stable arc burning;

- hot metal hardly splashes;

- formation of an easily removable slag layer;

- seam strength;

- lack of sensitivity to galvanic protection and traces of rust on the edges of the metal being welded;

- reduced toxicity.

Negative features:

- welds only metals up to 5 mm thick;

- the use of fluxes is required;

- impossibility of welding high pressure pipelines.

Prices cover all existing shortcomings. You can purchase materials of different diameters in specialized stores by paying 70-152 rubles per 1 kg.

A pack of electrodes weighing 5 kg.

Advantages and disadvantages of consumables

Like any other type of consumables, Ano 21 welding electrodes have their advantages and disadvantages during operation. Among the advantages are:

- Availability and popularity.

- Reasonable price.

- Simple arc ignition independent of operating conditions.

- Smooth slag formation and ease of removal after work.

- Obtaining a seam with a fine-scale structure.

Inherent disadvantages include:

- Quite a narrow range of interaction.

- Unreliable coating protection, which requires the use of additional flux and metal preparation.

- Low strength of the seam, unable to withstand high pressure and physical impact.

- Impossibility of working with thick-walled metals.

- Reduced quality of the seam connection when difficulties arise during the welding process.

Features of operation and storage

The main property of rods coated with rutile coating is that they work in conditions of high humidity of the parts being welded and with metals with traces of rust on the edges being joined.

The electrode must remain dry. Therefore, it is better to store it in a hermetically sealed box in a warm room, away from the ground, away from sunlight. If it gets wet, it is dried for 40-60 minutes at a temperature of +90 ... +120 ° C.

Vertical fillet welds are made by holding the electrode at an angle of 40-70°. Do not exceed the recommended currents, this will lead to metal burns. The seam always turns out strong even by welders without experience. Waste is easily removed from metal.

Rods should be purchased from specialized stores that comply with the rules for storing welding consumables. The temperature in the warehouse must be at least +15°C.

conclusions

The brand of welding electrodes ANO-21 will be of help to both novice welders and professionals. Some will not have to worry about igniting the arc, while others will not have to worry about the stability of the main process. The result will be high-quality welded joints.

Not the last advantage will be the price criterion. When choosing, you need to carefully inspect the rods for deformation and dampness.

Giving preference to brands of a low price category is a dubious decision. It is better to pay attention to brands of well-known manufacturers.

When purchasing welding rods in basement stores, you may encounter failure to comply with favorable storage conditions. Do you have experience working with ANO-21 brand electrodes? Share it in the comments below. We wish you success in your work!

Comparison table

Electrode products, including ANO-21, are produced by several enterprises. The manufacturing technology is not followed at all, for this reason the properties of products from different manufacturers differ in ignition, maintaining arc stability and the appearance of pores.

We recommend reading How graphite electrodes are used

Masters conducted comparison tests with the participation of ANO-21, MR-3 and SSSI. The test results depending on the welding direction are shown in the table.

| Index | ANO-21 | MR-3 | SSSI |

| Metal consumption (1 kg) | 1,7 | 1,7 | 1,6 |

| Viscosity (J/cm²) | 80 | 80 | 200 |

| Elongation (%) | 18 | 18 | 26 |

| Capacity (kg/h) | 1,4 | 1,7 | 1,3 |

| Yield Strength (MPa) | 460 | 400 | 350 |

| Maximum current (A) | 220 | 260 | 200 |

| Minimum current (A) | 40 | 30 | 40 |

| Calcination (min.) | 60 | 60 | 60 |

The table will help in selecting the electrodes needed for the job.

Electrodes MP-3

In terms of their advantages, MRZ and ARS electrodes are similar to ANO-4 brand electrodes, but there are still some differences that make them even more popular. The welding workflow with this type of electrode is much easier than when using other models. Arsenal MP-3 electrodes can be used in industrial production and for domestic use.

One of the main features is that there is no need to remove slag residues from the surface of the seam, since it separates on its own. All that remains is to remove him from the place of work.

Another undeniable advantage is the ability to use MP-3 Arsenal electrodes for surfacing metal with gaps of a sufficiently large size. Their use allows welding not only on a short arc, which is still difficult, especially for beginners in this matter, but also on a long one.

The rutile coating, which includes titanium dioxide, provides strength and resistance to the formation of defects such as pores and cracks, and also reduces the susceptibility to corrosion. The coating has a slightly greenish color.

Arsenal 3mm electrodes allow you to work with a long arc, which is important when the surface is of poor quality and there are oxides on it. Arsenal 3 mm electrodes allow you to fill cracks and gaps of any size. The resulting seam is of high quality and even. The average consumption of electrodes for one hour of welding work is 1.7 kilograms, that is, in order to weld one kilogram of metal, 1.7 kilograms of MP-3 welding electrodes will be required.

The diameters are as follows: 2.5; 3.0; 3.2; 4.0; 5.0 millimeters. Such a large selection simplifies the welding conditions. Depending on the diameter of the electrode, the current value is set. If you have to work with structures that have walls of medium and large thickness, then the mode is set to the maximum, and the electrode is moved along the welding process with a slight inclination. You can weld using the short tack method.

If thick-walled parts are welded, then a reinforced seam is applied and the current size is increased. Electrodes with a diameter of 5.0 millimeters are used for work in the lower and vertical positions. Ease of use allows you to perform various types of welding work.

The best manufacturers

The rods are manufactured at various enterprises in Russia and abroad.

Popular companies producing rods:

- Lincoln Electric (USA);

- ZELZ (Zelenograd);

- LEZ (Moscow);

- "Paton" (Kyiv);

- "PlasmaTek" (Ukraine);

- "Strength" (Kyiv);

- "SpetsElectrod" (Volgodonsk);

- "TANTAL LTD" (Syzran);

- "Sumy-Electrode" (Ukraine);

- YaEMP (Yaroslavl).

Analogues of products are considered to be:

- ESAB OK 46.00;

- BÖHLER FOX SPE;

- ANO-4;

- OZS-6;

- MP-3;

- RC standard;

- OZS-12.

Top businesses:

- "Paton";

- "Granite";

- LEZ;

- KOMZ;

- MaxWeld;

- "Tigarbo";

- "Monolith".