Impurities in copper alloys

Impurities contained in copper (and, naturally, interacting with it) are divided into three groups.

Forming solid solutions with copper

Such impurities include aluminum, antimony, nickel, iron, tin, zinc, etc. These additives significantly reduce electrical and thermal conductivity. The grades that are primarily used for the production of conductive elements include M0 and M1. If the copper alloy contains antimony, its hot pressure treatment becomes significantly more difficult.

Impurities that do not dissolve in copper

These include lead, bismuth, etc. Although they do not affect the electrical conductivity of the base metal, such impurities make it difficult to process by pressure.

Impurities that form brittle chemical compounds with copper

This group includes sulfur and oxygen, which reduces the electrical conductivity and strength of the base metal. The sulfur content of the copper alloy greatly facilitates its machinability by cutting.

Copper grades and their applications

Physical and mechanical properties of alloy M1 (GOST 859-2001)

Pure copper is a material with high electrical conductivity and low electrical resistance (0.0180 μOhm). These characteristics can only be affected by impurities: by increasing the proportion of iron, tin or phosphorus in the alloy, you can reduce the cost of the finished material, but also significantly reduce the electrical conductivity of copper.

The main mechanical and physical characteristics of M1 copper are presented below:

Standards for Copper Alloys

State standards stipulate the rules for marking copper and its alloys, the designation of which corresponds to a certain structure.

The fact that this is one of the copper grades is indicated by the letter “M” in its designation. After the initial letter in the marking of copper and its alloys there are numbers (from 0 to 3), conventionally indicating the mass fraction of the base metal in their composition (for example, M3 copper). The numbers are followed by capital letters, by which you can determine how this grade of copper was obtained. Technological methods for producing copper include the following:

- cathode (k);

- deoxidation method, which assumes a low content of residual phosphorus (p);

- deoxidation method, which assumes a high content of residual phosphorus (f);

- without the use of deoxidizers - oxygen-free (b).

Examples of markings for such grades and copper alloys may look like this: M2p, M1b.

Chemical composition of copper GOST 859-2014

A number of copper grades, distinguished by unique characteristics, are actively used in various industries.

- M0 - this grade is used for the production of conductive elements and for adding to alloys of high purity.

- M1 - this grade is also used to produce current-conducting elements, rolled products of various profiles, bronze, parts for cryogenic equipment, electrodes for welding copper and cast iron, wire and rods (used for welding work under a submerged arc layer and in an environment of inert gases), consumables for performing gas welding of copper parts that do not experience significant loads during operation.

- M2 - this brand allows you to obtain products that are well processed by pressure. M2 copper is also used for cryogenic equipment parts.

- MZ - parts from this grade of metal are produced by the rolling method.

Spatial distribution of copper reserves in Russia

GOST 859-2001, which specified the requirements and characteristics of copper alloys, was replaced in 2014 by a new state standard (859-2014), which was recorded by the relevant Order of the Federal Agency for Technical Regulation and Metrology. The new standard in its main points is almost identical to GOST 859-2001.

GOST 859-2001 on copper grades

This state standard document applies to cast and deformed semi-finished copper products, as well as copper manufactured in the form of cathodes.

Copper grades - characteristics and markings with explanation

The designation of metal alloys based on the use of copper begins with the letter “M”. This is followed by a number characterizing the mass fraction of copper in the composition (alloy class). So, when the metal is designated “M3”, the amount of the main element reaches 99.5%, and “M00” - 99.96%. Also, the marking usually indicates additional letters informing about the method of producing the alloy. Methods for creating copper alloys are divided into:

- cathode (denoted by the letter “k”);

- deoxidation with low phosphorus content (“p”);

- without deoxidizing additives – oxygen-free (“b”);

- deoxidation with a large amount of phosphorus (“f”).

The general marking of alloys looks like “M1r”. However, the production method is not always indicated or is not used at all if the processes of hydrolysis, pyrometallurgy or hydrometallurgy were used. In such cases, the designation is limited to the mass fraction. Without taking into account alloy modifications, copper is classified into four main grades:

- M0. The highest class of copper alloys, containing about 99.93-99.99% copper. Sometimes, to improve the physicochemical properties, silver is added to the composition and the percentage of the main element is indicated as copper + silver as a single main component. M0 is the purest copper alloy, which is used for the manufacture of conductive products (power cables, conductors in electronics, household wires, and so on).

- M1. An alloy more common in modern conditions. It is also used to make electrical products with less stringent quality requirements. M1 is also used for the production of rolled metal products, welding electrodes, wire, and so on. The percentage of copper content in M1 is 99.9%.

- M2. This brand is widely used in the production of products requiring high pressure processing. M2 is a less ductile metal, since it contains 99.7% copper. The alloy is often used for the manufacture of cryogenic equipment parts.

- M3. The grade belongs to alloys with the lowest copper content (99.5%). Such metals contain large amounts of impurities and are often obtained from the recycling of copper products. M3 alloy is used to manufacture parts by rolling.

Individual modifications characterize the type and number of additional elements. Detailed information about brands is specified in GOST 859-2001.

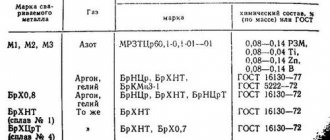

Chemical composition of cast and deformed copper

| Brand / Alloy | Basis, no less | Impurities, no more | ||||||||||||||

| Copper | Copper+Silver | Bismuth | Iron | Nickel | Zinc | Tin | Antimony | Arsenic | Lead | Sulfur | Oxygen | Phosphorus | Silver | Selenium | Tellurium | |

| Cu | Cu+Ag | Bi | Fe | Ni | Zn | Sn | Sb | As | Pb | S | O | P | Ag | Se | Te | |

| M00b | 99,99 | — | 0,0005 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,0003 | 0,002 | 0,0005 | 0,0005 |

| M0b | — | 99,97 | 0,001 | 0,004 | 0,002 | 0,003 | 0,002 | 0,002 | 0,002 | 0,003 | 0,003 | 0,001 | 0,002 | — | — | — |

| M1b | — | 99,95 | 0,001 | 0,004 | 0,002 | 0,003 | 0,002 | 0,002 | 0,002 | 0,004 | 0,004 | 0,003 | 0,002 | — | — | — |

| M00 | 99,96 | — | 0,0005 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,002 | 0,03 | 0,0005 | 0,002 | 0,0005 | 0,0005 |

| M0 | — | 99,93 | 0,0005 | 0,004 | 0,002 | 0,003 | 0,001 | 0,002 | 0,001 | 0,003 | 0,003 | 0,04 | — | — | — | — |

| M1 | — | 99,9 | 0,001 | 0,005 | 0,002 | 0,004 | 0,002 | 0,002 | 0,002 | 0,005 | 0,004 | 0,05 | — | — | — | — |

| M1r | — | 99,9 | 0,001 | 0,005 | 0,002 | 0,005 | 0,002 | 0,002 | 0,002 | 0,005 | 0,005 | 0,01 | 0,002-0,012 | — | — | — |

| M1f | — | 99,9 | 0,001 | 0,005 | 0,002 | 0,005 | 0,002 | 0,002 | 0,002 | 0,005 | 0,005 | — | 0,012-0,04 | — | — | — |

| M2r | — | 99,7 | 0,002 | 0,05 | 0,2 | — | 0,05 | 0,005 | 0,01 | 0,01 | 0,01 | 0,01 | 0,005-0,06 | — | — | — |

| M3r | — | 99,5 | 0,003 | 0,05 | 0,2 | — | 0,05 | 0,05 | 0,05 | 0,03 | 0,01 | 0,01 | 0,005-0,06 | — | — | — |

| M2 | — | 99,7 | 0,002 | 0,05 | 0,2 | — | 0,05 | 0,005 | 0,01 | 0,01 | 0,01 | 0,07 | — | — | — | — |

| M3 | — | 99,5 | 0,003 | 0,05 | 0,2 | — | 0,05 | 0,05 | 0,01 | 0,05 | 0,01 | 0,08 | — | — | — | — |

By agreement with the consumer, it is allowed to produce M0b grade copper with an oxygen mass fraction of no more than 0.002%.

The designation of copper grades M1 and M1p, intended for the electrical industry and subject to testing for electrical conductivity, additionally includes the letter E.

It is possible to agree on the mass fraction of elements not indicated in the table.

Requirements for the physical properties of copper - electrical resistivity, helical elongation (ability to recrystallize under given heat treatment parameters), mechanical properties are established in standards for specific products and (or) by agreement of the parties.

2 Normative references

This standard uses references to the following standards: GOST 9717.1-82* Copper. Method of spectral analysis using metal standard samples with photoelectric recording of the spectrum GOST 9717.2-82 Copper. Method of spectral analysis using metal standard samples with photographic recording of the spectrum GOST 9717.3-82 Copper. Method of spectral analysis for oxide standard samples GOST 13938.1-78* Copper. Methods for determining copper GOST 13938.2-78* Copper. Methods for determining sulfur GOST 13938.3-78* Copper. Method for determining phosphorus GOST 13938.4-78* Copper. Methods for determining iron GOST 13938.5-78* Copper. Methods for determining zinc GOST 13938.6-78* Copper. Methods for determining nickel GOST 13938.7-78* Copper. Methods for determining lead GOST 13938.8-78* Copper. Methods for determining tin GOST 13938.9-78* Copper. Methods for determining silver GOST 13938.10-78* Copper. Methods for determining antimony GOST 13938.11-78 Copper. Method for determination of arsenic GOST 13938.12-78* Copper. Methods for determining bismuth GOST 13938.13-93 Copper. Methods for determining oxygen GOST 13938.15-88* Copper. Methods for determination of chromium and cadmium GOST 27981.0-88* High purity copper. General requirements for methods of analysis GOST 27981.1-88 High purity copper. Methods of atomic spectral analysis GOST 27981.2-88 High purity copper. Chemical-atomic emission analysis method

GOST 27981.3-88* High purity copper. Method of emission spectral analysis with photoelectric recording of the spectrum

GOST 27981.4-88* High purity copper. Methods of atomic absorption analysis ________________ * The documents are not valid on the territory of the Russian Federation. GOST 31382-2009 is valid, hereinafter in the text. — Note from the database manufacturer.

GOST 27981.5-88 High purity copper. Photometric methods of analysis GOST 27981.6-88 High purity copper. Polarographic methods of analysis ST SEV 543-77 Numbers. Recording and rounding rules