The IT-1M model lathe is specialized turning equipment designed for mobile automobile workshops of the Ministry of Defense, housed in standard KUNGs. The dimensions of its working space are almost the same as those of the most popular Soviet lathe 16K20. At the same time, its weight is almost three times less, and the power of the main engine is only 3 kW (versus 11 kW for the 16K20).

The machine can be powered either from a 220 V or 380 V network, or from an autonomous generator. IT-1M is the best model for “garage use”, because can process parts of the same size as industrial lathes, but is powered from a household electrical outlet. In addition to the mobile version, a stationary version of this lathe was also produced, which is designated IT-1GM.

Specifications

IT-1M is a standard screw-cutting lathe and can perform all types of processing typical for equipment of this type.

Its main feature is the low power of the main drive with a significant working space.

With a light weight for its class, the IT-1M lathe has good rigidity and vibration resistance. He owes this to the successful design of the frame - a hollow cast base with partitions and stiffeners. Another advantage of IT-1M is the ability to increase the turning diameter to 550 mm. For this purpose, a recess with an insert is provided in the bed, which is removed when turning large workpieces.

The technical parameters of the machine are quite sufficient for work in the machining departments of small enterprises. The maximum turning diameters for products in the form of a shaft and disk depend on the dimensions of the workpiece and are above:

- bed – 400 mm;

- recess – 550 mm;

- caliper – 225 mm.

The maximum processing length on IT-1M is 1400 mm (with a remote insert - 300 mm), the diameter of the spindle through hole is 36 mm. The scale division on the caliper controls is 50 microns, and the rotary scale is 1°.

If you need to install plastic windows, insulate a balcony or loggia, we recommend contacting the Window Master company. You can learn more about their services on the official website: https://okonniymaster.ru/balcons/vnutrennyaya-otdelka-balkona.html. You can not only insulate the balcony, but also cover its floor with plywood, linoleum, parquet or laminate. For wall decoration, lining, plastic PVC panels, decorative plaster, cork or decorative stone are used.

The IT-1M lathe was produced in two modifications: basic and shortened. In the first case, the center-to-center distance of the headstocks is 1400 mm, and in the second - 1000 mm. The basic version weighs 1.33 tons, the shortened version is 190 kg lighter: its weight is 1.14 tons.

Typical options for planning IT processes for 1 year or more

Recommendations depending on what needs to be improved:

- if the current state of IT processes is not clear, how bad or good it is, or rather, it is not clear on what basis to further plan improvements to IT processes, then it is better to conduct an audit of IT processes. An audit should provide an independent assessment of whether your company's IT processes are adequate. It’s unlikely that your company needs to work as efficiently as Google and IBM, but it also seems like there’s no need to regularly lose user requests, i.e. For each company, at a particular point in time, there is a small range of optimal levels of IT process maturity. All that remains is to determine what this “optimal level of maturity” is for each of the main IT processes. That's the whole problem.

- if it is absolutely necessary to improve IT processes by planning their development for 1-3 years, but at the same time the remaining elements of IT (information systems, infrastructure, IT management) are not necessary or cannot be planned, then it is possible to propose developing a strategy for improving IT processes. Although it is much better to plan the development of not only IT processes, but also all the main elements of IT, doing this within the framework of a comprehensive IT development strategy (if such a strategy does not yet exist, then it is better to start by developing an IT strategy jointly with consultants).

- If the CEO of your company is concerned (or, on the contrary, inspired) by the digital transformation of business, then you can plan the development of IT processes (and all the main elements of IT) as part of the development of a digital business transformation strategy (or its first step - a strategy for creating a unified digital business platform).

Here are recommendations depending on the size of the company:

- For small companies, consulting on improving IT processes is hardly appropriate. It’s not that it’s inappropriate, but it can just be expensive for very small companies and individual entrepreneurs. However, it may be appropriate to improve IT processes as one of the important IT elements considered in the IT strategy. Consulting on IT strategies for small companies is rather expensive, but as part of training in IT strategy with parallel development of an IT strategy, all work can be appropriate both in cost and in quantity;

- For medium-sized companies, it is appropriate to develop an IT process development strategy or a comprehensive IT strategy together with consultants, as well as an audit of IT processes;

- For large companies, any consulting is appropriate, taking into account all the characteristics of the company.

Areas of application of machines

The unusual relationship between the geometry of the working space and the power of the main drive of the IT-1M lathe is explained by the fact that it was initially developed according to the technical specifications of the Ministry of Defense as standard equipment for field auto repair units of the Soviet Army.

The army mobile auto repair shop (PARM) included several units of special equipment, including the MRM-M1 (mechanical repair workshop) based on the ZIL-131. It was a KUNG, which housed an electric power plant and several machines: a screw-cutting lathe, a drilling machine, a sharpening machine, and a sharpening and grinding machine.

How to save on machine parts without harming production

Sometimes it happens that spare parts for drilling machines and other categories of units are purchased with a greater resource than required by the procurement regulations. In this case, the full potential of the components will simply be unclaimed. Provided that the full resource has not been exhausted, it is possible to install an engine of much lower power to reduce wear rates

It is important to maintain correspondence between the nodes. Reduced power will make it possible to save money on system repairs, since they will be under much less load

This will often be irrelevant with the mechanical part, since the design of the machine may not allow changing important elements.

Design features

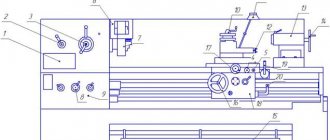

The IT-1M screw-cutting lathe has the usual layout for this type of equipment: a bed with guides, headstock and tailstock, and a support with cutting slides. Among its features are an insert into the bed, the removal of which allows you to process larger workpieces, as well as the low power of the main engine, which makes it impossible to turn with large cutting depths. The machine's passport indicates that it can be used to mount devices for milling planes and grooves, as well as performing boring and grinding operations.

Overall dimensions of the workspace

The processing geometry of IT-1M is almost the same as that of the most common screw-cutting lathes 1K62 and 16K20. It allows you to turn shaft-shaped parts with a length of up to 1400 mm and a diameter of up to 225 mm and disc-shaped parts with a maximum diameter of 400 mm (with the insert removed - up to 550 mm). The shortened version of this model has a maximum workpiece length of 1000 mm.

Location and operation of controls

Most of the controls of the IT-1M lathe are mounted on its front headstock. On its upper part there is a panel with toggle switches (from left to right): voltage selection switch, cooling motor switch and circuit breaker, and in the lower part there is a spindle speed selection lever. Above it there are three knobs in a row, through which the feed amount, type and pitch of the thread are set, and to the right of it is the spindle rotation control lever (on, reverse and braking). Under the toggle switch panel there is a thread type selection knob and a selection knob.

The following controls are mounted on the apron: caliper positioning handwheel, carriage and cross slide positioning handle and running nut handle. Above the handwheel is a handle for transverse movement of the carriage, and above it is a lever for turning and fixing the tool holder. The tailstock controls are few: the steering wheel for moving the quill and the lever for its clamping. In addition, there is also a nut that secures the position of the tailstock.

Location of components

Like any lathe, the basic component of the IT-1M is a bed with two rows of guides. On the left is a headstock with a spindle assembly and gear mechanisms, and on the right is a tailstock with a quill. A caliper with longitudinal and transverse slides and a four-position tool holder moves along the guides.

Screw-cutting lathe IT-1M

This unit is one of the most popular brands, which has found application in many workshops. Even educational institutions use the IT-1M lathe to develop the skills of their students.

This model first appeared at the Ivanovo Machine Tool Plant, where employees were able to combine the best in one equipment: acceptable dimensions, high power, the ability to install additional components, etc.

It is important to note that this device belongs to the turning-screw-cutting group, but is lightweight. This feature makes it possible to operate the machine in mobile workshops, where the following types of technological operations are often carried out:

- processing of cylindrical blanks;

- axial drilling;

- carving;

- turning of conical blanks and much more.

Nowadays, machine tools are also produced in Ivanovo, however, this model has already been discontinued. But many devices in excellent condition are sold on the secondary market. To understand their uniqueness, it is recommended to familiarize yourself with the main parameters.

Specifications

The designers were tasked with making a machine for working in rooms with a small area, so the weight and dimensions of the IT-1M lathe are 216.5 × 96 × 150 cm and 1.14 tons.

Such parameters allow you to open a workshop in any room, and thanks to the mass, large workpieces can be processed with high precision.

Also, for each type of turning there are replaceable parts that allow you to work with both 140 cm blanks and 36 mm rods.

Download the passport (operating instructions) of the IT-1M lathe

Another lightweight unit has a 12-speed gearbox, where the rotation is adjusted from 18 to 1250 rpm. Additional specifications and features are as follows:

- cast square frame, where transverse ribs create additional rigidity;

- location of the main components in the front headstock;

- the presence of a plunger pump that provides lubrication to all working units;

- free movement of the carriage (90-130 cm);

- two types of bearings are used on both supports, which increases the accuracy of the finished items;

- special guides for moving the tailstock;

- design features that make it possible to work with cone-shaped objects.

It is also noteworthy that the IT-1 lathe has an engine of unusual characteristics , which can operate both from a standard 220 V network and from an industrial network of 360 V. This option allows you to operate the unit in private business. The voltage regulation itself is carried out using a special switch.

Also, for comfortable work, auxiliary lighting in the form of a large lamp is installed on the device body, and the specialist can independently adjust the direction of the light.

Important! Before starting work on the lathe, make sure that it is properly grounded (located on the rear stand). Otherwise, the employee may be seriously injured.

This information is already enough to verify the uniqueness of such technology. However, the structural elements of the device are also non-standard, because they can be easily modernized and thereby solve many production problems.

Although the equipment is a lightweight version, it looks very massive. On the right side there is a cabinet responsible for two functions: reliable support and placement of the cooling pump. There are also two pipes, one of which is responsible for draining, and through the second the excess goes away. The system lubrication device includes 4 units:

- oil reservoir;

- liquid supply pump;

- filter;

- Magnetic type cartridge.

The functionality of the lubrication mechanism depends on the rotation of the gearbox, and it can rotate in any direction. And everything is located on the left side of the device, under the feedbox and behind the engine.

This lathe and screw cutter is driven by a gear box, and adjustment is carried out by two levers on the front side. The support consists of an upper carriage, a slide for various movements and a mechanism for fixing the cutter. Rotation and fixation also occur due to manipulations with the handles.

On top there are two guides that have undergone heat treatment and grinding. Thanks to this, the machine's tailstock and carriage can move smoothly, providing maximum comfort while working. On the left cabinet (above the spindle control handles) you can see three toggle switches, which are responsible for the following functions:

- Far right - adjusts the feed amounts and turns off the box.

- Central - establishes a standard thread and performs feeding.

- Far left – adjusts the thread pitch.

At the top there is a table with symbols, and in the center there are two flywheels (the lower one provides the longitudinal movement of the caliper, and the upper one moves the carriage).

This device is equipped with PVG wires, the cross-section of which is 2.5 square meters. mm. They are designed for transmitting electricity in stationary installations. They should be located in places where there is no danger of mechanical damage, and the ambient temperature should be from -50 to +50 degrees.

These and many other characteristics show that IT-1M is a reliable lathe that combines reliability, safety and ease of use. It can also be used to perform a lot of technical tasks.

The metal machine is suitable for applying both internal and external threads with any pitch, performing milling, boring and cutting metal products. Its main functions include:

- drilling;

- sharpening of cutters;

- trim;

- turning.

Also, a lathe can perform many functions not related to cutting, and a description of all the possibilities is unlikely to fit into one article. However, you can learn more about the capabilities by reading the instruction manual.

It should be noted that this model has been assigned an accuracy class of “H”, which indicates the increased quality of the finished product.

But the creation of parts is always accompanied by certain risks, and in order to protect yourself, it is recommended that you familiarize yourself with the work rules.

Safety precautions when working on the machine

The IT-1M metal lathe belongs to the high-risk category, so there are strict rules here:

- a person without qualifications is prohibited from working on such equipment;

- During all procedures, the correct position of the torso and arms should be observed;

- before starting actions, the master is required to provide instructions;

- there must be a fire extinguisher and other fire-fighting systems in the equipment room;

- If a malfunction of the unit is detected, you should immediately stop work and call a specialist;

- DIY repairs are strictly prohibited;

- the worker's eyes must be protected from metal shavings;

- It is forbidden to carry out manipulations with lowered sleeves.

This is just part of the rules that every employee must know. A more detailed version can be found in the full version of the safety and operating rules.

Source: https://stankiexpert.ru/stanki/tokarnye/tokarnyj-stanok-it-1m.html

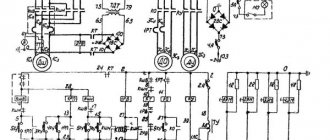

Electrical diagram

On the IT-1M lathe, three-phase voltages of 380 V and 220 V are used to power the electric motors. The signal and lighting circuits are powered from the on-board 12 V network.

The electrical equipment of the machine includes the following components:

- main electric motor;

- circuit breaker;

- main engine reverse switch;

- main engine voltage packet switch;

- batch switch of engine voltage of the coolant system;

- coolant system electric motor;

- coolant pump switch.

In addition, a lighting lamp on a flexible stand with a switch is installed on the machine support.

Description

The operating principle of the meters is based on the Hall effect method. The magnitude of the magnetic flux passing through the Hall sensor mounted on the pole of a permanent magnet depends on the thickness of the material being tested placed between the sensor and the inductor.

The signal from the magnetic field sensor is amplified and fed to an analog-to-digital converter (ADC), where the analog signal is converted into digital form. To process measurement results and visually display them, a processor module is used, which has a liquid crystal display and a two-color LED.

The meters consist of a measuring unit, a sensor, measuring heads and a set of inductors.

On the top panel of the measuring unit there is a liquid crystal display and control buttons, on the rear end wall there is a power socket and a power switch.

The meter is connected to the AC mains using a power cord with a power plug. To connect the communication cable to a personal computer, use the RS-232 connector on the left side wall of the measuring unit, which allows you to transfer measurement results to a computer for data processing.

Kinematic diagram

The kinematic diagram of the lathe is similar to the diagrams of other universal screw-cutting lathes of medium size. The spindle receives rotation both directly from the driven pulley and from a system of switchable gears. The feed box receives movement from the spindle assembly through a system of replaceable gears and transmits rotation to the apron mechanism through the lead screw and the lead shaft.

The apron gear system imparts movement to the caliper, ensuring its transverse and longitudinal movement. The kinematic diagram of the machine also includes mechanisms for manual movement of its working parts and mechanical locking devices.

User manual

The only documentation that came with the IT-1M lathe was a 66-page brochure called “Operating Manual.” The last chapter of this manual is the passport of a specific product indicating the delivery set, marks on acceptance, preservation and packaging, as well as signatures of the quality control department and the customer. It is noteworthy that the acceptance tests were carried out in a “van body of a mobile repair shop of the MRM type.”

In general, the operating instructions are quite traditional and contain general views, drawings of individual components, instructions for installation, configuration, commissioning and operation, as well as kinematic and electrical diagrams of the machine. The only thing that attracts attention is the lack of information about repair cycles and the scope of work for certain types of repairs.

Safety precautions

The operating manual for the IT-1M lathe contains section 2.1 “Safety Precautions”, which contains only two general sentences. They indicate the need for instruction and study of the operating manual before operating the machine.

Other instructions on safety precautions when operating the machine are included in separate sections of the first and second chapters. These include requirements for grounding, use of guards, testing of interlocking devices, chip protection, etc.