Specific volume is the volume per unit weight of a given substance. Dimension: m 3 / kg The reciprocal of the specific volume is the specific gravity. Dimension: kg/m3 In addition to the specific volume, the state of the body can be characterized by molar volume = specific volume x μ, where μ is the molecular weight of the substance.

Methods for experimental determination of specific volumes of substances

Various methods are used: a method based on weighing, a pycnometer method, a hydrometer method and others, depending on the state of aggregation of the substance under study, pressure and temperature, as well as the possible conditions of the experiment.

Determination of metal specific gravity

The body under test is first weighed in the air, let its weight be = g1, and then immersed in water. Due to the loss in weight of the object (according to Archimedes' law), the scale pan to which the body is suspended rises. To bring the scales to the equilibrium position, it is necessary to put some weight - g2. Body specific gravity = g1 : g2

The body under test can have any shape, but it must not be too small (so that, in comparison with its weight, the weight of the thread used for hanging can be neglected).

Example: A piece of high-speed steel weighs g1 = 450 g Additional load g2 = 55 g Specific gravity ϒ = g1/g2 = 450/55 = 8.3 g/cm 3

Cast iron has become quite widespread. Like other metals, it has a fairly large number of physical and mechanical properties, among which specific gravity can be noted. This indicator is often taken from technical literature in the production of a wide variety of products.

Definition and characteristics of density

Density is a physical quantity that determines the ratio of mass to volume. Almost all materials are characterized by a similar physical and mechanical indicator. It is worth considering that the corresponding density of aluminum, copper and cast iron differ significantly.

The considered physical and mechanical quality determines:

- Some physical and mechanical properties. In most cases, an increase in density is associated with a decrease in the grain structure. The smaller the distance between individual particles, the stronger the bond formed between them, the hardness increases and the ductility decreases.

- As the distance between particles decreases, their number and weight of the material increase. Therefore, when creating cars, airplanes and other equipment, a material is selected that is lightweight and sufficiently durable. For example, the density of aluminum kg m3 is about 2,700, while the density of metal kg m3 is more than twice that.

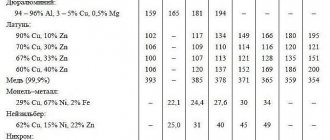

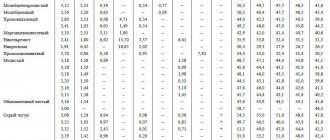

There are special tables of metal density , which indicate the indicator in question for steel and non-ferrous alloys, as well as cast iron.

Read also: Do-it-yourself device for testing thyristors

Distribution and use of cast iron

Cast iron came into widespread use many years ago. This is due to the fact that the material is quite simple to produce and has quite attractive performance properties. The following varieties of this material are distinguished:

- High-strength: used in the production of products that must have increased strength. A similar structure is obtained by adding magnesium impurities to the composition. It is highly resistant to bending and other impacts not associated with variable loads.

- Malleable cast iron: has a structure that is easily forged due to its high ductility. The production process involves annealing.

- Half: has a heterogeneous structure , which largely determines the basic mechanical qualities of the material.

The specific gravity largely depends on the production method used, as well as the chemical composition. The properties of cast iron are affected by the following impurities:

- When sulfur is added to the composition, the refractoriness decreases and the fluidity value increases.

- Phosphorus allows the material to be used for the manufacture of various complex products . It is worth considering that by adding phosphorus to the composition, strength is reduced.

- Silicon lowers the melting point and significantly improves casting properties.

- Manganese can increase strength and hardness, but adversely affects casting properties.

When considering cast iron, it is worth paying attention to the following information:

- Gray cast iron grade SCh10 is the lightest of all produced: 6800 kg/m 3 . As the grade increases, the specific gravity also increases.

- The malleable variety of this metal has a value of 7000 kg/m3.

- High strength has a value of 7200 km/m 3.

The density of metals, like other materials, is calculated using a special formula. It has a direct bearing on specific gravity. Therefore, these two indicators are often compared with each other.

Features of the table used

In order to calculate the weight of the future product, which will be made from cast iron, you should know its dimensions and density index. Linear dimensions are determined in order to calculate the volume. A calculation method is used to determine the weight of a product in cases where it is not possible to weigh it.

When considering methodological tables, it is worth paying attention to the following points:

- All metals are divided into several groups.

- For each material, the name and GOST are indicated.

- Depending on the melting point, the density value is indicated.

- To determine the physical value of specific gravity in kilograms or other changes, conversion of units of change is carried out. For example, if you need to convert grams to kilograms, then multiply the table value by 1000.

Determination of specific gravity is often done in special laboratories. This value is rarely used when carrying out actual calculations during the manufacture of products or the construction of structures.

Read also: Etching metal in saline solution

Cast iron is one of the most common and well-studied alloys in metallurgy. This material has long been known to man and is easy to manufacture and is used in all sectors of the national economy. At first glance, it does not seem particularly valuable: a hard but brittle metal cannot be used in the same way as steel. But the volume of its smelting is still very significant.

Historical reference

Iron smelting has been known to man for quite some time. The first mention of the alloy dates back to the sixth century BC.

In ancient times, cast iron was produced in China with a fairly low melting point. In Europe, cast iron began to be produced around the 14th century, when blast furnaces were first used. At that time, such cast iron was used for the production of weapons, shells, and parts for construction.

In Russia, cast iron production began actively in the 16th century and then rapidly expanded. During the time of Peter I, the Russian Empire was able to surpass all the countries of the world in terms of pig iron production, but after a hundred years it began to lose its position in the ferrous metallurgy market again.

Iron casting was used to create a variety of works of art back in the Middle Ages. In particular, in the 10th century, Chinese craftsmen cast a truly unique figure of a lion, whose weight exceeded 100 tons. Starting from the 15th century in Germany, and then in other countries, cast iron casting became widespread. Fences, trellises, park sculptures, garden furniture, and tombstones were made from it.

In the last years of the 18th century, cast iron was used to the maximum in Russian architecture. And the 19th century was generally nicknamed the “cast iron age”, since the alloy was very actively used in architecture.

Chemical composition

This metal is an alloy of iron and carbon that contains small amounts of impurities. The percentage of iron reaches levels of more than 90%. Silicon, phosphorus, manganese and sulfur are also present. Carbon - no less than 2.14%. It defines the properties of the entire connection.

The role of carbon

First of all, carbon gives hardness. It is carbon that forms the strength characteristics of the alloy, which is an excellent material for foundry production. But it also reduces ductility and malleability.

Therefore, a hard but brittle metal has a limited range of applications. These are mainly metallurgy, mechanical engineering, automotive manufacturing, production of heavy special equipment, utilities and industrial design.

In cast iron, carbon is present in different forms: as cementite (Fe 3 C), or graphite (lamellar, spherical, flake). Graphite largely determines the properties of this material, which is currently divided into the following types:

Types of cast iron

Depending on the state of carbon in cast iron, there are:

- The most common is gray cast iron. It has high strength, low shrinkage, low crystallization temperature, and is easy to process. It produces high-quality housings and parts for mechanical engineering (pistons, cylinders, boiler bodies and shut-off valves). Cast iron parts that work with shock-free loads have also proven themselves well: machine tool beds, various shafts and pulleys. Carbon content - from 2.4 to 3.8%. Marking - MF.

- High-strength cast iron (DC) is produced using special heat treatment and the addition of additives (alloying). The graphite in it has a spherical shape and, when melted, combines with the elements of the iron crystal lattice. This improves mechanical properties, which makes it possible to produce reliable crankshafts, cylinder covers, cast pipes and heating devices. According to its characteristics, this type is close to some grades of steel.

- Malleable cast iron is used for the manufacture of artistic products, metal decoration, but mainly for the production of manifolds and the production of parts for agricultural machinery and cars that have to work in difficult conditions. Along with others, it is used in the electrical industry. This alloy is a variety of white.

- White cast iron. So named because of the characteristic white color at the fracture sites. Contains about three percent carbon in the form of carbide and cementite. It is fragile and brittle, therefore it is used in the manufacture of parts that are not subject to special loads.

- The transitional stage between MF (gray) and BC (white) is half cast iron. It contains graphite and carbide in equal proportions, with a total carbon content of 3.5-4.15%. The material is used in the production of parts operating under friction conditions.

Read also: Lift dimensions for passenger cars

home

What is the density of cast iron? The question, strange as it may seem, worries many people. Why do you need to know the density of cast iron? Usually to calculate the weight of some cast iron product. If you have geometric dimensions and know the density of cast iron, then calculating the weight is not difficult. The catch is that the density of cast iron varies and greatly depends on the brand of cast iron. In principle, the density of cast iron can be found from reference literature. However, it is not very convenient to use, so we have provided here data on the density of gray cast iron. We hope that this information is useful to you. You can find out on our website the density values for other types of cast iron. So, in particular, we present the density of cast iron for the following types of cast iron: white cast iron, gray cast iron, high-strength cast iron, malleable cast iron, alloy cast iron and pyroferal cast iron - aluminum cast iron HERE.

Density of cast iron. Subsection: density of gray cast iron.

Table 2. Density of gray cast iron or density of cast iron grades SCh.

The density of gray cast iron grades SCh15, SCh18 is 6.8 - 7.2 tons per cubic meter of cast iron.

The density of gray cast iron of grades SCh20 - SCh25 is 7.0 - 7.3 tons per cubic meter of cast iron.

The density of gray cast iron grades SCh30, SCh35 is 7.2 - 7.4 tons per cubic meter of cast iron.

Properties and characteristics

The density of cast iron ranges from 6800 to 7200 g/cm2. Due to the presence of graphite, it is significantly less than the density of steel - by about 8-10%. Density also depends on the content of magnesium, silicon and carbon.

Modifiers can significantly increase density, which increases the corrosion resistance of the material. This feature is taken into account in the manufacture of sewer pipes, manhole covers, etc.

The specific gravity of cast iron largely depends on the smelting method and the modifiers used. Even in a product (blank), the specific gravity indicators in its upper and lower parts differ by several percent. The content of graphite and the conditions of primary crystallization of the metal are also important. The average value varies from 7.1 to 7.5 g/cm2.

Other characteristics, such as the mass of cast iron in the product and ductility, depend on the production technology. Thermal conductivity remains unchanged - 1200 degrees Celsius.

Interesting facts about cast iron

Interesting information about cast iron is as follows:

- Not found in nature, it is an alloy.

- First obtained by the Chinese.

- Cast iron coins were in circulation for some time.

- The production technology came to Russia through the masters of the Golden Horde.

- The British built the cast iron bridge in the 18th century.

- The world's main producer is China.

- Household items (pans, pots, irons) have been used for many centuries with minor modifications.

Relevance of cast iron

At least one and a half thousand years have passed since the production of the first iron-carbon alloy. It would seem that the latest technologies of scientific and technological progress should have completely supplanted it. But no.

Simple and reliable, cast iron is still indispensable in many areas of human activity. And in some cases it is preferred to new, more “advanced” materials.

A cast iron bathtub can be an indicator of a good financial situation for a middle class representative. The wrought-iron fence of the mansion characterizes the owner not only as a rich man, but also as a person with a certain artistic taste. And the famous Kasli casting is ranked by art historians on a par with the best examples of artistic sculpture.

Production

Cast iron

The technology for the industrial extraction of iron from iron-containing raw materials and the production of cast iron is quite labor-intensive and complex. There is no point in describing all chemical and technological processes and delving into terminology. If you wish, you can study the issue in sources on metallurgy.

Cast iron is smelted from magnetic, red, and brown iron ore at metallurgical plants and in special blast furnaces. The fuel is coke, which can be partially replaced by fuel oil or gas.

The ore undergoes preliminary preparation before entering the blast furnace. In addition to ore and fuel, fluxes are used for smelting - limestones, which are necessary to form slag and remove sulfur from the melt.

Preparation methods depend on the quality of the ore - crushing, sorting, agglomeration, beneficiation and others.

After going through all the complex processes, the ore turns into a charge, which is continuously loaded into the blast furnace.

Through tuyeres in the lower part, hot air enriched with oxygen and natural gas are supplied, which burns under the influence of high temperatures, forming oxygen dioxide. Rising higher, the gas combines with oxygen and unburned carbon, transforming into carbon monoxide CO. It reacts with iron oxides, “taking” oxygen from them.

The result is an almost pure metal. The molten cast iron mass flows into the furnace. Non-combustible residues also flow down.

The finished cast iron is poured at certain intervals into special ladles.

While the smelting process is underway in the furnace, the hole through which the cast iron is released is plugged with a special plug made of a refractory mass. To release the metal, a hole is punched in the cork. Through special channels in the floor of the workshop, the flow of molten metal flows in a “red drain”.

Liquid slag is also discharged from the furnace through another channel.

A sample is taken from each melt. The metal is poured into a special mold and analyzed. All processes are automated. Operators are watching them.

To the average person, a blast furnace appears to be a giant test tube in which the “mystery” of turning iron ore into cast iron takes place.