CNC lathes are well-proven equipment designed for mass production. Thanks to it, it becomes possible to make parts with high precision, which is important for lathes.

CNC allows it to improve its operation without human intervention, making it almost ideal for turning work and giving it autonomy.

Purpose of the CNC device

Numerical control (CNC) is designed for cutting threads on workpieces, turning parts from them, etc., without human intervention to avoid defects in production.

Thanks to fairly flexible settings, they have proven themselves much better than humans, and due to the fact that they have minimal defects, machines equipped with such a system are simply irreplaceable in mass production, where it is important to produce many parts that meet the quality. There are also types of turning work that only numerical control can handle.

If we divide CNC machines into types, then we need to take into account the purpose and the work they perform. In this case, they can be divided into five types:

- vertical and horizontal milling;

- console;

- longitudinal;

- widely versatile;

- instrumental.

Purpose

CNC lathes are modern versions of standard machine analogues, equipped with a number of additional functions, one of which is the presence of a CNC system. Such devices are designed for processing metal workpieces by turning, but can also be used to work with other materials. Thanks to this, lathes have become universal devices used in various fields. The main area of application is in factories and at home.

Using CNC machines:

- External and internal turning of parts is carried out;

- cone-shaped elements or having other complex shapes are manufactured;

- longitudinal processing of the workpiece is performed;

- roughing and finishing processing is carried out;

- the length of the parts is adjustable;

- grooves, recesses, holes are machined;

- Inch and metric threads are cut.

This machine is able to cope with a task of almost any level of complexity. Therefore, the scope of application of CNC machines for turning work is in enterprises engaged in the serial production of parts. Also, the use of lathes is noted in frequent production in small businesses.

Main advantages

Compared to manual machines, those equipped with CNC are four times more productive. Although the performance range varies from the specified settings and can be from one and a half to five times.

Due to the fact that a CNC machine combines the flexibility of universal equipment and the high productivity of an automatic machine, the problem of using such technology in both serial and individual production is solved.

Important!

Thanks to the latest electronics and the best computer technology, mechanical engineering, namely the production of parts for automobiles, is reaching a predominantly new level.

Due to the fact that the process is becoming almost completely automated, the need for qualified workers to operate the machines is falling. However, this cannot lead to unemployment, since craftsmen are now required who will monitor the serviceability of the CNC machine. Thanks to this, the quality of work improves without consequences.

The time required for fitting work is significantly saved due to the fact that the parts are made, one might say, according to one template, so they are interchangeable.

Due to the fact that all programs for the production of new products are recorded in the computer, there is no need to retrain personnel before switching to working with new products. You just need to turn on the desired program.

Parts that are made on a CNC machine are produced much faster. In addition, due to the absence of a person, the level of defects and unfinished work is significantly reduced.

Area of use

CNC machines and machining centers are widely used in the following areas:

- Metalworking. They are capable of providing 2D and 3D milling, engraving, threading, turning, drilling complex holes, creating complex volumetric parts with high precision, manufacturing injection molds and other processing of parts of almost any complexity. The machines provide one-time, small-scale and industrial (large-scale) production with high repeat accuracy.

- Electronics. In the electronics industry, machines are used in the manufacture of instrument panels, printed circuit boards, cooling radiators, and machining holes in equipment.

- Aerospace industry. Machine tools are used to produce high-precision parts from difficult-to-cut materials. They are capable of machining chassis components, titanium skins, bushings, fender parts, manifold pipes, gear components and connectors.

- Telecommunications and telecommunications. The machines are used in the manufacture of radiators, parts of antenna masts, casings, and corrugated horns.

- Healthcare. The medical industry uses CNC machines in the production of pacemakers, joint and bone prostheses, and medical instruments.

- Automotive industry. Machining centers are actively used in the manufacture of engine parts, internal panels, cylinder heads, drive axles, gearboxes, and other components.

- Furniture manufacturing. The machines are used in the production of complex furniture facades, cutting sheet materials (chipboard, fibreboard, MDF), parquet tiles, wooden rosettes of complex shapes, curved cutouts in doors and windows, panels, artistic carving, production of exclusive furniture parts and doors.

- Advertising. The equipment is widely used for cutting sheet plastic and composite materials, making logos, emblems and letters, engraving inscriptions and drawings, creating templates, patterns, price tags, stands, trays, applying images to glass and plexiglass.

- Modeling. On CNC machines you can create various models, prototypes, new architectural forms, stamps, cliches.

It is difficult to find areas of human activity where CNC machines cannot or are pointless to use. They are actively used in woodworking, metallurgy, the military-industrial complex, construction, production of agricultural machinery and equipment, and jewelry. They are capable of processing almost any materials: ferrous and non-ferrous metals, including high hardness, plastic, wood, glass, fiberglass, stones, concrete, etc.

What metal operations can be performed

Thanks to the fact that the human factor has been reduced to a minimum, metal operations have become much easier and result in less waste. It turns out this way because of the program that is embedded in the computer.

It is a kind of template by which the computer understands whether the part is ready or not. This section will talk about the operations that a CNC machine can perform on metal.

External and internal turning of parts

Everything is simple here, at least for the car. The installed workpiece, which in the future will become a part, is fixed on the machine. It can be secured manually or, if the appropriate equipment is installed automatically (most often the automatic option is used).

Afterwards, external turning of the part begins using either a laser or a blade that is installed on the machine. Gradually cutting off the excess, the workpiece takes the shape of the desired part. This is how external turning of parts is done on a CNC machine.

With the internal everything is about the same, only with changes. After installing the workpiece, the machine begins to drill, or as it is called differently, drill a hole at the base of the workpiece.

Once the hole is ready, the computer will compare it with the template that is written in the given program. If there are any flaws, he will analyze whether it can be corrected (as a rule, yes, because machines rarely make mistakes). Afterwards the workpiece is polished and the part is ready.

Longitudinal processing of the workpiece

Longitudinal processing is a method that is used for the manufacture of strips, strips, tapes. Depending on the program that is installed on the computer.

Such work on a CNC machine is carried out mainly using a laser, as this allows you to get rid of defects and speeds up the work process. After installing the workpiece, the numerical control on the machine will process it in accordance with the specified algorithm of actions. The laser portal is driven by stepper motors on which it is mounted.

Roughing and finishing

To begin with, what is this anyway? Roughing of metal consists of adjusting the part to the desired size by removing layers of metal.

Typically, in a CNC machine, this role is performed by the computer after the part has already been cut. Finishing comes next and consists of polishing the surface of the product. The machine performs all this according to given algorithms.

Adjusting the length of parts

The program that is given to the computer clearly states the dimensions of the part. The blanks are also given in suitable sizes. Before inserting a part, the machine adjusts and sets itself up for production.

After that, he begins to do the work, after which he compares the size with those given by the person. If there are no deviations, the part is ready. If there is, the CNC machine begins to grind the part, removing layers of metal and adjusting the length.

Making grooves, recesses and holes

Grooves and recesses are holes that are made into a part. Such holes can serve either to allow another part to fit into them, or for installation to some device. A CNC machine makes such holes using a laser, making high-precision cuts.

They can be rectangular, T-shaped, dovetail, shaped, through, open, closed and others. What shape the hole will be depends on the part and the program that the person has installed in the numerical control.

Inch and metric thread cutting

Almost everyone has seen this type of carving. It is used mainly so that one part can be screwed to another. The main parameters in the manufacture of such threads are pitch and size. In this case, a step means:

- outer diameter, measured between the top points of the threaded ridges located on opposite sides of the pipe;

- internal diameter as a value characterizing the distance from one lowest point of the cavity between the threaded ridges to another, also located on opposite sides of the pipe.

All parameters need to be entered into the machine’s computer, after which it will cut out an excellent and even thread using a laser.

Reference! In any case, the parameters for making threads on a product are entered by a person into the computer of the machine, and the latter, acting according to an algorithm, uses a laser to make an excellent thread.

Types, purpose and advantages of CNC machines

Computer numerical control (CNC) machines are used both in large manufacturing enterprises and in small workshops, and even in home workshops. This equipment has become widespread because it provides automation of production, that is, the execution of various technological operations according to a given program, minimizing human participation. Automation allows you to achieve impeccable quality of products, reduce labor costs, and increase production profitability.

An important condition for introducing automation and obtaining its benefits is to equip the enterprise with reliable equipment that best suits production tasks. CNC laser machines can be purchased on INLASER.PRO - the largest laser equipment marketplace in Russia. INLASER specialists will conduct an on-site technical examination of the enterprise, select the optimal machine models, deliver, assemble, launch and configure the equipment, and also implement a digitalization system that allows you to manage production from a smartphone. When purchasing equipment, you can enter into a subscription service agreement, which provides for regular maintenance and the supply of consumables and components with favorable discounts. If necessary, the INLASER online educational academy will develop individual programs for training your company’s employees in the skills of working on purchased or existing laser equipment, prepare qualified CNC operators, designers and technologists, and staff the new production site.

Operating principle of CNC

CNC is an automatic machine control system using a controller that reads the control program and, in accordance with it, sets the coordinates for moving the working tool of the machine.

Software for CNC machines is divided into CAD and CAM programs. In CAD programs, designers create 3D models of future products. Then the designs created in CAD are imported into the CAM program, in which technologists enter the data necessary for the manufacture of products, for example, the type and thickness of the material, its processing parameters, etc. The CAM program converts the received data into control program codes, which are read by the machine controller.

Main advantages of CNC machines

- Using the same program, it is possible to produce large batches of absolutely identical products with a consistently high level of accuracy and quality of their manufacture.

- Quick and convenient reconfiguration of equipment from the manufacture of one product to another. To do this, you need to select the appropriate control program from the list of programs stored in the CNC memory. The control program can be used an unlimited number of times. CNC machines that perform machining are equipped with an automatic turret that holds several tools. It allows the machine to independently change working tools. In laser machines, the universal working tool is a focused laser beam, with which a wide variety of production operations are performed.

- Higher processing speed of products compared to conventional machines.

- Productivity is 2-5 times higher compared to manually operated machines.

- Highest precision processing, which cannot be achieved on manually operated machines. CNC equipment allows you to process the smallest parts and produce products of complex shapes. Accuracy is maintained when the control program is run multiple times.

- Possibility of manufacturing products with particularly complex configurations or large sizes. Such products are problematic or even impossible to produce on conventional machines.

- The operation of the machine according to the control program allows you to more accurately calculate the production time of a specific batch of products and, accordingly, to use the equipment as fully as possible in the production process.

- The ability to provide full automation of production by combining several CNC machines into a conveyor-type production line.

- Human participation is minimized, which makes it possible to reduce the number of personnel and the cost of paying them. The operator’s functions are reduced mainly to daily maintenance of the machine, as well as to preparatory and final production operations: installation of material or workpiece for processing, selection of a control program, removal of finished products, etc. One operator can operate several CNC machines.

- Since the machine is controlled automatically and not manually, the risk of defects due to human errors is minimized. The release of defective products may occur due to incorrect preparation of the program. In this case, production must be stopped, the program corrected, and the process started again.

The disadvantages of CNC equipment include its high cost and significant costs for its setup, maintenance and personnel training. However, the investment quickly pays off, especially at enterprises producing large batches of products.

Scope of application of CNC machines

Various types of machines are equipped with numerical control, including milling, turning, grinding, laser, electroerosive, waterjet and plasma cutting machines, universal and many others. Due to their wide variety, CNC machines are used in many industries, namely:

- metalworking: 2D and 3D milling of parts, thread cutting, drilling holes, production of volumetric parts of complex shapes, production of molds for casting, turning, metal cutting, engraving of serial numbers and barcodes;

- manufacturing of high-tech equipment for the aerospace industry: engine and wing parts, chassis elements, gearbox components and connectors, bushings, manifold pipes, titanium casing;

- production of equipment for the energy sector: steam and gas turbines, housing elements and pipelines of nuclear power plants, etc.;

- manufacturing of equipment for the oil and gas industry;

- machine tool industry;

- automotive industry: production of engine parts, gearboxes, drive axles and other parts, surface treatment, cylinder honing, thread cutting, etc.;

- electronics: manufacturing of printed circuit boards, cases and front panels, cooling radiators, milling of technological holes, etc.;

- production of furniture: facades, legs, supports, artistic carving, drilling holes for fasteners and accessories, cutting sheet materials (MDF, fiberboard, chipboard);

- serial production of entrance and interior doors and production of unique doors for individual orders;

- production of platbands using various carving techniques;

- production of interior decorations: carved ceiling and wall panels, columns, imitation stucco, etc.;

- production of artistic parquet;

- creation of architectural 3D models;

- production of small architectural forms;

- production of models and prototypes of products;

- production of advertising products: signs, advertising structures, cutting sheet materials, etc.;

- production of corporate identity elements;

- production of souvenirs and engraving;

- engraving on jewelry, exclusive weapons, awards and cups, dishes, interior items, clothing, etc.;

- production of seals and stamps;

- production of containers and packaging from various materials.

Types of CNC machines

This equipment is classified according to various criteria.

By accuracy class

, depending on which the quality of product processing varies.

In Russia, in accordance with accuracy classes, machines are labeled:

- A – with particularly high accuracy: within 0.25 deviations obtained on machines of class H;

- B – with high accuracy: within 0.4 deviations;

- P – with increased accuracy: within 0.6 deviations;

- N – with normal accuracy.

In foreign countries the following designations are used:

- UP – ultra-precision;

- SP – super precision;

- P – precision;

- H – high precision.

Machines with normal accuracy are not marked.

By type of movement of the working tool:

contour and point.

By number of axles:

two, three, four or five axes;

By drive type:

- with a stepper, hybrid (servostep) or servo motor;

- with stepwise, stepless or combined regulation;

- with hydraulic, electric or pneumatic drive.

By control system:

closed and open.

By weight:

- light – up to 1 ton;

- medium - up to 10 tons;

- heavy – up to 100 tons;

- unique – more than 100 tons.

By processing method

– this is the most common sign of classification of CNC machines, according to which the following groups of machines are distinguished:

Milling machines

Milling machines process metals, wood, plywood, plastic, acrylic, glass, plexiglass, composite materials, and stone. Processing is carried out by a rotating cutter mounted on a spindle - a cutting tool equipped with teeth. The cutting part of the cutter is made of diamond or hard alloys. Milling cutters have many design options: disk, angle, end, cylindrical, worm, end, side, shaped, ring. Each cutter shape is designed to perform specific production operations.

The milling process involves gradually removing material from a workpiece to shape the product or part. Submitting a workpiece for processing can be done in several ways:

- movement of the workpiece to the cutter;

- movement of the cutter along a stationary workpiece;

- movement of the workpiece and cutter along each other.

The movement can be curvilinear, rectilinear or combined.

By design, milling machines are divided into three groups:

- universal - the spindle in such a machine is located horizontally, and the work table can move at different angles;

- vertical - the spindle is located vertically (perpendicular to the table surface). The work table is equipped with a rotating mechanism, which allows you to process complex curved surfaces.

- horizontal - the spindle is located parallel to the table surface, this makes it possible to process the workpiece from all sides without the need to re-fix it.

CNC milling machines are often equipped with an automatic tool changer (turret or tool magazine), which expands the capabilities of the equipment. In addition to the cutter, the machines are equipped with other working tools, this allows you to cut threads, drill, boring and perform other operations.

Lathes

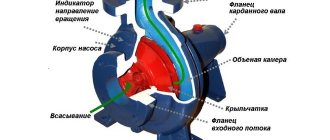

Turning is the turning of a product or part from a rotating workpiece by removing chips using a cutter. To fix the workpiece, a chuck mounted on the spindle is used. The spindle axis can be located horizontally or vertically. The workpiece can rotate in one direction or alternately (in one direction, then in the other). The turning cutter is fixed in the tool holder. Modern machines are equipped with cassette tool holders that can accommodate up to 12 working tools.

CNC lathes are classified according to the type of work performed:

- center – designed for turning parts of straight and curved, cylindrical, conical shapes;

- cartridge - used for cutting parts of complex shapes, threading, drilling, countersinking, turning for flanges, bushings, gears and disks. Processing of workpieces is carried out both inside and outside;

- cartridge-center (combined) – used for external and internal processing of particularly complex products. The machines combine the functions of cartridge and center models;

- carousel – used for processing workpieces of irregular shape or large size. Single-column rotary machines process workpieces with a diameter of up to 2 meters; double-column machines are designed to work with larger workpieces.

Metals and wood are processed on CNC lathes. Turning is mainly used for parts that have the shape of bodies of revolution.

Multi-purpose machining centers

This equipment combines the functions of CNC milling and lathes and uses combined software. Multifunctionality is realized through the use of a variety of different tools (from 10 to 100), which are located in interchangeable tool magazines. Thanks to the CNC device and automatic tool change, it is possible to perform various production operations on one machine without relocating the workpiece, including:

- milling;

- turning;

- boring;

- threading and chamfering;

- countersinking;

- drilling;

- grinding;

- open.

Multipurpose machining centers are equipped with rotating work tables to move the part in several planes. This equipment is also characterized by the use of low-inertia high-torque motors.

Horizontal multi-purpose machining centers make it possible to process large workpieces on one side. Vertical centers allow you to process parts from two to five sides at the same time.

Waterjet cutting machines

This equipment is used for cutting steel, metal, natural and artificial stone, reinforced concrete slabs, hardwood, ceramics, glass, and composite materials. The working tool of the machine is a waterjet mixture. Purified tap water is fed into the pump, compressed under high pressure and fed into the nozzle. When the water valve opens, a stream of water comes out of the nozzle and enters the mixer, where it mixes with the abrasive. The waterjet flow comes into contact with the material at high speed and cuts it in accordance with a given program. Then the mixture of waterjet flow and particles of cut material enters a bath installed under the work table.

Electroerosive machines

Metal processing on these machines is carried out by exposure to electrical discharges. As a result of the operation of an electric generator, spark electrical discharges arise between the electrode and the surface of the material, which destroy the metal in the processing zone. At the same time, coolant enters the working space, which removes metal particles from the treated surface. The electrode is brass or molybdenum wire; the movement of the electrode is controlled by the CNC. This type of machine has a significant limitation in application, since they can only process conductive metals and alloys.

Plasma cutting machines

Metal cutting is carried out by a directed flow of plasma, that is, hot ionized gas, which is supplied under high pressure and at enormous speed. The key element of the machine is the plasmatron - a device for generating plasma. The trajectory of its movement is controlled by CNC.

During the cutting process using the plasma-arc method, an electric arc is formed between the conductive metal being cut and the electrode of the plasma torch. The compressor supplies air or other gas to the nozzle under high pressure. A jet of gas is combined with an electric arc, heated to an ultra-high temperature, turns into plasma and melts the metal.

The plasma jet cutting method involves the formation of an arc inside the plasma torch between the electrode and the nozzle. The arc converts the gas into a plasma jet, which flows from the plasma torch into the processing zone and cuts the metal. This method is used for cutting non-conductive materials.

The plasma heats up to 5 - 30 thousand degrees Celsius, which makes it possible to cut any metals, including refractory and thick ones, in particular:

- steel (carbon and low-alloy) – up to 150 mm;

- aluminum and its alloys – up to 120 mm;

- cast iron – up to 90 mm;

- copper – up to 80 mm.

Plasma cutters have a fairly impressive number of advantages:

- high cutting accuracy, including when manufacturing parts of complex shapes;

- high speed and productivity, especially when cutting thick material;

- thickness range of processed material from 0.5 to 150 mm;

- minimal scale formation;

- the ability to perform bevel cutting, that is, at a certain angle;

- a minimal heat-affected zone prevents deformation of the material, including thin ones;

- lower price compared to laser machines.

This equipment also has disadvantages, including:

- the appearance of scale in places where the direction of movement of the cutter changes, which makes it necessary to process the resulting products;

- it is economically unprofitable to process materials up to 10 mm thick;

- unsatisfactory quality of edges, the taper of which reaches 5 degrees;

- inability to drill holes with a diameter of less than 4 mm;

- narrower scope of application compared to laser machines;

- high costs for consumables.

Due to the listed disadvantages, plasma cutting machines are inferior in distribution to laser machines. Plasma cutters are used for cutting sheet materials, cutting pipes, cutting holes, and artistic figure cutting. Their main area of application is cutting thick metals.

CNC laser machines

The working tool of such a machine is a laser beam focused into a point of very small diameter. It acts on the material in a non-contact manner exclusively in the processing zone, so deformations and other damage do not occur in the material.

In our country, the most common laser machines are fiber and gas (CO2) laser radiation sources. Fiber sources generate radiation with a wavelength of 1.064 µm. It is perfectly absorbed by metals, which is why fiber laser machines are most often used for processing all types of metals. They are also used to work with stone, ceramics, rubber, some types of plastics and polymer materials.

CNC fiber laser machines perform a wide range of manufacturing operations:

Cutting materials.

The machines provide very high cutting speed and accuracy, form perfectly smooth cut edges that do not require additional processing, cut out parts of complex and unique configurations, and create microscopic cuts that cannot be made on other equipment.

Two methods are used for cutting:

- melting

- the metal is heated by a laser beam to the melting temperature, and the auxiliary gas blows the resulting melt out of the cutting area. The gas cools the cut edges, preventing their deformation, and also performs other technological functions. Oxygen enters into an oxidation reaction with the heated metal, as a result of which additional heat is released in the cutting zone, which helps to increase the cutting speed and the thickness of the material being cut. Non-alloy steels and ferrous metals are cut with oxygen. Inert gases (nitrogen, argon) prevent oxidation of the cut edges, as they prevent atmospheric air, which contains oxygen, from entering the cutting area. The edges remain perfectly smooth and clean. Argon is used for cutting titanium, and nitrogen is used for stainless and other types of alloy steel, non-ferrous metals and their alloys. - evaporation

– the laser beam heats the metal in the cutting area to boiling point, and the material evaporates. This method requires high energy consumption, so it is used less frequently than the melting method. Its scope of application is cutting out thin parts and cutting thin sheets.

Engraving.

This processing technology involves removing the top layer of material to a specified depth. The beam moves along the trajectory set in the program and creates any image on the surface of the material: from the simplest to the most complex, such as a photograph or painting.

Welding.

The thinnest laser beam provides high-speed welding with the creation of deep welds. A fiber laser allows you to weld not only metals, but also non-metallic and even dissimilar materials that cannot be joined by other welding methods.

Fiber laser machines can perform other operations, including:

- perforation;

- laser cladding;

- soldering;

- laser cleaning;

- thermal hardening of surfaces;

- applying a metal coating to the surface;

- 3D printing.

CNC fiber laser machines are easy to change from one operation to another. These machines are quite easy to operate and are highly reliable and durable. The service life of the fiber laser source is 100 thousand hours.

Gas (CO2) laser sources generate radiation with a wavelength of 10.6 microns, which is well suited for cutting and engraving non-metallic materials: wood, plywood, cardboard, paper, glass and plexiglass, plastic, acrylic, rubber, fabric, leather. CO2 laser machines are not suitable for working with metals, since the surface of metals reflects short-wave radiation. The advantages of these machines include low cost and lower energy consumption. However, CO2 emitters, which are glass tubes, are fragile and have a short service life.

If you are planning to equip your production with a CNC laser machine, this equipment can be purchased at reasonable prices on the INLASER.PRO marketplace. Our catalog contains machines based on fiber and CO2 lasers, components and a large selection of consumables. You can also contact our service department to modernize your existing equipment by replacing the gas laser source with a fiber one.

Design and principle of operation

Lathes equipped with a CPU are of three types - contour, positional and adaptive. Each has its own advantages and may be suitable for different types of work.

The first type of machine cannot be called maximally independent, since human intervention is necessary for its operation. It works only along the trajectory specified by the operator.

The second type of machine can perform work on a part in a point-by-point manner.

The third type is universal. It can perform the work of both machines, while having the same functionality, so this type is the most expensive and most useful in the production of various parts.

Compared with older analogues that are already outdated, the latest machines with an installed numerical control system have increased rigidity, which allows reducing production time even for quite complex types of work. This level is ensured by the design features of the machines.

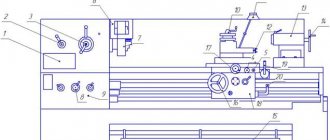

The CNC lathe consists of:

- beds;

- spindle or headstock;

- calipers;

- feed boxes;

- electrical part;

- turret heads.

The bed is one of the main parts of any machine, since it is on it that all other parts of the machine are located. The spindle (or headstock) has two parts of the machine: the spindle itself and boxes for changing speeds on the machine.

Another important part is the caliper. It is he who regulates the rotation speed of the workpiece, which is fixed in the lower and upper carriages. The caliper is controlled using one of the spindle parts, namely the gearbox.

Turrets are also very important for the operation of the machine, as they automatically replace worn-out equipment. The workpiece is installed in the machine, and then it does the work itself, using a program pre-written by the operator.

Principle of operation

Operation of CNC lathes depends on the characteristics of the device used. The choice of machine depends on:

- permissible thickness of the workpiece being processed;

- the maximum distance that can be set between the central parts of the headstocks;

- permissible diameter of the part installed above the support.

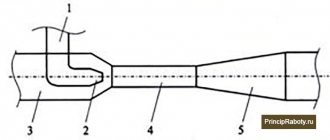

The tailstock is used to install a cutter or other working tool. The movement of the headstock is carried out along the trajectory of the rails located on the frame. The length of movement is equal to the dimensions of the workpiece. The working tool moves along the workpiece, the movement of which depends on the carriage. The caliper is responsible for ensuring that its position does not get lost during turning.

The single holder is used for simple machining. More complex tasks are accomplished with heads that can accommodate multiple cutters. The largest number of incisors is four.

The use of parts using such a device should be preferred when working with complex shapes.

The electric motor uses a belt drive. It is capable of providing high performance. The disadvantage of this transmission is that the belt stretches. To maintain performance at a high level, the belt is periodically tightened.

How to write a control program

Programs for operating CNC machines are made in three steps, each of which determines what the new part will look like:

- Creation of a three-dimensional model. This stage is the creation of a model of the workpiece with which the work will be carried out. This is mainly done not by operators, but by designers, since not everyone understands so well how to make a good three-dimensional model.

- Instructions. Having a three-dimensional model, the operator sets the parameters that the machine will have to perform when working with the workpiece in order to get the part.

- Test run. It is necessary to check whether the program was written correctly to work. After all, if you run a bad program on a machine right away, without a test, it will ruin all the workpieces. Therefore, the operator looks to see whether the machine is performing the job correctly with the given program, and then looks at the result and decides whether modification is required or not. Most often it is, of course, required, but it cannot display any critical errors.

Once the program has been installed, the machine is ready for use. There are five special applications for writing such programs:

- AutoCAD.

- T-FlexCAD.

- NanoCAD.

- ArtCam.

- SolidWorks.

Now we will talk about each one separately.

AutoCAD

This program was developed by Autodesk specifically for automatic design of turning operations. AutoCAD has 3D modeling functions, as well as the ability to work with 3D scan data, which allows you to save money on designers. But, due to the lack of three-dimensional parameterization, this program is not the best choice.

T-FlexCAD

This program was developed to develop different types of work with lathes. It has all the necessary functions, but it is not the best choice and is not popular.

NanoCAD

This program can work with both three-dimensional and two-dimensional models. With its help, work calculations can be carried out, 3D and 2D models, various drawings and much more can be prepared. Thanks to this program, the work of operators is greatly facilitated.

ArtCam

This program is needed exclusively for creating a three-dimensional model. Calculations of work or anything similar cannot be done on it, but the models are of very high quality.

SolidWorks

This is not just a program, but a whole software complex. It was released back in 1995, but is still considered one of the best among the development of programs for lathes using a CNC system. True, this software package costs a decent amount, but it perfectly demonstrates the principle “price equals quality.”

Varieties

There are enough varieties of lathes to perform a wide variety of jobs. There are five of them in total:

- horizontal turning-turret;

- tokor-frontal;

- rotary turning;

- multi-spindle;

- turning and milling.

Now we will talk about everyone separately.

Horizontal turning-turret

Designed mainly for mass production of parts. Using a chuck, parts are installed that will process the workpiece before it becomes a part.

Torque-frontal

This machine is used for processing parts whose diameter exceeds the size of the workpiece. These are mainly railway wheels, flywheels and others. It can also remove ends, make cylindrical parts, make grooves, and so on.

Lathe-rotary

Such machines are designed for workpieces that weigh several tons. Also, the workpieces for such a machine have a diameter greater than their height. Thanks to the chuck and the cutting parts installed on it, it is possible to apply threads to the workpiece or drill holes.

Multi-spindle

As the name implies, the design of this machine contains several spindles, which ensure processing of the workpiece to the state of the part in several places, either simultaneously or in shifts after every certain period of time.

Turning and milling

Turning and milling machines with installed CNC are universal. They can perform a wide variety of work with products. Everything will depend on what program was installed in the numerical control computer and what tools were installed on the chucks.

This machine can perform any functions of highly specialized equipment, be it turning, drilling, milling. He can handle any type of work.

Review of modern models of CNC turning machines

Compared to older models, modern lathes have become easier to use and can perform many more functions. The operation of such machines has become faster and better, providing better quality and fewer defective products.

Thus, we can say that CNC lathes are the future. Thanks to him, the number of defects due to human defects has become almost zero, despite the fact that no one has lost their jobs - it’s just that now the specialists who previously worked on the machines now monitor the operation of these machines, correcting breakdowns and giving them new programs.