For high-quality roof construction, professional tools are required, and for some types of work, modern equipment is also required. Their range is constantly updated with more advanced devices. Each of them is designed to make roofing work easier and to make it better.

Roofing tools are:

- manual. A roofing tinsmith's hand-held roofing tools, such as special scissors or pliers, are excellent for working with steel or copper, but for soft roofing a roofing knife is required. All hand tools for roofing work are convenient and easy to use.

- semi-automatic roofing tool. They are widely used when laying long picture panels. For example, with the help of seaming machines, you can productively and quite simply roll up seams and at the same time ensure complete tightness of the seams.

- electric roofing tools. They are in maximum demand for the installation of seam coverings. Roll forming equipment is equally effective when working with both rolled material and a coated polymer protective and decorative layer.

Arrangement of the premises

If single repair work can be carried out in the everyday conditions of an ordinary garage, then for regular body repairs it should be turned into a specialized room. First of all, you should equip the garage with an inspection hole or overpass, depending on the characteristics of the room. Lumber can be used to create an overpass.

Also, to ensure the possibility of working in the garage throughout the year, it should be equipped with heating, and insulation will also be required.

The room will need to be heated only for the duration of the body work, and not constantly, so the best option for heating equipment for such a garage is a heat gun.

This device provides the intense heat required for painting.

To connect the heat gun you will need a network. In addition, during body repairs, both pneumatic and electric tools are used, which require a power source, therefore, it is necessary to install a network in the garage. Finally, it is advisable to create spaces in the form of pits for large tools, such as a compressor and welding machine.

How to choose the right roofing tool

There is a large selection of both manual and electric roofing tools. It should be borne in mind that instruments that look identical can differ significantly in quality, so it is better to purchase them in specialized stores and give preference to trusted manufacturers.

When choosing an electric tool, you need to pay attention to its power and performance. In addition, you need to consider what kind of work you need it for. If these are one-time roofing jobs or they are of small volumes, then manual devices are quite sufficient. In the case when you have to work on long slopes or roof installation is your professional activity, in addition to hand tools you will have to buy semi-automatic and electrical equipment.

To carry out repairs or small amounts of roofing work, it is enough to have hand tools

In addition to the tools described, auxiliary tools may be needed to perform roofing work:

- a jack or lifting mechanism used to deliver heavy elements to the roof of a building;

- brushes, spray gun, spatula - they are used during paint and varnish and priming work;

- scribers - they are better used for marking metal products instead of a pencil;

To mark metal surfaces, it is convenient to use a scriber with a tungsten tip.

- punch, it is used to apply marks to metal sheets, which serve for the convenience of drilling holes.

A professional roofer should have about 40 tools in his arsenal, then he will be able to perform high-quality work quickly and solve all the problems that arise when creating a roof.

If you decide to invite a contractor to create or repair a roof, be sure to inquire about the technical equipment of the workers. This way you will draw a conclusion about their qualifications and readiness to complete the assigned tasks and will be able to choose truly professionals.

Equipment classifications

There are several classifications of tools for body repair. So, according to their purpose, they are divided into the following systems:

- welding;

- compressors;

- grinding;

- straightening;

- finishing tools;

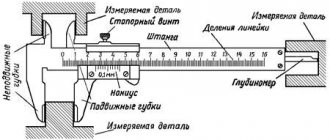

- measuring systems.

According to the stages of body work, which include straightening dents, removing corrosion, painting and preparing for it, tools are divided into appropriate categories. In addition, the classification under consideration includes a group of additional materials.

Based on the operating principle of body repair equipment, it is classified into manual and automatic tools. Models of the second subtype are divided into pneumatic and electric tools based on the power source. The former include, for example, grinding machines, while a paint sprayer is a pneumatic tool.

Tools for roll installation of seam roofing

To implement roll technology, domestic Mobiprof machines are most often used, which make it possible to create roofing clamps without seams. It is best to carry out this type of work under the supervision of a professional roofer.

Installation is carried out using the following technology:

- First you need to lift the selected machine and rolled metal onto the roof;

- The metal strip is inserted into the working elements of the machine, rolled and cut;

- The prepared roofing panels are laid properly;

- Clamps (small-width metal strips that allow you to close all the gaps that may be in the roof) are attached to the sheathing;

- Using a hand-held roofing tool, a double seam joint is rolled up.

In order not to bother with manually creating a connection, you can use a machine that allows you to create self-locking folds. The SFPZ machine significantly speeds up the process of installing roofing panels. As a rule, such equipment is used on large gable roofs with a slope above 15 degrees.

Welding

Welding machines are also divided into several types, each of which has certain features of operation and implementation of work. At the same time, they provide different quality of welds. Therefore, you need to choose a welding machine for doing body work yourself based on the requirements for their quality and the skills of the performer.

Thus, AC units are suitable for repairing large faults such as frame welding, but such tools are not used to eliminate minor defects.

When doing body repairs with your own hands, you usually use a tungsten electrode or a carbon dioxide semiautomatic device.

Semi-automatic seaming machine ↑

The tool consists of two separate seamers, which are driven by the pulling force of the roofer. The principle of operation of the tool is the same as that of a manual grab - a double fold is formed in two passes. Particularly effective when installing seam roofs on long slopes, over 10 m.

This type of seaming machine has a number of advantages:

- its productivity is three times higher than that of a manual device.

- Guaranteed high quality seam.

- it is possible to adjust the metal thickness: from 0.4 to 0.7 mm.

- completely safe for polymer coating:

- provides rebate height: from 25 to 35 mm.

Compressors

These devices also differ in design. There are piston and diaphragm compressor models, and the receiver volume can be from 20 to 50 liters. It is advisable to equip the tool in question for body repair with an oil separating filter. Compressors provide air to pneumatic tools. Also, for painting work, you will need to purchase the pneumatic tool itself, represented by a spray gun.

The considered tools for body repair are the largest, so the above-mentioned pits in the garage are equipped specifically for them.

Tool sharpening

It is necessary to ensure that the tools are in good condition, then the work will not require much effort. The sharpness of the sharpening is important if, for example, roofing scissors are used.

To sharpen a roofing knife or other tools, you can use:

- sharpener;

- sharpening stones;

- touchstone

Sharpener

. It is used for sharpening cutting tools, such as roofing metal shears, taking into account the following main points:

- Coarse-grained sharpeners leave defects - jagged marks and scratches, to remove which fine-grained ones are used;

- When sharpening planes and chisels, a round sharpener is directed towards the blade;

- The tip is placed completely on the surface of the sharpener and is moistened with water during the sharpening process.

Sharpening stones

. They are made from sandstone and used for rough sharpening. Large grains remove metal quickly. The blade is brought to working condition using a whetstone.

Touchstones

. When, for example, hand-held metal nibblers are sharpened, a whetstone moistened with water is used to polish their blades and remove burrs until a smooth, shiny surface is obtained. Sometimes files are used for sharpening, for example saws. Sharpening of drills for metal is done using sharpening discs, emery or corundum whetstones.

When sharpening hand electric shears for metal, it is done at an angle of 70 - 74 degrees.

Before you begin repairing or creating a roof, you should prepare tools and machines for roofing work in advance (if the roof surface is large in area). Modern equipment, such as a roof cutter, makes the work easier and allows you to equip the roof in the shortest possible time. Article on the topic: “Contract for roofing work and its significance.”

Straightening

Devices for repairing dents and body defects are varied. Straightening tools are presented:

- hammers;

- spoons;

- anvils;

- notch blocks.

The most optimal options for straightening hammers are considered to be double-sided tools with sides of different shapes. Straightening hammers differ from other hammers in weight and materials. To ensure the ability to straighten dents of various sizes and shapes, you should purchase a set of straightening hammers.

For do-it-yourself body repairs, straightening hammers are used in combination with an anvil or with various blocks designed to soften impacts.

Another tool for car body repair, related to straightening, is represented by a spoon. It is designed for straightening small flat tubercles by distributing the hammer blow over an area. Moreover, you can use a regular hammer with this tool, but sharp folds must be processed with a straightening hammer before using a spoon.

A body repair tool called a figure rod is used to straighten dents in hard-to-reach places. It is a tool from 30 cm to 1 m long with a tip in the form of a chisel or punch. The principle of application is close to the technology of using the above tools.

Anvils intended for body work differ in shape from ordinary ones. There are options in the form of a heel, a chicken egg, and a thumb. Various anvils are used for straightening depending on the shape of the dents, so to carry out body work with your own hands, it is advisable to have several options for these devices.

Knurling blocks are auxiliary tools for body work. They serve to determine where force is applied and support the metal during straightening. To do this, the devices in question are placed on the reverse side of the body fragment being processed. After hitting it, marks remain on the notch block.

Folding machines: for large and small areas

For the production and installation of seam roofing, a mobile roofing machine is required. It is produced for renting paintings and closing double folds:

For example, such machines are produced in Russia, although such Western analogues as Wuko lock'n'rolle are also in demand.

To work with the roof of an ordinary private country house, it also makes sense to use modern equipment, which significantly improves the final quality of the roof. But for some reason, most teams still work the old fashioned way, using a traditional mallet and hammer.

It’s better to rent the necessary tools for a few days, and then the seams on the roof will be perfectly smooth and reliable. Moreover, the machine is usually capable of producing seam roofing from any roofing metal, be it copper, steel or aluminum.

So, let's take a closer look at what this tool is. Today, folding machines on the Russian market are provided by seven major manufacturers. This indicates the possibility of a good choice.

For example, an electric folding machine joins and closes profiled panels with a double standing seam. Moreover, she does this in one pass, quickly moving along the seam directly on the roof.

Advice: when choosing such a tool for yourself, it is better to give preference to a domestic one, since it is designed to withstand possibly careless handling during operation, and therefore has a more durable body and protection from moisture penetration.

Keep in mind that European folding machines are usually designed for a fold height of 25 mm, and American equipment is designed for 38 mm. Therefore, it is necessary to calculate in advance the compatibility of various equipment.

The fact is that for some machines you can adjust the height of the legs, while for others you will have to separately order such legs for 38 mm (and this is an additional cost). By the way, for small manual machines the issue of rebate height is not important.

Mobile equipment is installed directly on the roof and solid panels are made for double standing seams. Here it is important to purchase a really high-quality machine.

Otherwise, installers manage to cut the panels lengthwise into several parts, and then join these parts with rivets, which is absolutely wrong. This results in roofs made from expensive materials such as zinc or copper, but with big problems in terms of airtightness.

Here is an example of how such a machine works:

Mechanical folding machines are cheaper, but you will also work slower with them. There is also always a human factor - the risk of simply not pressing the fold.

The set of Mobiprof machines includes two machines for joining panels with a double standing seam. With a slight movement, you need to move the first machine in order to make L-shaped folds, and then the second machine to form the folded lock itself.

These machines have a special adjustment for the degree of clamping of the fold, which is very important for working with different types of metal. In this case, the seams are closed quite quickly, almost the same as with electromechanical machines.

The Wuko lock'n'rolle device is used to close rebates and double standing seam panels. It is convenient for them to work in any direction, but they will have to hold the machine itself with both hands, like a plane. Among the advantages we can name low price and weight.

Separately, we note such a seam-rolling machine as the Wuko 1006. It is small and light, and, perhaps, the only one that can be used for installing roofs of complex shapes, which have many junctions and transitions. The machine itself covers single and double L-shaped standing seams well.

It differs in its design from other models in that it has a special closing mechanism - a special hammer, which seems to tap the fold (while all other models press this fold with rollers). This is noticeable in his work: such a machine moves slowly, sometimes leaving marks on the metal. But it works great on any type of joint.

Let us note separately that quite a lot of folding machines were originally designed to work with expensive ductile metals. They are not suitable for rolling high-hardness galvanized steel.

There is also special equipment for making seam roofing on radius rafters. These are car models that differ from each other in terms of the minimum roof radius. Therefore, if you buy the wrong machine, you will also have to arm yourself with hand-held roofing tools to finish off the seams.

Look what all these cars look like:

Sanding and polishing

Equipment designed for cleaning, which includes sandpaper, grinding and polishing machines, are called finishing tools.

As for sandpaper, when doing body work, the most commonly used options for straightening and cleaning working surfaces are P120 - P500 grit.

For stripping sheet metal and processing putty, body files are used, which are distinguished by the presence of a curved holder with variable geometry, which makes it possible to straighten hard-to-reach places.

Power tools, represented by grinding machines, are used for straightening large irregularities, as well as for removing paint and varnish material and primer.

Electric sheet metal rolling machines

To minimize the amount of work that needs to be done manually, it is worth using electric seaming machines, which provide high-quality double joints with minimal effort from the roofer.

The work process looks extremely simple: the folding machine is installed on the required area and started. Moving along the site, the device reliably and efficiently closes the double vertical fold - and all this in a single pass over the panels. The result is a significant saving of effort and time.

When choosing electric tools for iron roofing, you should pay attention to the following models:

- Dimos K9. The French device with an electric drive is valued not only for the qualities inherent in similar devices, but also for the ability to process seams on arched roofs.

- Mobiprof FZM. This model of electric seaming machine uses unique profiling and drawing rollers.

- Schlebach Piccolo, FK1, Flitzer. All these brands of electric machines are manufactured in Germany and are distinguished by their original German quality.