A jigsaw is a hand-held tool designed for cutting various materials at home. With its help you can get straight, round, oval, and curly cuts. Moreover, the tool is able to cope not only with wood, but also with materials of varying strength. However, in order to achieve an accurate cut, you need to know the features of preparing the tool for work, and how to use a jigsaw correctly. Otherwise, the final result will differ from the desired one.

To cut thin and thick materials you need different jigsaw files

General cutting principles

It should be understood that a jigsaw produces an uneven cut. And to minimize the spread of the saw, you don’t need to make any special efforts when working with the tool. Simply press it to the surface of the material and set the direction of movement. The slower the cutting, the higher its quality.

Other general recommendations on how to use a jigsaw:

- During the cut, you need to constantly monitor the sharpness of the file and, if necessary, replace it in a timely manner. As soon as it becomes dull, the instrument begins to behave unpredictably.

- You should monitor the temperature of the cutting surface and avoid overheating. After all, this leads to rapid wear of the saw teeth.

- There are many types of jigsaw files. And each of them is designed for a specific type of material. To do quality work, you need to take this into account.

- Its functionality directly depends on the power of the tool. The higher this indicator, the more types of materials it can cut.

- Files with large teeth should be used for thick materials, and with small teeth - for thin materials.

- To get the most even seam, you should use additional devices such as a side stop, a jig, or a guide rail. This will allow you to move the tool through the material as smoothly as possible.

Important! As a guide when working with a jigsaw, you can choose any material with a smooth edge; the main thing is to align it correctly and secure the supporting end.

Tips for choosing saws

If a craftsman is interested in a decent result of his work, it is better to purchase files from trusted companies. They are a little more expensive, but already a reliable option. Inexpensive canvases wear out faster and break more often.

There is a more detailed classification of files:

- Т101В – for cutting plexiglass and plywood;

- Т101ВR – for laminated wood and laminate;

- T101D – for boards, timber, chipboard;

- Т224D – for working with aluminum;

- T118A – for sawing metal and plastic elements;

- T119VO – for shaped cutting on chipboard, laminated chipboard, fiberboard.

To know how to change a file on a jigsaw, you need to have one in stock that is suitable for cutting the prepared material.

The T-shank is considered the most common

Features of preparing a jigsaw for work

At the stage of preparing the tool for work, you need to inspect it for damage and check the integrity of the power cable. You also need to immediately prepare all the files that may be needed to complete the task and set up the appropriate modes.

Before cutting, mark the material.

When purchasing, it is better to choose a tool equipped with a laser guide.

How to work with a jigsaw: features and rules

Depending on the type of material, the rules for making a cut are slightly different. And to avoid mistakes, you need to familiarize yourself with how to work with a jigsaw in a given case.

How to cut metal

When cutting metal, you should use a fine-toothed file. For thin and soft materials such as copper, aluminum, the speed can be set higher. A level above 750 W is considered optimal. And to reduce the friction force, you should periodically drip oil during operation.

Important! When cutting sheet metal, it is better to place plywood under it, which will reduce vibration.

How to cut wood, chipboard, plywood

The largest range of files is presented specifically for cutting these materials. But they must be used for their intended purpose. The number of strokes should be set based on the maximum values of the tool.

To make a cut in this case, you will need files with large teeth from 2 to 6 mm. The more complex the type of work, the smaller their size. A straight cut can be made at high speeds, and with a curly cut, the rotation speed can be reduced.

Having mastered the basic principles of how to properly work with an electric jigsaw on wood, plywood and chipboard, not only an adult, but also a child will be able to cope with such a task.

How to cut metal tiles

In this case, the greatest difficulty is the metal tile profile. And, in order to make the cut correctly, it is recommended to secure a sheet of material between the bars on both sides. This will eliminate vibration and create a certain gap for comfortable work.

Important! In order not to spoil the metal tile coating during the cut, you need to wrap the sole of the tool with a cloth.

How to cut plexiglass, plastic

For cutting this material, the same files as for metal are suitable. The pendulum stroke should be set to the minimum position or turned off completely. Plastic and plexiglass need to be processed at minimum speed.

How to cut ceramics, porcelain tiles

When cutting these types of materials, you should use files with an abrasive edge. In this case, the pendulum motion must be turned off, and the work process must proceed at maximum speed. To cut ceramics and porcelain stoneware, you should rarely use a jigsaw, as these files quickly become unusable and require replacement.

How to cut laminate

When cutting this material, the only difficulty is that chips form along the edge. To avoid this, you must use a saw with diversified teeth. And at the same time, make the cut not from the front, but from the inside.

For laminate, you can also use a file with teeth oriented downward from the jigsaw.

Kinds

Depending on the area of application, jigsaws are divided into two main classes - household and professional. Regardless of the type, the design of the tool is equipped with a saw mounted in a special frame.

For home use, small devices for cutting materials are used. These jigsaws can be manually or electrically controlled. Each type of tool has its own technical and design characteristics.

Manual

This tool is of the simplest type. It consists of a frame, a saw blade with clamps and a handle. A manual jigsaw is used mainly for small jobs that require a certain precision of cutting.

The bottom tool allows you to perform artistic cutting of the material. But using it requires patience and skill. The sawing speed of a manual device is low, so it is not practical to use it for large volumes.

Electric

A jigsaw powered by an electrical network is considered the most convenient tool. It allows you to quickly and efficiently cut any material. The depth of the cut mainly depends on the power of the device. For modern devices, this figure can range from 200 to 900 watts.

Electric jigsaw 620 Watt

Low-power jigsaws are suitable for household use. They have a relatively low cost and do an excellent job of sawing wood products up to a depth of 50 millimeters, and metal ones - 23 millimeters. More complex work requires the use of tools with the highest technical parameters.

Features of cutting straight elements

This type of work with a jigsaw does not require complex manipulations. It is enough to make a marking and smoothly move the tool along it. But you can also make the process easier by using special devices.

Sawing with a guide bar

This metal ruler has a groove, which is necessary for installing a special jigsaw sole and can greatly simplify the work. When using a guide bar, you first need to make a marking and then fix it. In this case, the jigsaw moves along the device and makes an even cut.

Using the rip fence

All models of jigsaws from Bosch, Interskol and other manufacturers have a hole in the sole for a rip fence bar. This device ensures an even cut of various materials. But when using it, you need to press the jigsaw tightly onto an absolutely flat surface.

Important! It is not recommended to install a parallel stop on parts that will move to the side when cutting.

In most cases, a parallel stop is included with the tool.

Nuances of an electric jigsaw

Modern manufacturers produce various models of jigsaws. The design of any type of tool consists of the following basic elements:

- Cutting blade. All electric jigsaws are equipped with a special file, which is used to cut the material. The processing process is carried out due to the rapid reciprocating movements of the cutting element. Moreover, depending on the model, the device makes from 43 to 58 revolutions per second.

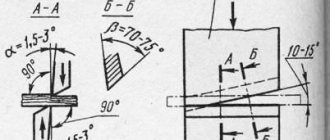

- Support sole. This design detail ensures cutting accuracy. For most manufactured electric jigsaws, the guide plane rotates at any convenient angle up to 45 degrees. Some models have a fixed slope value.

- Engine. An electric tool is necessarily equipped with a special driving system that drives the rotating mechanism. The greater the power of the device, the higher its operational capabilities.

- Holder. This element allows you to keep the tool in the correct position during the entire working process.

Some models of electric jigsaws have additional equipment. This could be a backlight or devices for automatic chip removal. Many tools have cut regulators, which make it possible to independently set the rotation speed of the cutting element for each individual type of material being processed.

Sawing with a saw table

This design allows you to significantly simplify the process of cutting different materials. When using, you need to move not the tool, but the workpiece. This allows you to control the marking line without much difficulty. But at the same time, increased forces on the surface being processed should be avoided.

You can buy a saw table or assemble it yourself

Fastening material

In order for the cutting line to be smooth, the working surface must be as stable, rigid and durable as possible. When working at home, this can be an ordinary table with reliable legs and a flat tabletop.

The board is fixed to the surface using clamps secured on both sides with moderate force. The sheet to be processed must be positioned in such a way that the tool does not rest against the surface during operation. To prevent pressure from being applied to the saw during the cutting process, you can weigh down the protruding edge hanging from the surface using an attached weight.

The most common breakdowns, how to avoid them and safety precautions

High-quality jigsaws such as Bosch, Vortex, Zubr have a long service life. But even these tools can break down from time to time.

Common problems:

- If metal dust gets into the case, the start button may stop working. In this case, it should be cleaned with a special vacuum cleaner and, if necessary, replaced.

- The tool rod often fails because it is subjected to increased mechanical stress. As a result, a breakdown occurs and the fixing device connected to it deteriorates. This occurs when dust and particles of various materials get inside the housing. Good quality jigsaws do not have such problems.

- Engine stops often occur as a result of burnout of the stator, rotor, or wear of a notch on the shaft. In this case, the parts must be replaced.

Important! When performing various types of work, the power of the jigsaw should be taken into account.

Jigsaw safety and maintenance

Safety precautions must be followed when using this tool. It is important not only to know how to sit correctly when working with a jigsaw, but also how to hold it so as not to cause injury.

Primary requirements:

- sit upright, half sideways to the cutting table;

- securely fasten the file;

- Make the cut on a flat surface after fixing;

- cut at a distance of 40 cm from the eyes;

- use special glasses;

- securely secure the handle of the tool so that it does not slip.

Knowing how to use a jigsaw correctly, you can cut any material without much difficulty. Indeed, unlike hand tools, it is able to cope with the task much faster. The main thing is to follow the instructions included with the jigsaw in order to correctly calculate the load and avoid injuries.