When laying communications, installing lighting fixtures or installing household appliances, it is almost always necessary to drill round holes of large diameters in walls, ceilings or interior items. A comfortable ballerina drill will be a good helper in your work.

You can drill a small diameter hole (10-12 mm) in the surface using a simple electric drill. But even when trying to cut large diameter holes in the working surface, even a metal drill begins to vibrate and deviate from the vertical axis.

Specifications

To obtain a high-quality hole of the required size in such cases, you will need a special tool - a ballerina (round drill).

| Tool Options | Parameter values |

| Tool weight | 0.1-0.110 kg |

| Length | 90-120 mm |

| Shank type | Cylindrical |

| Shank length | 8-9 mm |

| Maximum outer circle diameter | 140-160 mm |

| Minimum outer circle diameter | 20-30 mm |

| Diameter of support bar | 7 mm |

| Working surface processing depth | 30 mm |

| Number of working cycles (for ballerina on tiles) | 30-40 |

Characteristics of metal for drill

The ballerina is made of high-quality carbon (tool) steel, which does not contain alloying additives or impurities. Carbon steel is used for the manufacture of high-strength static cutting tools that experience significant mechanical and physical stress.

The properties of carbon steel provide the ballerina with the following characteristics:

| Characteristic | Content |

| Hardness | Ensures that the drill remains in a vertical position when working with it |

| Strength | Ensures uninterrupted operation of the ballerina when drilling deep layers of the working surface |

| Cyclic strength | Maintains performance characteristics after repeated use |

| Plastic | Possibility of adjusting cutters |

| Heat resistance | Possibility of maintaining the working qualities of the tool when drilling at high speeds and heating |

| Wear resistance | Long tool life and resistance to corrosion processes |

Characteristics of a metal drill

The ballerina allows craftsmen to work with metal surfaces (steel, cast iron, brass, aluminum, bronze) up to 14 mm thick. Using this type of drill, mounted in a drill or in a tabletop drilling machine, you can cut a hole with a radius of 22-105 mm in a metal surface.

What is a ballerina

The cutting tool, commonly called a ballerina, also has a more professional name - “circular adjustable drill with cutters.” The drill is located in the central part of the tool and is used to center the hole. The radius of the circle that the cutters will describe is measured from the center line of this drill.

To equip ballerinas, drills of the first or auger type are used, since a conical tool does not cope well with ceramic materials and can slide off their surface. The result of such slipping can be damage to both the tool itself and the surface of the tile.

Ballerina on tiles differs from a nozzle designed for drilling holes in wood materials

Adjustable tool overview

Ballerina – adjustable drill. One of its structural elements is a bracket with a scale printed on it. With its help, you can independently set the required diameter. And in a three-cut drill, the cutting elements move synchronously along special grooves.

Before starting work (drilling), it is necessary to set both cutters at the same distance from the central hole.

Types of circular drills

Manufacturers of adjustable ballerina drills produce devices that differ in the following characteristics:

- designs (detachable, one-piece);

- diameter of holes made, mm (20÷80; 20÷90; 30÷80; 30÷100; 30÷120; 30÷130; 40÷120; 40÷200; 40÷300; 40÷400);

- material drilling thickness, mm (15÷20);

- number of cutting elements, pcs. (1, 2 and 3);

- type of processing, which depends on the shape of the cutting edge of the cutter (straight, rounded);

- the presence of a protective device (with or without a protective grille).

Single-cut annular ballerina drills, in which the cutting element is secured with a screw on the bracket, due to the asymmetry of the design, cause beating during the operation, which affects the quality of the surface of the resulting hole.

The two-incisor ballerina is considered a classic option. The picture shows the appearance of the product. The fastening elements of such products are located on special holders. They are secured in the manner specified by the manufacturer.

In three-incisor models, the incisors are mounted on a round disk. They move along the slots with a mark of the value of the set diameter synchronously.

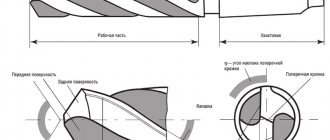

Ballerina design

- Centering drill.

- Working incisors (from one to three)

The main drill can be firmly fixed on the work surface (drilled) and prevent the tool from slipping when working with tiles or laminated surfaces. The cutters move in a circle and cut a groove in the working surface. The drill is driven using power tools (drill, machine, hammer drill) or manually (using a brace).

A tool with replaceable cutters is used to work with surfaces of varying strengths - from soft plastic to porcelain stoneware. The master can independently set the working cutters to obtain a hole of a given diameter. This operation can be performed using an adjustable wood ballerina.

Features of the device

The design of the device is simple, reliable and high-performance. A circular drill, or ballerina drill for cutting gaskets, consists of a central drill with a groove, a round or triangular shank, two carriages and cutters located on the arms of the bracket.

The purpose of the drill is to mark the center for the hole and provide support for the device during rotation. There are special markings on the bracket rod for installing the sliding carriage in the desired position. The cutters are fixed with screws, and the spread of the working edges is checked with a caliper.

A distinctive feature of a ballerina with one knife is the asymmetrical design and a noticeable lever that counteracts rotation, creating a high range of oscillation of the instrument. For this reason, experts recommend using the device on a stationary drilling machine. This will help prevent the work material from falling off and protect the worker.

The best option when working with a drill, screwdriver, hammer drill or rotary hammer is a system of two cutters that compensate each other in terms of balance during rotation. The disadvantage of the design is the rapid heating of the cutting part; the drill must cool down several times during the task. To maintain the functionality of the tool, it is recommended to maintain an operating mode ranging from 1000 to 1400 rpm.

Types of ballerinas

To work with materials of different densities and structures - soft and hard wood, plastic, plasterboard, concrete, stone, brick, porcelain stoneware - drills made from various grades of steel and having special designs are used.

For woodworking

You can drill a large diameter hole in a wooden surface using a 200 mm wood ballerina.

Before you start drilling in a wooden surface (especially laminated or veneered), you need to make a shallow hole with an awl. This will allow you to accurately comply with the specified dimensions. Drill at low or medium speeds (1000-1200 rpm) to avoid chipping at the exit (if necessary, drill a through hole).

To work with hard wood, use wood ballerina 40 (300). In some cases (hardwoods) a wood ballerina with a diameter of 30 200 mm mk is used (category Strong -stk, 057)

Drilling drywall

The design of the ballerina on plasterboard includes a centering tip and a rod attached above. The rod mount can rotate around its own axis.

At one end of the rod there is a disk cutter. It easily withstands several drilling cycles, holds tightly to the rod during operation and does not require sharpening for a long time.

For tiles

To drill hard tiles, a tile ballerina is used. The main difficulty in performing this operation is the need to cut through the glazed coating.

Immediately after this, experienced craftsmen advise drilling a groove on the back side of the tile. And then complete the drilling from the front side. For ballerinas on tiles 300 (057), a pobedit tip is often used, with which you can cut neat holes.

It is recommended to start working with a ballerina drill on tiles at low speeds (about 1000 rpm). And lubricate the drawn contour of the future hole with machine oil.

For porcelain stoneware

Porcelain stoneware is a very hard material. Working with him is always a difficult task. If it is necessary to cut a hole in porcelain stoneware, a ballerina with special cutting edges and a diamond tip is used. Its use extends the service life of the tool and significantly increases the speed of the operation.

On ceramics

When using a ballerina when working with ceramics, you should apply minimal physical effort. Ceramics is a fragile material. And even slight vibration can lead to cracks and chips. To avoid this, drilling should be carried out at low speeds (about 1000 rpm). Typically, diamond-coated tips are used for work.

For metal

A metal-cutting tool that makes it possible to obtain a hole with a diameter of 40-150 mm in sheet iron is a metal drill. Before starting the operation, a depression (up to 9 mm) is made in the center of the required cutout. It will be possible to install and securely fix the central axis of the ballerina.

For cutting gaskets

Car enthusiasts often encounter wear on the oil pump and overdrive gaskets. Of course, you can order and buy a new one in auto supply stores and online stores. But even in a home workshop, with the help of a ballerina, you can cut out a gasket from paronite. You need to have a sheet of paronite 0.5 mm thick, a measuring tool (ruler, tape), glue, several blades for stationery knives and a marker for marking. Place the worn gasket on the paronite sheet, glue it (without drying the glue) and trace along the contour.

To cut out the gasket along the outer and inner contours, a wood ballerina is used. Internal holes and grooves are cut with blades and finished with a round file or sandpaper.

For plastic

Plastic is a soft material and can be easily processed. But there is always a danger of cracking of the working surface. Therefore, when drilling plastic, you should not use much physical effort.

This material is quickly exposed to high temperatures and melts. It is necessary to work with it at low drill speeds (about 1000 rpm).

Compass ballerina

This type of drill is used for working with tiled surfaces. The design of the instrument includes:

- The pen tip acts as the main axis.

- Movable part (fastening mechanism, extension lever, cutting edge).

The cutting edge should be 5-8 mm shorter than the pen tip. This is due to the difficulty of processing tiles (there is a danger of the drill slipping).

You can use masking tape (adhesive tape) to firmly hold the markings. It also improves the adhesion of the drill to the surface, allowing it to be fixed on the drilling axis and make a central recess.

Due to the difficulties with sharpening a cutter made of hard alloys at home, a compass is considered a disposable tool. However, you can find sales of drills with replaceable bits.

Types by number of incisors

On sale you can find three types of drills, differing in the number of working cutters. A special bracket with a perpendicular tightening screw has a single-cut drill. Before starting the operation, the working cutter is simply set to a given length and tightened with a screw.

But in a double-cut ballerina, the bolts for fastening are located on the holders of the working cutters. The master sets them at the same distance from the central axis before starting work. The most complex design is a circular tile drill with three cutters. They are fixed on a circular platform and are aligned when moving along the grooves provided for this purpose.

Use of special drills

Special drills for ceramic tiles are used in cases where it is necessary to create a hole of small diameter. As such a tool, if you need it to make just a few holes in the tile, you can use a regular wood drill, sharpening it sharper, but a metal drill equipped with pobedit tips is better suited for these purposes. The resources of the latter, if it is provided with high-quality cooling, will be enough to make more holes.

Among the inexpensive drills for ceramics, with which it is convenient to create holes for dowel fasteners, spear-type tools should be distinguished. Using one such drill, the diameter of which can be up to 12 mm, you can create up to five holes in the tile. When using this tool, you should keep in mind that you can drill tiles with it only at low speeds of the drill.

Varieties of spear-shaped drills for tiles and ceramics

You can also drill tiles to accommodate dowel fasteners using drills equipped with carbide plates and toothed cutters. The latter differ from conventional carbide-type drills in that their cutting plates have a one-sided and sharper sharpening. The disadvantages of using such tools are that it is quite difficult to obtain a high-quality result with their help, and before drilling, the center of the future hole must be punched.

A pen tool for drilling tiles is more convenient to use. The advantages of such a drill are that before using it there is no need to pre-core the tile, and it is much easier to aim it at the center of the future hole. Using tile drills, the cutting part of which is shaped like a feather, you can make holes with a diameter of up to 30 mm.

The most expensive, but also characterized by the longest service life, are spear-shaped drills, the cutting part of which is coated with diamond. It is advisable to purchase such expensive and reliable drills when a large amount of work needs to be done with their help.

Tubular tile drills with diamond coating

Experts advise adhering to the following recommendations when drilling holes in tiles intended to accommodate dowel fasteners.

- Once the tiles already attached to the concrete wall have been drilled through their full thickness, the tile drill should be replaced with a concrete tool. In this case, the drill or hammer drill can be set to impact mode. This approach can significantly extend the service life of a drill designed for working only on tiles.

- To prevent accidental damage to a tile fixed to a concrete base when driving in a dowel, the hole in it must be larger in diameter than in the concrete.

- In order to drill a hole in the seam between two tiles without damaging them, you should choose a tool whose diameter is smaller than the width of the seam.

- When hammering in a dowel, you must act very carefully so as not to accidentally damage the surface of the tile.

Making a ballerina cutter

A ballerina drill significantly saves time when processing (milling) the contours of a cut hole. Processing is carried out automatically using power tools (drill, hammer drill).

Therefore, the physical effort expended when working with a ballerina is also insignificant. Given these advantages, home craftsmen want to have such a tool in their workshop. Moreover, making a ballerina with your own hands is not at all difficult for a competent craftsman.

For this you will need materials:

- Working (metal) plate with dimensions 200x25x4-6 mm.

- Bolts: M8 grade - 2 pieces (in addition to them you need to take 2 nuts and 4 washers) and M10 grade - 1 piece (in addition to them you need to take 2 nuts and 1 washer).

To work you will need tools:

- To mark the work surface: a marker and a ruler with centimeter divisions.

- Painting tape.

- Stationary machine or power tools (hammer, drill).

- Vise.

- File.

- Kern.

- Grinder equipped with grinding and cutting discs.

- Drills for metal with a diameter from 9 mm to 10.5 mm.

- Keys: open-end and adjustable.

- Screw clamps.

Step-by-step instructions on how to make it yourself

- Marking and processing of the work plate.

- Creation and processing of working grooves.

- Manufacturing of cutters.

- Connection of cutters to the working plate.

- Marking (gradation) of the finished drill.

- At the first stage, we cut a 20 cm long strip from the metal sheet. This will be the basis of the tool being created.

- Using a drill with a diameter of 10.5 mm, we drill a through hole on the machine in the pre-punched center of the work plate.

- Stepping back 1 cm from the drilled hole to the edges of the working plate (at the same level as the central hole), we make marks (punch) on the plate for future drilling.

- The distance between the marks must exceed the diameter of the holes that will subsequently be drilled. This precaution will help preserve the drill.

- Using a grinder cutting disc, you need to create two oblong grooves by combining the existing holes. The working plate is in a vice during this operation.

- Using a file (square or flat), we process the resulting holes. The free movement of the incisors will depend on the thoroughness of this operation (we remove irregularities, hangnails, and tubercles).

- Pressing the work plate tightly against the table (we use clamps or a vice), we smooth out all the irregularities and sharp corners with a grinding disc. We insert an M10 bolt into the central hole and screw one of the nuts onto it from the reverse side.

- We put the second nut (lock nut) on it and press it tightly using an open-end (or adjustable) wrench. To make the cutters, we wrap the upper parts of the M8 bolts with masking tape. We fix the bolt heads in a vice.

- Using a grinder's grinding disc, we cut off the thread, processing the bolt on both sides until a metal handle 4-5 mm thick is formed.

- The pointed ends of the bolt, shaped like a one-sided hook, will serve as the working cutters of the drill. The resulting cutters must be inserted into the grooves, having previously been laid with washers on both sides.

- This will increase the area of their contact with the working plate.

- The rod of the future tool and the cutters should be located in opposite directions. The thread sections remaining on the side surfaces of the bolts will allow you to screw on the nuts and secure the cutters tightly.

- Using a ruler and a marker, we mark the entire plane of the working plate, making marks every 0.5 cm. Later on these marks it is necessary to make notches that will be clearly visible during operation.

How the tile cutting process is performed

There is a certain algorithm that should be followed when using a tool for drilling holes in tiles, like a ballerina.

- First of all, on the front side of the tile it is necessary to mark the center of the future hole, for which you can use a regular core.

- The cutter or cutters of the ballerina, which will do the main work of cutting the material, are installed and fixed at the required distance from the axis of the central drill.

- It is advisable to lubricate the area of the tile on which the cut will be made with machine oil. In this case, you should make sure that it does not fall into the center of the circle, which can lead to the drill slipping.

- The drill, located and rotating in the center of the future hole in the tile, must pass through its surface before the cutters, so it must be longer than their protruding part.

- The tile in which the hole is made using a ballerina must be firmly fixed on a flat surface of a wooden board or drywall. To ensure such fixation, you can use ordinary clamps.

- Drilling the hole is carried out at low speeds of the tool, and it is advisable to constantly water the groove formed on the tile with machine oil.

- After the cut in the tile has been made to more than half its thickness, and the central drill has passed through the material being processed, the product is turned over and similar processing is performed on its reverse side.

- The tile is drilled to the end from the back side, and the edge of the resulting hole, which may not be too smooth, is processed using a file, emery cloth or a grinding machine.

Despite the fact that the holes made with the help of a ballerina do not have very smooth edges, it is quite reasonable to use it to perform not too voluminous work. In addition, the uneven edges of the holes will later be hidden by external panels of electrical outlets and other decorative elements.

Advantages and disadvantages

Working with a ballerina is not particularly difficult for a home craftsman. However, even when using a three-cut drill, special skills are required.

| Advantages | Flaws |

| Saves time when you need to make a large diameter hole Exact compliance with specified dimensions Carefully processing the contour of the drilled hole Saving physical strength | Possibility of vibration when working with a single-tip drill Wear and destruction of cutters Clamp screw breakage The need to take breaks during work, which prevents overheating of the nozzle |

Precautionary measures

- All parts of clothing (work apron, robe, shirt cuffs) must be secured (tied, buttoned).

- To prevent metal shavings and dust from getting into your eyes, you must wear work glasses.

- It is advisable to tuck long hair under a cap (beret, bandana).

- Rotating parts of drills and power tools (machine) must be securely fastened.

- It is advisable to use a ballerina equipped with a protective grille.

The working surface should be less hard than the steel from which the drill is made. Bring the already rotating drill to the surface. These tips will help extend the life of your tool.

How to choose the right one

When purchasing a drill, be sure to evaluate the configuration of the ballerina. Three-cut drills are considered the most reliable and in demand.

They have good mounting screws that firmly secure the working cutters. The length of the working cutters should be 4-5 mm less than the length of the centering cutter.

Some models use standard clamps to secure the incisors. They require a Phillips screwdriver and are much less reliable than models with hex screws.

- For drilling tiles, it is better to choose a ballerina with two incisors. With its help, you can make a hole with a diameter of up to 160 mm, whereas when working with a single-cut tool, the maximum diameter will be only 120 mm.

- A double-sided wood ballerina will allow you to make a hole with a diameter of up to 300 mm. And for working with thin (less than 5 mm) sheets of wood, a special drill is included in the kit.

- To work with hard surfaces (metal, porcelain stoneware, stone), use a one-sided ballerina. Before drilling begins, its central axis is securely clamped in the drill chuck.

On the brackets of branded ballerina models there is a ruler with clearly visible divisions. As a rule, the movement of the cutters is carried out synchronously. You should also pay attention to the width of the incisor run (it can be up to 150 mm). This parameter determines the radius of the future hole. Usually, the quality of the working surface (wood, metal, tile) is taken into account when choosing the permissible width of the cutters.

Some models are equipped with a protective plastic grid that holds large sawdust.

Criterias of choice

Before choosing a “ballerina”, you need to know its main advantages over other devices for cutting large holes, be it crowns, jigsaws, etc.

Advantages of adjustable circular devices:

- the ability to replace the central drill or lateral incisors at any time;

- reliability of design;

- if necessary, cutting elements can be sharpened;

- adjustable hole width.

Now let's look at the parameters you need to pay attention to when purchasing

- Reliability. It is unlikely that you will be able to determine this criterion visually, so it would be better to check the quality certificates for the products from the seller. For low-quality goods, they most likely will not be available.

- Workmanship. Before purchasing, you need to carefully inspect the device for shells, chips and other flaws. The cutters must be well and accurately sharpened. If the drill is very long, then you need to check whether it is even. Usually these defects are visible immediately and by eye.

- Package. Quality products from well-known manufacturers usually come with bright and good packaging. There will be no grammatical errors in the text accompaniment. None of the well-known brands can afford to package their products poorly.

- Price. Cost can also be considered an indicator of quality. Inexpensive models last a very short time.

Famous brands care about their reputation, and their products will meet all quality criteria. Therefore, it is better to contact official dealers so that the money is not wasted.

The following video talks about the ballerina drill.

Other tools used for the same purposes

Craftsmen can use several more tools to produce large-diameter holes. When drilling wooden surfaces (the diameter of the required hole exceeds 25 mm), you can use a Faustner drill.

Unlike a ballerina, it has a number of disadvantages:

- A large contact area with the working surface is accompanied by strong heating of the drill.

- It is difficult to align the central tip with the applied markings, because only the outer circle with the working incisors is visible.

- The Fostner drill bit is primarily intended for drilling blind holes (to hide the head of a nail if necessary).

- High price (due to the high heat resistance of the drill).

A hole saw is useful for drilling large diameter holes in hardwood, drywall, brick, and laminated surfaces. Some models of this tool are adjustable; you can set the required diameter yourself. When drilling hard surfaces (stone, porcelain tiles, concrete, tiles), you can use crowns. However, they are already produced with a given diameter. And the master has to buy several pieces of crowns or even a whole set. Such financial costs are not always justified. In addition, when working with crowns, a lot of fragments and construction dust are formed. Therefore, drilling using crowns in an already finished and furnished room is impossible.

Where and what drill is best to buy?

As for foreign-made tile drills, the domestic market offers mainly American, Polish and German models. Their price is much higher than domestic ones, and the packaging is more beautiful. In terms of quality, they are not much different from Russian ones. Therefore, there is no need to overpay. A separate price category consists of the so-called “professional” tile drills. Not everyone can afford them. But they are also very easy and convenient to work with. Their appearance is also simply amazing. The soldering of the plates is carried out with the highest degree of care and precision, the joints are almost invisible. The tip is sharpened in such a way that it is simply impossible to replicate at home. In addition, these tile drills also differ from ordinary ones in that they have a set service life, during which they cannot become dull. After its expiration, the drill loses its “professional” status and, after sharpening at home, can be used as usual.