The appearance of “saffron milk caps” on the car body is an extremely dangerous problem that requires an immediate solution. Otherwise, the metal under the chips will begin to succumb to oxidation, and the scratches will increase in size and deepen. Through holes will appear on the surface, and the body will lose its attractive appearance and strength. As a result, a seemingly harmless speck of rust will cause the need to completely replace the damaged part.

In addition, if you decide to sell a corroded car, do not count on a good deal: the cost of the car will drop by 2 or even 3 times. Therefore, you will have to replace the rusting elements, and this procedure is neither quick nor cheap.

It is very difficult to stop the development of the corrosion process, but in less advanced cases it is possible. The most common method for removing rust stains on a car body is to treat them with phosphoric acid.

What is phosphoric acid and how is it used?

Orthophosphoric acid is a powder that is diluted with water and is used in various industries, as well as medicine. The acid is used in diluted form, 85% aqueous solution, which does not have a pungent odor. The acid is used in the production of household products that are used to remove rust. It is also added to primer mixtures for metal. After treating the surface with orthophosphoric acid, a protective layer is formed that prevents the material from destruction.

Rust converter

A rust converter (rust modifier) is a solution of the same orthophosphoric acid, but with special additives. Depending on the additives, these drugs are divided into several groups:

- primers,

- modifiers-stabilizers,

- rust converters.

An example of the first group is the EVA-0112 primer, which consists of two components - a base and 85% acid. It is used as a base for paint for steel products. The Tsinkar converter also contains orthophosphoric acid with the addition of zinc and manganese salts. Thanks to these additives, a hardened protective layer is obtained from the converted rust (metal alloying effect). Before using the converter, you must read the instructions, and the composition can only be used in accordance with the manufacturer’s recommendations.

Basic precautions when working with phosphoric acid

When removing rust chemically, it is necessary to protect the respiratory tract and hands; for this, use a respirator and gloves. Since the evaporation of acid can cause burns to the respiratory tract and skin. In addition, the product is a fire hazard, so when working it is necessary to ensure good ventilation in the room. If acid gets on the skin, you must immediately rinse the area with plenty of water for about 15 minutes. If the damage is significant, you should immediately visit the hospital. Do not wipe the product with a napkin or towel.

How to make, what is included?

Any converter must contain two main substances that react and form a protective film on the metal surface.

The step-by-step algorithm for manufacturing a home converter is as follows:

add 1.3-1.5 liters of citric acid to 1 liter of water;- stir the solution to distribute the acid evenly;

- add 15 g of baking soda to the lemon liquid, mix;

- wait for the end of the chemical reaction (this is about 40 minutes);

- pour the converter into a convenient-to-use bottle.

Citric acid can be replaced in the recipe with oxalic acid. The technology for preparing anti-rust with this organic acid does not change.

How to properly remove rust using phosphoric acid

The advantage of phosphoric acid is that it removes loose rust and also forms a thin layer that serves as protection. The acid is capable of corroding rust and providing a protective film in the form of an oily surface.

Methods for removing rust depend on the degree of damage:

- cleansing of elements by complete immersion in the product;

- surface treatment using a roller or spray;

- applied to metal products after mechanical cleaning.

Tips for choosing a rust remover

When choosing a product to remove traces of corrosion, you need to proceed from the situation. If you plan to clean surfaces using the immersion method, you will need a lot of acid. In this case, it is recommended to purchase 85% phosphoric acid. If there is a need not only to remove rust, but also to create a protective film under the paint, then you won’t be able to make the solution yourself. In this situation, it is more correct to purchase a factory-made converter, which contains all the necessary additives.

In addition, you need to know whether the surface is planned to be primed. Converter-modifiers improve the inhibitory and hydrophobic qualities of the primer composition, but still do not belong to primers. In such cases, priming converters will help, after processing, with which a paint and varnish composition can be applied to the surface.

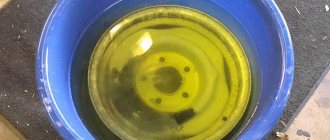

Purification of elements by complete immersion in phosphoric acid

If you have a sufficient amount of the product, you can use the full immersion method to remove rust. To do this, you first need to degrease the element to be cleaned using a detergent composition, and then wash it thoroughly. After this, pour 100 grams of an 85% acid solution into the prepared container and add 1 liter of water. The element to be cleaned is immersed in the solution for one hour, stirring the product periodically. Then the product must be removed and washed well. After such cleaning, the product is washed with another solution consisting of 50% water, 2% ammonia and 48% alcohol. Then the product is washed again with plain water and dried. All stages must be performed in strict sequence. If you do not degrease the product, the cleaning will be uneven, since the product may not corrode normal stains, and additional cleaning will be required. In this way, you can clean any products with varying degrees of rust, but the thicker the coating, the more time you need to keep the element in the solution. If the element is not dried after washing, hydroxide appears on it. Drying can be done using any method.

Which is better to choose?

When choosing a rust remover, you need to focus on the place where it will be used. Full immersion cleaning of parts requires a large volume of acid. Here, the purchase of orthophosphoric acid of 85% concentration will be justified from both a practical and economic point of view. If you need to not only remove rust, but also create a protective layer under the paintwork, then a self-made solution will not work. In this case, it is better to buy a factory converter with all the necessary additives.

You also need to consider whether a layer of primer will be applied or not. Converter-modifiers increase the water-repellent and inhibitory properties of the primer, but are not primers themselves. But after treatment with the converter-primer, you can immediately coat the metal with paint.

In conclusion, I would like to focus on the fact that phosphoric acid creates a protective layer during the interoperative period. That is, without paint coating, the metal will be susceptible to corrosion.

Cleaning rust by applying phosphoric acid to the surface

If the product cannot be immersed due to its size or there is a small amount of product available, then the method of applying acid to the surface with a spray, roller or brush is used. But first it is necessary to indicate the extent of the damage.

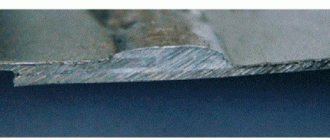

If there is significant plaque, you must first remove the top layer using a grinder and a metal brush. Then the surface is degreased and a solution of orthophosphoric acid is sprayed. In this case, the solution should be applied to the entire affected surface, without gaps. After two hours, wash the area with a neutral solution. At the end, a final rinse is performed and the treated area is thoroughly dried.

If the rust layer is small, you can skip cleaning with a brush, but immediately begin degreasing and applying the solution. But re-spraying may be required if cleaning is not complete.

Using orthophosphoric acid, you can clean bathtubs, washbasins and toilets; it completely cleans rusty deposits on enamel surfaces. For products made of acrylic material, such cleaning is not acceptable.

For enameled and earthenware products, you need to dilute 100 grams of acid with 500 milliliters of water. First, the surface is degreased using a detergent and thoroughly cleaned from household contaminants. Then apply acid and wash it off with soda solution. To do this, dilute 1 spoon of soda in a liter of water. In this case, no friction is produced, as a result the enamel surface retains its integrity.

When using acid, do not allow it to come into contact with the skin, otherwise it is necessary to rinse the area with water for a long time.

Pros and cons of a homemade product

The anti-rust product, made by yourself, has a number of advantages. However, it cannot completely replace professional converters. Due to the existing disadvantages, many users prefer ready-made store-bought chemicals. For an objective assessment, it is necessary to consider both the pros and cons.

Homemade composition is valued for the fact that it:

It is not toxic to humans, as it consists of harmless substances.- Does not require very complex and time-consuming manufacturing technology.

- Has simple and clear instructions for use.

- Helps achieve rust removal and coating protection.

- It is much cheaper than branded analogues.

The disadvantages of a homemade converter make its use limited and reduce its popularity among motorists, housewives and production workers.

The weak points of the homemade corrosion modifier are:

- The need to find a convenient container and method of application.

- Can only be used with a thin layer of rust.

- Lower efficiency compared to special means.

- The need for mandatory coating of the product with paint or varnish.

How to properly store and transport phosphoric acid

Phosphoric acid is an aggressive agent, so it is necessary to follow certain rules when transporting and storing this substance. The powder must be placed in an airtight container. To prevent foreign elements from getting into the acid, all containers must be used clean and dry, then the prepared solution will be of high quality.

Preparing a low-quality composition can result in dangerous vapor poisoning or lack of the desired result. Store containers with acid in a dry and warm place where there is no dampness or condensation. There is no need to pour the powder into another container; it is better to leave it in the original packaging. Such cargo is considered dangerous, so special documentation is required to transport it over long distances.

Rules for transporting acid

Acid can be transported with strict adherence to the following precautions:

- the packaging must be chemically inert (preferably plastic - glass cannot ensure safety during transportation due to its fragility);

- the container must prevent spilling or evaporation of the liquid preparation or scattering of crystals;

- It is necessary to exclude the possibility of foreign moisture or dust getting inside the package.

Important! Safety signs must be placed on the outside of the container.

Recommendations for cleaning products with phosphoric acid

Cleaning is done with care so that the metal surface does not become too thin and holes are formed. During preliminary mechanical cleaning, disks with large elements cannot be used, otherwise significant damage to the surface can be caused.

Before starting the main work, the remaining surface must be covered with film, since exposure to such a strong product may damage the rest of the coating. Therefore, processing must be carried out carefully so that the damaged surface does not have to be restored, which will lead to additional costs.

If the work is done correctly, the result is a reliable and durable surface that does not contain rust stains, which lead to the destruction of metal products.

When applying orthophosphoric acid to a surface, it is necessary to wear gloves and a respirator; they serve as means of protection against the harmful substance. If acid gets on clothing, it must be removed immediately so that the product does not get on the skin and cause a burn.

How does it work

The process is simple. You buy a converter; it usually comes in spray cans. Next, it is sprayed onto the site of the outbreak, then it is advisable for us to leave this place for about half an hour - an hour.

The product does not remove rust at all, if I may put it roughly, it freezes it and prevents it from spreading further. An iron phosphate film forms on the affected surface, which is a protective element. The work period is approximately one to two years, then it is advisable to repeat the procedure.

I would like to note from personal experience that my uncle is a minibus taxi driver and works on his minibus almost every season before winter. And you know, it really rots less when compared with untreated neighboring cars along the route.

But we are wondering whether it is possible to produce it with our own hands, what is the approximate composition. I’ll say right away that there are two compositions, the one that is used in production, and the one that is made at home.

Basic rules when using phosphoric acid to remove rust

- Before starting the main work, it is necessary to prepare all protective equipment, since the substance is aggressive and leaves burns if it comes into contact with the skin.

- First, the surface must be cleaned of normal contaminants so that the product can perform its functions fully, otherwise the surface will be cleaned in parts.

- If the rust layer is too thick, then it is necessary to resort to mechanical cleaning of the surface; for this, use a grinder and a metal brush.

- The cleansing area must be degreased and then rinsed with water so that the product adheres well and works effectively.

- After finishing the cleansing, the acid must be washed off with a neutral solution and then with water.

- Since the substance is aggressive, it can damage the main surface, so it must be covered with film.

- If it is not possible to clean by immersion, then use sprayers or apply acid with a brush or roller to the rusty surface.

- If the surface is not clean after the first application, additional spraying will be required. After this, the area to be cleaned must be washed with a neutral solution and then with water.

- Phosphoric acid cannot be used to clean rust on acrylic surfaces.

Can it be done at home?

The purpose of any rust converter is to convert iron oxides into inert compounds that form a hydrophobic film on the metal surface.

In order to achieve this goal, manufacturers select a specific chemical composition. Each company has its own secret nuances, which it tries not to disclose , so as not to provoke the creation of fakes.

In addition, the converter may include:

- tannins (convert iron oxides into neutral tannate complexes);

- zinc compounds (after reaction with phosphoric acid forms a protective layer);

- corrosion inhibitors (form an additional film, slowing down the corrosion process).

At home, it is easy to find analogues of the main active ingredients and prepare a simple but effective converter. It is prepared from a smaller number of components by conventional mixing in a container.

Benefits of Phosphoric Acid for Rust Removal

- Orthophosphoric acid removes rusty deposits well on enamel and earthenware products, on metal surfaces, and is actively used in the automotive industry.

- Using this product you can remove rust without rubbing the surface, this helps preserve the enamel.

- Phosphoric acid forms a film on the cleaned area, which serves to protect the surface from new corrosion and other damage.

- This acid can be used to clean bathtubs, toilets and washbasins, as well as other household appliances that have a similar surface.

- Phosphoric acid helps remove rust stains and subsequently protect the surface from corrosion damage.

When working with acid, it is necessary to wear protective equipment, a respirator and gloves, as the substance is aggressive. Before applying acid, the surface must be degreased using detergents, then rinsed well with water, and then sprayed with acid. After the required time has passed, the acid is washed off with a neutral solution based on alcohol, ammonia and water. After this, the surface is washed with water and dried. If the rust layer is too thick, then it must first be cleaned with a metal brush or grinder with a special attachment. The work must be performed in the correct sequence; if you skip at least one step, this will lead to poor quality cleaning.

Areas of use

Phosphoric acid and its derivatives have found wide application in a wide variety of areas of human life. Among the main directions are:

- Production of simple phosphorus (superphosphate and phosphate rock), complex and complex mixed fertilizers.

- The use of feed phosphates as one of the important additives in agriculture makes it possible to increase the average daily weight gain in pigs and bulls, and increase milk productivity and egg production.

- Esters and salts are widely used in the manufacture of additives for water softening and synthetic detergents, and are part of surfactants in the manufacture of cement. They bind calcium and magnesium ions, which are responsible for hardness and worsen the quality of washing.

- In foundry production and metalworking, orthophosphoric acid has been used for rust - for phosphating, as a flux for soldering on stainless steel, ferrous metals and oxidized copper, for polishing and cleaning surfaces.

- In the textile industry - for fire-retardant impregnation and dyeing of wool and leather, natural and synthetic fibers.

- In chemical production, it serves as a catalyst for organic synthesis and raw material for reagents.

- In the aerospace field, its esters are components of the hydraulic fluid of aircraft engines and rocket fuel deicers.

- In the mining and oil industries, sodium phosphates are used to enrich ores and prepare drilling slurries.

- In freezing units it is part of freon. It is also used for the manufacture of various brands of special glasses, including optical glasses, ceramics and porcelain, photosensitive emulsions for photographic paper and film.

- In the production of refractories, phosphates serve as fillers for refractory concrete, raw materials for phosphorus wood boards and non-combustible foam, fire-resistant paints and materials (varnishes, paints, enamels, primers and impregnations).

- In medicine, its solutions are used to prevent urolithiasis and stomach problems. In dentistry, it is used for the manufacture of cements, compositions for etching tooth enamel and treating the internal surfaces of crowns.

- The woodworking industry has found application in the fact that impregnation with phosphoric acid makes the material non-flammable - it imparts fire resistance. For example, when making matches, aspen sticks are impregnated with a 1.5% solution to prevent smoldering.

- In the food industry, the E338 additive regulates acidity, increases shelf life, preserves flavor characteristics and enhances the effect of antioxidants. It is widely used in baking powders, processed cheeses, carbonated drinks, baby formula, marmalade and cakes, sausage production and sugar production.