The concept of “precious metals” includes gold, silver and platinum group metals.

Due to their high chemical inertness, they do not oxidize or corrode, thereby maintaining their characteristic shine and visual appeal.

Historically, precious metals have been used to make jewelry, and the high cost has placed gold and platinum in the same price range as precious stones.

In our age of high technology, precious metals are widely used in the production of products for the electronic, radio engineering and space industries, in the manufacture of laser technology and medical equipment, household appliances, computers and various gadgets.

Many parts included in hi-tech equipment contain precious metals in microscopic quantities.

Modern technologies for extracting this valuable material from secondary raw materials have turned the recycling of precious metals into a highly efficient production, surpassing in its profitability the extraction of gold, silver and platinum group elements from primary natural raw materials.

What it is?

Noble metals are distinguished from other elements by their ability to maintain their molecular structure under the influence of an unfavorable environment.

They cannot be decomposed, and the melting point of these elements is extremely high. They do not react with oxygen and do not produce oxides. Alloys with precious metals can only be obtained through complex chemical manipulations using the strongest reagents. The mass share of precious metals in the total production of natural resources is very small, which explains the high price of these elements, as well as their special status.

A complete list of names of precious metals was prescribed in 1998 in the Federal Law “On Precious Metals and Precious Stones”. According to Russian legislation, platinum and five of its group metals, as well as the popular silver and gold, are considered precious.

List of precious metals

The list of precious metals is presented in GOST R 52793-2007 “Precious metals. Terms and definitions" and legalized by the Federal Law of March 26, 1998. for No. 41-FZ “On Precious Metals and Precious Stones” (Article 1).

According to GOST R 52793-2007 (section 2), only 8 are considered precious metals, here is a list of them:

- gold;

- silver;

- platinum;

- palladium;

- iridium;

- rhodium;

- osmium;

- ruthenium.

As you can see, the list also includes silver, this will be interesting to know for those who are wondering whether silver is a precious metal.

Which metals are noble and their properties?

This group of metals received the name “noble” due to their special characteristics. Depending on the variety, their physical and chemical properties may manifest themselves to varying degrees, but they always remain unique.

Rhodium

Rhodium is a member of the platinum group. It is a light metal and has a pale blue color. It is distinguished by a high degree of hardness and, at the same time, fragility.

Valued for its high reflectivity and resistance to chemical attack. Rhodium can only be oxidized with hot sulfuric acid. The melting process begins when heated to almost 2000 °C.

Platinum

Because of its white luster, platinum, discovered in the mines of America, was originally called “silver.” Only in 1751 platinum received the status of a precious metal, and its value instantly surpassed the then known silver and gold. It has high ductility and can be easily forged (which is why it is loved by jewelers). At the same time, platinum is harder than gold, refractory, resistant to chemical influences, and not subject to oxidation.

Gold

Like platinum, it has good ductility and malleability, but has lower melting points. Reacts only with aqua regia, invulnerable to alkalis, salts and acids. In nature, specimens of pure gold with a pronounced yellow color and characteristic shine are rarely found. Most often, miners encounter green faded ore.

Osmium

The most refractory of the noble metals. The melting point reaches 2700 °C. In addition, osmium does not dissolve in acids. External characteristics are white and hard. Belongs to the group of heavy metals.

Iridium

Like osmium, it is a heavy metal. The most durable, dense, refractory and insoluble in acids, gray-white in color. The melting point is slightly lower than that of osmium and is 2454 °C.

Ruthenium

In terms of external characteristics, ruthenium can easily be confused with platinum. The noble metal resembles iridium in its melting point and has increased strength and density. It is interesting that only ruthenium and osmium form water-soluble cakes under the influence of alkali, oxidizing agent and high temperatures.

Palladium

Soft, malleable, white with a silver tint. When heated to 860°C, palladium forms oxides, but becomes pure again as the temperature rises further. The melting point is 1554 °C.

Silver

Among the noble metals, silver has the lowest density and a relatively low melting point - 960 ° C. It is best forged and serves as an excellent heat and electrical conductor. It practically does not react with acids, but darkens under the influence of hydrogen sulfide, which is part of the atmosphere.

List of semi-precious metals

In jewelry production and instrument making, metals are actively used that are not essentially precious, but have a certain value. They are conventionally called semi-precious. Among the most popular types are the following:

- titanium;

- tungsten;

- cupronickel

Their price fluctuates in the average price range and does not exceed $2 per gram.

List of precious metals

The following precious metals are known:

- Gold.

- Silver.

- Platinum.

- Rhodium.

- Osmium.

- Iridium.

- Ruthenium.

- Palladium.

Some scientists identify another element that can be classified as a noble metal - technetium. However, due to its radioactivity, it is not included in the general classification.

Each of the materials occurs in nature either in the form of nuggets or as part of ores or alloys. There are not so many deposits of precious metals throughout the Earth, so their development is carried out under the strict control of those state enterprises on whose territory they are located.

Positive aspects of recycling

The main positive aspects of using the so-called “secondary” precious metals are the following circumstances :

- Unlike natural mineral raw materials used for primary mining and extraction of precious metals, secondary raw materials, represented by scrap gold, silver or platinum group metals, are much richer in the content of precious metals.

- Due to the increasing growth in the consumption of computer equipment, radio and television equipment, various gadgets, office equipment and household electrical appliances, the number of those that fail or are rejected during production or warranty service, which inherently serve as an endless source of precious metals in the form of recyclable materials, is correspondingly increasing. At the same time, the painful issue of recycling monitors, televisions, computers and other products that are subject to disposal in specialized organizations is being resolved.

- Precious metals recycling technologies do not require large production areas and have fewer technological stages compared to primary mining.

The gold content in secondary raw materials, depending on the type of scrap, can range from 1% to 50% by weight; for silver the figure is somewhat more modest - from 0.1% to 15%. This means that 100-200 kg or more of the precious metal can be extracted from 1 ton of gold scrap.

Main characteristics and features

So, the eight existing noble metals are united by similar physical and chemical properties, which, in addition to resistance to oxidative and corrosive processes, include:

- softness;

- high plasticity;

- incredible strength;

- excellent thermal conductivity;

- high refractoriness (except for silver and gold);

- good ductility;

- excellent electrical conductivity.

Also, among the characteristics of substances of the noble category, it is worth especially noting their beautiful appearance. Thanks to the highest chemical resistance, products made from such materials retain their attractive, shiny appearance for a very long time.

For comparison, the most striking counterexample is copper. The initial appearance of products made from this base metal is practically not inferior to jewelry in terms of bright shine and beauty. But the attractive appearance disappears very quickly - upon contact with air, the element reacts and the oxidation process begins. As a result, a kind of film or, in other words, plaque is formed on the surface of the metal, which is why the product becomes dull and changes its original shade.

Representatives of the precious metals of the noble group constitute a single category of elements. But, of course, each of them has its own individual characteristics.

Gold (aurum)

A truly unique element is the only metal in existence that, in the form of a pure substance, has such a bright, expressive yellow color. The chemical resistance of gold is noticeably higher than that of its “comrades” in the noble category.

Even such well-known destroyers as:

- alkalis;

- salt;

- acids;

- high temperatures;

- moisture.

The density of gold is 19.3 g/cm3. This substance is one of the densest and heaviest among metals. The melting point of the metal exceeds a thousand degrees Celsius.

Silver (argentum)

This light gray metal stands out among its peers due to its excellent reflectivity. Silver, of course, is inferior in weight to gold. The same applies to density - it reaches only 10.5 g/cm3. The melting point is 962 degrees Celsius.

There are two types of acids with which silver reacts:

- salt;

- fluorescent

Resistant to moisture. But it darkens under the influence of hydrogen sulfide in the air.

Platinum and “subsidiary” representatives

A worthy rival to gold for the title of heaviest metal. The density of platinum is 21.5 g/cm3. This white-silver shiny substance melts at a temperature of 1773 degrees Celsius.

Representatives of the platinum group and their individual properties:

- Palladium (palladium). Unlike other noble representatives, under certain conditions this silver-colored substance still oxidizes. These conditions consist of heating in the temperature range of 300−860 degrees. However, if you exceed the upper threshold, the resulting oxide deposit will disappear, and the metal itself will become even lighter. The density of the substance is 12 g/cm3. And palladium melts at a temperature of 1554 degrees Celsius.

- Rhodium. The bluish substance has good reflectivity almost on par with silver. A hard but rather brittle metal. Its density is 12.4 g/cm3. The temperature required to melt rhodium is 1962 degrees Celsius.

- Ruthenium. Outwardly, it is almost identical to platinum, but in its properties and characteristics it is close to rhodium. In particular, this concerns density. In terms of melting point, among all the noble group metals it is second only to osmium and iridium. For ruthenium it is 2330 degrees Celsius.

- Iridium. The gray-white substance is identical in properties to ruthenium and rhodium. But in terms of density it surpasses even platinum - for iridium this parameter is 22.4 g/cm3. In terms of melting point, this metal is one of the top three among the elements of the noble group (together with ruthenium and osmium). Iridium melts at 2466 degrees Celsius. This substance is the most resistant metal. It is not affected by acids, salts, or any chemical elements.

- Osmium. The white substance is completely impossible to dissolve in acid. This is the absolute champion among noble substances both in heaviness and density, and in melting point. The latter in osmium reaches 3035 degrees Celsius, and the density is 22.5 g/cm3.

Characteristics of precious metals

Let's look at the main characteristics of precious metals:

- Gold, or aurum (Au) is element 79 of the periodic table, a metal with a natural luster and yellow color. It has a density of 19.32 g/cm3, melts at a temperature of 1064°C. Gold is highly ductile, easy to process and shape, and is not subject to corrosion. It can only be dissolved in a mixture of nitric and perchloric acids in a ratio of 1:3.

- Silver, argentum (Ag) is in 47th place in the periodic table of chemical elements and has a characteristic white color with a shine. The density of silver is 10.5 g/cm3, and it can be melted at 961.9°C. Among the advantages of silver are its ductility and ductility, ease of processing and forging, as well as thermal and electrical conductivity and reflectivity (up to 95%). Despite its resistance to moisture, silver can react with acidic and alkaline environments, as a result of which it begins to become covered with a black patina.

- Platinum (Pt) occupies position 78 in the periodic table. The metal is white and shiny. Platinum has a higher density (21.45 g/cm3) and melting point (1772°C). In addition, the metal is insoluble in any liquids except aqua regia (a mixture of perchloric and nitric acids). Platinum is flexible and stretches well, although it is a refractory material. In addition, it does not oxidize and is not susceptible to chemical reagents. This metal is not found in its pure form; it can only be isolated from alloys with noble and base non-precious metals.

Product marking

In the production of technical products for various purposes and jewelry, precious metals are used exclusively in the form of alloys with other metals.

Precious metal alloys get their name from their main component (gold alloys, platinum alloys, etc.). The main materials used for jewelry are gold, silver, platinum and palladium.

Other platinoids (rhodium, osmium, iridium and ruthenium) are added to precious metal alloys in order to adjust the physical and technical properties of the product being manufactured - color changes, ductility and hardness, heat resistance and melting point.

To identify products containing precious metals, markings are used (from German markieren - to put a mark, a symbolic mark) with marking information applied in the following ways:

- using a mark (branding) directly on the surface of the product - for jewelry;

- entries in product passports, forms, labels, operating manuals, reference books and catalogs.

Purpose and methods of branding

According to the “Regulations on hallmarking and hallmarking of products made of precious metals...” (Decree of the President of the Russian Federation dated October 2, 1992 No. 1152), all jewelry and household products made from precious metals for sale must be branded with the state hallmark (clause 2 ).

The mark is applied only when the jewelry is made in accordance with all official canons and meets state quality standards.

The absence of a mark clearly indicates that it has not passed the inspection of the state inspection service, or was simply not presented to it and is being sold in circumvention of legal regulations.

Another marking on the product is the name tag, which is an imprint designating the manufacturer who manufactured the product.

Selling jewelry made of precious metals without a name stamp and inspection by the assay service is illegal.

At its core, hallmarking is an assay-technological operation of applying an hallmark to products made of precious metals. The method of its application is determined by the degree of complexity of the shape and purpose of the product on which the marking must be applied.

Currently, three branding methods are used:

- A mechanical or impact method of applying a mark, based on mechanical action on the surface of the jewelry (hitting a tool with a mark on the tip with a hammer after applying the mark to the surface of the product). Until now, about 80% of all products made from precious metals are branded in this way. Only the hammer has been replaced by automated stamping machines.

- Electroerosive or electro-spark method, which is essentially the burning of a mark with an electric spark. This branding technique is convenient for working with fragile hollow products. About 10-20% of all jewelry products are branded using the electrospark method.

- Laser method, in which the outline of the mark is applied with a laser. This mark is small in size, but has clear outlines. It is considered the only way to brand convex and concave hollow products.

How to read the mark?

The mark consists of two marks, which are either applied separately or presented together on one print:

- images of the sample mark;

- identification design - a five-pointed star with a hammer and sickle (for products produced before 1994) or a female head in a kokoshnik with a profile turned to the right for products of a later release, as shown in the table below.

The presence of an identification mark indicates that it has been assayed and stamped by the Assay Supervision Inspectorate.

The shape of the mark depends on the type of noble alloy. Below are sketches of hallmarks:

Analysis

The noble metal analyzer aims to answer two main questions:

- what kind of raw material is in front of us: pure precious metal or an alloy with an insignificant content of a noble element;

- what is the percentage of precious metal in the alloy mass presented for analysis.

The first sample is qualitative, the second gives a quantitative result. They are performed in strict sequence, one after another. After conducting a qualitative test, establishing that the alloy actually contains a precious metal, you can proceed to determining its quantity. If, when examining the analyzed sample by reacting with assay acid, nothing remains, then it is a base metal.

The results established during the examination were reflected in the samples. This is a numerical marking; it shows the percentage of precious metal in the presented alloy.

However, it should be borne in mind that the test in Russia is not applied to all alloys, but only to those in which the concentration of the noble element is more than 30%.

Natural mining and production

The share of precious metals in the production volume of the global mining industry is only 0.00005%. The content of noble elements in the earth's crust is small; accordingly, the volumes of their extraction are not comparable with the development of other minerals. For example, less than 30 tons of rhodium are mined annually .

However, taking into account the high prices of gold, platinum and other precious metals, the cost of mined precious metals exceeds 5% of the value expression of the volume of production of all minerals.

That is, it is reasonable to estimate the cost of mining precious metals in a proportion that is 100 thousand times higher than the cost of mining any other natural raw material (except diamond).

The extraction of gold and other precious metals plays a special role in the state development system, since the available reserves of precious metals determine the strategic state of the gold and foreign exchange reserves of any country.

With the development of technologies for extracting precious metals from various types of raw materials in industrialized countries, three areas of production have emerged, each of which contributes to the replenishment of state gold and foreign exchange reserves:

- Primary mining associated with the extraction of precious metals from ore and the production of concentrated (enriched) materials, as well as the processing of industrial waste.

- Associated production associated with the extraction of precious metals from polymetallic ores mined for the production of non-ferrous metals.

- Recycling, which is the recovery of primarily gold, silver and platinum from scrap precious metals and waste.

In the Russian Federation, gold production indicators for 2014 were as follows :

- primary production – 232185 kg;

- associated production – 16880 kg;

- secondary production – 38913 kg.

Let's show similar indicators for silver for 2014:

- primary production – 510272 kg;

- associated production – 287978 kg;

- secondary production – 249139 kg.

There are several articles on the topic of independent mining of precious metals on our website:

- Search magnets for gold and silver.

- Metal detector for gold and silver mining.

- How to look for gold with a metal detector.

- We make a metal detector with our own hands.

Areas of application

Noble metals are widely used in a variety of fields. Here are just a few of them

Electrical engineering

Unique physical and technical characteristics in tandem with chemical and biological inertness make it possible to create effective protection of electrical contacts from burning and oxidation. This makes the metal safe and practical for use in electrical engineering.

It is no coincidence that alloys of most precious metals are in widespread demand in the manufacture of high-precision instruments.

Silver salts (chlorides and bromides) are used to create photosensitive elements. Solders made from noble metals are in demand when creating electrical devices, which are subject to increased reliability requirements. The rarest elements are used to create thermocouples and other heating elements.

Jewelry

From time immemorial, precious metals have been in demand in the jewelry industry. They are used to create exclusive chains, earrings, bracelets, rings, pendants, crosses, as well as eyeglass frames, expensive cigarette cases and many other products. Jewelers highly value the color, exquisite shine of metals, as well as their unique properties.

Precious metals do not react with human skin, so they do not lead to skin diseases and allergic reactions. It is allowed to use noble metals as a coating layer for jewelry made from cheap metals. Such jewelry delights its owners for many years and is often inherited from generation to generation.

Chemistry

The resistance of precious metals to acid-base compounds, as well as catalytic parameters, make their use in the chemical industry relevant. They are used to create equipment for aggressive compounds. Many of these metals are used as catalysts in the production of gasoline.

Automotive industry

Catalysts are also used to create exhaust devices. That is why noble metals are in demand in the manufacture of auto parts. They allow you to quickly and reliably neutralize toxic chemical compounds. Most often, palladium and rhodium are used for these purposes.

Medicine

Biological and chemical inertness make it possible to use noble metals in the production of surgical instruments and all kinds of parts for medical equipment. Many metals are in demand in prosthetics and dentistry. A number of compounds have become widespread in the manufacture of medicines as an integral component.

Space Science

Precious alloys are relevant in the construction of aircraft and spacecraft, since only they can ensure maximum reliability and safety of these systems. Only a noble metal can cope with the loads that a space station may experience in orbit.

Glass industry

Precious metals have also found their use in glass production. Very often they are used to make glass melting tanks.

Banking sector

It is also impossible not to mention the role of precious metals as a monetary exchange measure. In ancient times, gold and silver were used to make coins, although nowadays silver has already lost its function in this circulation. And yet investment bars are still cast from gold and platinum to this day.

This allows everyone to invest their free funds with high profits. As practice shows, traditional currency depreciates over time, while gold bars invariably remain in value.

Nowadays, anyone can invest their savings in precious metals of the highest standard.

Many banking and financial organizations even offer depositors to open special metal accounts. These are profitable investments, since in the long term the owners of such bullion can make serious profits. Metal accounts have only one drawback - the lack of a deposit insurance system, which can entail considerable risk if the bank goes bankrupt.

Spheres and areas of use

The unique inimitable qualities of these substances have led to their use in a wide variety of industries and areas. Even the high cost of such materials did not prevent this.

Of course, the first thing precious raw materials are associated with is jewelry. Jewelry and other items made from such metals are in great demand, which is understandable. It is not only beautiful, but also profitable. Jewelry has always been an excellent investment.

No less famous is the use of noble materials as currency . However, in the modern world, coins made of such metals are an object of investment or collecting. In the field of investment, precious metals are invariably popular and in demand. This is especially true for gold.

In addition, these elements are widely used (for the manufacture of complete products, individual parts, and so on):

- in the production of various equipment and electronics, including microtechnology;

- in aviation and astronautics;

- in mechanical engineering (from various units to cars);

- in the production of radio equipment;

- in the chemical industry, including the laboratory sector (from glassware to equipment);

- in medicine;

- in the production of various protective coatings for absolutely any surface (from rockets and equipment to mirrors, pipes, ceramics, metals and wood);

- in the film and photographic industry;

- in the production of watches and watch movements.

Moreover, in medicine, noble metals are used not only for the manufacture of instruments and medical equipment, but also in the production of medicines . And this is not all - it is impossible to list all the areas and areas of application of precious materials.

Substances classified as noble play an extremely significant role. They are found every day in some form and are used in almost every industry. One can only guess what the life of mankind and the world around will become when the natural reserves of these metals run out.

Noble metals from the platinum category

Five more types of precious metals come from the platinum category:

- Palladium (Pd) is the 46th element of the periodic table and has a silvery-white color. The melting point is 1552°C, and its density is 12.02 g/m3. This is the metal with the smallest mass among others from the platinum category. At the same time, it is extremely resistant to aggressive environments and chemicals. Other advantages of palladium include ductility, ease of processing and polishing, and the ability to retain shine.

- Rhodium (Rh) is a white metal with a blue tint, located at position 45 of the periodic table. Among the chemical characteristics, its high density is noted - 12.42 g/m3, as well as its melting point - 1960 ° C. This is one of the refractory metals; along with sufficient hardness, it is also brittle. Rhodium is highly reflective and resistant to water, oxygen, and is not affected by any acids. Only alkaline cyanide mixtures dissolve rhodium.

- Ruthenium (Ru) is an element of the periodic table with atomic number 44. This metal is white in color with a silvery tint and its appearance is very similar to platinum. However, it is distinguished by great hardness with simultaneous fragility, as well as very difficult fusibility. Ruthenium melts at 2950°C, and its density is 12.37 g/m3. A distinctive feature is its resistance to chemical attack. It is the rarest of the platinum group metals.

- Iridium (Ir) is a precious metal located at 77th place in the table of chemical elements, colored white with a gray tint. The main qualities of iridium are high refractoriness, brittleness and at the same time increased hardness. The density is 22.42 g/m3, and the melting point is 2450°C. This is the reason for the difficulties in processing it, since it can only be worked under high pressure and at high temperature. In addition, this metal does not interact with any chemical compounds, be it alkalis, acids or mixtures thereof.

- Osmium (Os) is an element from the group of platinum metals, occupying 76th place in the periodic table. This material is the most difficult to process, extremely brittle, but at the same time it is very hard and extremely refractory. The density of osmium is 22.48 g/m3, and its melting point is the highest among platinum metals - 3047 ° C. A special feature is its pungent odor, as well as absolute resistance to any alkaline or acidic environments.

Areas of application of precious metals

Each of the noble metals has its own scope of application. Precious metals are used:

- In the production of jewelry.

- For minting coins of various denominations, as well as commemorative and anniversary banknotes.

- As hard currency for investing and opening deposits in banking institutions.

- In mechanical engineering for the production of various parts.

- In the field of radio and electrical engineering, microelectronics, as well as in the field of high technology.

- In the chemical industry, as well as medicine.

- In the space industry.

Sources of secondary raw materials

Sources of precious secondary raw materials can be:

- failed parts of industrial equipment, measuring equipment and control automation;

- waste from the production of radio electronics, television equipment, chemical industry, metallurgy, printing and other industrial sectors;

- jewelry production waste;

- scrap of precious metals.

Scrap of precious metals, considered as secondary raw materials, is represented by the following main groups of used products :

- For gold and silver scrap, the sources are used jewelry, thermocouples and temperature sensors, parts of household refrigerators, televisions, elements of office equipment (computers and printers), radio components, gadgets, telecommunications equipment, catalysts and catalytic grids, batteries, etc.

- For platinum group metal scrap, sources include jewelry made from various alloys of platinum and palladium, catalytic meshes and thermocouples, electrolysis equipment, laboratory glassware, crucibles and lids for them, other laboratory supplies, cases of glass melting equipment, dies, fragments of products coated with precious metals .

Investing in precious metals

Is it profitable to invest hard currency in a bank? Precious metals are the most stable currency, which, if successfully invested, can increase the owner’s profit, as well as protect him from market fluctuations. All over the world, banks practice opening impersonal metal accounts, which can be held as deposits or participate in exchange transactions. Banking transactions involve: gold, platinum, palladium and silver.

Precious metal products

Precious metals are used in large quantities in the manufacture of jewelry. Moreover, metals can be used both in pure form and as part of alloys, while they enhance and compensate for each other’s qualities. What is the most popular precious metal in jewelry? They mainly use three metals that have been known since ancient times: gold, silver and platinum.

What is the significance of precious metal content in jewelry? Their sample depends on this.

Content of precious metals in secondary raw materials

By its chemical composition, secondary raw materials of precious metals are complex multicomponent metallurgical raw materials.

As a rule, in addition to precious metals, scrap and waste contain alloys of iron, aluminum and copper, glass, glass ceramics, fiberglass, and polymers.

The content of precious metals in various objects and devices can only be determined after they have been processed in a refining organization capable of purifying gold, platinum, palladium and other metals to the highest standard.

The status of refining organizations is assigned to enterprises that carry out industrial purification (French affinage - purification, purification) of impurities of precious metals and bringing their quality to the requirements of the relevant standards.

to assess the quantitative content of gold, silver or other noble element in the “secondary” material prepared for processing on the basis of reference data that is available for each product or group of identical parts, or by a hallmark stamp on a piece of scrap jewelry.

For example, for a transistor of the KT 203 B series, the reference book indicates that it contains 0.0076 g of gold as gold plating on the terminals.

We offer you several articles on the topic of the content of precious metals in various products and their refining:

- Content of precious metals in radio components.

- Gold content in radio components.

- Contents in cars.

- Precious metals in household and office equipment.

- Refining of radio components.

- Refining of various items.

- Gold refining.

Properties of noble metals

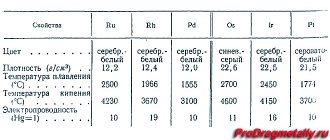

Noble metals received this name due to their high corrosion resistance in the atmosphere, water and some other media. Some of these metals have a fairly high melting point and density. All metals have a relatively high cost, but it is, of course, negligible compared to the most expensive metal in the world, California. The table below shows their physical and mechanical properties.

History of appearance

Noble metals are a valuable and non-renewable natural resource. None of the precious metals can be obtained experimentally, so for the scientific community the appearance of these elements on Earth still remains a mystery. At the moment, there are two working versions of their appearance:

- Space. Proponents of this hypothesis believe that we owe the appearance of precious metals in the earth's crust to meteorites that bombarded the Earth at the dawn of its formation. However, this version has a serious drawback - scientists have found that the average meteorite contains only about 0.005% of the total weight of noble metals, which in no way correlates with the volumes mined at different deposits.

- Tectonic. According to this assumption, all precious metals were born under the influence of high temperatures and in the presence of special conditions in the core of the planet, and then were thrown to the surface with lava flows. This version has more supporters than the space version, however, it cannot answer all the questions. In particular, it is not clear why these natural resources stopped forming again and entering the upper layers of the earth's crust along with volcanic lava emissions.

The question of the origin of noble metals and their alloys is one of the most important. If scientists are ever able to answer it, it will change the entire existing system of relationships in the world.

Industrial Applications

Noble metals are widely used in industry. High-temperature thermocouples are made from platinum-rhodium alloy (90%Pt - 10Rh), which can operate up to 1700°C. The platinum-based alloy is used to make oxygen probe tips for monitoring the protective atmosphere in heat treatment furnaces. Alloys based on palladium, iridium, and silver are used in contacts of critical electronic products. If high wear resistance and hardness are required from a part, then an alloy of osmium and iridium is used.

Application of noble metals in the automotive industry

If you open the car’s operating manual, then in almost every one of them you can find information about which components and in what quantities precious metals are used.

The main metals used in cars are silver, gold, palladium and platinum. Thus, according to the operating manual for LADA 110 cars from 2007, cars of the tenth family use 0.103 grams of palladium, less than 0.1 grams of gold and more than 3 grams of silver. These metals are mainly used in contacts and conductors in the production of relays, breakers, sensors or control units. GAZ cars, for example model 2217, do not use palladium, but about 0.1 grams of platinum and more than 5 grams of silver are used. Even more precious metals are used in the production of KAMAZ trucks.

Current state of primary production

Gold mining occupies a priority position in the mining industry of any country.

A distinctive feature of modern primary mining of precious metals is the depletion of almost all known deposits .

For gold mining, industrial processing of ore from a primary deposit is recognized as profitable when extracting gold in the range of 1-5 g per ton of rock, and for placer mines the content of 0.1-0.5 g of gold grains per ton of processed sand is already welcomed and is considered beneficial for development.

quite large undeveloped gold deposits in Russia .

Against the backdrop of problems associated with the practical implementation of technologies for primary mining and processing of millions of tons of rock for the sake of just a few kilograms of gold or platinum, methods for processing metal-containing secondary raw materials are gaining popularity.

Scrap of precious metals and waste from the production of products containing noble metals are hundreds and thousands of times higher than natural sources in terms of the content of noble components in them. You can read about the cost of scrap precious metals in this article.

In many industrialized countries, recycling technologies return precious metals in quantities of up to 40% of the total volume of gold and other precious metals produced.

Despite the obvious stagnation of primary gold production, the level of its production, like other precious metals, is growing year after year. This is due to an increase in the volume of secondary production of precious metals.

Where can I buy or sell?

The main lots on the market remain platinum and gold. If you represent a company or have an individual entrepreneur, it is more profitable to buy metals from officially registered brokerage companies that work with leading manufacturing plants.

Which precious metal is the most expensive?

If we are talking about the most popular and popular metals, then the leading place in the price ranking is occupied by palladium, platinum and gold.

However, Californian is rightfully considered the most expensive metal on earth.

It is mined during the operation of powerful nuclear reactors. The price for 1 gram of Californian is 6.5 million dollars. Next on the list of expensive metals is rhodium. It is estimated at 225 thousand dollars per gram.

Sources

- https://zhazhdazolota.ru/interesnoe/blagorodnye-metally

- https://BusinessMan.ru/new-dragocennye-metally-opisanie-vidy-perechen-i-xarakteristiki-monety-iz-dragocennyx-metallov.html

- https://VseoMetallah.ru/raznoe/blagorodnye-metally

- https://stone-stream.ru/metally/blagorodnye.html

- https://vplate.ru/metally-i-splavy/vse-o-blagorodnyh/

- https://HeatTreatment.ru/blagorodnye-metally-svojstva-i-primenenie.html