There are many types of mechanical processing of metals by cutting, but slotting work seriously stands out among them. The cutting tool used to perform such a technological process is called a cutter.

Experts in the field of metal cutting knowledgeably claim that procedures such as chiselling and planing are very similar. When carrying out the technological process of chiselling , the cutting tool, that is, the chiselling machine , is imparted a reciprocating motion in the vertical direction, which is the main working motion. As for the feed movement, it is communicated directly to the workpiece, which is fixed on the table of the slotting machine.

Slotting work is used when it is necessary to process various surfaces of those products that have the shape of cylinders, unequal geometric shapes and polyhedra. In addition, it is used when it is necessary to cut gears, both internal and external gears.

Slotting work

With the help of slotting operations, such technological operations are carried out as the production of inclined grooves for wedge keys; keyways located in the holes of gears and bushings; slotted holes; internal guides; grooves for various purposes.

The use of slotting in metalworking

Processing of metal parts using the slotting method is suitable for both single products and small-scale production. When it is necessary to obtain a keyway in a hole, a through and non-through (especially!) hole of a square or rectangular shape, to process polyhedrons, guides on the inside, to make slotted holes, this method is used.

Slotting is a simple and effective method of processing metal parts, especially when compared with other technologies. When cut with a dowel, the part retains its strength without being subjected to unnecessary stress.

Planing and slotting cutters and working devices

When working on a planer, a horizontal component of the cutting force acts on the cutter. If a straight cutter is installed on the machine (Fig. 31, a), then under the influence of force P it will bend along an arc of radius r and crash into the machined surface (shaded area), therefore, when planing, curved cutters are used (Fig. 31, b). In this case, the cutter, bending, moves away from the machined surface, which leads to an increase in the resulting size, but this can be taken into account when setting up the machine.

Rice. 31. Cutters : a – bending of a turning cutter; b – bending of the planing cutter; P – cutting force; r – radius of bending of the cutter; c – straight stroke of the cutter on a swinging plate; d – reverse stroke of the cutter on a swinging plate; Dr – cutting movement

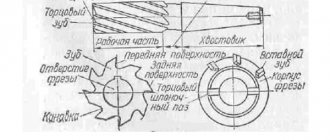

Planing cutters, depending on their purpose, are divided into passing, cutting, shaped and scoring. They are performed right or left, rough or finishing. Slotting cutters are usually made of four types: through, slotted, for keyways and special (slotters), with a soldered plate made of high-speed steel.

When the cutter is idling, it is possible that the rear surface of the tool touches the machined surface, so the tool holder is installed on a rotary plate (Fig. 31, c, d) or at the beginning of the reverse stroke the cutter is moved 0.1–0.5 mm from the machined surface (rebound) .

The processed workpieces of small sizes and simple shapes are placed on the machine in a vice. Large workpieces and workpieces of complex shapes are installed directly on the table, which has T-shaped grooves, and are secured with clamps, prismatic or wedge pads and clamps (Fig. 32, a, b).

Blanks with cylindrical base elements are mounted on prisms (Fig. 32, c). The cutting tool is fixed in a tool holder, single-position (Fig. 32, d) or multi-position (Fig. 32, e, f) holders.

Rice. 32. Working devices for planing and slotting machines : a – linings; b – clamp; c – prism; g–f – holders

In the holders shown in Fig. 32, d, the tool is installed with the height of the subsequent cutter exceeding the previous one, which makes it possible to process the workpiece to a significant depth in one pass, i.e., use the principle of dividing the allowance into parts. The holders shown in Fig. 32, e, allow parallel processing of the workpiece.

About the company

The MegaStils enterprise is a full range of metal processing services in Perm. The machine park (including CNC machines) provides a full cycle of manufacturing any parts and metal products: from cutting to painting.

We work not only with enterprises and organizations, but also with individuals , providing convenient service and fast execution of orders. Payment is possible either by agreement to a bank account or in cash when placing an order.

MegaStils specialists will help you create an electronic drawing based on your sketch, give advice on choosing material for the product, and select the most suitable metal processing and painting method.

Excerpt characterizing metal chiseling

A strange feeling of embitterment and at the same time respect for the calmness of this figure was united at this time in Rostov’s soul. “I’m not talking about you,” he said, “I don’t know you and, I admit, I don’t want to know.” I'm talking about staff in general. “And I’ll tell you what,” Prince Andrei interrupted him with calm authority in his voice. “You want to insult me, and I am ready to agree with you that this is very easy to do if you do not have sufficient respect for yourself; but you must admit that both the time and place were chosen very badly for this. One of these days we will all have to be in a big, more serious duel, and besides, Drubetskoy, who says that he is your old friend, is not at all to blame for the fact that you had the misfortune of not liking my face. However,” he said, getting up, “you know my last name and know where to find me; but don’t forget,” he added, “that I do not consider myself or you at all offended, and my advice, as a man older than you, is to leave this matter without consequences. So on Friday, after the show, I’m waiting for you, Drubetskoy; “goodbye,” Prince Andrei concluded and left, bowing to both. Rostov remembered what he needed to answer only when he had already left. And he was even more angry because he forgot to say this. Rostov immediately ordered his horse to be brought in and, having said a dry goodbye to Boris, went home. Should he go to the main apartment tomorrow and call this broken adjutant or, in fact, leave this matter like that? there was a question that tormented him all the way. Either he thought angrily about the pleasure with which he would see the fear of this small, weak and proud man under his pistol, then he felt with surprise that of all the people he knew, there was no one he would want to have as his friend. , like this adjutant he hated. On the next day of Boris’s meeting with Rostov, there was a review of Austrian and Russian troops, both fresh ones who came from Russia and those who returned from a campaign with Kutuzov. Both emperors, the Russian with the heir, the Tsarevich, and the Austrian with the Archduke, made this review of the allied army of 80 thousand. From early morning, the smartly cleaned and groomed troops began to move, lining up on the field in front of the fortress. Then thousands of legs and bayonets moved with waving banners and, at the command of the officers, they stopped, turned around and lined up at intervals, bypassing other similar masses of infantry in different uniforms; then the elegant cavalry in blue, red, green embroidered uniforms with embroidered musicians in front, on black, red, gray horses, sounded with measured stomping and clanking; then, stretching out with its copper sound of cleaned, shining guns trembling on carriages and with its smell of armor, the artillery crawled between the infantry and cavalry and was placed in the designated places. Not only the generals in full dress uniform, with extremely thick and thin waists pulled together and reddened, propped up collars, necks, in scarves and all the orders; not only the pomaded, well-dressed officers, but every soldier, with a fresh, washed and shaved face and his equipment cleaned to the last possible shine, every horse groomed so that its fur shone like satin and its mane was soaked hair by hair, - everyone felt that something serious, significant and solemn was happening. Each general and soldier felt their insignificance, recognizing themselves as a grain of sand in this sea of people, and together they felt their power, recognizing themselves as part of this huge whole.

Course of lectures on the discipline “Technological processes in mechanical engineering” (page 8)

Modern machines and devices are subject to high demands on technical and operational characteristics, accuracy and reliability of operation. These indicators are ensured by high dimensional accuracy and quality of machined surfaces of machine parts and devices. Therefore, despite the great achievements in technology for the production of high-quality workpieces, the role of cutting processing and the importance of metal-cutting machines in mechanical engineering are continuously increasing.

Modern metal-cutting machines are diverse and sophisticated working machines that use mechanical, electrical and hydraulic methods of movement and control of the work cycle, solving the most complex technological problems.

The machine tool industry is developing both quantitatively and qualitatively. The accuracy, productivity, power, speed and reliability of machine tools are continuously improving. The operational characteristics are improved, the technological capabilities are expanded, and the architectural forms of the machines are improved. The successful development of machine tool industry ensures the re-equipment of all sectors of our industry with high-performance and high-quality machine tools, many of which meet the requirements of world standards.

The classification of metal-cutting machines adopted in our country is based on the technological method of processing workpieces. Classification by technological processing method is carried out in accordance with such characteristics as the type of cutting tool, the nature of the processed surfaces and the processing scheme. Machine tools are divided into lathes, drilling, grinding, polishing and finishing, gear-processing, milling, planing, cutting, broaching, thread-processing, etc.

Classification according to a set of characteristics is most fully reflected in the national Unified System of Symbols for Machine Tools. It is built according to the decimal system; All metal-cutting machines are divided into ten groups, the group into ten types, and the type into ten standard sizes. The group includes machines based on the common technological method of processing or those similar in purpose (for example, drilling and boring). Types of machine tools are characterized by such features as purpose, degree of versatility, number of main working parts, and design features. Within the type, machines are distinguished by technical characteristics.

There are universal, general purpose, specialized and special machines. A wide variety of work is performed on universal machines, using many types of workpieces. Examples of such machines can be screw-cutting lathes, horizontal-milling cantilever machines, etc. General-purpose machines are designed to perform certain work on workpieces of many types (multi-tool, turning-cutting machines). Specialized machines are designed for processing workpieces of the same name, but of different sizes (for example, machines for processing crankshafts). Special machines perform a certain type of work on one specific workpiece.

Lecture 20. Processing on planing machines.

Characteristics of the planing method

The technological method of shaping the surfaces of workpieces by planing is characterized by the presence of two movements: a translational cutter or workpiece (cutting speed) and an intermittent translational feed directed perpendicular to the vector of the main movement.

The workpieces are processed on cross-planing or longitudinal planing machines. On cross-planing machines, the cutter makes a reciprocating movement v, and the workpiece makes a transverse feed movement in the horizontal plane (Fig. 50, a). In some types of machining, the feed movement has a cutter. On longitudinal planing machines, the workpiece performs a reciprocating movement v, and the cutting tool (Fig. 50, b) performs a feed movement.

Rice. 50. Schemes for processing a flat surface on transverse planing (a), longitudinal planing (b) and slotting (c) machines

A type of planing is chiselling on slotting machines. On them, workpieces are processed with a reciprocating movement v of the cutting tool, performed in a vertical plane, and a feed movement Sn of the workpiece in a horizontal plane (Fig. 50, c).

The cutting process during planing is intermittent, and material removal occurs only during a straight (working) stroke. During the reverse (idle) stroke, the cutter does not perform any cutting work. The intermittent cutting process helps cool the tool while processing the workpiece, which eliminates the use of cutting fluids in most cases.

The intermittent cutting process leads to significant dynamic loads on the cutting tool, since the cutter, cutting into the workpiece material with each working stroke, experiences an impact. Therefore, planing is carried out at moderate cutting speeds, and the cutting tool is made more massive and durable compared to cutters used in turning. The presence of idling during planing increases processing time and reduces productivity.

Due to low productivity, planing is in many cases replaced by milling.

Planing machines are widely used in machine tool building and heavy engineering, when it is necessary to process large heavy workpieces of beds, bodies, frames, bases, columns and other parts. Planing machines are also used in auxiliary shops of machine-building plants: repair shops, tool shops, pilot shops, etc.

Cutting mode. Cutting forces

Cutting mode. When planing, the cutting mode is a combination of the following values: cutting speed v feed s and depth of cut t.

The cutting depth is measured in millimeters. When planing, it is determined by the amount of allowance left for processing. Rough planing is performed with a greater depth of cut than semi-finish and fine planing. When planing and chiselling, the feed movement (mm/dv. x.) is intermittent and occurs at the end of the reverse idle stroke of the workpiece or cutter. The values of t and s are selected from reference books. Having specified the cutting depth and feed, the estimated cutting speed is determined using an empirical formula. Cutting speed during planing and chiselling is measured in meters per minute.

For planing machines with a hydraulic drive of the main movement, the number of double strokes of the slider (table) per minute:

,

where L = l + (l1 + l2) – stroke length of the slider (Fig. 51), mm; l – length of the workpiece surface being machined, mm; l1+l2 – length of cutter overtravel in both directions, mm; k – ratio of working speed to idle speed

| Rice. 52. Diagram of forces acting during planing |

| Rice. 51. Schemes for calculating the main time when planing a flat surface. |

After calculating the cutting speed, the number of double strokes of the slide of a cross-planing or slotting machine or the table of a longitudinal planing machine is determined.

Cutting forces.

The diagram of the forces acting during the processing of a workpiece on a planing machine is shown in Fig. 52. As with turning, the cutting force R is divided into three force components: Pz; RU; Rx.

The tangential component Pz of the cutting force is determined by an empirical formula, just as in turning. The values of the vertical Ru and horizontal Px components are usually taken in fractions of the force Pz.

The force Pz determines the effective cutting power, the elastic deformation of the cutter during the working stroke, and the cross-sectional dimensions of the cutter rod. The feed mechanism of the machine is calculated based on the force Px; by force Ru - elastic pressing of the cutter from the workpiece, which affects the accuracy of the size of the machined surface, and the strength of the tool holder mechanism and the machine support.

For longitudinal planing machines, effective power:

where Pz is the vertical component of the cutting force, N; v—cutting speed, m/min.

Basic (technological) time. The main time (in minutes) for processing the workpiece surface on a planing (slotting) machine:

,

where B is the width of planing (chiselling), mm (Fig. 51);

B=b+b1+b2

Lecture 21. Planing and slotting tools, devices and machines

Planing cutters, compared to turning cutters, work under more severe conditions, as they experience shock (dynamic) load. Under the influence of this load, the cutter bends towards the supporting surface of the rod.

If the tip of the cutter is located to the left of the axis of the rod, then due to deformation it will describe an arc, and the depth of cut changes. To avoid this, it is necessary that during deformation the tip of the cutter describes an arc of radius R, tangent to the machined surface (Fig. 53, a). To do this, the tip of the cutter must be located between the supporting surface of the rod and the plane passing through the axis of the cutter rod. To withstand this condition, planing cutters are curved.

Depending on the purpose, the following types of planing cutters are distinguished (Fig. 53): passing (b), scoring (c), cutting (d) and shaped. These cutters are performed right and left, roughing and finishing; their designs are similar to those of turning cutters.

Rice. 53. Planing and slotting tools

Slotting cutters are made of three main types (Fig. 53): through (d), slotted (f) and for keyways (g). Slotting cutters are usually made with high-speed steel plates.

Devices for processing workpieces on planing machines

The processed workpieces of small sizes and simple shapes are secured in a universal machine vice, installed and secured on the table of the planing machine.

Rice. 54. Devices and tool holders for planing machines.

Workpieces of large sizes and complex shapes are installed directly on the machine table, which has T-shaped grooves, and secured using clamps, prismatic (Fig. 54, a) and wedge (Fig. 54, b) linings, stops (Fig. 54, c ), prisms (Fig. 54, d), etc.

Special devices are rarely used when performing planing work.

Cutters on planing machines are secured in special holders: single-cut (Fig. 54, e, f), two-, three- and four-cut. In Fig. 54, g shows a three-cutter holder for planing a flat surface according to the scheme of dividing the feed into parts. This allows you to process workpieces with a large amount of transverse feed, while each cutter has . Using similar holder designs, you can plan surfaces according to the scheme of dividing the allowance into parts.

These machines are included in the seventh group. These include cross-planing, longitudinal planing (single-post and double-post), slotting and various planing machines.

Cross-planing machines are used in mass production and in auxiliary workshops of machine-building plants. They process workpieces when the planing length does not exceed 1000 mm. The general view of the cross-planing machine is shown in Fig. 55.

Fig.55. General view of the cross-planing machine

Foundation plate 1 is used to install and secure the machine on the floor foundation. A frame 2 with a flanged electric motor 8 is mounted on the plate. The machine gearbox and a rocker mechanism or hydraulic drive are mounted in the frame, ensuring reciprocating movement of the slider 7 along the horizontal guides of the frame.

A traverse 3 with horizontal guides moves along the vertical guides of the frame. On the traverse, a table 4 with T-shaped slots is mounted on a cantilever, on which the workpiece being processed is fixed.

At the end of the slider 7 there is a vertical support 6, which can be installed at an angle when planing inclined planes. A folding tool holder 5 is mounted on the support, in which the planing tool is secured. The tool holder is made folding and can be rotated on a hinge pin, which is necessary for the free sliding of the cutter along the machined surface of the workpiece when the slide is idle.

Large heavy workpieces are processed on longitudinal planing machines. The machines are characterized by the longest planing length (table stroke), which is 1.5–12 m, and the planing width, equal to 0.7–4.0 m. Longitudinal planing machines are divided into single-column and double-column. On two-rack machines, which have a more rigid structure, larger workpieces are processed.

The general view of a two-column longitudinal planing machine is shown in Fig. 56. Bed 1 has longitudinal horizontal guides along which table 2 performs reciprocating motion. The table with the workpiece fixed on it receives linear motion from a rack and pinion transmission, a worm and a worm rack, or from a hydraulic cylinder. The main movement is driven by an electric motor.

Rice. 56. General view of a two-post longitudinal planing machine.

Two racks are rigidly connected to the frame: left 3 and right 8, connected at the top by a crosspiece 7, which increases the overall rigidity of the machine. A traverse 5 moves along the vertical guides of the racks, which, depending on the size of the workpiece being processed, is installed at a certain level from the plane of the table. Two upper supports 6 and 9 are mounted on the traverse, receiving transverse feed from the feed box 10. The supports can be rotated in a vertical plane. The supports are equipped with folding tool holders for securing the cutters. Side supports 4 and 11 move along the vertical guides of the racks, on which folding tool holders are also installed. The side calipers have individual feed boxes.

The presence of four supports allows you to simultaneously process several surfaces of the workpiece.

Lecture 22. Slotting machines

Slotting machines

. Slotting machines are characterized by the fact that the main cutting movement is carried out in a vertical plane. This movement has a slider on which a tool holder is mounted to secure the slotting cutter. The stroke length of the slider usually does not exceed 200 mm. The workpiece is fixed on the machine table, which has longitudinal and transverse feeds. In addition, the table has a circular feed relative to its vertical axis.

Planing machines process flat surfaces - horizontal, vertical and inclined; ledges; T-shaped, V-shaped, dovetail, prismatic rectangular, trapezoidal grooves; corrugated surfaces; shaped surfaces (using shaped cutters or using a carbon copy). In addition, blanks are cut onto them.

Rice. 57. Schemes for processing the surfaces of workpieces on planing and slotting machines.

Slotting machines process flat vertical surfaces, polyhedrons, multifaceted holes, external grooves, and shaped surfaces.

In Fig. 57 shows examples of processing various surfaces on planing and slotting machines.

Processing of workpieces on cross-planing machines is shown by planing schemes for horizontal (a), vertical (b) and inclined (c) planes. In Fig. 57, d shows planing of corrugations. An inclined plane is processed by rotating the upper support at an angle equal to the angle of inclination of the plane being processed and by feeding directed parallel to the surface being processed.

Processing of workpieces on longitudinal planing machines is shown by diagrams of simultaneous planing of the horizontal and vertical planes of the workpiece (e); simultaneous planing of a prismatic groove and a dovetail groove (e); planing of a shaped surface (g) according to a copying machine.

Processing of workpieces on slotting machines is shown by diagrams of slotting a vertical plane (h), a cylindrical surface (i) and a keyway (k).

Planing of horizontal planes is performed with passing cutters, vertical and inclined planes with scoring cutters, grooves with slotted cutters, etc.

Lecture 23. Processing on broaching machines

Characteristics of the broaching method

Broaching is a high-performance method of processing internal and external surfaces, ensuring high accuracy of the shape and dimensions of the processed surface. They are pulled with a multi-bladed cutting tool - a broach during its translational movement relative to a stationary workpiece (the main movement).

| Rice. 58. Schemes for pulling (a) and stitching (b) holes. |

The principle of broaching is that the size of each subsequent broaching tooth is larger than the previous one, and each tooth cuts chips of small thickness from the processed surface of the workpiece, as a result of which the processed surface has low roughness. Despite the relatively low cutting speed when broaching, this method is highly productive due to the large total length of simultaneously operating cutting blades.

In Fig. 58, a, b shows diagrams of pulling and stitching holes. When broaching, the end part of the workpiece 2 rests on the machine bracket 1. By force P, the broach 3 is pulled through the workpiece hole being processed. When piercing, the workpiece 2 rests on the press table 5. The force P applied to the end of the piercing 4 pushes it through the workpiece hole being processed.

Unlike broaching, which works in tension, broaching works in compression. To avoid longitudinal bending, the length of the firmware does not exceed 15 of its diameters.

Cutting mode

Cutting speed

. When broaching, the cutting speed v is the speed of translational movement of the broach relative to the workpiece. The cutting speed is limited by the conditions for obtaining a high-quality machined surface and is limited by the technological capabilities of broaching machines. Typically v = 8–15 m/min.

Innings

. There is no feed movement during broaching as an independent movement of the tool or workpiece. The feed rate sz, which determines the thickness of the layer cut by a separate broach tooth, is taken to be the rise per tooth, i.e., the difference in size in height of two adjacent broach teeth; sz is also the depth of cut. The feed mainly depends on the material being processed, the broach design and the rigidity of the workpiece and is 0.01-0.2 mm/tooth. The optimal cutting mode values are selected according to reference data.

Broaches

Based on the nature of the surfaces being processed, broaches are divided into two main groups: internal and external. Internal broaches process various closed surfaces, and external broaches process semi-closed and open surfaces of various profiles.

The shapes are divided into round, slotted, keyed, multi-faceted and flat broaches. According to the design of the teeth, broaches are either cutting or compacting. In the first case, the teeth have sharp cutting blades, in the second - rounded ones, working by the method of plastic deformation of the surface without removing chips. There are also prefabricated broaches with insert knives equipped with hard alloy plates.

In Fig. 59, and the elements of a round broach are shown.

Round broach elements.

The locking part (shank) l1 is used to secure the broach in the chuck of the machine pulling device; neck l2 - for connecting the locking part with the front guide part; front guide part l3 together with the guide cone - for centering the workpiece at the beginning of cutting.

The cutting part l4 consists of cutting teeth, the height of which successively increases by the thickness of the layer being cut, and is intended for cutting off the allowance.

The calibrating part l5 consists of calibrating teeth, the shape and dimensions of which correspond to the shape and dimensions of the last cutting tooth, and is designed to give the machined surface the final dimensions, the necessary accuracy and roughness.

The rear guide part l6 serves to guide and maintain the broach from sagging at the moment the last teeth of the calibrating part exit the hole. To facilitate the formation of chips on the cutting teeth, chip-breaking grooves are made in a checkerboard pattern.

Rice. 59. Elements and geometry of a round broach tooth

Broach tooth geometry

. The geometry of the teeth of the cutting and calibrating parts is shown in Fig. 59, b. The front and rear broach angles are measured in a plane perpendicular to the main cutting blade. The rake angle γ (5–20°) is selected depending on the properties of the material being processed, the clearance angle α (1–4°) – depending on the class of processing accuracy.

The calibrating teeth have a chamfer (ribbon) width f = 0.2 – 0.3 mm on the rear surface, with a rear angle αk = 0°. The chamfer is necessary so that after regrinding along the front surface of the tooth, the dimensions of the broach do not change.

The pitch of the cutting teeth tp of the broach is determined depending on the length L of the broached surface, and it is assumed that at least three teeth are simultaneously involved in cutting. Cutting tooth pitch tp = (1.25–1.5) mm; pitch of calibrating teeth tk = (0.6 – 0.7) tp mm.

Cutting forces and pulling power.

The cutting force during broaching consists of the forces applied to all teeth simultaneously involved in cutting.

The force acting on each broach tooth can be decomposed into two components: Pz, directed along the axis, and Pu, directed perpendicular to the axis.

Of practical importance is only the axial component Pz, directed in the direction opposite to the movement of the broach. Ohm creates stress in the broach. For round broaches cutting force (in N):

,

for keyed and splined broaches:

,

where Cpz is a coefficient characterizing the workpiece material and processing conditions; sz—feed per tooth, mm; xpz – exponent when feeding; D—hole diameter, mm; z is the number of simultaneously working broach teeth; n—number of splines; kγ, Ka, Ki, Ko - respectively, coefficients characterizing the influence of the front and rear angles, wear and cutting fluid.

The values of Cpz, xpz, kγ, Ka, Ki, Ko are given in reference materials on the selection of cutting modes. Using the cutting force Pz, the tensile strength of the broach and the effective power are calculated and the possibility of performing a given cutting process on a given machine is checked (the traction force of the machine must be greater than the cutting force).

Effective power (in kW):

Processing of workpiece surfaces on broaching machines

Broaching machines are characterized by simplicity of design and operation. This is due to the fact that the shape of the surface when processed on a broaching machine depends on the shape of the cutting blades of the tool teeth. The main characteristics of a broaching machine are the traction force and the length of the broaching stroke. Broaching machines are hydraulically driven and often operate in a semi-automatic cycle. Depending on the type of surfaces being processed, they are divided into machines for internal and external broaching; in the direction of the main movement—horizontal and vertical.

Rice. 60. General view of a horizontal broaching machine

Horizontal broaching machine

. This machine for internal broaching (Fig. 60) consists of a frame 1, a pumping station 2, a hydraulic cylinder 3, a carriage 4, a support bracket 5 and a trough 6. The broach with its tail is inserted into the pre-processed hole of the workpiece and secured in the carriage chuck 4. The carriage with by drawing it receives translational movement from the piston rod of the hydraulic cylinder - the main movement is vp

When pulling, the workpiece rests with its end on the supporting surface of the bracket 5. Translational motion is imparted to the broach until it comes out of the hole in the workpiece. When the broaching is completed, the workpiece falls into trough 6, the broach is removed from the carriage 4, the latter returns to its original position (idle vx) and the processing cycle is repeated.

Rice. 61. General view of a vertical broaching machine.

Vertical broaching machine

. This machine for external broaching (Fig. 61) consists of a base 7, a frame 5, a pumping station 4, a carriage 3, a table 2. The workpiece is installed in a fixture on the machine table. The broach is fixed in the carriage and a hydraulic drive imparts translational movement to it - the main movement. The broach, going down (working stroke vp), processes the workpiece. The processed workpiece is removed and the movable carriage quickly returns to its original position (idle speed vx).

Long flocks of continuous processing

(Fig. 62). These machines are high performance machines. They process workpieces continuously. Workpieces 2 are installed in devices of a closed chain 1 and impart to them the main translational movement at a speed v relative to a stationary broach 3. Rigid guides 4 ensure parallel movement of the chain in the area where the workpieces pass under the broach.

On rotary-type continuous processing broaching machines, the workpieces are placed on a rotating round table.

Rice. 62. Scheme of processing workpieces on a continuous broaching machine.

Holes of various geometric shapes are drawn on horizontal broaching machines for internal broaching. The dimensions of the drawn holes are 5–250 mm.

Cylindrical holes are drawn using round broaches after drilling, boring or countersinking. They also use broaching holes obtained during casting and stamping without pre-processing them. Typically the length of the holes does not exceed three diameters.

If the end of the hole in the workpiece is not processed, then devices with a spherical supporting surface are used to install it (Fig. 63, a). In this case, the workpiece can self-align (center) along the broach axis, even if the end of the workpiece is not perpendicular to the axis of the hole. In cases where the previous processing provides for obtaining the end of the hole perpendicular to its axis, the workpiece rests on a rigid (stationary) surface.

Multifaceted holes (triangular, square, etc.) are drawn with multifaceted broaches. The starting surface for broaching is a round hole

In Fig. 63, b shows a diagram of drawing a square hole.

Spline holes with different spline profiles are drawn with multi-slot broaches, which simultaneously form the entire hole profile.

In Fig. 63, c shows a diagram of drawing straight splines. Helical splines are pulled through a broach, the cutting teeth of which are located along a helical line, with a device that provides additional rotation of the broach (Fig. 63, d) or the workpiece.

Keyway and other grooves are pulled through with broaches, the shape of the teeth of which in cross section corresponds to the profile of the groove being pulled. The keyways are pulled through with a flat keyway broach (Fig. 63, e) using a special device - guide sleeve 3. A rectangular groove is cut along the entire sleeve, which serves as a guide for broaching.

External surfaces of various geometric shapes with a rectilinear generatrix are drawn on vertical broaching machines for external broaching, as well as on conveyor-type continuous processing machines.

Pulling of external surfaces is successfully used instead of other processing methods in order to reduce its labor intensity and cost. External broaching can replace planing, milling, and in some cases grinding. When drawing complex shaped contours instead of milling (for example, flat cams), not only the labor intensity of processing is reduced, but also the high quality of the machined surface is ensured. Flat and more complex external surfaces are pulled with flat broaches of straight and shaped profiles.

Rice. 63. Schemes for processing the surfaces of workpieces on broaching machines:

1 – workpiece, 2 – broach, 3 – guide sleeve

In Fig. 63, e shows a diagram of stretching a vertical plane.

On special broaching machines, it is possible to process the outer surfaces of workpieces in the shape of bodies of rotation using flat (Fig. 63, g) and disk (Fig. 63, h) broaches. In both cases, the workpiece is given a circular feed. A flat broach has a main movement that is translational, while a disk broach has a rotational movement around its axis.

Cylindrical and bevel gears of external gearing are pulled as follows. Cylindrical gears with straight teeth and other parts with external grooves are manufactured by successively drawing the cavity between the teeth in one or several passes on horizontal and vertical broaching machines with automatic dividing devices. On special broaching machines with a continuously rotating circular broach of a special design, cylindrical and bevel gears with straight teeth are cut.

Lecture 24. Processing on drilling machines

Drilling

is the main method of producing blind and through cylindrical holes in solid workpiece material.

A drill with two main cutting edges is used as a drilling tool.

Drilling machines and lathes are used for drilling.

On drilling machines, the drill makes a rotational (main) movement and a longitudinal (feed movement) along the axis of the hole, the workpiece is motionless (Fig. 64.a).

When working on lathes, rotational (main movement) is performed by the workpiece, and translational movement along the axis of the hole (feed movement) is performed by the drill (Fig. 64.b).

Rice. 64. Schemes for drilling, countersinking and reaming

The diameter of the drilled hole can be increased with a larger diameter drill. Such operations are called drilling

(Fig. 64.c).

When drilling, relatively low accuracy and surface quality are ensured.

To obtain holes of higher accuracy and surface finish, after drilling, countersinking and reaming are performed on the same machine.

Countersinking

– processing of previously produced holes to give them a more regular geometric shape, increase accuracy and reduce roughness. A multi-blade cutting tool - a countersink, which has a more rigid working part, the number of teeth is at least three (Fig. 64.d).

Deployment

– final machining of a cylindrical or conical hole by reaming in order to obtain high accuracy and low roughness. Reamers are a multi-bladed tool that cuts very thin layers from the surface being processed (Fig. 64.e).

Schemes for drilling, countersinking and reaming are presented in Figure 64.

LECTURE 25. Machining on boring machines

Processing workpieces on boring machines

Characteristics of the boring method

. Surfaces on boring machines are formed by a combination of the main rotational motion of the cutter or other cutting tool and the feed motion imparted to the tool or workpiece. The feed direction can be longitudinal, transverse, radial and vertical, depending on the nature of the surface being processed.

Boring machines perform drilling, countersinking, reaming and boring holes, turning external cylindrical surfaces with a cutter, trimming ends, cutting threads and milling planes.

Boring machines are used mainly for machining holes with precisely coordinated axes in large and medium-sized blanks of body parts.

Processing the surfaces of workpieces with cutters is most typical for boring machines.

Boring cutters operate in less favorable conditions than turning cutters. They have smaller dimensions, depending on the size of the mandrels in which they are fixed and the diameter of the hole being processed. The mandrel with the cutter may bend under the action of the cutting force. The non-rigidity of the tool causes vibrations during the cutting process and reduces the quality of the machined surface. Therefore, to ensure high precision of machined surfaces, boring machines have increased rigidity.

Cutting mode.

When working on boring machines (Fig. 65), the main rotational movement of the tool is characterized by cutting speed.

Rice. 65. Hole boring scheme

The cutting speed (m/min) is taken as the peripheral speed of a rotating cutting tool:

| Due to its large volume, this material is placed on several pages: 8 |