Explosion welding is used to create structural materials with the necessary physical properties. Scientists began to think about this method of joining metals when they studied fragments of shell casings from the Second World War. In 1960, Americans developed and patented a method of using detonation for mutual deformation of alloys with different physical properties. The era of creating metal multilayer “sandwiches” in the form of plates and cylinders began; surfaces began to be coated with metals with high anti-corrosion properties.

Welding modes and process

Today, explosion welding is carried out without the use of precise modes and calculations. This is due to the fact that the technology has not yet been fully developed. That is why explosion welding can be considered more of an experimental processing method rather than an accurate one suitable for mass production. When considering the explosion welding process, attention should be paid to the following points:

- A process has not been developed that produces an accurate result. Explosion welding is considered experimental.

- After carrying out the procedure in question, it is difficult to predict the final result. This is due to the fact that it is practically impossible to control the blast wave.

- The explosion welding scheme is developed based on the characteristics of the materials used. The main parameters are selected depending on the specific case.

Explosion welding process

It should be taken into account that there are pre-developed process parameters. They can be used to achieve specific results.

Selection of electrodes

The technology of manual arc welding with coated electrodes requires the use of high-quality filler material, this is an important condition. The quality of the weld depends on the choice of electrodes. The rods are selected in accordance with the type of metal that will be welded.

When carrying out manual arc surfacing with coated electrodes, it is worth taking into account the properties of the rods, which depend on the type of coating. Electrodes used for RDS typically have a rutile or basic coating.

These electrodes have important features:

- Rutile-coated electrodes are often used by beginners. This is due to the fact that when using them it is much easier to ignite and conduct an arc.

- On sale you can find a huge selection of rutile-coated electrodes - budget and expensive brands. Experienced welders do not recommend using too expensive types for welding at home, because they will not be able to fully reveal their potential.

- Rutile rods have a significant drawback - when they are used in a weld, an increased hydrogen content is observed, which can greatly deteriorate the quality of the joint.

- When using rutile-coated electrodes, it prevents excessive metal spattering during melting.

- Basic coated rods are often chosen by professional welders with extensive experience. They are quite difficult to work with, because the arc is quite difficult to ignite, and during the welding process it must always be short.

- The use of electrodes with a basic coating makes it possible to obtain excellent quality welds.

- Core coated rods are ideal for welding thin metal.

Electrodes for RDS and other types of arc welding should be selected depending on economic factors. The manual arc welding process is quite slow, so it is recommended to know the deposition rate of the rod to determine how much time and electrodes will be required to form the weld.

Note! There are high-performance seams on sale that increase the productivity of the work process. However, they are suitable for creating horizontal seams

Explosion welding methods

Today, there are two main explosion welding schemes. This technology can be used for various alloys and metals. The production of bimetallic blanks is carried out as follows:

- The main workpiece is located on the supporting foundation. It can be made by making concrete, which is strengthened with metal rods. In addition, a sand cushion is created to dampen the blast wave.

- The technology involves moving a second sheet of metal, which is located at an angle of 3-10 percent relative to the first.

- The explosives are evenly distributed along the length of the second sheet. A detonator is required to explode.

- After a controlled explosion, the second sheet moves within a few fractions of seconds. Due to the strong impact, the individual metal sheets are connected.

A similar technology is used when it is necessary to pair sheet materials.

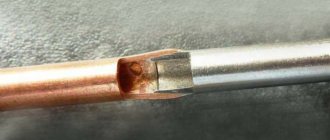

The second technology concerns the melting of pipes at the joint. In this case, explosion welding is also used. The features of this method include the following points:

- An explosive is placed at the joint. It is worth considering that it should be located in the form of a ring-shaped strip.

- In order to eliminate the possibility of deformation of the pipe itself, a metal core is inserted inside. If this is not done, the pipe may collapse.

Welding diagram at the explosion stage

Both technologies can lead to damage to the workpiece if the quantity and type of explosive is chosen incorrectly. That is why it is necessary to carry out accurate calculations.

How to prepare

Before starting work, perform the following steps:

- Prepare the surfaces to be joined. Scale, traces of oil, oxide film or protective coatings are removed from them.

- Straighten the workpieces. A curvature of 2 mm/m² is allowed.

- Creates slight roughness.

- Compare details. When working with sheet products, the lower part is placed on a substrate, the upper part is placed parallel or at an angle. The inclination should not exceed 30°. Hollow parts are secured using special devices. A core is inserted into the pipe to prevent deformation.

- Calculate the required volume of explosive charge.

Explosion welding is used in the manufacture of billets for bimetal rolling.

What equipment is needed?

A targeted explosion requires special equipment. To carry out such work you will need:

- Explosive. There are quite a large number of similar substances that can be used for explosions. Only a specialist can choose the most suitable one

- Two pieces that need to be connected. They can be represented by sheet metal or cylindrical blanks.

- A detonator that supplies current for an explosion.

- If you are connecting small products, you can use a special chamber to carry out the explosion. It is usually located at the production site. In manufacturing, high-strength materials are used that can also withstand high temperatures.

The result of welding is bimetal

It is worth considering that to carry out the work you need to prepare a testing ground and an explosion site or a special chamber. Some elements are designed to redirect the blast wave, thereby increasing the effectiveness of the technology used.

List of equipment and consumables

To perform explosion welding you will need:

- 2 parts that will be connected. They can be in the form of sheets or pipes.

- A detonator that produces the current needed to cause an explosion.

- Chamber for carrying out the process. It is installed at a construction or production site. Impact-resistant materials that are insensitive to high temperatures are used to make the camera.

To carry out large-scale work, a landfill will be required. It is equipped with elements that redirect the blast wave. This increases the efficiency of welding work.

Selecting Explosives

There are many substances designed to explode. They are selected taking into account the physical properties of the metals being joined and the conditions of use. The following means are used:

- Bulk explosives. With its help, you can create a charge of any volume and shape.

- Solid explosives. Due to some features it is used less often.

Most explosives consist of chemical compounds.

Explosion welding technology

It is worth considering that the technology in question is characterized by quite a large number of features. Let's take the following points as an example:

- It only takes a few moments to complete the connection. Due to the strong mechanical impact, a strong connection is created that can withstand severe mechanical stress.

- The technology under consideration does not limit the size of the workpieces to be joined. If you need to melt large products, then the usual technology associated with the use of a conventional inverter is not suitable. The method under consideration is characterized by greater productivity.

- A special feature of the technology is that it is used to connect materials of different chemical compositions.

- After using explosion welding, it must be remembered that when the joint zone is reheated, intense diffusion may occur.

- When exposed to high temperatures, the properties of the seam may disappear over time. At the same time, the strength and reliability indicator will decrease significantly.

Types of welding

When joining steel and titanium, vanadium and niobium can be used as a layer. Otherwise, over time, the joint will not withstand strong mechanical stress.

Don't forget about safety precautions. The blast wave carries with it a danger to the performer himself and those around him. When developing the method under consideration, we paid quite a lot of attention to safety precautions. Let's call its features the following points:

- Landfills should be located away from residential facilities and populated areas. This is due to the fact that the blast wave can damage buildings.

- A work platform is often created by using sand. The recommended thickness of the sand cushion is 1 meter. If the estimated impact force is 200 kilograms, then special preparation of the site is carried out.

- When processing small products and applying a charge with an impact of 20 kilograms, an explosion chamber is used. A similar structure can be located in a factory or in a special room. The recommended wall thickness is 25 cm. In the manufacture of such a structure, materials are used that can withstand this kind of impact.

- The operator must use special clothing and personal protective equipment. Particular attention is paid to fire safety, since an explosion can lead to a fire.

It is worth considering that the technology can only be carried out by persons who have received the appropriate permission.

What you need to know

The main feature is the ability to process metal surfaces of any type. The selected connections can be of any size, which is an additional advantage. Explosion welding, the diagram of which is presented above, provides instant high-quality joints, which are formed in less than a millionth of a second.

It is worth noting that if it is necessary to reheat finished surfaces, one should remember the high risk of developing active diffusion; it may appear at the site of the previously obtained connection. Because of this, there is a high probability of a significant decrease in strength and reliability characteristics, especially when exposed to a high temperature range.

To prevent such detrimental changes during the joining process, special metal-based interlayers are used, while the surfaces undergoing treatment and the additives used do not form chemical compounds. An example is the welding of titanium and steel; in this case, materials such as vanadium or tantalum are used as a special layer.

Preparing for work

The quality of welded metals can be improved with careful preparation for the process. To carry out explosion welding you need:

- A more suitable explosive for the case at hand.

- A supporting foundation that must withstand strong impacts. Before starting work, you need to check the condition of the supporting foundation. Various defects can lead to the fact that the base will not withstand the impact.

- Parts to be joined. They are pre-prepared. To do this, the surface layer can be removed with an abrasive material.

- A detonator is required for an explosion.

It is worth considering that the features of the preparatory process largely depend on the type of materials being joined. Examples include the following:

- Large parts.

- Cylindrical parts.

- Multilayer and fiber reinforced parts.

Welding range

Don't forget that a foundation slab can only withstand a few explosions. After this, it is destroyed and the site has to be prepared again.

Advantages and disadvantages of explosion welding

Like many other technologies, explosion welding has a fairly large number of positive and negative aspects. The advantages are:

- High speed of processing of connected elements. As previously noted, it only takes a few fractions of a second to join the metal. However, it takes quite a lot of time to prepare the site and the materials themselves.

- It is possible to obtain high-quality bimetal compounds. It is worth considering that other technologies do not allow combining materials with different physical and mechanical parameters.

- The technology makes it possible to join materials that are characterized by a low degree of machinability.

- You can create a product for further forging and stamping. Recently, forging and stamping have been carried out to harden the surface. A conventional seam is characterized by the fact that it cannot withstand variable loads.

- You can get a product with complex corner shapes. An example is products with curves.

Explosion welding is considered a complex technological process, but it can be used to produce the most complex products. There are also several serious disadvantages:

- Low degree of safety during an explosion. This is due to the fact that it is quite difficult to control the blast wave.

- In order to provide the services in question, you need to undergo special training and obtain permission to do so. Failure to comply with the technology leads to the fact that the workpiece may be damaged.

- Work can only be carried out if there is a special protective chamber or testing area.

- It is almost impossible to automate the process in question. That is why it is necessary to carefully prepare for each process of joining products.

The above information determines that the positive aspects of explosion welding are much greater than the negative ones.

general characteristics

Explosive welding is a type of welding technology that uses pressure. Using the kinetic energy of a part accelerated to high speed, plastic deformation of the contacting layers of metal on the required parts is performed.

To accelerate the part to the required speed of several hundred meters per second, explosion energy is used. For maximum effect, one part is accelerated, and the second is fixed in a stationary state. And at the moment of their contact, the required deformation is performed.

It is worth noting! In order for the necessary movement to occur, an explosive and a detonator are placed on the surface of the moving part. The explosive is initiated and an explosion occurs, which causes movement of the moving part.

Explosion welding makes it possible to obtain composite products; it can also be used to produce elements with a multi-level and bimetallic structure. The finished product will be highly resistant to corrosion and mechanical stress. This welding technology is used in various fields of production - in oil, engineering and many others.

Features of micro-inhomogeneity of welded joints

Chemical and physical microheterogeneity of welded joints manifests itself when using almost all types of welding. The features include several points:

- Physical heterogeneity is detected using metallography. Due to this, the strength of the resulting structure is significantly reduced.

- Chemical heterogeneity can also significantly reduce the quality of the connection.

That is why, when the connection zone is exposed to high temperatures, the strength and reliability coefficient can significantly decrease.

Compliance with quality standards and compliance testing

To assess the strength and homogeneity of a welded joint obtained by explosion, the following methods are used:

- Ultrasonic flaw detection. The method is used to assess the strength of seams. The fluoroscopic method is used to check important connections.

- The seam is cut or torn. Also used to evaluate strength.

- Deflections and torsion of the connection. They help evaluate the ductility of the resulting structure.

If in doubt, a warp check is required. To do this, measure the thickness of the material in several places.

Influence of the initial state of the materials being welded

The initial condition of the products largely affects the quality of the connection. The condition of the seam may be affected by:

- Presence or absence of contamination. In addition, corrosion on the surface can significantly reduce the quality of the connection.

- The degree of manifestation of micro-irregularities. If the surface is characterized by strong waviness, then it is necessary to pre-level it.

- Type of metals being joined. If necessary, it is possible to connect alloy alloys and carbon steels, non-ferrous metals.

Welding seam during explosion welding

The welding method under consideration is characterized by the fact that there is no need to prepare the surface for processing. This greatly simplifies the process and reduces costs.

Explosives for welding

There are quite a large number of different explosives that can be used in welding. Among the features of their choice, we note the following points:

- Bulk substances are more popular, since their use can create a charge of the required shape and size.

- Attention is also paid to the choice of detonator.

For each case, a substance is selected experimentally. In specialized stores you can find the required materials.

Rice. 1. Roll welding scheme:

1 - roller; 2 - workpieces to be welded.

Deformation of the workpieces being welded begins upon entering the rolls. At the exit from the rolls, compressive stresses act on the metal (here, the initial stress level corresponding to the initial moment of relaxation).

The duration of stress relaxation during rolling welding is understood as the duration of deformation, upon completion of which

where is the level of critical stresses during the relaxation process, at which the interatomic bonds formed in the connection zone are not destroyed.

The formation of a connection in this case ends with the setting of contact surfaces and stress relaxation to the extent necessary to preserve the formed interatomic bonds.

1.1 Technological capabilities.

Roll welding produces corrosion-resistant, wear-resistant, anti-friction, electrically conductive, instrumental, heat-resistant, thermoelastic, contact, and decorative multilayer structures, the cross sections of which are shown in Fig. 2.

Difficulties of the explosive process

Explosion welding is characterized by quite a lot of difficulties. An example is the following information:

- The main difficulty concerns the storage and use of explosives.

- In the event of an explosion, the possibility of a blast wave affecting the environment cannot be excluded.

- In order to eliminate the possibility of the procedure’s impact on the environment, welding should be carried out at special sites. However, they should be located away from industrial and residential areas.

- If small products are being connected, special chambers can be used.

- Joining dissimilar metals also leads to significant problems. An example is a decrease in strength.

- To improve the quality of the connection, it is recommended to thoroughly prepare the surfaces to be joined. Cleaning is carried out until a metallic shine is obtained.

- Another serious difficulty is calculating the required amount of explosive. In some cases, such parameters are tested experimentally.

Example of products obtained using explosion welding

It is quite difficult to provide the most favorable conditions for explosion welding.

Material requirements

When welding metals with low ductility, difficulties may arise. Connecting parts made of fusible materials requires less energy. Surfaces must be protected from the negative effects of the blast wave. It is quite difficult to produce compositions from steel with titanium or aluminum using the explosion method. The process takes place at average parameters. When joining thick sheets, interlayers are used that do not form fragile compositions with the metals being welded. The strength of the seam also depends on the hardness of the parts.

Recommended Reading: Friction Welding Information

Explosion welding allows you to obtain high-quality welded joints.

Areas of use

The method in question is used extremely rarely. This is due to a large number of problems associated with preparing the site and storing explosives. Explosion welding is effective in the following cases:

- When creating high-quality and reliable pipe joints.

- When combining metals with different properties.

- When obtaining monolithic products of complex shape.

- When connecting metal structures of complex configuration.

- When obtaining composite blanks that have a cylindrical shape.

In general, we can say that the technology is not used to produce conventional products. This is due to the high cost of the materials used and difficulties in preparing the site for the work.

In conclusion, we note that explosion welding should be carried out exclusively in compliance with safety precautions. Even the smallest errors can lead to product deformation and some other problems.

The layer that performs the function of the strength element is called the main one.

A layer that has special properties that are determined by the requirements for the structure is called cladding. The main layer, as a rule, is thicker than the cladding layer and is made of cheaper material.

Welding can be carried out when the materials being joined are heated (hot rolling welding) and in a cold state when producing multilayer materials from ductile metals (cold rolling welding).

Roll welding is a type of pressure welding and is characterized by the fact that the connection is carried out under conditions of forced deformation for short durations of interaction.