Hot-melt adhesive for a glue gun can have different characteristics and purposes. First of all, they take into account what material the surfaces to be glued are made of. When purchasing, it is also important to evaluate the diameter and length of the glue cartridge and its melting speed. The most in demand is universal, inexpensive hot-melt adhesive based on ethylene vinyl acetate (EVA). When working with special materials, a special adhesive composition is used.

Choice

A wide area of use, fast fixing time and versatility ensured the popularity of this product. Its release form can be any - pillows, blocks, granules and rods, which have become most widespread and have a variety of diameters and sizes. The main advantage is the ability to use glued elements within a few minutes. Before choosing a hot melt adhesive gun, the characteristics of which depend on the shape, you need to purchase the tool with which it is used. Of course, working with this product is possible without a special gun. For example, using heating with a candle or soldering iron. But this is at least inconvenient.

Top 2. Steel STG-1, 4 g

Rating (2021): 4.57

269 reviews from resources taken into account: Yandex.Market, OZON, DNS

A high-quality remedy for overheating. The composition contains silicon carbide, which increases thermal conductivity. Hot-melt adhesive effectively conducts heat and prevents overheating of system components.

- Characteristics

Country Russia

- Average price: 257 rub.

- Purpose: protection against high temperatures, installation of radiators

- Hardening time: from 5-7 minutes. up to 36 hours

- Thermal conductivity: 1.8-2.2 W/(m K)

Another domestic hot melt adhesive that performs well in its work. The main purpose of the two-component product is to install heat removal systems to PC and digital equipment elements that are subject to constant heating. The package includes a tube with a hardener, a syringe with a heat-conducting compound and a cloth soaked in a degreaser. Before application, hot melt adhesive must be mixed in equal proportions and the element must be installed as quickly as possible. Yes, its hardening speed is optimal for installation, but the glue begins to set already during the mixing process. Also, some users complain about the product drying out quickly inside the syringes, but there are still fewer negative reviews about its use than positive ones.

Advantages and disadvantages

- Two-component composition

- Optimal hardening speed

- High thermal conductivity

- Degreasing wipe included

- Completely dried specimens are occasionally encountered.

- The glue is difficult to squeeze out of the tubes

Size

Glue sticks are suitable for any material, including fabric, paper, cardboard, metal, wood, plastic and others. The exceptions are PVC, plaster and concrete. The tool provides a strong bond with all other materials. Hot melt glue gun is divided by diameter. The most common are 11 and 7 mm. There are many other sizes available. In this case, the choice of one or the other depends on the available pistol. Also, stickers can have different lengths: in the range from 4 to 20 cm.

Top 1. REXANT 7.4x200 mm, 10 pcs.

Rating (2021): 4.80

1474 reviews taken into account from resources: OZON, Wildberries

Optimal price-quality ratio The material was liked by builders and handicraftsmen. It combines an affordable price and a high-quality composition that ensures reliable gluing.

Popular hot-melt adhesive The product has the largest number of positive reviews in the selection. This glue is considered one of the best budget materials.

- Characteristics

Country: China

- Average price: 259 rub.

- Number of colors: 1

- Melting point: 85-120 °C

Budget and high-quality hot melt adhesive for universal use. Used for gluing products made of ceramics, cardboard, metal, paper, plastic, glass and wood, forming a durable and almost invisible seam. After heating it does not leak: judging by the responses, the rods are very convenient to use. Heats up quickly and does not spread. Also in their reviews, users talk about the environmental friendliness of the composition. The adhesive consists of EVA resin, which is odorless and does not release hazardous substances into the environment. Rods of size 7.4x200 are sold in one shade, but this does not make them less functional. Only certain types of glue guns are suitable for their use. If you make the wrong choice, you may end up with poor-quality gluing and problems during the work process.

Advantages and disadvantages

- Doesn't spread

- No odor when heating

- Suitable for most household glue guns

- Forms a strong adhesive seam

- One color in stock

See also:

- 10 best glue guns from AliExpress

to the beginning of the rating

Transparent glue

Hot melt adhesive guns, whose specifications may vary, are suitable for certain materials. It comes in many shades. All types of this substance differ in properties and component composition. The white transparent sticker has become most widespread due to its versatility. It can be found in any relevant store. It is suitable for working with any base. Therefore, this option is optimal for household use and creating crafts. The transparent yellow compound is used on cardboard, paper and wood.

Top 4. HY910 Halnziye

Rating (2021): 4.00

15 reviews taken into account from resources: Amazon

Minimum consumption One small drop is enough to install the elements. Hot-melt adhesive is quickly and evenly distributed over the surface.

- Characteristics

Country: China

- Average price: 275 rub.

- Purpose: installation of transistors, chips, LEDs

- Hardening time: from 3 min. up to 24 hours

- Thermal conductivity: 0.975 W/(m K)

Economical and easy to use hot melt adhesive. Sold in tubes of 5 g and 10 g. It has good thermal conductivity for its price category, is non-toxic, and begins to dry out after installing the components for heat removal. Judging by the reviews, the product may well replace thermal paste. It dries very quickly along the edges of the installed elements, and remains wet underneath them for at least 24 hours. If during this period it is necessary to dismantle the component, then it is removed without the use of solvents or additional devices. This hot melt adhesive can also be used in LED lamp assembly without welding. But it’s quite difficult to find it for sale on domestic sites. It is mainly sold abroad and by Chinese online retailers, but it is also available on Ozone.

Advantages and disadvantages

- Allows you to dismantle the glued element within 24 hours.

- Tight adhesion when completely dry

- Does not conduct electricity and does not corrode metal

- Hard to find on sale

- For some users, it takes longer than a day to polymerize

Colored rods

The universal category also includes options with any shades, with the exception of black. A wide range of colors allows you to choose hot melt adhesive for the gun that matches the palette of parts. For example, when working with a red vase, in order to get invisible joints, you need to take a scarlet cartridge. Opaque white stickers are suitable for gluing a white base and elements stylized as metal or glass. When purchasing, you should pay attention to the properties. But, as a rule, the shade performs only decorative functions, and the adhesive mass is universal. Hot-melt adhesive for the 11 mm "Bison" gun, gray and black, can act as an insulating material and sealant. It is ideal for sealing joints and insulation.

Identical parts are easier to glue together

If you have several identical parts, it is easier to process them in glued form: cutting, grinding, drilling, etc. After processing, the parts can be easily disassembled. The main thing is not to use too much glue. Spot gluing allows not only to securely fasten the parts together, but also to easily dismantle the connection after processing. To disassemble, you can use a spatula, and to remove residual glue, you can use a chisel.

Temperature

Melting point is an equally important characteristic. For some rods it is 150 degrees. For others, a lower temperature is enough to work. It is worth noting that for places characterized by slight heating, less fusible glue should be selected. When choosing, it is necessary to take into account the characteristics of the heat gun and the materials used for the work. Hot melt adhesive for a gun can be applied using various tools:

- Glue roller or head.

- With a special machine or applicator.

- Foot pedal used for equipment of professional devices.

- Household glue gun.

Types of hot melt adhesive

Hot melt adhesive (hot melt adhesive, hot melt adhesive) is a thermoplastic solid substance with a specific operating temperature.

When heated, the consumables soften, acquire a viscous-flow state, and connect various materials, and when cooled, they polymerize, reliably gluing the surfaces.

Hot-melt adhesive gained popularity primarily due to its wide range of applications, short setting time and, of course, versatility.

To apply hot melt adhesive use:

- Standard manual glue guns.

- Professional pistols with connected foot pedal.

- Glue machines.

- Rollers or glue heads.

- Other special equipment.

For ease of use, hot melt adhesive is supplied in various release forms, which are also called cartridges, due to the fact that, by analogy with a firearm, they are loaded (filled) into a glue gun.

As mentioned above, cartridges can be in the form of rods, pads or granules, used in some types of professional tools and automatic packaging lines.

Properties of hot melt adhesive

Thermoplastic adhesive has a number of interesting properties, due to which it has become widespread:

- Tensile strength. According to the manufacturers, in order to separate glued objects from each other, a force of up to 150 kg will be required.

- Short polymerization time of a few seconds, however, depending on the thickness of the applied layer and the ambient temperature. Good fusibility should also be noted. So hot melt adhesive begins to liquefy at a temperature of 80 degrees, depending on the composition.

- Long service life, frost resistance, resistance to excess moisture, direct sunlight.

- Relatively low cost.

- Adhesiveness that allows you to reliably connect a huge number of different materials.

- Hot-melt adhesive, depending on impurities, may have increased stickiness and reduced viscosity. To do this, in the first case, rosin is added, and in the second, paraffin or wax. Also, the addition of heat-resistant antioxidants when heated slows down the oxidation reaction. However, all this applies only to organic glue.

- High temperature resistance. Some types of hot-melt adhesive have a softening temperature of 80°C, while for others this figure reaches 150°C.

- Heated hot melt adhesive does not have an unpleasant odor, and when heated there are no toxic fumes. But despite the low toxicity of the composition, safety precautions must still be observed.

Characteristics of hot melt adhesive

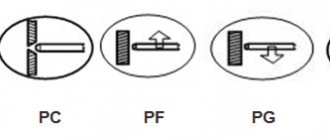

As already mentioned, hot melt adhesive has several forms of release:

- Rods (sticks) – we will talk about them separately.

- Granules – due to their flowability, they are easy to deliver to the heating chambers of semi-automated and automated lines, suitable for professional heat guns. Among the advantages are convenient transportation and storage, a wide selection of compositions for any task. It should also be noted that it can be applied in a variety of ways, including applicators.

- Pillows are small rectangular pieces, used in professional heat guns. Also produced for various tasks.

- Cylinders - similar to the previous option.

Compound

Ethylene vinyl acetate compounds have become most widespread. They allow you to work with a variety of substrates, including fabrics, ceramics, certain types of metals, plastics, wood and paper. There is also a polyophinol hot melt adhesive for the gun, the use of which is necessary for items exposed to a wide range of temperatures. The chemical formula ensures that the bath, nozzle and the entire tool system are cleaned of the composition that was previously used. Products based on this type are more stable, which is why they have become widespread in the electronics, packaging and automotive industries. They can be used on light metal, foil, leather, hardwood and other materials characterized by the presence of synthetic and hard resins.

Classified as a pressure-sensitive adhesive, the adhesive maintains tack. The scope of application is wide. It includes difficult-to-glue planes. It is used in the construction, automotive and large surface areas. Hot glue gun (black or any other color) with medium pressure sensitivity provides a sticky surface for 5 minutes. This is the best option for connecting elements that are not resistant to heat and large surfaces.

Top 5. GM Inform Alsil-5, 3 g

Rating (2021): 4.00

293 reviews from resources taken into account: Yandex.Market, Citilink, DNS

The most popular hot melt adhesive with the maximum number of reviews. One of the oldest tools for upgrading/maintaining the heat dissipation system in a PC.

- Characteristics

Country Russia

- Average price: 227 rub.

- Purpose: mounting radiators

- Hardening time: from 60 min. up to 24 hours

- Thermal conductivity: 1.4 W/(m K)

One of the most popular hot melt adhesives on the domestic market. Produced for 20 years. Used for servicing PCs, laptops and netbooks, smart TVs, installing radiators on microcircuits. Helps reduce system heating and prevent system failure due to high temperatures. By the way, the operating temperature of the composition is from -60 °C to +200 °C, which means that it is resistant to freezing. It is easy to apply and spreads easily over the surface. Only it is rarely found undried: hot-melt adhesive is very demanding on storage conditions. Therefore, copies ordered online often arrive to users already completely dry, even in closed packaging. Therefore, many buyers advise purchasing the product in offline stores and carefully checking its freshness. The maximum shelf life of the composition is 3-5 months.

Advantages and disadvantages

- Excellent adhesion to plastic and metal

- Provides efficient heat dissipation

- Vibration resistant

- Some retailers sell it already dried

- Limited shelf life

What do you need to know?

There are many different characteristics. But, first of all, it is necessary to build on the intended materials. It can be polypropylene with the addition of aluminum, spunbond, plastic, laminated surface, paper and cardboard coated with ultraviolet varnish. The subsequent impact on the material must also be taken into account. For example, transportation, contact with food and water, and temperature conditions are taken into account.

To obtain reliable bonding, characteristics such as shade, hardening time, and structure viscosity play a special role. The feed rate of the mass can be different. The application method is divided into automatic and manual. At the same time, a different form of composition is suitable for each type of base: tablets, pads, blocks, pins. The speed of preparation of the mass and its fluidity directly depend on the melting rate of the rod. As a rule, a tool is designed to work with a certain type of composition. Some professional options have a temperature change function.

Fixing wobbly furniture

A table with four legs has one significant problem - it wobbles. As a rule, the culprit is either an uneven floor or unprofessional furniture makers. The problem is noticed when the table is in active use and solved by placing folded pieces of cardboard under the leg. Unreliable and temporary solution.

You can get rid of the problem once and for all by simply gluing a few coins to the table leg with hot glue.

Features of application

Hot-melt adhesive for the gun, the photo of which is presented above, can have different viscosity, depending on the distribution method. Compositions with a dense structure are applied using a disk or roller method, and a nozzle or nozzle is suitable for low-viscosity material. Compliance with the operating cycle of the equipment and the setting time is required. Also, if there is a need to replace the gluing base, you need to make sure that you do not need to replace the glue itself. Rods from different manufacturers may have different component compositions. Therefore they should not be mixed. Otherwise, the structure and characteristics may change.

Who is handyman?

Handyman is almost as popular in America as Supermen. Just targeting different age groups. All American teenagers dream of becoming supermen in order to “save the world.” Many of them, having matured, become “handymen” and “save” their own home.

Handyman is a “jack of all trades,” a person who likes to do things with his hands (hand). A very popular activity in the USA.

Don’t believe it when they tell you that they are all “stupid”, they don’t know how to do anything with their hands... they can’t even screw in a light bulb. Perhaps the “office plankton” living in rented apartments in big cities is just that. But they are not the “real Americans.”

Every real American has his own house, which necessarily has a basement (ground floor, basement), which, in turn, is equipped with a workshop.

From our point of view, people become “handymen” by force. Unlike an apartment, when you can call someone and someone will do everything, your own house always means something needs to be nailed down, sawed off, etc. As for furniture, inexpensive mass-produced furniture has a lot of limitations and disadvantages. And many people simply cannot afford individual production. With basic skills and the appropriate tools, you can always customize finished furniture to suit your needs.

If we take into account the fact that all of America is “one-story” (see Ilf and Petrov) and the majority of Americans live in their own houses, the number of “handymen” is simply off the charts. They publish their own magazines, TV channels and online sites. Familyhandyman.com is one such resource.

Safety precautions

Hot-melt adhesive for a gun, the melting point of which depends on the composition, belongs to the category of substances with a medium degree of danger. It is characterized by low toxicity. But vapors entering the respiratory tract can contribute to short-term depression of the central nervous system. Short-term use does not require equipment with protective tools. In this case, it is advisable to ensure ventilation of the room. It is also worth noting the damage that the working method can lead to. In particular, these are burns that occur when the molten composition gets on the skin.