Among connoisseurs of edged weapons, knives made of Damascus steel are especially popular. There are several misconceptions and myths surrounding this material. Here are some of them: the technology for creating Damascus has long been lost, a blade made from this metal does not need to be sharpened, Damascus blades cut steel and down pillows equally well, and Damascus and damask steel are the same thing.

In fact, like other weapons, Damascus steel knives require regular sharpening and careful care. The technology for producing such blades has been preserved, so now there are various models on sale - kitchen, hunting, tourist and others. Damascus and damask steel are far from the same thing.

Damascus and damask steel: history of origin and distribution across the planet

Damascus knives have been used for hunting since ancient times. They were used for cutting game, skinning dead animals, and in everyday life as a kitchen tool.

Such weapons were considered elite. It was valued for the following qualities:

- durability;

- excellent cutting qualities;

- the beauty of the material and patterns;

- strength, but at the same time flexibility of the blade.

The first mention in history of Damascus steel is associated with the time of Alexander the Great’s campaign in India. Then he clashed in battle with the army of the local king Porus. He was wearing a protective shell made of this alloy, on which Greek swords did not leave a scratch. The swords of Indian warriors were made from the same material.

During the Crusades, European warriors were amazed by the sharpness of Arab sabers made of Damascus steel. The crusading knights happily bought such weapons and brought them home as trophies.

There are three theories about the origin of the name of Damascus weapon:

- Damascus means “water” in Arabic. In documents of that time it was described as a blade, on the surface of which there is a pattern in the form of a rippling surface of water.

- This steel was produced in Damascus. However, this ancient city was more of a major trading city, rather than a weapons city. Therefore, most likely, it was only brought here from outside.

- Supporters of the latter refer to a certain weapons maker Damascus, after whom this material was named.

The manufacturing technology has spread around the world and received various names.

Mentions of damask blades are found in Aristotle, during the times of Ancient Greece. It is believed that Damascus was invented as a cheap analogue of damask steel.

The cutting qualities of both materials are approximately the same, but damask steel is somewhat stronger.

It should be noted that the secret of damask steel was lost. The second discovery of the secret of damask steel is associated with the name of Pavel Anosov.

He made cast damask steel in 1837, although he knew that this alloy had been produced in Russia even earlier, in the 16th and 17th centuries. (under the name “cold steel” or “haraluzhnaya” steel or “Russian damask steel”).

But the Russian gunsmith did not leave precise instructions for creating damask blades. And it remains unknown whether the domestic metallurgist reproduced the ancient manufacturing method, or created a new one.

Interesting Facts

Information about the superiority of ancient Damascus steel over other types appeared in romantic literature and the media. However, scientists have not proven this fact. The same applies to the fictitious fact about prevalence among peoples. Archaeologists have not yet discovered a Damascus blade in Western Europe dating earlier than the 15th century.

Armor, spathas or gladiuses forged from Damascus have also not been found in Rome. Although there is a myth that the material was widely popular and was worth its weight in gold.

Damascus blades were also not used in the Crusades. According to historical documents, Damascus was first mentioned in the 13th century. The information that appeared in the 19th and 20th centuries about the ability of Damascus swords to cut weapons and plate armor made of other types of steel is not true. This has been confirmed experimentally. Steel with 55-58 HRC cannot be damaged by a weapon of similar hardness.

Damascus was endowed with unnatural properties in various sources. However, metallurgical research and attempts to recreate the manufacturing technology of Damascus steel proved that the material did not have characteristics that defied the laws of physics.

What is real damascus and damask steel

For damask steel, knife blanks are obtained by heating, twisting and re-forging several hundred layers of steel. The materials alternate according to the hard layer-soft layer principle. One layer is carefully placed on top of the other, and then the entire package is reforged. The output is a blade of several hundred layers.

To ensure that the plates fit tightly to each other, they are pulled together with rods. Forge welding of metal layers is carried out until a blade of the required quality is obtained. Forging must be accurate and of high quality, defects in the form of slag are not allowed, the metal is carefully forged.

The pattern should be clearly visible across the entire blade.

It follows the structure of the metal: the more different layers were used, the finer the patterns on the blade. Moreover, they are never repeated. Plus, it is the multilayer composition of the blade that ultimately gives the unique characteristics of a weapon made of Damascus steel - a sharp and durable blade, a unique appearance, etc.

Before you start sharpening your blade, you need to put it in order. Examine it carefully. The sharpening angle of the knife is selected depending on the purpose of its use. It is the task of the blade that determines at what angle you need to work with the abrasive stone.

Bulat is, according to P. Anosov himself, a high-carbon steel. No special impurities are added to it. On the contrary, the main thing is clean raw materials. You will need to combine iron and carbon, after which you need to:

- Heat to desired temperature.

- Cool the resulting alloy until the metal crystallizes.

To produce damask steel, two materials are melted - high and low carbon. The melting point of the latter is somewhat lower. When cooled, the surface becomes coated with carbon, which makes the blade unusually strong.

As a result, the differences in production technology are as follows:

- Damascus is made by layering and forging hard and soft layers of metal.

- Bulat is a cast alloy, the creation of which is based on temperature changes.

Types of patterns

Before listing the different types of Damascus, it is worth making a short note. In order to produce stainless Damascus, it is necessary to assemble a package of alloy steel with the correct additives. It is welded in a vacuum.

This steel is then forged and the heating cycle is repeated. Modern technologies can handle such a process, despite the complexity of the process. Sometimes you can find kitchen products with patterned stainless steel linings.

Wild Damascus

It got its name because of the disordered pattern. It is quite simple to manufacture and is considered the most common type. A package is made from several types of steel and welded into a single block. It is repeatedly bent and forged.

The layers of metal mix randomly. The surface of the finished product looks uneven. This method goes back hundreds of years. Due to the uniqueness of the pattern, it is highly popular among collectors.

Wild Damascus.

Stamped

This is one of the varieties of traditional damask, with a more uniform pattern. It can alternate geometric shapes: stripes, circles and rings. It is made in two ways:

- the pattern is applied using a metalworking method, using a drill or a router, and only then the package is forged;

- The package is welded, and the stamp is struck in a given order. The finished blade must be polished. This way they achieve a clearer picture.

Stamp patterns can be mesh, wavy, stepped, ringed and rhombic. The patterns look like wood veneer or circles on water. The types of patterns are in turn divided into a wide variety of patterns.

By the corporate style, you can even recognize the hand of the master. In America, damask with a type of pattern - peacock eye - is very popular. The pattern looks like crosses, resulting in an imitation of barbed wire or mesh. To produce such a pattern, uniform drilling of the workpiece is used.

Example of stamped Damascus.

Mosaic

It is classified as a modern type of Damascus. Thanks to the specific manufacturing method, it got its name. The layered structure gives a beautiful decorative effect. The steel is assembled into a package similar in principle to a mosaic.

A subspecies of this type can be called mosaic end damask. This is a blade with welded strips of mosaic damascus cut from the end of the finished block. Such a strip or several strips can be applied in the middle of the blade.

Mosaic Damascus.

Turkish Damascus steel

One of the traditional varieties of patterned steel. A bundle of intertwined steel rods is used for forging. It is clear that the composition of the rods is varied. A complex pattern with many smooth wavy lines appears on the finished product. Their size depends on the chemical composition of the metal and the diameter of the rods.

Examples of Turkish Damascus steel.

Japanese

Laminated steel has a fine structure. The surface of such knives is etched. The structure of the steel is revealed through unusual polishing. Only the blade itself is hardened. The result can be seen in the properties of the Japanese sword. The handle remains elastic, and the blade becomes hard and brittle.

Japanese knives made of Damascus steel.

Shell

A metal pipe or container is used to connect mosaic elements. Various steels are placed inside. Next, the container is filled with inert gas or oil. In the process of heating the workpiece, oxygen is bound.

A neutral environment is obtained inside the shell, and the pipe is completely welded. In this state, the package is heated to welding temperature. After the formation of a single mass of steel, the shell is removed. Next, the workpiece can be forged.

Shell Damascus.

Fiber Damascus

This method is used in the manufacture of high-quality Japanese swords. When the package is properly forged, the steel hairs do not stretch over the entire length of the blade, but, on the contrary, are finely chopped and arranged in layers at right angles. This metal is very similar in structure to damask steel.

Fiber Damascus knives.

Technological

Holes are cut out in the steel bar in accordance with the specified pattern. Rods of another metal with a different chemical composition are inserted into these holes. Inserts and holes are cut with a plasma cutter. The package is then diffusely welded.

The advantage of this method is the ability to create the necessary drawing and various images. The pattern covers the entire thickness of the blade, which distinguishes it from surface engraving or etching.

Examples of technological Damascus knives.

Combined

This method includes the classical and traditional manufacturing method. Hence the name of the method. A stamp pattern is applied to the block assembled using the mosaic method. If a relief is applied by drilling or milling, then the alloy is forged and etched.

In this case, grinding is not used. It is also possible to combine the wild Damascus technique with metal inserts with contrasting properties. Nickel may be another alloy in composition. The white color will stand out against the overall black and gray pattern of the blade.

Combined Damascus knives.

Industrial

This method is used at large production sites of metallurgical enterprises. The quality of such blades is in no way inferior to the handmade work of masters. The scale of the process is, of course, large. Wild, combined and mosaic damask is produced industrially.

Industrial Damascus.

Knives and other edged weapons made of Damascus steel

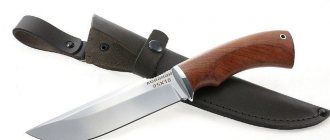

A Damascus steel knife should fit easily in your hand. Since it is used as a cutting tool, the blade is sharpened only on one side. On the other hand, there is an unsharpened part a couple of millimeters thick. The crosshair is either absent or small, but the grip usually has small rests for the index finger.

Any materials are used to make the handle. Natural ones include various wood or animal horns. Typically, a handle made of natural materials is impregnated with special oils, which help protect it from moisture and dirt. Some models have a plastic handle, which is cheaper and much more convenient in everyday conditions - it does not slip and lies securely in the hand.

The sheath can be made from any material. Usually made of genuine leather. The main thing is that the knife is reliably protected from the external environment. The advantages of Damascus knives are as follows:

- light weight;

- beautiful appearance, unique patterns;

- good cutting properties;

- With proper use and care, the knife will last for many years.

These knives have several disadvantages:

- They are quite expensive and not available to the general public. A high-quality knife, made to order by a master, costs from 50,000 Russian rubles.

- The knife is used as a cutting tool. Since it has a small blade, it will not be able to cut branches or denser materials (although edged weapons - axes, swords, etc. - can easily cope with this task).

- Like all knives, the blade needs regular sharpening.

- The steel from which the knife is made reacts poorly to a number of alkalis and acids, and is therefore vulnerable to corrosion.

Chemical composition

Due to the manufacturing characteristics, it is not homogeneous. The composition includes both stainless steel grades with a high chromium content and low-alloy ones.

The norms and quantitative content of alloying components of Damascus steel are not regulated by any domestic or foreign standard. It is produced differently in each workshop, so the content of chromium and other metals in each blade is different. As a rule, the quantitative carbon content in it does not exceed 2%.

The amount of other alloying components depends on the set of components from which it was made.

For example, for manufacturing, blacksmiths can use the set of steels presented in the table.

| Name | Alloying component | Mass fraction in metal, % | Purpose |

| X12MF | WITH | 1,45 – 1,65 | Carbon gives the alloy hardness and increases wear resistance. |

| Cr | 11,0 – 12,5 | Increases the metal's resistance to corrosion and improves its wear resistance. | |

| V | 0,4 – 0,6 | The use of vanadium improves hardness and extends its service life. | |

| Ni | 0,15 – 0,3 | Alloying the metal with nickel increased its strength and corrosion resistance. | |

| 40Х13 | C | 0,36 – 0,45 | Gives the metal hardness and makes it more resistant to wear. |

| Cr | 11,0 – 12,5 | Chromium prevents local corrosion of the alloy. |

Household and travel knives made of Damascus steel

Kitchen knives are suitable for cutting meat, fish and poultry, fruits and vegetables. This is a reliable cutting tool for everyday use. For meat and poultry, a fillet knife with a wide blade is used.

Tourist models are valued primarily for their durability. Especially among fans of extreme tourism. Plus, damask steel does not require frequent sharpening. Usually such a knife has a small blade. It is used during hunting or fishing.

Fishing knives made of Damascus steel have a small blade designed for processing fish and working with nets.

It is convenient to use folding knives made of Damascus steel on a hike - they are ergonomic, safe when moving, do not require a sheath, they can be put in a pocket and quickly pulled out. The only drawback is reliability. Due to the presence of the mechanism, the design becomes more complicated.

And in the wild, weapons that are simpler are valued. After all, the more mechanical components there are, the more likely it is that one of these components will fail at the most inopportune moment.

Modern survival knives have a rather complex design, but this is a special type. After all, they are designed for one-time use, only in extreme cases; the rest of the time, a survival knife should lie and wait in the wings.

Do damascus and damask steel rust?

Damascus and damask steel are susceptible to rust. It is removed using a rag, which is soaked in gun oil (alkaline or neutral type). But you shouldn’t use an abrasive for cleaning: the polished blade can be scratched. You can use hard rubber or special solutions.

No need to remove it unnecessarily. After use, the knife should be thoroughly cleaned, wiped, lubricated with oil or grease, and then stored in a dry place. If it is stored or used in an environment with high humidity, you need to wipe the blade with regular Vaseline.

Leather sheaths can also be impregnated with special products designed specifically for leather care.

However, there are also stainless steel models of knives made of Damascus steel and damask steel. Thanks to the use of special additives, the blade is protected from rust, while maintaining sharpness and strength. However, stainless steel cannot maintain an edge for a long time, for this reason it is not very valued by true connoisseurs of Damascus knives.

Folding knives are more susceptible to corrosion, so they should be made only from stainless materials. It is desirable that it have a plastic handle. However, the technology for producing high-alloy Damascus is quite complex, which is why the cost of such knives is much higher than conventional models.

Modern manufacturers of damask steel knives

Both foreign and domestic manufacturers are engaged in the production of damask knives. They can be divided into three conditional groups:

- Individuals producing knives in “artisanal conditions”. The quality and appearance of the product will be worse, but it will cost much less.

- Trademarks engaged in mass production and sale. They are of good quality, and the price ranges from 3,000 to 10,000 Russian rubles. Most people buy industrial knives.

- Masters specializing in the manufacture of damask knives. They sell products, as a rule, at exhibitions, providing complete information to buyers. For example, famous blacksmiths who create weapons from damask steel are I. Pampukha, S. Baranov and A. Biryukov. The price reaches tens of thousands of rubles, but such a weapon will last for many years, becoming a family heirloom.

Currently, knives made of damask steel and Damascus steel from Zlatoust and Kizlyar, as well as from smaller manufacturers, are widespread in Russia. These mass products are much worse in quality than the products of craftsmen, but they fully satisfy the requirements of the mass consumer, and they are affordable.

You can purchase them both in hunting and online stores. It is more convenient for hunters and fishermen to use a knife with a hook blade to cut up carcasses.

Damascus, damask steel and modernity

Despite the emergence of new alloys and materials, knives made of Damascus steel and damask steel still remain the most desirable. Both have the same cutting properties, but damask steel is stronger, which is why it costs more.

Their main competitor in the market is ceramic knives.

They have almost identical cutting properties, but damask and Damascus knives are more reliable and elegant.

In the manufacture of Damascus, various alloys, advanced heating, forging and sharpening technologies are used. Thanks to this, original models are created with unique carvings and patterns.

When purchasing a knife, you should also take into account the legal requirements in relation to edged weapons. The knife must have a certificate stating that it is not a bladed weapon, or can only be distributed under a license to own a civilian weapon.

Analogs

The only grade of steel that has similar characteristics to Damascus is damask steel. It has exceptional strength and toughness. Damask steel blades are resistant to impacts, bends and hold the factory sharpening for a long time.

Their hardness reaches 64 units on the Rockwell scale.

Damask steel blade is an alloy of iron and carbon with a low content of alloying elements. A special technology of melting and hardening, combined with a high-tech forging process, gives it a dark, almost black color. In addition, it has a fibrous pattern, which gives it a similarity to Damascus steel products.

Prospects for Damascus knives

Damascus knives are a popular weapon among both beginners and professional hunters. And the unique appearance of steel attracts collectors of bladed weapons.

The combination of beauty, functionality and reliability make them a popular tool.

Various models are created from this steel. Damascus steel folding knives are popular. Thin blades and cleavers are better suited for the kitchen. Therefore, such a tool will not have problems with buyers.

Finding real Damascus steel is another matter. Since such knives have acquired cult status, many sell low-quality goods under the guise of popular material. This is what Arab traders did before, in the Middle Ages, and this is what happens now.