| Tensile strength, N/mm2 | Relative extension, % | Impact strength, J/cm2 |

| ≥450 | ≥22 | ≥78 |

Special properties

A distinctive feature of MONOLITH RC products is the low intensity of aerosol and manganese formation during welding. Thanks to this, the product compares favorably with other brands of electrodes. The developers managed to achieve this result through the correct selection of raw materials and careful control over the technological and production process.

High quality indicators have been repeatedly noted by the country's leading scientific institutes. It is the MONOLITH RC electrodes that produce 30% less manganese and 28% less harmful substances in the aerosol.

MONOLITH RC products provide easy initial and re-ignition, as well as stable and soft arc burning. When using electrodes of this brand, it is possible to reduce metal loss due to spattering. It is possible to achieve excellent weld quality, uniform melting of the coating and good separability of the slag crust.

When using MONOLITH RC electrodes, welding can be carried out even at extremely low currents. If we are talking about using products of small diameter, then an ordinary household network can become a power source for them.

The electrodes are very easy to handle. Even young specialists can work with them.

When bending the electrode, the coating does not break. For this reason, they are convenient to use for welding in hard-to-reach places.

The products can be used when connecting metal to painted, oily and oxidized surfaces.

Welding modes

| Welding current strength (A), for electrode diameter, mm | |||||

| 2,0 | 2,5 | 3,0 | 3,2 | 4,0 | 5,0 |

| 40-80 | 50-90 | 70-110 | 80-120 | 110-170 | 150-220 |

For welding, it is allowed to use direct current of any polarity (the desired polarity of the electrode is reverse “+”, or alternating current of a transformer with an open circuit voltage of more than 50 V.)

Packaging details

| Diameter, mm | Length, mm | Number of electrodes in a pack, pcs. | Pack weight, kg |

| 2,00 | 300 | 50-54; 99-108 | 0,5; 1 |

| 2,50 | 350 | 27-28; 53-56; 133-140 | 0,5; 1; 2,5 |

| 3,00 | 350 | 18-19; 35-37; 89-93 | 0,5; 1; 2,5 |

| 3,20 | 350 | 16; 32; 78-81 | 0,5; 1; 2,5 |

| 4,00 | 450 | 8; 16-17; 40-41; 81-83 | 0,5; 1; 2,5; 5 |

| 5,00 | 450 | 53-54 | 5 |

Analogs

| Manufacturer | Electrode brand |

| ESAB | OK 46.00 |

| Oerlikon | Overcord, Overcord Z |

Calcination before welding

If the electrodes were stored under normal conditions, then calcination will not be required before use. But if moisture was allowed, then pre-drying is necessary for 25-30 minutes at a temperature of about 110 degrees.

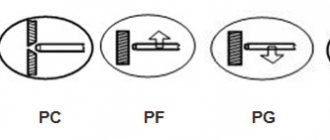

Position of seams during welding

Welding electrodes MR-3 ARS

Type of coating – rutile

| AWS A 5.1:E 6013 | ISO 2560-A-E 38 0 R 12 | GOST 9466 | E 46 –MR-3 ARS-Ø – UD E 432 (3) P21 |

TU U 28.7-34142621-007:2012-09-14

Purpose

Products of the MR-3 ARS grade can be used for manual arc welding of steel grades according to DSTU 2651/GOST 380-2005 (St 0, St 1, St 2, St 3), having any degree of deoxidation.

Conditions of use

The deposition rate of electrodes is 8.0-9.0 g/Ah. And the consumption per kilogram of deposition is 1.7 kg.

The products can be used to create lap, butt and corner joints. Metal thickness is allowed from 3 to 20 mm. This brand of electrodes with a thickness of 2.5 to 4.0 mm is suitable for welding in any spatial position. The 5.0mm diameter is ideal for vertical bottom-up position, horizontal on vertical plane and bottom position.

MP-3 APC electrodes require direct current of any polarity, or alternating current from a transformer with an open circuit of more than 50 V.

Chemical composition of deposited metal, %

| Mn | C | Si | P | S |

| 0,40-0,70 | no more | |||

| 0,10 | 0,15-0,35 | 0,030 | 0,030 | |

Mechanical properties of weld metal

| Tensile strength, N/mm2 | Relative extension, % | Impact strength, J/cm2 |

| ≥450 | ≥22 | ≥78 |

Special properties

- When using the products, simple closing of gaps is ensured;

- MP-3 ARS is the ease of performing work and re-igniting the arc, as well as excellent welding and technological properties;

- Great looking seams;

- Easy separation of the slag layer;

- Possibility to extend the arc to treat oxidized surfaces;

- Compliance with all sanitary and hygienic standards.

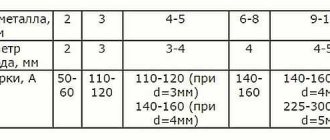

Welding data

| Welding current strength, A, for electrode diameter, mm | ||||

| 2,5 | 3,0 | 3,2 | 4,0 | 5,0 |

| 50-90 | 70-110 | 80-120 | 110-170 | 150-220 |

Packaging details

| Diameter, mm | Length, mm | Electrode weight, g | Number of electrodes in a pack, pcs. | Pack weight, kg |

| 2,50 | 350 | 17-18 | 55-58; 139-147 | 1; 2,5 |

| 3,00 | 350 | 25-26 | 38-40; 96-100 | 1; 2,5 |

| 3,20 | 350 | 30-31 | 32-33; 80-83 | 1; 2,5 |

| 4,00 | 450 | 58-59 | 42-43; 84-86 | 2,5; 5 |

| 5,00 | 450 | 91-92 | 27; 54 | 2,5; 5 |

Analogs

| Manufacturer | Electrode brand |

| LEZ | MR-3S, ANO-4 |

| SpecialElectrode | MR-3S, ANO-4 |

| Thyssen | Phoenix SH Gelb R |

Calcination before welding

In cases where the electrodes were stored under normal conditions, preliminary calcination is not required. If moisture was allowed, then the electrodes need to be dried at a temperature of about 150 degrees for 40-60 minutes.

Position of seams during welding

Certification

UkrSEPRO, StB, GOST R

Welding electrodes TM: Monolith, Arsenal, Continent, Standard

Monolith RC

TYPE OF COATING – rutile cellulose .

A universal electrode for wide use in industry and everyday life with a reduced amount of welding aerosol emission.

Monolith RC electrodes are insensitive to the quality of edge preparation, the presence of rust and other surface contaminants.

During installation welding, it is possible to work in all spatial positions without changing the welding current. Welding vertical seams using the top-down method is carried out with a short arc or support.

Monolit RC electrodes differ from similar products from other manufacturers in the reduced amount of emissions and the intensity of the formation of welding aerosol and manganese during metal welding.

Allows welding at extremely low currents.

Welding in hard-to-reach places. Ability to bend the electrode without damaging the coating.

Welding on oxidized, oily and painted surfaces is possible.

Easy handling of the electrodes makes welding possible for novice welders.

Monolith UONI-13/55 Plasma

TYPE OF COATING – basic with iron powder .

UONI-13/55 PLASMA electrodes are intended for welding in all spatial positions of critical structures and pipelines made of carbon and low-alloy steels with a tensile strength from 500 MPa to 640 MPa

Deposition rate – 10.5-11.5 g/Ah. Electrode consumption per 1 kg of deposited metal is 1.58 kg. Rated performance up to 115%.

Monolit UONI-13/55 PLASMA electrodes are distinguished by high strength of the weld metal, and also ensure the production of weld metal with special metallurgical purity and low hydrogen content. The possibility of welding on alternating current eliminates the effect of magnetic blast.

Thanks to the addition of iron powder to the electrode coating, the efficiency of using UONI 13/55 PLASMA increased by 20%:

- Reduced consumption of electrodes by 10-15%;

- Surfacing productivity increased by 8–10%.

Monolith Professional

TYPE OF COATING – thick rutile .

The electrodes have the ability to weld in conditions unfavorable for other brands of electrodes.

A gas bubble appears around the arc, which displaces water and provides acceptable conditions for the welding process, which makes it possible to weld damaged water pipes under pressure of up to 1 atm.

For welding sheet steel and steel structures subject to static and dynamic loads, welding tanks and pipelines where high mechanical properties of seams are required.

ANALOGUES: OK 43.32 (ESAB), Overcord S, Fincord (Oerlikon); MGM-50 (Lincoln Electric - Mezhgosmetiz-Mtsensk)

Arsenal MR-3 ARS

TYPE OF COATING – rutile .

MR-3 ARS electrodes are intended for manual arc welding of structures made of carbon steel grades in accordance with GOST 380-2005 (St 0, St 1, St 2, St 3) and GOST 1050-88 (05kp, 08kp, 08ps, 08, 10kp, 10ps , 10, 15kp, 15ps, 15, 20kp, 20ps, 20)

Relative elongation of weld metal ≥22%

Electrodes with a diameter of 2.5 to 4 mm are suitable for welding in all spatial positions.

Welding with Arsenal MP-3 ARS must be performed with direct current of any polarity or alternating current from a transformer with an open circuit voltage of at least 50 V.

MP3ARS electrodes provide easy gap bridging.

Welding with an extended arc on an oxidized surface is allowed.

Standard RC

TYPE OF COATING – rutile cellulose .

Electrodes Standard RC are intended for manual arc welding of ordinary and critical structures made of carbon steel grades

Electrodes provide:

- good welding and technological properties when welding from small-sized (household) transformers:

- easy arc ignition;

- fine-flaky formation of weld metal;

- easy or spontaneous separation of the slag crust.

It is possible to use electrodes for tack welds, short and root welds at low network voltage.

Welding using the “top-down” method is carried out with a short arc or support, while the electrode must be in a bisector plane at an angle of 40-70° to the welding direction

Continent MP-3 PLASMA

TYPE OF COATING – rutile .

MR-3 PLASMA electrodes are intended for manual arc welding of ordinary and critical structures made of carbon steel grades in all spatial positions, except vertical, top-down method

Relative elongation of weld metal - no less than 18%

Deposition coefficient – 8.5-9.5 g/A*h

Welding with Continent MP-3 PLASMA must be performed with direct current of reverse polarity (“+” on the electrode) or alternating current from a transformer with an open circuit voltage of at least 60 V

Welding with an extended arc on an oxidized surface is allowed

Welding electrodes UONI-13/55 PLASMA

Type of coating – basic with iron powder

| WS A 5.1 : E 7018 | ISO 2560-A-E 42 4 B 42 H 5 | GOST 9466 | E 50A – UONI-13/55 PLASMA – Ø – UD E 51 5 - BZ 26 |

TU U 28.7-34142621-001:2008

Purpose and scope

UONI-13/55 PLASMA are high-quality electrodes that can be used for welding work in any spatial position. They are suitable for pipelines and critical structures. Products made from low-alloy and carbon steels having a tensile strength of 500-640 MPa can be processed. Electrodes become an ideal option when joint resistance to hot cracks is required. Most often, the products are used in ship repair, shipbuilding, bridge construction and for the manufacture of vessels resistant to high pressure.

Cook in any position, do not clean the parts to be joined, do not calcinate the electrodes and do not worry about observing strict rules for their storage - this is the minimum list of advantages associated with Ukrainian-made products. MONOLITH electrodes of the STANDARD series are deservedly considered universal consumables. They are actively used by both individuals in everyday life and in production. What makes them so popular and suitable for solving the most diverse problems?

Basic information

STANDARD electrodes are designed for arc welding with alternating/direct current, manually and in all spatial positions. The only exception is consumables 5 mm in diameter. They fail to form connections by moving the electrode from top to bottom. Otherwise, STANDARD is ready to create critical and ordinary structures from steels with low carbon content. The maximum thickness of processed metals is 20 mm, the minimum is 3 mm.

MONOLITH STANDARD electrodes allow you to quickly form high-quality fillet, lap and butt welds. In this case, there is no need to change the welding current parameters or clean parts from rust or dirt.

Of the negative aspects of operation, only the nuances of welding vertical joints can be highlighted. When moving the electrode from top to bottom, you need to either use a short arc or achieve deep penetration (support method). It is important to prevent slag from flowing ahead of the arc, which is achieved by constantly monitoring the angle of elevation. The latter should be 40-70 degrees.

Distinctive features

During welding with MONOLITH STANDARD electrodes, a low intensity of manganese and aerosol release is observed. At the same time it happens:

- Simple and fast starting/re-ignition of the arc, its subsequent even combustion.

- Reduced metal losses due to minimal spattering.

- High quality indicators of the finished connection.

- Easy and complete separation of slag crust.

- Ability to operate at minimally low currents.

- Easy to use.

- Easy and simple welding of workpieces with painted, oxidized or oily surfaces.

MONOLITH STANDARD are suitable for welding in hard-to-reach areas of structures. The coating of the electrodes does not crack when they are bent, and arc burning does not deteriorate. As for small-diameter consumables, to work with them it is enough to power the welding machine from a household outlet.

Share on social networks:

Similar materials

Types of welding: MMA, MIG/MAG, TIG and their advantages and disadvantages

Diopter lenses for welding helmet

Classification of PPE

Is it worth buying Monolith electrodes?

Absolutely yes. Whether you're an experienced welder or just starting out. With these electrodes you will be able to weld even if you see a welding machine for the first time. The most popular brand is MP-3. They are used for welding carbon and low alloy steels. You can easily evaluate the quality of PlasmaTek products if you read reviews of Monolith electrodes. We present some of them below. You can always buy Monolith electrodes in Minsk at the best price at Welder Buy. We offer not only reasonable prices for all brand products, but also fast delivery throughout Belarus, and the opportunity to choose electrodes of various packaging from a large catalog. If necessary, our specialists will be happy to help with the selection of welding materials, equipment and components. Contact us!

Characteristics of Monolith electrodes and their main advantages

The manufacturer's electrodes have many fans and those who categorically dislike them.

This is due not only to personal preferences, but also to the fact that they often try to fake materials. You can only be sure that what you are brewing is original if you made a purchase from an official representative. This is exactly what our online store Welder Buy is. Among the many advantages of this Monolith, it is definitely worth highlighting:

- Electrodes can be used to cook with both direct and alternating current. This is a big plus, because... You don’t have to worry about whether they will fit your welding machine.

- Minimum amount of slag. Not only is there little of it, but it also lags well behind the surface.

- Fast and trouble-free ignition. This is especially true for professionals with little or no experience. The main thing is to follow the storage rules and not allow the materials to be exposed to high humidity.

- Lack of a lot of sparks. Minimal metal spattering allows you to keep the surface of the workpieces being welded clean and save yourself from unnecessary problems.

- Fumes when welding with Monolith are much less toxic than when working with other electrodes. This factor is especially relevant for those who cook often and a lot, and at the same time care about their health.

- Affordable price. The price of Monolith electrodes is quite affordable. Especially when you compare them with similar materials from other manufacturers.