Burrs, which can be used in conjunction with both a stationary machine and a conventional electric drill or screwdriver, are an almost indispensable tool in cases where it is necessary to process metal products. In addition, a burr, which is also called a roller cutter or a roller bit, is actively used to carry out such technological operations as cleaning a metal surface and grinding it, engraving, boring holes to the required size. In order for the processing performed using a metal burr to be effective, it is necessary not only to understand the design features of such a tool, but also to learn how to choose it correctly.

Burrs for metal processing

Purpose and features of the tool

The history of burrs goes back decades, during which this tool has been constantly improved. Meanwhile, in the time that has passed since the invention of the burr, its design has remained virtually unchanged. As before, any cutter consists of a shank, with which it is fixed in the chuck of the equipment used, and a working part, which performs the main cutting job.

Processing with burrs is carried out with a rotating tool, and its rotation speed can reach up to 60,000 rpm. In this regard, when using cutters, it should be taken into account that the equipment on which they will be installed must provide them with a high rotation speed.

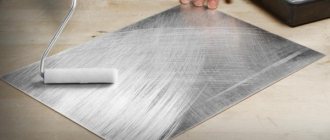

The advantage of using burrs paired with hand tools is the ability to process hard-to-reach surfaces

When choosing metal burrs, you are guided by the following parameters:

- the type of processing to be performed;

- characteristics of the material from which the processed product is made;

- dimensions of processed elements.

It should be borne in mind that it is the correct choice of tool (along with its quality characteristics) that has the main influence on the results of the processing performed.

The cut of the burr must match the type of material being processed

Burrs designed for metal work, due to their characteristics and functionality, are widely used in many areas. This is, in particular, the mechanical and automotive industry, the electronics industry, jewelry, printing, etc.

Burrs, the working part of which can have very miniature dimensions and different configurations, are used to process the working surfaces of dies and casting molds, apply various patterns and inscriptions to the surface of metal products, bore and grind holes and grooves that even differ in significant depth and complex configuration.

Engraving burrs for miniature work

Metal burrs are also very popular among home craftsmen. Using such a universal and effective tool mounted on a regular electric drill or screwdriver, you can quickly and accurately clean a weld, bore a hole or groove, remove sharp edges from a part, grind small metal elements, and make the surface of a metal product perfectly flat and smooth.

Solid carbide burrs (cutters) for metal

Monolithic burrs are made of tungsten-cobalt alloy VK8 with a hardness HRA of at least 88.0. The hard sintered alloy is used in cutting and mining tools, for the manufacture of wear-resistant parts, etc.

What does the EAC on the packaging of WOLFSTAR burrs? This is a special sign of product circulation on the international market. It is uniform for states that are members of the Eurasian Economic Union and indicate that products with this designation have passed the assessment and conformity assessment procedures specified in the technical regulations of the Customs and Eurasian Economic Unions. That is, such products meet all the requirements that apply to these products in the technical regulations of the Customs and Eurasian Economic Unions. This is another confirmation of the high quality of the WOLFSTAR brand.

Solid WOLFSTAR cutters with a carbide head perform roughing and finishing machining of metals of the highest hardness: steel (carbon, chromium-nickel, stainless steel) and titanium, as well as copper, brass, bronze and general-purpose cast iron.

Burrs are produced in various configurations and sizes, so they can be used from dentistry and jewelry, electronics industry to automobile and mechanical engineering, and in other areas of the national economy. This is an important and indispensable tool in any home workshop.

WOLFSTAR burrs are used to grind the surfaces of dies and casting molds; various designs, letters and numbers are engraved on metal surfaces. Even significant depth and complex shape are not an obstacle for a burr to smooth or bore a hole or groove.

Burrs are manufactured in the following types:

- A - cylindrical;

- B - cylindrical with a cutting end;

- C - spherocylindrical;

- D - spherical;

- E - oval;

- F - spheroconic;

- G - spheroconic with a pointed end;

- N - flame-shaped;

- J - conical with a taper of 60°;

- K - conical with a taper of 90°;

- L - conical with a rounded end;

- M - conical with a pointed end;

- N - conical in the shape of a reverse cone.

You can recognize the type of burr by the first capital letter of its designation. For example, the designation C061606 will tell you that the letter symbol C is a spherical burr, the number symbol 06 is the diameter of the cutter 6 mm, the number symbol 16 is the length of the cutting part 16 mm, the number symbol 06 is the diameter of the shank 6 mm.

Each burr has individual packaging - a plastic box.

When ordering burrs of one article (from 10 pcs.), they are delivered in a cardboard box of 10 pcs.

The chemical composition of WOLFSTAR brand tools was analyzed in a laboratory at one of the most prestigious narrow-profile universities in Russia: National Research Technological University "Moscow Institute of Steel and Alloys" (NUST MISIS), the results of which confirm that tools from all categories correspond to the chemical composition requirements of GOST. The result of the analysis

Burrs of any type and size of the WOLFSTAR brand can be bought in the online store wolfstar.ru at an affordable price and in a wide range.

Classification of burrs

Differences in the design of burrs of different categories make it possible to optimally select such a tool for solving certain technological problems. Burrs for metal are classified according to their design. So, depending on this parameter, they can be:

- single-cone;

- double-cone;

- three-cone.

Each of the types of burrs presented above is selected depending on the nature of the technological problems to be solved with their help.

Marking of carbide burrs

The shape of the working (cutting) head is another parameter according to which burrs are divided into different categories. Today, burrs are produced with working heads of the following shapes:

- cylindrical;

- conical;

- round;

- semi-oval;

- oval.

Shapes of the cutting part of burrs for metal

The choice of a tool with a working head of a certain shape is also influenced by the nature of the upcoming technological tasks. For example, for engraving on metal, a conical burr is used, for boring and grinding holes and grooves - a tool with a cylindrical working head, for cleaning welds and processing flat surfaces - rollers, the cutting part of which has a round shape.

The shape of the burr is selected depending on the configuration of the surface being processed

If we talk about the material used to make metal burrs, then depending on this parameter they are divided into the following categories:

- made of carbon steel;

- abrasive (burrs in this category are divided into two types: with a metal working head, the surface of which is coated with abrasive material, and with a cutting part made entirely of abrasive - electrocorundum);

- coated with diamond chips (diamond burrs);

- carbide (a hard alloy working head is attached to their carbon steel shank by soldering).

Metal burrs made of carbon steel are the most inexpensive of those presented, but their working life is minimal. You can purchase rollers of this type if they are not used too often and not intensively. Burrs made of carbon steels demonstrate their effectiveness when processing simple materials that are not too hard.

Plain Carbon Steel Burrs

Diamond burrs, which can be used to successfully process high-strength and brittle metals, are professional tools suitable for both home and industrial use. With the help of such cutters, the working heads of which can have any size and configuration, it is possible to bore and finely grind holes, and the surface formed after such processing is perfectly flat and smooth. It is diamond burrs that are most often equipped with engraving machines.

Diamond burrs

Carbide burrs, characterized by the highest working life among tools of this type, are used primarily in production conditions. Using carbide burrs, which are equipped with powerful and high-speed equipment, it is possible to process metals of the highest hardness (cast iron, stainless and heat-resistant steel, titanium, etc.).

Carbide burrs are suitable for shaping and finishing a variety of metal surfaces

Burrs used to perform metal work also differ in the type of sharpening of the cutting part. So, depending on this parameter, burrs can be:

- with fine cutting of the cutting part;

- with universal cutting;

- with ultra-thin slicing;

- designed for work on aluminum.

Burr sets

Sets of burrs (from 5 to 50 pcs.) in a durable plastic case.

Available with ready-made content or for individual selection up to 138 pcs.

Carbide Burrs Review: Carbide burrs for all types of steel, including stainless steel, hardened steel, and difficult-to-cut materials such as titanium, Inconel, Hastelloy, Waspaloy, Duplex, Amanox.

Carbide burrs for non-ferrous metals such as aluminum, copper, brass.

Carbide burrs for plastics, including fiberglass (GFK) and carbon fiber reinforced plastic (CFK).

Carbide burrs for metalwork.

Carbide mini-burrs with a diameter of 1, 1.5, 2 and 2.5 mm.

Main characteristics:

- 15 different shapes.

- 9 types of working surface.

- The largest assortment in the world - about 1800 models.

- Patented BLUE-TEC coating for steel processing.

- BLACK-TEC coating for processing non-ferrous metals, plastics, fiberglass (GFK) and carbon fiber reinforced plastic (CFK).

- Burrs for metalwork.

Burrs , often called cutters or carbide burs , are clear and thin tools designed for use in straight grinders with different types of drives: electric drive or pneumatic. Most often, mechanics carbide burrs to clean up seams obtained during welding. The advantages of a burr include: always excellent quality of work; the fact that the tool ensures smooth polishing of manufactured products and their strength , wear resistance, and this, in turn, gives better efficiency indicators compared to other tools in this series. A machinist usually has burrs of various shapes at his disposal.

The main types of burrs that can be used by craftsmen and mechanics:

- Cylindrical.

- Conical.

- Spherical.

- Spherocylindrical.

- Flame-shaped.

- Oval.

- Parabolic (with a rounded and pointed end).

- With disc ends and angled ends.

- Radius Multipower - New!

For what purposes can a master use burrs:

- For removing specks and flash from workpieces or for working with parts made of different metals, for processing welds, cutting steel with a hardness of more than 70 HRC;

- Burrs can also be used to process holes in order to adjust them to the required dimensions to match the drawing.

- A burr is used instead of a grinding wheel, while productivity also increases and ensures processing of the product without dust and dirt.

Why do they use burrs where another tool can be used? Because the wear resistance of this tool far exceeds that of a steel cutter - 10 times and 100 times that of a grinding wheel.

The variety of shapes allows you to finely process different surfaces; even with complex shapes and in hard-to-reach places you can work efficiently with this strong tool. For different metals and plastics, special burrs designed for these materials are used. For example, a tool with unidirectional teeth, but for complex tasks you can use one with multidirectional teeth. This will significantly increase the productivity percentage. Burrs operate at speeds of up to 50,000 rpm, on powerful machines, which allows the task to be completed.

Pros of carbide burrs:

- Strong and powerful design of the tool surface and working part - carbide head and shank, which guarantees wear resistance and stability of the cutting edge.

- Thanks to the modern coating, the hardness on the surface of the tool and heat resistance are significantly increased - up to 400°C; this combination extends the service life of the tool.

Aluminum burrs are used for working with non-ferrous metals and plastics. If a person is a master of his craft, then the job will be done. And working with a good tool always brings satisfaction!

Recommendations for correct use

To extend the service life of metal burrs, and also to avoid causing damage to the equipment, you should follow a number of simple recommendations.

- The working part of the cutter must be maintained in full contact with the metal being processed: this will increase the efficiency of its use.

- It is necessary to ensure that the shank does not come into contact with the workpiece, which can lead to breakage of the burr.

- During processing, strong mechanical pressure should not be applied to the tool: this will not only reduce its efficiency, but also increase the load on the equipment used, which can cause it to overheat and quickly fail.

- To avoid problems such as the formation of irregularities and burrs on the workpiece, as well as jamming of the cutter in the metal, it is necessary to set a high rotation speed of the tool. Working with a burr rotating at high speed also allows for more thorough processing of grooves and corners.

- To prevent intense wear of the tool, it is necessary to periodically apply a special lubricant to its working head during processing, which will reduce the load on the cutter and improve its sliding along the surface being processed. A suspension consisting of wax or synthetic machine oil, into which the burr is periodically dipped during processing, can also slow down the wear of the cutting part.

- Do not process with a heavily worn burr. The use of such a tool requires significant physical effort, and can also cause failure of the equipment used and the final breakdown of the tool itself.

Recommended operating speeds

When processing metal with a burr, safety precautions should be observed, since this process is associated with the formation of a large amount of small chips and metal dust. In addition, if you use a substandard tool, you must be aware of the risk of it breaking and the work head being thrown out of the processing area, which can cause serious injury. Thus, when preparing to work with a metal burr, it is necessary to reliably protect your hands, eyes and breathing organs.