Home / Consumables

Back

Reading time: 3 min

1

2396

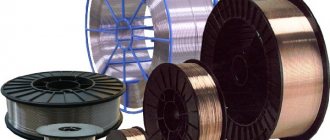

The welding wire used in acetylene gas welding is made by many manufacturers.

The products are presented in the form of filler rods and drawn wire, with or without a sheath of non-ferrous alloys, and metal granules.

Welding material is available in the following types:

- activated - reduces spattering, improves seam quality;

- powder - allows you to obtain a seam with a composition similar to the elements being welded;

- solid section - used in the form of filler rods.

The materials allow you to work with any type of metal.

However, the diameter of the wire must not only correspond to the thickness of the product being welded, but also be similar to its chemical composition.

The material examines some types of welding material used in the process of welding and surfacing of products made of ferrous and non-ferrous metals.

- Wire for steel

- Welding of aluminum and copper alloys

- Welding cast iron

- Nuances of use

Wire for welding steels

Most often, filler wire is purchased in stores for gas welding of steels. Note that this wire is manufactured according to the same standards as for arc welding. Therefore, there is no difference between wire for gas and for RDS welding. For ordinary welding of most types of steel, wire made from low-carbon and alloy steel is used. For welding critical and especially critical structures, it is recommended to use low-alloy wire.

If you need to achieve the best quality of welds or surfacing seams, then use manganese and silicon-manganese wires. These include brands Sv-08GS, Sv-08GA, Sv-08G2S, Sv-10G2. When using these brands, the seams are strong and reliable. They are resistant to mechanical damage.

When working with low-alloy steel, purchase the same low-alloy wire, but with chromium content. The resulting seams have a high tensile strength. But when welding high-alloy steel, wire should be selected with a similar chemical composition.

How to replace carbon dioxide for a semi-automatic machine

The very idea of converting a semi-automatic burner for propane is already dangerous. This cannot be done for a number of reasons. And the point is not so much the danger of explosion as the fact that when propane burns, it forms many other completely unnecessary components besides carbon dioxide.

Therefore, the best solution to the question of what can replace carbon dioxide is flux-cored wire. Below we will look at its advantages, but in the meantime, let’s look at why exactly you shouldn’t give up carbon dioxide when welding semi-automatically in a protective gas environment.

Wire for welding aluminum and its alloys, copper and its alloys

Aluminum welding wire, as well as wire made of aluminum alloys, is manufactured in accordance with GOST No. 7871-75. To work with aluminum, we recommend using the brands Sv-AK-5, Sv-A1 and Sv-AMts. The composition of the wire should be similar to the composition of the part.

For welding copper and copper alloys, wire manufactured according to the GOST standard No. 16130-90 is used. We recommend using wire grades M1 or MSr1. You can also use filler rods of the M1r and M3r brands.

To work with other non-ferrous metals (for example, bronze or brass), use wire with the same composition as the part itself. In this case, the brand of wire is not so important.

Pros and cons of gas welding

This method of joining metals, such as gas welding, involves melting the materials being joined, resulting in the formation of a homogeneous structure. The combustion of gas, due to which the metal is heated and melted, is ensured by introducing pure oxygen into the gas mixture. This method of joining metals has a number of advantages.

- This welding method does not require the use of complex equipment (welding inverter or semi-automatic machine).

- All consumables for such welding are easy to purchase.

- Gas welding (and, accordingly, gas welding of pipes) can be performed even without a powerful energy source and sometimes without special protective equipment.

- The process of such welding can be easily regulated: you can set the required burner flame power and control the degree of heating of the metal.

This method also has disadvantages.

- The metal heats up very slowly, unlike using an electric arc.

- The heat zone that is formed by the gas burner is very wide.

- It is very difficult to concentrate the heat created by a gas burner; it is more dispersed compared to the electric arc method.

- Gas welding can be classified as a fairly expensive method of joining metals when compared with electric arc welding. The cost of oxygen and acetylene consumed significantly exceeds the cost of electricity spent to weld similar parts.

- When welding thick metal parts, the speed of the connection is significantly reduced. This is due to the fact that the heat concentration when using a gas burner is very low.

- Gas welding is difficult to automate. Only the process of gas welding of thin-walled pipes or tanks, which is performed using a multi-flame torch, can be mechanized.

Gas welding of a pipe from the bottom position

Features of application

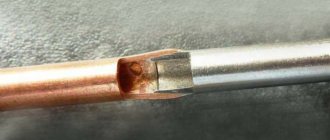

Before use, welding wire for gas welding with acetylene (or any other flammable gas) must be thoroughly cleaned of dirt, oil, traces of corrosion, paint, scale, etc. Form the seams slowly and evenly. Avoid splashing metal while welding. After cooling, the seam bead should be smooth and uniform in appearance. The presence of defects (pores, cracks, slag inclusions, etc.) is not allowed. Watch out for refractory oxides; they should not get into the weld pool. And most often they enter the welding zone with filler material. The oxides themselves are formed due to the reaction of nitrogen with oxygen. Their melting point is higher than that of the base metal. For this reason, the seams become uneven and of poor quality.

Types of fluxes for gas welding

Gas welding of copper, aluminum, magnesium and their alloys is accompanied by the active formation of oxides on the surface of the metals being welded under the influence of oxygen contained in the air. Refractory oxides significantly complicate the welding process.

In order to protect metals from oxidation during welding, fluxes for gas welding are used, which are special welding powders or pastes. Boric acid and calcined borax are used as fluxes. They are applied to the edges of the metal being welded, to the welding wire and rods. At welding temperature, low-melting fluxes form slags that float to the surface of the molten metal and protect it from oxidation.

For those who constantly weld using manual arc welding, the relevant question is how to weld with a semi-automatic machine. Creating a resistance welding machine with your own hands will help you save a tidy sum. You will find detailed instructions in this article.

Do you want to weld aluminum or copper? There is an alternative way! More details at the link.

How gas welding is performed in semi-automatic mode

Semi-automatic gas welding technology requires the use of an electric arc and shielding gas, which makes this method of joining metals a hybrid.

This technology, if we look at it in more detail, looks like this:

- turning on the device;

- threading the wire through a hole located in the burner;

- setting the required gas pressure using a reducer;

- setting the required wire feed speed;

- setting all other welding parameters (voltage and current);

- positioning the torch at the required angle before starting welding.

For each of the welding parameters performed semi-automatically, there are parameters that are specified by the relevant GOSTs:

- pressure generated by the reducer;

- acetylene generator parameters;

- type of hoses used;

- requirements for gas cylinders;

- type of torches used for welding;

- type of wire used for welding.

Purpose and scope

The use of a gas welding machine allows you to carry out the following operations:

- welding of various parts;

- soldering (including repair of damaged products);

- surfacing;

- cutting sheet metal and pipes into separate pieces.

The advantages of gas welding make it possible to use it in construction, industrial production, public utilities, car repair, and when solving everyday problems in dachas and country houses. Gas welding can join almost any material. It is used when connecting assemblies of products made of non-ferrous metals, thin-walled pipes, and elements of complex structures. With the right selection of conditions and solder, it is possible to weld cast iron and fuse brass onto its surface. Connecting and cutting metal elements allows you to obtain the required result of good quality.

Soldering is carried out by heating the parts being soldered and melting the solder with the addition of flux. In this case, surface diffusion occurs at the joints of the part with the molten solder. After cooling, a reliable and aesthetic seam is obtained that can be processed.

Surfacing is intended for applying a metal of a different type or structure to the surface of the main product. In this case, the surface being treated is heated to the so-called fogging temperature. This method restores worn parts, increases their size, and deposits material with higher strength and wear characteristics. The use of surfacing increases the service life of parts, reduces the consumption of scarce materials, and reduces the cost of repairs.

List of gases used for different metals

During operation, different types of gases may be required:

- acetylene;

- light hydrogen;

- coke coal gas;

- flammable oxygen;

- kerosene;

- propane;

- butane;

- pyrolysis gas, etc.

The characteristics and purity of the gas affect the quality of welding and cutting of metals.

Light hydrogen

It is a colorless, odorless gas that is approximately 14.5 times lighter than air. This substance is obtained by decomposing water molecules with electric current. The combination of hydrogen and oxygen in the wrong proportion forms an explosive mixture.

It is necessary to strictly follow safety precautions.

Gas for welding must comply with the requirements of GOST 3022-80. The oxygen-hydrogen compound burns with a blue flame without clear outlines, which makes it difficult to regulate.

We recommend reading Classification of the main types of fusion welding

Pyrolysis gas

It is obtained during the processing of petroleum products at a temperature of +720 °C...+740 °C. Pyrolysis gas is packaged in cylinders under a pressure of 1.9 MPa. Its combustion characteristics are similar to acetylene. Rarely used for welding and cutting, because provokes corrosion of the welding machine. The burner end requires careful cleaning after each use.

Kerosene fuel

It is a yellowish transparent liquid resulting from the refining of petroleum products. Kerosene evaporates quickly at above-zero temperatures, forming a flammable gas. When working with it, special precautions must be strictly observed, because... This substance may explode if not used correctly.

Gas is often used for processing non-ferrous metals. Kerosene for welding and cutting must meet the requirements of TU 38.71-58-10-90.

Coke Coal Gas

It is colorless, but has a characteristic odor of hydrogen sulfide. The substance is obtained during the processing of coal into coke. It contains propane, hydrogen, methane, etc. The gas intended for welding is pre-cleaned from impurities, resins and sulfur compounds.

Combustion is possible only when combined with oxygen.

Coke oven gas is used for welding and soldering of non-ferrous metal products. It is supplied to the work site through pipelines under a pressure of 1.3-1.5 kPa. Cylinders are used less frequently.

Combustible oxygen

Necessary to maintain the combustion process. It is supplied to the welding site in cylinders. In a special apparatus, oxygen is mixed with the selected combustible gas and supplied to the burner.

Acetylene

Most often used in welding. It is colorless, but has a characteristic garlic odor due to the inclusion of impurities of hydrogen sulfide, hydrogen phosphide and ammonia. Inhaling it can cause dizziness, nausea and other signs of poisoning. Acetylene is lighter than air. It is supplied to the work site in pressurized cylinders.

Natural gas

Natural gas used for welding contains impurities of hydrogen, methane, carbohydrate oxide, etc. More often it is used for processing light alloy metals.

General safety rules

When performing welding work, safety rules must be observed. Only serviceable equipment may be used. The work place must be at least 10 m from the source of open fire.

We recommend reading: Pros and cons of laser welding

The post must be equipped with individual means for extinguishing fires. If only acetylene is used, then a carbon dioxide fire extinguisher or sand is required.

Water should not be used to extinguish fires caused by this substance. If there is a fire, you need to bend the hose in the area of the gearbox, and then close all the valves.

Gas welding equipment

Gas welding technology involves the use of certain equipment.

Equipment required for welding

Water seal

A water seal is necessary to ensure the protection of all equipment elements (acetylene generator, pipes) from the backdraft of fire from the burner. Such a valve, in which the water must be at a certain level, is placed between the gas burner and the acetylene generator.

A cylinder containing gas

Such cylinders are painted with different colors depending on what gas is planned to be stored in them. Meanwhile, the top part of the cylinder is not painted to prevent gas from contacting the paint components. It should also be borne in mind that cylinders in which acetylene is stored should not be fitted with copper valves, as this may lead to a gas explosion.

Gearbox

It is used to reduce the pressure of the gas leaving the cylinder. Gearboxes can be direct or reverse acting, and for liquefied gas, models with fins are used, which prevent it from freezing upon exit.

Special hoses

Gas welding cannot be performed without the use of special hoses, through which both gas and flammable liquids can be supplied. Such hoses are divided into three categories, marked with 1) a red stripe (operate at pressures up to 6 atmospheres), 2) a yellow stripe (for supplying flammable liquids), 3) a blue stripe (operate at pressures up to 20 atm).

Design of a gas welding cutter

Burner

Mixing of gases and their combustion is ensured through the use of a burner, which can be of an injection or non-injector type. Burners are also classified according to their power, which characterizes the amount of gas passed per unit of time. So, there are burners of high, medium, low and micro-low power.

Special table

Gas welding is carried out in a specially equipped place called a post. Essentially, such a place is a table, which can have a rotating or fixed top. This table, equipped with exhaust ventilation and everything necessary for storing auxiliary tools, greatly facilitates the work of the welder.

How to choose gas depending on the type of metal

The correct choice of the required gas is mainly influenced by the thickness of the sheet of metal with which to work. This choice can be easily made by referring to the appropriate tables. They are compiled on the basis of calculations and taking into account the experience of using gases in various conditions. For example, to weld carbon steel sheets, it is advisable to use a mixture of argon and carbon dioxide followed by the addition of oxygen.

Do you have experience with gas welding? Be sure to share it in the comments to this article!