Artistic processing of metal

Modern technologies have made it possible to largely automate all processes for processing metal products and have minimized manual labor, however, for small-scale production and the manufacture of unique products, manual methods are still widely used, thanks to which artistic metal processing is carried out. At the same time, it is possible to replace many labor-intensive processes with automated ones.

Casting

The mold must be made of a metal whose melting point is higher than that of the raw material.

Those metals that have a high degree of fusibility can easily be modified using molds. This method is called casting, it is one of the oldest, but even today it remains relevant and often used. Even before our era, people mastered and widely used casting.

Before starting work, you need to make a mold. The choice of material can be any convenient, for example, wax, sand, if you plan to manufacture several identical parts, the form can be used many times. In the case when the future metal product will have a complex structure, it is advisable to make several molds for different parts, and then connect them to each other by soldering.

Casting can be classified according to casting metal:

Sand casting is a widely used casting method in the industry.

- cast iron;

- copper;

- gold and silver.

By design and materials of molds:

- temporary forms - earth, sand;

- shell;

- permanent – wax, plaster, metal.

By casting method:

- centrifugal;

- under pressure;

- classic.

After preparing the molds, you need to bring the metal to liquid form - melt it. This can be done in a special furnace; in ancient times, metal was melted in cauldrons over a fire. The melting point of different metals is different, so if there is no automated heating detection, it is necessary to monitor the process and after the metal becomes liquid, it is poured into the mold.

Metal casting at home

When the material has hardened, the product can be removed from the mold; to achieve perfectly smooth surfaces, the workpiece is cleaned and ground.

At the stage of heating and melting the metal, various components can be combined to obtain improved characteristics, for example, copper and tin form a more durable alloy - bronze.

painting

Tagil painting

This type of tray painting appeared in the Urals, Nizhny Tagil, Verkh-Neyvinsk and Nevyansk, and the date of its “birth” is considered to be 1746 - it was then that the first mention of tin trays with artistic painting appeared.

The famous factory owner N. Demidov organized the first painting school at his mining factories in the 18th century, which is why this painting was first called mining. At first, it was carried out exclusively by men, and only boys were accepted as apprentices, but over time, due to a shortage of masters, women began to be hired as well.

During the era of the Russian Empire, many Old Believers lived in the Urals, so Tagil painting adopted the artistic techniques of the Old Believer icon painting school - decor made of gold, silver and metal sands. In addition, it was based on folk art and painting traditions.

For painting, special mineral paints were created that adhered well to metal surfaces: powdered minerals were mixed with resin in linseed, walnut or poppy seed oil. But the most important secret of metal painting is varnishing. For it, in the 19th century, self-taught artists the Khudoyarovs came up with a special recipe from resin, linseed or hemp oil, as well as turpentine from local conifers dissolved in turpentine.

Copies from engravings, scenes from city life, historical and mythological paintings, which were framed with elegant floral or fruit and berry ornaments, were written on the trays. Painting was divided according to the style of painting into multi-layered, with the smallest details recorded, and “fly” painting, which appeared towards the end of the 19th century, which became a response to the acceleration of the pace of time and the desire to reduce the cost of production.

Enterprises

“Metal shop – Tagil trays”

Zhostovo painting

Only in the first half of the 19th century did the painted craft of tin trays come from the Urals to the Moscow province. They began to practice it in the villages of Troitskoye, Sorokino, Novoseltsevo, Khlebnikovo, but the most famous fishing became in Zhostovo. In 1825, the Veshnyakov brothers, who bought themselves off from serfdom, created the first workshop here, and after the revolution, united with other artels, it became the basis of the Zhostovo decorative painting factory, which operates to this day.

In Zhostovo painting, with rare exceptions, a black background and multi-layered writing are used. Forged trays are first primed and sanded so that the surface is perfectly smooth, and then painted with oil paints and varnished. Among the main subjects are floral patterns, as well as landscapes, everyday scenes and folk festivals. The most common type of painting, which has become the hallmark of Zhostov, is a large bouquet framed around the edges of a tray with gold ornaments. There are no two identical trays - the artist does not paint from sketches or from life, so even when painting identical subjects he uses his imagination.

Enterprises

LLC "Zhostovo Factory"

Kemerovo painting

Kemerovo painting arose in the early 80s of the twentieth century in the city of Kemerovo, where the Vesna arts and crafts factory was founded in 1981. Then a group of artists led by Valentina Panteleeva developed a new painting technique based on a mixture of Zhostovo and Nizhny Tagil techniques. The factory's assortment included painted trays of various shapes and sizes, dishes, and jars for bulk products.

Kemerovo painting belongs to one of the schools of Ural-Siberian painting. Its distinctive feature is a two-color brushstroke, which is obtained when the main color is applied to one edge of a flat brush, and a lighter color is applied to the other, then drawn several times across the palette and a color stretch is obtained. The painting is done with oil paints, then after drying it is varnished. The shelf life of such painting is several decades.

Photo source: libraries.kemerovo.rf.

Unlike Nizhny Tagil, which used to be more decorative, Kemerovo painting has become more realistic; the composition includes pine needles, cones, and taiga grasses. In Nizhny Tagil painting they use round squirrel brushes, and in Kemerovo they immediately began to use flat synthetics, which gives the work individuality. The painting motifs are very diverse: these include forest and wildflowers, pine cones, berries, pine branches, and the whole variety of garden plants.

The Vesna factory was closed in 2001. However, the masters remained, and some of them still continue to independently develop this wonderful technique.

Forging

Processing heated metal with a hammer is forging, and it is also the oldest method. Under uniform blows of the hammer, the metal workpiece gradually acquires the required appearance, however, alloys of different compositions behave ambiguously during forging - cracks and breaks appear.

Hot forging - deformation of hot metal with a hammer

The degree of malleability of the metal to such processing is measured in the value of malleability. Depending on this parameter, a distinction is made between cold and hot forging.

Precious and non-ferrous metals (gold, silver, copper) are soft enough that they can be processed by cold forging.

Table of melting points of the most common metals

Iron and alloys based on it can be forged only in a heated state. Heating occurs in a special furnace to a temperature of 1000°C, then the metal can be deformed, bent, and, in general, given the desired shape.

Based on the principles of forging, an artistic processing technique was developed - cutting. It consists in giving the sheet of metal an openwork appearance.

Cold forging is changing the shape of a product by hammer blows of varying strength. As a result, the metal quickly loses its ductility, becomes compacted, and hardening appears. The next step is annealing, which is used to remove the formed hardening.

In modern conditions, cold forging is often used in the jewelry industry.

Handmade artistic metal forging

Tools

For many centuries, the standard set of blacksmith equipment and tools has not changed. A forge with coals, bellows for fanning them, a hammer and anvil, tongs and a barrel of water were the main tools of the blacksmith. The development of medieval production introduced elements of mechanization into this set, and the industrial revolution turned blacksmithing into an industry aimed at mass production of products.

Hammer and anvil

This direction received at its disposal a whole range of special equipment for artistic forging - machines and devices that made the blacksmith’s work easier and made it possible to produce complex products.

The classic coal forge still remains in the blacksmith's arsenal, but muffle furnaces and induction heaters have also come to its aid. Many forging machines retained their historical names, corresponding to their purpose - benders, snails, waves, twisters and torsion bars - but received a powerful electric drive or turned into universal multifunctional machines.

Coinage

Embossing a relief on a thin metal sheet or plate is called embossing. This process is carried out using a hammer and a special rod. As the hammer hits the rod, it leaves a mark on the plate or gives it a three-dimensional appearance. The hammers are called accelerating hammers, and the metal is preliminarily cold rolled to obtain the desired thickness.

Artistic embossing of products requires high precision due to the complexity of the forms; accordingly, you need a material that can be easily processed

This is the initial stage, preparatory, after its completion they proceed directly to artistic decoration. This is a very delicate and painstaking work, for it they use a whole set of rods of various shapes and sizes, they are called mints. It is much easier to carry out embossing on several small plates, which can then be joined into a single three-dimensional object by soldering.

Even in ancient times, a method of chasing figures was invented. It consists of several processes: first, thin sheets of metal, mostly precious, are pressed onto a tin or bronze model, then a shape or design is given using hammers, and finally the sheets are carefully removed from the mold and soldered together.

Often, the artistic processing of metal by hammering can combine the processes of engraving, casting and carving.

There are three types of minting technique:

- from sheet metal;

- for defense or casting;

- embossed.

The traditional method of minting is on the thinnest sheet with rods, and the processing is completed and the artistic form of the cast products is completed in two other ways. Modern casting techniques make it possible to achieve ideal shapes and designs of the product, however, various defects can often occur:

- shells;

- growths;

- neslitins;

- skew;

- roughness.

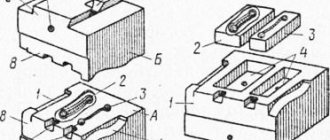

Embossing is a process of embossing using matrix boards, which are called basma boards, from which another name for the technology is basma. The embossing process is carried out as follows: a wooden matrix is prepared, which will display the relief of the future product.

Basmen board

A thin gold or silver sheet is placed on the matrix, then covered with a thicker lead sheet. The blows applied by the hammer fall on the lead cushion, which becomes compacted and acquires the relief of the matrix, repeating all the contours, volumes and patterns. The metal, sandwiched between the lead gasket and the matrix, takes exactly the same shape.

When the embossing process is completed, the lead pad is removed and the layer of metal - basma - is carefully removed; it has softer design features than the matrix, as if smoothed out. The thicker the sheet layer, the smoother the image will be, so it is not recommended to use metal larger than 0.3 mm for basma.

Basma, as a minting technology, is used for forging products such as iconostases, frames, book bindings, caskets, and to create portrait images.

Metal minting technology

Story

In Kievan Rus, the filigree technique began to be used from the 9th-10th centuries. At that time, twisted wire was not yet used for production, but grains were used. Products of the 12th-13th centuries are of high quality; at that time, brazed technology began to be used more often, and from the 13th century - openwork and relief filigree; stones began to be used in production.

The 15th and 16th centuries saw the heyday of Moscow filigree. A variety of materials were used: precious stones, enamel, wood, carved bone. The most famous scanners at that time were Ambrose and Ivan Fomin.

In the 18th and 19th centuries, filigree items were produced in many art centers in Russia. Both large works of art and small items (vases, salt shakers, boxes) were created. Crystal and mother-of-pearl began to be used in production. Since the 19th century, industrial production has been established on a significant scale using various technologies. The factories produced dishes, church utensils, and toiletries.

During the years of Soviet power, filigree was widely used in the art industry. Along with jewelry, household items were made: openwork filigree vases, glass holders, miniature sculpture, etc. Filigree: the art of lightness. Lace, the finest threads, the most delicate weaves, reminiscent of thin frost on the windows... And all this is made of metal! Is this possible, you ask, and you will be incredibly surprised, because yes, it is possible. And this is not magic at all, but just filigree! Filigree art in Rus' has long been famous, because it made it possible to obtain the most striking and highly artistic products. And today “metal lace” is produced no less readily than in ancient times, although, of course, the techniques for their production have been significantly improved. Secrets of grain and thread.

Highly artistic filigree can be made from several types of metals and alloys, although silver and cupronickel are mainly used. Using filigree techniques, you can make any product, but most often this method is used to produce the finest jewelry. And the main secret of such jewelry is a special technique of execution, which allows you to distinguish one master from another.

The range of filigree jewelry is extremely wide - from simple rings and earrings to intricate bracelets and necklaces. They are made from smooth or twisted wire, which craftsmen intricately bend to produce various patterns. Next, the filigree is joined by fine soldering, and despite the apparent simplicity of the work, this process is very labor-intensive: not only are all the patterns made by hand, but the process also requires high temperatures. But the resulting product looks incredibly thin, which, in fact, is what the word “filigree” itself implies, derived from the Italian words “thread” and “grain”. Metallic "frost"

The delicacy and subtlety of filigree patterns are explained not only by the characteristics of the material, but also by the specifics of the ornaments and designs used. Of course, each master has his own secrets, but we can highlight some general trends that have long distinguished filigree in various execution techniques.

Firstly, filigree jewelry can be openwork and applied: the first type involves sequential soldering of individual parts of the pattern, and the second - the application of the finest elements on a silver, copper or gold coating.

Secondly, filigree is especially beautiful in classical patterns, among which waves, zigzags, circles, semicircles and various complex figures stand out. In addition to the geometric pattern, a floral design can also be used (fancy flowers with delicate petals and leaves), as well as “curling” - openwork coils of wire laid out in the form of unusual curls. As a result, even if the same ornament is repeated in different decorations, each time it looks unique and original, distinguished by its extraordinary splendor. And in any case, the filigree product seems to be a true work of art that deserves to be admired endlessly.

Metal-plastic

At first glance, this method of artistic metal processing resembles embossing, but still has a number of distinctive features:

Metal plastic is performed on very thin metals up to 0.5 mm

- firstly, thinner sheets of metal are used - foil, no more than 0.5 mm thick, and for minting they mainly use from 0.5 to 1.5 mm.

- secondly, the use of sculptural tools - stacks, hammers are used for chasing;

- thirdly, the metal-plastic technology resembles sculpting, smooth lines and movements, while embossing has rougher deformations as a result of impact force.

Metal-plastic was invented back in the Middle Ages; in Russia, products made using this technology came into fashion at the beginning of the 20th century. The metalworking method became so popular that it was introduced into the curriculum for schoolchildren. Frames, iconostases, pectoral crosses and other decorations were made using metal plastic.

To start work, it is necessary to anneal the metal, tin sheets do not require annealing, zinc sheets only need to be heated once, and brass, copper and tin sometimes need to be heated several times. After annealing, the metal cools slowly. A sketch is first prepared - a drawing of the future product drawn on transparent paper.

Then this sketch is applied to a sheet of metal and traced with a special tool, pressing, thus imprinting a relief on the foil. This procedure is repeated on both sides of the sheet until the desired shape is obtained. For convenience, rubber or other soft but elastic material is placed under the bottom of the workpiece.

Application options

The most popular metal product: forged gates and fences. Massive or patterned, made of pure metal or alloy - they look equally sophisticated and elegant. But forged products are not just interior decoration. Metal shutters, stair railings, decorative gates and balconies are able to withstand high loads, sudden temperature changes and exposure to the elements.

Non-functional forms of interior elements include rotundas, fences for flower beds, figurines of plants and animals. They will decorate any garden and emphasize its individuality.

The ability to give a product any shape allows you to create designs of any complexity - thanks to this, artistic forging remains the most popular way of decorating a home.

A gate made in the shape of a dragon will attract the attention of guests and arouse the envy of neighbors

Engraving

Planar engraving

One of the main methods used for artistic processing of various metal products is engraving. It involves applying a relief or linear pattern to a workpiece using a cutter. Engraving can be of two types:

- planar – two-dimensional engraving, which involves processing the surface of the product;

- defensive - creates a three-dimensional image of relief, sculpture.

The most common planar engraving, its purpose is the final stage of decorating various products. The result of such processing will be the creation of contour drawings, patterns, tone compositions, inscriptions, and type works.

Armor engraving with metal sampling

Improving engraving technology, in the 17th century they already used machines for which wood lathes became the prototype.

A very interesting engraving technique for blackening, the design is cut deeper, and then it is blackened with a special substance, resulting in an original image that effectively stands out on the product.

Armor engraving is the creation of a three-dimensional relief or sculpture from a metal sheet. It can be convex, the pattern will be elevated above the background, and in-depth, when the pattern cuts into the workpiece and is located below the background.

Sales of metal crafts

The main goal of creating forged grilles with beautiful patterns, magnificent coinage, amazing tin soldiers or an unusual sculpture from spare parts of an old Zaporozhets is to earn money. It's important to think about how to market your creations.

In this matter, you cannot do without the help of advertising. The Internet is the best advertising platform. It is worth sharing with everyone you know your desire to sell your creation, asking them for help so that they pass on the information to their friends. There are special sites for such advertisements. Finally, you can use the services of online stores.

But you shouldn’t neglect the old proven method - go to the market and try to sell the products yourself. You can contact local commercial establishments that specialize in selling souvenirs and artistic products. It is important to remember that water does not flow under a lying stone. Therefore, if you want to make money, then do not give up and success will certainly come.

Making something worthwhile with your own hands from unnecessary things is not only interesting, but also quite profitable. It can improve not only your mood, but also your financial situation.

Etching

One of the subtypes of engraving is etching. His technique is simple: a metal product must be coated with wax or resin, then a design, inscription or other decor is scratched onto this coating. Next, the product is placed in an acid or alkali solution, under the influence of which the scratched images are etched and the surface becomes dull.

Chemical etching stainless steel, natural metal color

This technique came into widespread use in the 16th century and was most often used for inscriptions on goblets. In modern conditions, many craftsmen have begun to actively use it because of its originality and unusualness, when it is necessary to make a thing in a vintage style, to artificially age it.

Photo galleries

Gates and wickets

A family monogram on the gate will turn an ordinary house into a family nest

Gates made according to the client's sketch. Simple but tasteful

Beautiful gates can be made for a garage

Beauty is in every detail - that’s why artistic forging is so popular

Simple elements create a beautiful composition

Firebird on the gate - Russian fairy tales in the modern world

Fences and railings

Beauty is in simplicity. Behind such a fence can hide both a village hut and a three-story cottage

The stone pedestal and the fence, as if “grown” into it, create a single composition

Iron roses are in no way inferior in beauty to the tulips growing nearby. A professional blacksmith can breathe life into soulless metal!

It seems like an unremarkable fence. But even she is beautiful in some way

Interweaving of leaves and flower buds. The master did a great job

Thin branches, as if alive, entwine the fence. The composition seems fragile, but will last for centuries

Stairs and railings

Amazing beauty! Correctly selected colors create the impression of a play of light and shadow

Few people will notice a flower with four petals here, but everyone will appreciate the beauty of the pattern.

The staircase and chandelier were created by the same blacksmith and therefore fit perfectly together

Patterns, lines, flowers. Simple, elegant and beautiful

A very unusual pattern. Fancy forged railing elements

A wrought iron staircase complements the interior. And it seems that she and the chair are one whole. Here the work of the designer is no less important than the quality of forging

Decorative metal processing

In order to give the metal a different color and tone from the original, various methods are used:

Processing scheme for metal blackening

- blackening;

- matting;

- oxidation.

Blackening is most often used for artistic decoration of silver, copper and gold items. First, an engraving is applied, then the grooves are filled with niello - an alloy of lead, sulfur or tin. The finished product is annealed, excess ink is removed, and the surface around the design is polished to create contrast.

Matting or creating a texture on the surface of metal products is the creation of an effect different from polishing. The surface texture of the product can be finely lined, finely pitted or matte. These effects are achieved using various techniques:

- grinding;

- etching;

- processing with ground pumice;

- quartzization.

Often the surface of the product after casting is covered with a crust; it can also be cleaned to obtain a matte effect.

Oxidation is used for silver, it is treated with chemicals, sometimes using electrolytic methods. The technology is simple: a silver product is immersed in a solution, potassium dichromate is often used, this is an electrolyte, a current is connected and under this influence the silver changes color.

Electrochemical oxidation of steel in alkali solution

Veliky Ustyug mob

Niello as a type of metal processing has been known in Rus' since the 10th century. Archaeological materials provide the richest collections of works made of silver and gold, decorated with subtle elegant ornaments, engraved or minted by niello. The niello technology consists of smelting a black alloy of silver, copper, lead and sulfur into a base metal - silver or gold - to achieve color contrast. Small indentations should be made in the base metal by engraving, chasing or etching.

There are several options for the technological preparation, application and melting of niello. The most ancient and effective of them, preserved and used by the masters of Veliky Ustyug.

In the 17th and early 18th centuries, the art of the mob in Moscow developed widely. The active construction of religious buildings and palace ensembles gave impetus to the development of various artistic crafts, including the art of blackening. The best silversmiths from Pskov, Novgorod, Yaroslavl and other cities were invited to Moscow.

The 17th century was characterized by a significant influence on Russian art from works from Western European workshops brought by foreign ambassadors to Moscow. The masters of the Armory and Golden Chambers of the Kremlin quickly transformed the baroque motifs of Western ornamentation. Lush patterns of bouquets or garlands of fruits and overseas flowers began to decorate large silver dishes, goblets, and icon frames.

But the main center of blacksmith art in the second half of the 17th century was the city in the North - Veliky Ustyug. Since the second half of the 16th century and especially in the 17th century, Veliky Ustyug has been one of the largest trade and craft centers of Rus'. In the middle of the 17th century, about 500 residents of the urban settlement, who mastered 55 specialties, were engaged in crafts here.

The city found itself on a trade route connecting the European part of Russia with Siberia. This led to the rapid development of crafts, including blacksmith's art. Thanks to talented craftsmen, the Ustyug mob acquired its own identity, different from the art of other art centers. In their work, the plot engraving, very rich, much denser in color than Moscow or St. Petersburg, acquired special significance. The background was worked out with strokes, forming a kind of grid. The black composition was always very clearly linked to the gilded, slightly recessed background. The general solution was complemented by carved or chased details. For Veliky Ustyug, the 18th century was the period of greatest flowering of blacksmith art.

Veliky Ustyug is a city with rich traditions of artistic metalworking. It is the center of one of the most famous artistic crafts - the northern mob.

The first official mention of the Ustyug mob dates back to the middle of the 18th century, when Mikhail Klimshin was summoned to the capital to teach the rough art of “Moscow residents from the merchant class.” This fact confirms that the rough fishing industry is thriving at this time in V-Ustyug. The art of making rough patterns on silver items dates back to the 17th century.

Ustyug silver niello was valued due to its high artistic perfection and the extraordinary strength of adhesion of the rough composition to silver. Products of 18th century craftsmen. - snuff boxes, boxes, chalices, frames for gospels and icons, etc. - differ in elegant and varied shapes. The works combine a matte silver background with gold and a deep velvety rough pattern. The images are silhouetted and lack fine detail; their engraving is rich and soft. The development of draft art was also facilitated by the opening of the factory of the Popov brothers in 1762, which existed for 15 years. The influence of the Ustyug mob affected the development of all the artistic centers of the North - Vologda, Arkhangelsk. Vyatka. By the 19th century the city was unable to compete with large metropolitan industries, but the secret of the Ustyug “mob” of eternal strength was preserved.

In 1932, the Northern Mob artel was formed. Professional artists were involved in creating new drawings. Since 1936, the artel was headed by a graduate of the St. Petersburg Academy of Artists E.P. Shilnikovsky. An excellent draftsman and graphic artist, he turns to literary works and creates entire series based on the works of Pushkin, Gogol, and Krylov. The art of the mob in Veliky Ustyug was again raised to unprecedented heights. In 1937, at an exhibition in Paris, Veliky Ustyug rough silver was awarded a gold medal and a diploma.

In 1961, the artel was renamed into a factory, then. Leading contemporary craft artists: Tropina E.F., Bobyleva L.M., Shorokhov V.P., Menshikova L.S. turn to the traditions of ancient Russian applied art. Jewelry, glasses, glasses, shot glasses, table sets of spoons, forks and knives are decorated with large floral patterns with the introduction of images of birds, fairy-tale animals, and mythological creatures.

Silversmiths began to teach their craft not only in northern craft workshops, but also in Moscow silversmiths. The Moscow archive contains documents that indicate that in 1744 master Mikhail Klimushkin was summoned to Moscow from Veliky Ustyug “to teach this skill to Moscow merchants.”

In the middle of the 18th century, the northern masters were also influenced by the “Baroque” style widespread in Western Europe. Complex plot compositions began to be completed with lush frames. Hunting scenes and pastoral scenes were depicted in the center. The influence of Western European plots also affected the execution of the main part of the composition on snuff boxes, boxes, and bottles. In the 1780s Rocal and baroque motifs among the northern rabble are increasingly beginning to be replaced by subjects of a new style - strict classicism. The transition to classicism was marked by a rejection of excessive pomp of decoration and the solemn theatricality of plots. By the end of the 18th - beginning of the 19th centuries. include the works of master Zhilin, in which he applied a new technique - instead of radiating lines, he introduced a continuous pattern of black stars and miniature bouquets.

Since the middle of the 19th century, the blacksmith business has been experiencing a period of gradual decline. Masters are unable to fight the penetration of capitalist relations and industrial products. The competition of relatively cheap silver products with simple ornaments forces them to reduce production and turn a large center of blacksmith's art into provincial workshops, isolated from large markets. In order to revive this art during the Soviet period, it took a lot of effort. Mobile technology requires experience and special skills of craftsmen. The revival of the folk art craft “Northern mob” is associated with the name of the hereditary master M.P. Chirkov.

Under his leadership, young craftsmen mastered the technique of blacksmithing. Having united in the “Northern Mob” artel, they launched the production of glass holders, cigarette cases, spoons and other easy-to-produce products with simple floral designs. To improve the artistic quality of his products, Chirkov attracted the artist E.P. Shilnikovsky, a graduate of the St. Petersburg Academy of Arts. Having studied the features of old blacksmith art, the artist was able to identify and restore interrupted traditions. E.P. Shilnikovsky introduces new themes into the plot, in particular from Russian fairy tales.

The first largest batch of silver items with his drawings on the theme of the works of A.S. Pushkin received a Large Silver Medal and Diploma at the Paris World Exhibition in 1937. Since then, the plant has taken a large part in various exhibitions and competitions, both in our country and abroad. Products of the “Northern Mobile” visited the World Exhibitions in Brussels and Montreal, New York and Osaka.

Methods of decorating metal products

Decorating items made of precious metals is also to some extent akin to processing, the most common being filigree and enameling.

Depending on the design, the openwork pattern can be soldered onto metal or take on a relief shape

Filigree is a fairly ancient technique. The term itself consists of two Latin horses - “phylum” means thread, and “granum” means grain. Filigree is a collection of thin threads intertwined and decorated with polka dots. This technique was first used in ancient Egypt in the second millennium BC.

From those times to this day, filigree has been exclusively handmade. There are many techniques, they are named after the cities or localities where they are widespread. But in general they can be classified as follows:

The development of filigree art, suspended by the Mongol-Tatar invasion, flourished again in the 15th-16th centuries.

- soldered;

- openwork;

- volumetric.

Brazed filigree is the simplest way to decorate metal products. It is a wire pattern, with decorative elements, which is soldered to a sheet of metal; it will act as a background. Perforated filigree can also be used, when after soldering the base is removed by sawing it out.

There may be enameled filigree, when after soldering the pattern to the base, the space is filled with enamel. The openwork technique involves soldering wire elements together, without using a background, so the product becomes like lace.

Volumetric filigree is presented in such products as vases, goblets, boxes, caskets, etc. To obtain such an item, the elements are first prepared, which are then connected to each other by soldering or attached to the base.

Enamel is a substance obtained by melting glass or other inorganic materials that have an oxide composition. The enamel is applied to the metal in a liquid state and left to harden.

The variety of colors and the ability to paint on enamel have made this technique in demand and popular for many centuries. Products with the addition of enamel are most often found in jewelry, as well as in home furnishings.

Casting

Kasli casting

Kasli iron casting is named after the Chelyabinsk city of Kasli, where an iron foundry owned by the Demidov factory workers was founded in the mid-18th century. The art of foundry has been developed over centuries by Kasli sculptors, artists, foundries and minters; its tradition includes clarity of silhouette, a combination of elaborate details and generalized planes, “Dutch soot” - coating products with black paint created according to a special recipe.

Kasli foundry workers created statues and busts, tombstones and memorial plaques, grilles and bas-reliefs, lanterns and benches, gates and fences. In the 19th century, they began to produce dishes, small “cabinet” sculptures and objects of decorative and applied nature, many of which currently adorn the exhibitions of Russian art museums. The development of Kasli casting was directly related to the development of Russian sculptural art: many famous sculptors provided Kasli foundries with their models for reproduction, and the best works of Klodt, Lanseray, Liberich, Laveretsky, Kamensky and Zabello were cast here.

You can see Kasli casting in different cities of Russia. These are floor lamps in the Tsaritsyno estate in Moscow, a square around the monument to St. Catherine in Krasnodar, lanterns and gratings on the Imeretinskaya embankment in Sochi and on the Primorskaya embankment in Yeisk, the facade of the Drama and Sculpture Theater on a pedestrian street in Chelyabinsk.

Direct speech

From openwork stairs to Zheglov and Sharapov

Enterprises

LLC "Stone Belt" • LLC "Kasli Plant of Architectural and Artistic Casting"

Stove cutlery

The history of the largest manufacturer of cutlery in Russia and the CIS - the Pavlovsk plant of artistic metal products named after Kirov - began in 1890, then Alexander Genrikhovich Stange created a handicraft artel in the village of Pavlovo. The first great success came to the Pavlovsk residents already in 1900, when the artel received a gold medal at the Russian-French exhibition in Paris.

Currently, the plant specializes in the production of traditional metal products: cutlery and dishes, locks, household accessories. Regular modernization of technological processes and the use of modern equipment allows us to constantly expand the range. Every year the company creates new lines of cutlery, the design of which is based on traditional Russian ornaments.

Enterprises

Pavlovsk plant named after Kirov

Direct speech

How to instill culture through spoons and folk ornaments