Unified inch threads of the UN standard (UNC, UNF and UNEF) are widespread in America and Canada, where the inch measurement system is used. Here this standard is the main one for bolts, screws, nuts and many other fasteners used in mechanical engineering. Their production is regulated and controlled by ASME and ANSI organizations.

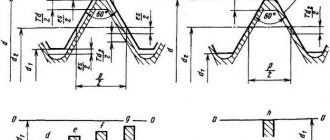

American thread has the same profile with an apex angle of

60°

as the metric ISO standard, but its main parameters are expressed not in millimeters, but in inches. Depending on the frequency of turns, it can also be large (main) UNC, small UNF and superfine UNEF. The number of turns per inch is called pitch TPI, while in the metric the pitch refers to the distance between adjacent vertices of the helix P (mm). These parameters are related by the ratio: P = 1″/ TPI (remember that 1″ = 25.4 mm).

Legend

The thread designation indicates its outer diameter - D

, followed by a pitch -

TPI

(threads per inch) and its type -

UNC

or

UNF

.

For diameters less than 1/4″,

the size is indicated by an integer from

0 to 12

, which appears after the

#

or

No

. Each number corresponds to a specific external D, the exact value of which can be found in the reference table. For all other diameters above 1/4″ this value is expressed in inches.

What is pipe thread

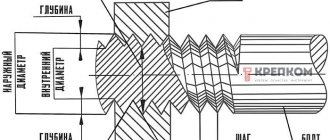

A thread is a groove that is applied mechanically or manually. It is characterized by the special height and relief of the spiral groove, its shape, the distance between the turns - the pitch. The thread can be applied to both the external and internal surface of the pipe. In addition, it may be present on a metal rod or conical surface.

The main purpose of pipe threads is to connect parts of the system. For a successful and tight connection, it is necessary that the grooves on both parts are identical in relief, pitch and shape. Moreover, they must be located on different surfaces - one inside, the other outside the pipe.

For reference: the above does not mean that the cutting can only be for fastening. Another type is the chassis. The latter is used in machine parts, where it is necessary not only to connect, but also to ensure the free movement of elements.

Inch dies for thread cutting UNC, UNF, 8-UN

Warehouse arrivals, promotions, sales!

Complex supplies of tools in small and large wholesale from 3,000 rubles for individuals and legal entities from St. Petersburg across Russia, to Belarus, Kazakhstan in the shortest possible time. Call or submit a request right now! We are updating the catalog. If you have not found the product you need, call back (from 9 to 17:30 Moscow time) or send a request through a convenient form (daily, 24 hours a day).

Inch dies for thread cutting UNC, UNF, 8-UN wholesale

Inch dies (dies) are a cylindrical tool designed for applying external threads to metal products: pipes, rods, rods.

This is a typical standard for America, since it is there that the inch as a unit of measurement is much more common than the centimeter. In Europe and Russia, the inch standard is quite rare.

When processing a pipe with a die, the cut inch thread has a conical shape (angle of inclination 60°), the relief is cut off - both the valley and the top.

Inch dies - features of marking and use

An inch die is marked with the letter K. It differs from R-lerks not only in that its diameter is measured not in centimeters, but in inches. Such a thread almost does not cause deformation of the turns. Also, the inch standard differs from the R type models in the wider profile of the threaded “tooth”. In this case, the pitch size is taken to be the number of thread turns per inch.

For the manufacture of blades, only durable material is used - hardened alloy or high-speed steel.

An inch die has a specific classification determined by the thread pitch size.

- Designation UNC - inch dies, allow you to create threads with a wide (large) pitch.

- The designation UNF is an inch standard, indicating that the thread has a fine pitch.

- The UNEF designation is an inch standard used to mark dies that cut threads with particularly fine pitches.

There are also dies marked 8-UN. This designation indicates that the lechers have a single pitch value, regardless of the diameter of the tool. It is 8 threads per 1 inch.

The thread that such a die cuts can be either left-handed or right-handed. It is possible to use both machine and manual pipe processing methods. An inch die is often used for carving non-ferrous metals. It is also used for cutting tool or structural steel.

"Metal Gears" - high-quality tools inexpensively

In the Metal Gears online store you can buy high-quality tools from Russian and foreign manufacturers. We cooperate with American, Asian, European factories and enterprises located in the CIS.

Our company works with manufacturers without intermediaries, therefore we offer goods with a minimal margin. From us you can buy tools wholesale or retail, order specific models or ready-made sets.

And we will contact the manufacturers and ensure prompt delivery of the tool.

For residents of St. Petersburg and the region, goods can be picked up from the warehouse. The remaining regions of the Russian Federation are served through transport or our own courier service “Metal Gears”.

Why are pipe thread sizes in inches?

One of the most common questions that can be found on thematic forums is why all pipe dimensions are given in inches and not centimeters. The thing is that GOST, which began to operate in the post-Soviet space, was formed on the basis of the English standard - BSW. Its founder, design engineer Whitworth, created a screw profile back in the first half of the 19th century. The connection in which it could be used was supposed to be detachable. Whitworth positioned his profile as universal, as reliable as possible. Naturally, the engineer gave all dimensions in inches familiar to his country. When drawing up our own standard, they did not give up accurate measurements.

For reference: there is a concept “pipe inch”. It is not scientific and it is not in GOST, but in practice it is simply irreplaceable. Let us immediately note that the parameters of this unit do not coincide with the usual ones. Although there is a direct relationship between them. One unit of pipe inch is the outer diameter, but the inner diameter is also important, which is equal to one ordinary one. The explanation for this discrepancy is simple - all pipes are produced in an assortment (diameter, length, etc.), but the wall thickness is different for everyone and depends on the purpose of the product. This is where the concept of “conditional diameter” appears - we mean the internal one, which is paired with a given external standard.

Example: inch water pipe. The conventional unit is 25 mm with an external 33.6. But the real D can be either 27.1 (standard walls) or 25.6 (if the walls are thickened).

Type 8 TPI

Fine unified thread 8 TPI according to ASME B 1 1 specification is developed for special applications, for example, critical parts of wood/metal lathes. The size range corresponds to the following values:

| Standard size | Pitch (mm) | Turns per inch | Drilling D (mm) | D outer (mm) | D outer (inch) |

| 1 1/16”-8 UN | 3,175 | 8 | 23,9 | 26,988 | 1,063 |

| 1 1/8”-8 UN | 3,175 | 8 | 25,5 | 28,575 | 1,125 |

| 1 3/16”-8 UN | 3,175 | 8 | 27,1 | 30,162 | 1,187 |

| 1 1/4”-8 UN | 3,175 | 8 | 28,75 | 31,175 | 1,25 |

| 1 5/16”-8 UN | 3,175 | 8 | 30,3 | 33,338 | 1,313 |

| 1 3/8”-8 UN | 3,175 | 8 | 31,75 | 34,925 | 1,375 |

| 1 1/2”-8 UN | 3,175 | 8 | 35 | 38,1 | 1,5 |

| 1 5/8”-8 UN | 3,175 | 8 | 38 | 41,275 | 1,625 |

| 1 3/4”-8 UN | 3,175 | 8 | 41,5 | 44,45 | 1,75 |

| 1 7/8”-8 UN | 3,175 | 8 | 44,5 | 47,625 | 1,875 |

| 2”-8 UN | 3,175 | 8 | 47,75 | 50,8 | 2 |

| 2 1/8”-8 UN | 3,175 | 8 | 50,9 | 53,975 | 2,125 |

| 2 1/4”-8 UN | 3,175 | 8 | 54 | 57,15 | 2,25 |

| 2 3/8”-8 UN | 3,175 | 8 | 57,2 | 60,325 | 2,375 |

| 2 1/2”-8 UN | 3,175 | 8 | 60,4 | 63,5 | 2,5 |

Weapon parts and fasteners for passenger cars from assembly lines in the USA and Canada often have this thread.

Types of pipe threads

Pipe threads allow you to connect elements and fittings in a non-welded way, while ensuring the tightness and reliability of the connection. As a rule, metal pipes are connected in this way, although recently it has also been used for plastic.

Types of pipe threads

What is a pipe thread? Its main features:

- special groove profile;

- the base is a triangle with an apex of 55 degrees, the edges are rounded;

- denoted by the Latin letter G;

- The digital marking after the letter indicates the nominal diameter of the pipe. According to the accepted standard, it is indicated in inches.

Pipe cylindrical thread - GOST 6357 81

Like other types, cylindrical pipe can be applied to the inner or outer surface of the pipe. Moreover, the standard contains an assumption under which a connection is possible when only the inner one is cylindrical, and the outer one is conical.

External cylindrical pipe thread

Pipe cylindrical thread internal

Legend

The standard designation is the Latin letter G. After the letter:

- digital indicator in inches - diameter of the nominal diameter of the pipe. For example - G 3⁄4”;

- letter designation of the type - right or left. It should be noted that no designations are provided for the right one. If the pipe thread is left-handed, it is marked LH;

- The next position in the pipe thread marking is marked with a hyphen. It denotes the accuracy class. There are two classes - A or B. The first is more “strict”; smaller permissible deviations are provided for it. In fact, the marking may look like this - G 1⁄2” LH - A;

- At the end of the pipe thread marking, the so-called make-up length is written. This is the area on which the thread is applied. For example: G 1”-B-35.

For reference: sometimes there may be a description for two connection elements at once. Example: G 3⁄4 “—A/B. The first place is always the description of the pipe, the second position is the coupling or the element that is connected.

size table

Important parameters for cylindrical pipe threads are internal, external and average diameter. Depending on this parameter, the pitch is selected, that is, the number of turns that need to be cut for a reliable connection.

| Pipe size (inches) | D (mm) | D1 (mm) | D2 (mm) | Pitch (mm) | Number of spiral grooves per inch (pcs) |

| 1/16 | 7,724 | 7,142 | 6,561 | 0,907 | 28 |

| 1/8 | 9,728 | 9,14 | 8,52 | 0,907 | 28 |

| 1/4 | 12,15 | 12,302 | 11,446 | 1,337 | 19 |

| 3/8 | 16,662 | 15,86 | 14,96 | 1,337 | 19 |

| 1/2 | 20,96 | 19,74 | 18,632 | 1,814 | 14 |

| 3/4 | 2,91 | 21,749 | 20,537 | 1,814 | 14 |

| 5/8 | 26,440 | 25,277 | 24,188 | 1,814 | 14 |

| 7/8 | 30,201 | 29,038 | 27,889 | 1,814 | 14 |

| 1 | 33,249 | 31,775 | 30,298 | 2,309 | 11 |

| 1 1/8 | 37,9 | 36,419 | 34,989 | 2,309 | 11 |

| 1 3/8 | 42 | 40,422 | 38,552 | 2,309 | 11 |

| 1 1/2 | 44,4 | 42,899 | 41,355 | 2,309 | 11 |

| 1 3/4 | 47,8 | 46,32 | 44,842 | 2,309 | 11 |

| 2 | 53,746 | 52,267 | 50,78 | 2,309 | 11 |

| 2 1/4 | 59,614 | 58,125 | 56,325 | 2,309 | 11 |

| 2 1/2 | 65,77 | 64,369 | 62,39 | 2,309 | 11 |

| 2 3/4 | 75,185 | 73,269 | 72,369 | 2,309 | 11 |

| 3 | 81,532 | 80,365 | 78,258 | 2,309 | 11 |

| 3 1/2 | 87,887 | 85,255 | 84,258 | 2,309 | 11 |

| 3 3/4 | 93,980 | 92,896 | 92,365 | 2,309 | 11 |

| 4 | 100,332 | 98,369 | 103,589 | 2,309 | 11 |

| 4 1/2 | 106,69 | 105,32 | 110,256 | 2,309 | 11 |

| 5 | 113,040 | 111,85 | 124,328 | 2,309 | 11 |

| 5 1/2 | 125,732 | 124,852 | 135,693 | 2,309 | 11 |

| 6 | 138,420 | 136,985 | 160,259 | 2,309 | 11 |

For reference: the pitch size and number of turns are the same for several pipe thread sizes.

Tapered pipe thread - GOST 6211 81

Necessary in situations where special reliability of pipe fastening is required. From the name it is clear that the main feature of this type is application to a conical shape. The profile remains the same, but new values are added:

- working thread length - L1;

- length from edge to working plane - L2.

Tapered pipe thread - GOST 6211 81

Legend

Denoted by the Latin letter R. Labeling rules:

- only the letter R is external;

- combination Rc - conical, applied to the inner surface;

- combination Rp - internal, applied to a cylindrical surface.

Further designations follow the standard - size in inches, an indication of double-sidedness (if it is right-handed, there is no indication). If the marking describes a compound, the indicators are written as a fraction. For example: Rp/R 1”. The first position is always the external element of the system.

size table

| Pipe size (inches) | D (mm) | D1 (mm) | D2 (mm) | Pitch (mm) | Number of grooves per inch (pcs) | L1 | L2 |

| 1/16 | 7,723 | 7,768 | 6,475 | 0,907 | 28 | 6,5 | 4 |

| 1/8 | 9,728 | 9,657 | 8,098 | 0,907 | 28 | ||

| 1/4 | 13,15 | 12,21 | 11,345 | 1,337 | 19 | 9,6 | 6,1 |

| 3/8 | 16,662 | 15,322 | 14,278 | 1,337 | 19 | 10,1 | 6,6 |

| 1/2 | 20,996 | 19,345 | 18,567 | 1,814 | 14 | 13,4 | 8,4 |

| 3/4 | 26,441 | 25,765 | 24,567 | 1,814 | 14 | 14,6 | 9,9 |

| 1 | 33,249 | 31,190 | 30,291 | 2,309 | 11 | 16,2 | 10,4 |

| 1 1/4 | 41,9 | 40,123 | 38,952 | 2,309 | 11 | 19,2 | 12,7 |

| 1 1/2 | 47,803 | 46,564 | 44,845 | 2,309 | 11 | 19,7 | 12,7 |

| 2 | 59,614 | 58,943 | 56,566 | 2,309 | 11 | 23,6 | 15,9 |

| 2 1/2 | 75,567 | 73,485 | 72,657 | 2,309 | 11 | 26,6 | 17,3 |

| 3 | 87,995 | 85,934 | 84,993 | 2,309 | 11 | 29,6 | 20,5 |

| 3 1/2 | 100,657 | 98,657 | 97,309 | 2,309 | 11 | 31,4 | 22,2 |

| 4 | 113,867 | 111,41 | 110,082 | 2,309 | 11 | 35,3 | 25,4 |

| 5 | 138,986 | 136,76 | 135,542 | 2,309 | 11 | 40,2 | 28,7 |

| 6 | 163,546 | 162,984 | 160,823 | 2,309 | 11 | 40.2 | 28,7 |

Conical inch thread - GOST 6111 52

This is a type of notch where all the protrusions are located on a conical surface in a spiral. This type of cutting is most often found in the production of couplings, elbows, and tees. Features of conical cutting:

- the tips and turns are blunted or cut off. This ensures a better fit and tightness of the connection;

- maximum cone diameter is 6 inches;

- the main cutting parameters - three diameters, stroke and pitch - can be found in the table. You don't have to calculate anything yourself.

Important: conical cutting is also used in cases where there are signs of wear, and it is not yet possible to replace the element. But such a measure is temporary. If the tightness of the connection is important, the worn element of the system will need to be replaced by selecting a cut of the required size according to the table.

Legend

On drawings and products, the cutting marking has the Latin letter K (sometimes you can find the designation NPT). Further decoding according to the standard - after the letter there is a size in inches, an indication of the right or left arrangement of the turns. In addition, the marking may contain an indication of external (A) or internal (B) cutting - after the size. At the end, the strength class (1-3) and make-up length may be indicated.

Conical inch thread - GOST 6111 52

size table

| Pipe cutting size (inch) | D (external) (mm) | D1 (medium) (mm) | D2 (internal) (mm) | Number of threads per 1 inch (pcs) | Pitch (mm) | Profile height (mm) |

| 3/16 | 4,77 | 4,14 | 3,13 | 24 | 1,25 | 079 |

| 1/4 | 6,25 | 5,43 | 4,89 | 20 | 1,33 | 0,92 |

| 5/16 | 8,72 | 7,58 | 6,27 | 18 | 1,58 | 1,01 |

| 3/8 | 9,81 | 8,93 | 7,54 | 16 | 1,67 | 1,25 |

| 7/16 | 11,52 | 10,23 | 8,23 | 14 | 1,98 | 1,38 |

| 1/2 | 12,38 | 11,18 | 10,59 | 12 | 2,24 | 1,46 |

| 9/16 | 14,49 | 13,67 | 11,756 | 11 | 2,24 | 1,46 |

| 5/8 | 15,55 | 14,32 | 13,34 | 10 | 2,43 | 1,57 |

| 3/4 | 19,28 | 17,23 | 15,93 | 9 | 2,61 | 1,76 |

Metric tapered thread - GOST 25229 82

Triangular cutting, the parameters of which are indicated in millimeters (mm). The profile angle is 60 degrees. Here we can distinguish two types of cutting - with large and small step sizes. The first option is the most common, since it protects the joint from wear.

Metric tapered thread - GOST 25229 82

Legend

In the first place are the letters (MK), then there are numerical designations of the step size and nominal diameter. For example: MK 24x1.5.

Size table according to GOST

| 1-2 row (D cuts) | P (step) | D | D1 | D2 | L | L1 | L2 |

| 6 | 1 | 6 | 5,35 | 4,917 | 8 | 2,5 | 3 |

| 8 | 1 | 8 | 7,35 | 6,917 | 8 | 2,5 | 3 |

| 10 | 1 | 10 | 9,35 | 8,917 | 8 | 2,5 | 3 |

| 12 | 1,5 | 12 | 11,026 | 10,376 | 11 | 3,5 | 4 |

| 14 | 1,5 | 14 | 13,026 | 12,376 | 11 | 3,5 | 4 |

| 18 | 1,5 | 18 | 17,026 | 16,376 | 11 | 3,5 | 4 |

| 20 | 1,5 | 20 | 19,026 | 17,376 | 11 | 3,5 | 4 |

| 22 | 1,5 | 22 | 21,026 | 20,376 | 11 | 3,5 | 4 |

| 24 | 1,5 | 24 | 23,026 | 22,376 | 11 | 3,5 | 4 |

| 27 | 2 | 27 | 25,701 | 23,835 | 16 | 5 | 6 |

| 30 | 2 | 30 | 27,701 | 36,845 | 16 | 5 | 6 |

| 33 | 2 | 33 | 31,701 | 30,835 | 16 | 5 | 6 |

| 36 | 2 | 36 | 34,701 | 33,835 | 16 | 5 | 6 |

| 39 | 2 | 39 | 37,701 | 36,335 | 16 | 5 | 6 |

| 42 | 2 | 42 | 40,701 | 39,835 | 16 | 5 | 6 |

| 45 | 2 | 45 | 43,701 | 43,835 | 16 | 5 | 6 |

| 48 | 2 | 48 | 46,701 | 45,835 | 16 | 5 | 6 |

| 52 | 2 | 52 | 50,701 | 49,885 | 16 | 5 | 6 |

| 56 | 2 | 56 | 53,701 | 53,835 | 16 | 5 | 6 |

| 60 | 2 | 60 | 58,701 | 58,835 | 16 | 5 | 6 |

Designation principles

To determine the main qualities, you need to understand its designation. The thread designation in the drawings is slightly different from those used by the manufacturer in the production of products. Thread tables allow you to determine the main characteristics only by designation.

The features of the marking include the following points:

- Symbol for the thread in question G.

- The diameter size is indicated after the letter. An example of notation is 1 ½.

- The symbol L indicates that the turns are left-handed.

- The next symbol H indicates the accuracy class.

- The make-up length is represented by numbers at the end of the marking.

The designation of a tapered thread in the drawing provides an indication of the accuracy class. A symbol indicating the accuracy class may be indicated in the technical documentation. The creation of turns is carried out in compliance with one of three classes. In addition, the letters “A” and “B” may be indicated next to the number: the first indicates an external indicator, the second internal. The first class corresponds to the coarsest threads, the third is the highest quality.

What are the main differences

The main differences between the types of pipe threads

Upon initial examination, it seems that it is difficult to distinguish one type of thread from another. This is not so; the main differences lie in the dimensions, profile angles, method of applying notches and the scope of application of such a connection.

Between pipe and inch

The main difference is the rounded cutting edges at the same profile angle.

Between pipe and metric

The main difference is the relief and size of the threaded ridge and depressions. In metric, an equilateral triangle (60 degrees) is used - all dimensions are the same. In a pipe one, the angle is smaller (55), and the dimensions may vary.

Another obvious difference is the units of measurement. Millimeters and inches are used accordingly.

In addition, when cutting pipes, the wall thickness of the product must be taken into account. The latter may vary depending on the operating pressure that the product can withstand and the scope of its application.

Between metric and cylindrical

The difference lies in the reduced profile angle (55 for cylindrical versus 60 for metric). In addition, dimensions are indicated in different units - millimeters and inches. The latter in a pair is applied to a cylindrical surface.

Type 12 TPI

The following table ANSI B 1 1 in Russian contains the dimensions of small special threads of the unified type 12TP1:

| Standard size | Pitch (mm) | Turns per inch | D drilling | D outer (mm) | D outer (inches) |

| 1 1/16”-12-UN | 2,117 | 12 | 24,9 | 26,988 | 1,063 |

| 1 3/16”-12-UN | 2,117 | 12 | 28,1 | 30,162 | 1,187 |

| 1 5/16”-12-UN | 2,117 | 12 | 31,3 | 33,338 | 1,312 |

| 1 7/16”-12-UN | 2,117 | 12 | 34,5 | 36,512 | 1,437 |

| 1 5/8”-12-UN | 2,117 | 12 | 39,7 | 41,275 | 1,625 |

| 1 3/4”-12-UN | 2,117 | 12 | 42,4 | 44,45 | 1,75 |

| 1 7/8”-12-UN | 2,117 | 12 | 45,6 | 47,625 | 1,875 |

| 2”-12-UN | 2,117 | 12 | 48,75 | 50,8 | 2 |

| 2 1/8”-12-UN | 2,117 | 12 | 51,9 | 53,975 | 2,125 |

| 2 1/4”-12-UN | 2,117 | 12 | 55,1 | 57,15 | 2,25 |

| 2 3/8”-12-UN | 2,117 | 12 | 58,3 | 60,325 | 2,375 |

| 2 1/2”-12-UN | 2,117 | 12 | 61,5 | 63,5 | 2,5 |

The symbol indicates the outer diameter Dн, pitch TPI and thread type UNC (large), UNF (fine) or UNEF (extra fine). Moreover, for small diameters up to ¼ inch, the integer 0 ... 12 without fractions with the index N or # in front of it is used to indicate the size. Decoding is done using a special table. Since each number corresponds to a specific size.

How to determine the pitch of an inch thread?

To understand whether the pitch size of inch cutting meets the requirements of GOST, you need to take measurements. You will need a template and tools. Any fitting can be used as a template, the step size of which exactly corresponds to the technical documentation. A bolt, the cutting pitch of which is measured, is screwed into the selected element. If the connection is tight, the notch pitch complies with GOST requirements.

You can determine the pitch of an inch thread using a thread gauge.

If the connection is loose or the bolt does not fit, the measurement is carried out with a thread gauge. The plate is tightly applied to the thread - a tight fit will indicate that the notches correspond to the size indicated on the body.

Can you supply inch fasteners with small diameters?

GOST R 50864-96 conical locking thread for drill string elements. profile, dimensions, technical requirements

These dimensions start from #1 (1.854 mm)

up to

#12 (5.436mm)

the TK Hardware company can supply for you to order.

The lead time for these items will be approximately 4-6 weeks

.

The average minimum packaging for such diameters is 200 pieces.

Fasteners with small diameters can be presented in the form of screws with a semicircular head (the so-called computer screws with inch threads), with a countersunk head, with a cylindrical head, in the form of bolts with a hexagonal head, as well as nuts and washers for them. The material in which they can be made is from black (without coating or black) to non-ferrous and stainless metal.

Tightening of threaded connections

To ensure the required strength and integrity of the fasteners, it will be necessary to ensure that the tightening torque corresponds to the value indicated in the table:

| Thread size, inches | Tightening torque for standard bolts and nuts | |

| N*m* | Pound-force foot | |

| 1/4 | 12± 3 | 9±2 |

| 5/16 | 25 ± 6 | 18± 4,5 |

| 3/8 | 47± 9 | 35 ± 7 |

| 7/16 | 70± 15 | 50± 11 |

| 1/2 | 105± 20 | 75±15 |

| 9/16 | 160 ± 30 | 120± 20 |

| 5/8 | 215± 40 | 160 ± 30 |

| 3/4 | 370 ± 50 | 275 ± 37 |

| 7/8 | 620± 80 | 460 ± 60 |

| 1 | 900 ± 100 | 660 ± 75 |

| 11/8 | 1300 ± 150 | 950 ± 100 |

| 1 1/4 | 1800 ±200 | 1325 ±150 |

| 1 3/8 | 2400 ± 300 | 1800 ± 225 |

| 1 1/2 | 3100 ± 350 | 2300 ± 250 |

This table applies only to bolts and nuts with a strength class higher than 5.

How to determine the thread pitch

This parameter indicates the distance between two adjacent threads or channels of a threaded connection. Universal options have a standard thread pitch indicated in specialized tables, which makes it easy to select the desired type of fastener.

You can measure the thread pitch yourself in several ways. The simplest one is to select a bolt or nut with a known pitch that fits the thread perfectly. In this case, the pitch of both cuts will be the same.

For the second option, you will need a ruler or caliper with an inch scale. The scale is applied to the thread and the number of threads per inch is calculated. For example, if there are 16 turns in one inch along the ruler, then the thread pitch in inches will be 1/16.