What to do first

Before proceeding to the main actions, you can carry out preliminary “operations” - this will increase the chances of successfully removing the debris, and, perhaps, will help get rid of it immediately.

First of all, you can try to knock on the fragment, if possible, with a hammer. No need to hit hard. Such actions will loosen the bolt, making it easier to remove.

You can also try to warm up the part well in the place where the fragment remains. A gas burner is used for this. This will relieve internal tension

Remember: it is important to use the burner carefully if the part is made of aluminum - it can simply melt it

You must first warm up the part in the place where the fragment is located.

This must be done extremely carefully. It wouldn't hurt to pour a little liquid like W-40 into the hole.

If not, you can use a dirt and rust remover. Such lubricating fluids will help facilitate the “exit” of the bolt fragment

It wouldn't hurt to pour some W-40 type liquid into the hole. If not, you can use a dirt and rust remover. Such lubricating fluids will help facilitate the “exit” of the bolt fragment.

W-40

If during the preparatory process the fragment has not yet come out, it’s time to move on to a more radical method. Let's look at it in more detail below.

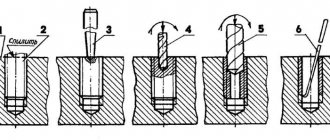

How to remove a broken bolt: step-by-step instructions

The most difficult thing to remove is a bolt fragment that has a non-flat surface - during the drilling process, the drill can simply slip, and the part will be damaged, and removing the bolt will become more difficult.

This is what a broken bolt looks like in detail

To make it easier, it is worth injecting the lubricant again, and then using a guide bushing that matches the thread. It must be screwed into the hole until it stops, and then tightened with a lock nut.

Matched bushing

Using a drill, you need to make a small hole in the fragment for the extractor. It is recommended to lubricate the end of the drill with lubricant.

Important! It is better to drill exactly in the center - this will make it easier to remove the fragment.

Making a hole with a lubricated drill

If everything is in order, you can continue drilling - you will not damage the thread, since the recess has already been created. You just can’t drill through the fragment - you can damage the part, especially if it is made of soft metal.

The next step is to drive a suitable size screw extractor into the hole. Make sure it is firmly secured and does not slip out. If this is the case, you can begin to carefully and slowly unscrew the extractor along with the fragment.

Screw extractor We turn out the fragment

The broken bolt has been removed, all that remains is to check whether the thread is intact - to do this, you need to screw a new bolt into the hole. To make this easier, you can lubricate the threads with lubricant.

The extracted bolt fragment. As you can see, his thread remained intact thanks to careful actions. The item is not damaged

In the process of removing the bolt, you will use chemicals, possibly heat the part in the hole, use impact tools and drill, so it is important to take care of personal protection: it is better to wear gloves, long sleeves, glasses, and, if possible, a respirator to protect the respiratory tract.

This method will help you remove a broken bolt even from a deep hole, if you do everything correctly and follow safety precautions. There are other methods, but we cannot vouch for their effectiveness, while the method described above always works flawlessly.

How to unscrew an internal hexagon with torn edges

To unscrew a bolted connection with a through hole, you can use a file. With its help, the hexagonal hardware is bored to the next size and unscrewed with a wrench.

The second way is to use Torx. They can punch out new splines and reuse the hex hardware, but subsequently it can only be unscrewed with a Torx sprocket.

Torx sprockets

In addition, before unscrewing the torn hexagon, you can saw through the internal axis of the hexagonal fastener for a screwdriver and unscrew it. With this method, it is not always convenient to get to the fastener; sometimes its location does not allow the use of a screwdriver.

Before screwing in the stud...

So that you don’t have to think about how to unscrew a broken pin, before getting to work, it is recommended to lubricate the part with graphite, or better yet, copper grease. It is better to let the element unscrew together with the nut than to break it. And finally, it is also better to treat the nut threads with graphite lubricant. In the future, this will prevent the part from breaking or breaking.

A situation where a bolt breaks during tightening and the broken piece remains in the part is not uncommon. But not many people know that there are quite a few effective ways to drill out a broken bolt.

A situation where a bolt breaks during tightening and the broken piece remains in the part is not uncommon. But not many people know that there are quite a few effective ways to drill out a broken bolt. The main thing is not to panic, but to carefully read this information material to the end.

Photo tips on how to unscrew a broken bolt

What do special bolts look like?

Special fasteners have been installed on the steering column for quite some time. It can be found on both domestic and foreign cars. There are three types of shear bolts:

- With a classic hat and an additional “skirt” at the bottom. Such structures work to break. That is, they are tightened with a certain force at the manufacturer’s factory. Once the fastener is in place, it can no longer be removed using a regular wrench. The top cap will simply break off under load, leaving a “skirt” in the form of a cone-shaped protrusion at the installation site. It cannot be picked up or unscrewed.

- With a round head without slots like a ratchet. Such a bolt can only be tightened using a special wrench. It will not turn back out due to angular lifts, which will rip any key off the head.

- With a regular hex head. Until they are screwed in, these bolts look like regular fasteners, but after tightening they take on a new look.

We will take a closer look at the design and operating principle of the latest product.

Method 3 - welding on the nut or head

Of course, not everyone is good at welding, but you can ask a friend. The essence of the method is to weld a nut onto the problem bolt and then unscrew it.

But, in most cases, this nut also breaks off, so many experts recommend welding a head instead, preferably an already broken one, so that it won’t be so bad.

The advantages of this method:

- The head is higher and you can insert a key with a large lever into it;

- It is more convenient to scald, the scalding area will be larger, which means the head will hold tighter.

The ideal option is to use a semi-automatic device; for a conventional inverter, a 2 mm electrode is used.

After welding, wait until the metal cools down. Then insert a wrench with a large lever into the head and begin to unscrew the bolt.

Replacing the stud

How to remove a bolt with stripped threads

It is better to carry out planned replacement of studs and repair of the head at the same time. For a simple replacement, before unscrewing it, it should be moistened with brake fluid or a brake fluid. It should be unscrewed using a special stud puller or a gas wrench. Unscrewing, especially at the beginning, should be done smoothly, without jerking.

If the force is not enough, you can use an extension cord

It is important to feel the effort here and not miss the moment when the pin begins to twist and break. At the first sign, it is better to reapply brake fluid and let it sit. Move on to the next part

The pin is unscrewed, move on to the next one. After unscrewing all the studs, we return to the soured part

Move on to the next detail. The pin is unscrewed, move on to the next one. After unscrewing all the studs, we return to the soured part.

We are trying to unscrew it. It may work out, but often such a part breaks off. If it works, install the head with the gasket in place and begin tightening the nuts according to the diagram, observing the tightening torque:

- First, we tighten each nut, going in a circle with a special wrench with a dynamometer;

- Then we go through it several times after a short break to seal the gasket;

- We do the final tightening of the nuts. The cylinder head tightening torque is different for different engine models; it is better to find out this value from the repair manual.

Let's sum it up

As you can see, there are several ways to unscrew a broken bolt or stud. Moreover, in each case, it is necessary to separately take into account in advance the nature of the broken body, the location of the fragment itself, the possibility of access to the problem area, the possible consequences of heating the remains of the bolt, etc.

The same can be said about tightening studs or bolts. The fact is that fasteners must be tightened with a strictly defined force and in the specified order (for example, covering the cylinder head). Ignoring this rule often leads to studs or bolts breaking, stretching, deforming, etc.

Common Mistakes

Despite the fact that automakers clearly indicate the procedure and nuances of tightening the cylinder head, many car enthusiasts make mistakes when assembling the engine. The most common of them are:

- Pouring oil into the mounting holes to lubricate the threads (the liquid is incompressible, so poured oil will not allow the head to be properly tightened);

- Over-tightening (exceeding tightening forces leads to damage to the cylinder head and the fasteners themselves);

- The use of damaged or inappropriate keys (the edges of the bolt heads may be torn off, after which it will be problematic to tighten or unscrew them normally);

- Use of unsuitable bolts as replacements (fasteners from different engines may differ in length, thread spacing, head height and diameter);

POPULAR WITH READERS: Cylinder misfires, causes, diagnostics, repair

To avoid problems in the future, you should use only fasteners designed for a specific engine and fully comply with the work conditions.

Method 7 – special extractor heads for licked edges

Special heads - extractors - are available for sale. They are precisely designed for unscrewing torn bolts with licked edges.

But such heads have their own peculiarity of use - they cannot be unscrewed using an impact tool, but only with a key with a 3/8-inch square.

The algorithm of actions is very simple. An extractor head of a suitable size is taken from the kit and, using a hammer, is pressed onto the licked head of the bolt so that it fits onto it.

Next, take a 3/8-inch square wrench, a lever, and unscrew the bolt.

Many people ask whether it is necessary to change the gasket if it was not possible to remove the cylinder head due to one broken bolt.

Most experts say that yes, it needs to be changed. After all, if all the bolts were torn off except for one, then the first clamping of the gasket was broken, and the second time it may not seat correctly and subsequently leak or burn out. Therefore, if you have already taken up the task, then bring it to the end. And we told you how to do this above.

How to unscrew the cylinder head stud

Threaded connections are the most widely used among detachable connections. They come in a variety of sizes; screws, bolts and nuts are found in both a smartphone and a nuclear reactor. Each connection must be tightened with proper torque. Sometimes the threads become clogged with dirt or become a victim of corrosion. When you try to unscrew the connection, the maximum force is exceeded and the thread breaks. It even reaches the point of destruction of the fastener body. In order to remove a damaged pin from the body, various techniques are used.

Features and advantages of cylinder head studs

In any engine, the cylinder head (cylinder head) is attached to the block itself with studs. They are screwed into the block in such a way as to ensure the best and uniform pressing of the cylinder head to the block. A high-quality compressed gasket prevents the leakage of oil and antifreeze and the penetration of gases from the cylinder into the engine crankcase. Fasteners are made from high quality steel. However, over time, the threads on them may corrode and become clogged with various contaminants. Due to exposure to high temperatures, these contaminants are sintered, and the nut “sticks.” When you try to unscrew such a stuck nut and exceed the maximum force, either the thread breaks off or the fastener breaks off. In both cases, it is necessary to replace the broken part.

Replacing the stud

Experienced craftsmen recommend unscrewing and changing all the studs at the same time. Parts from the same batch have similar physical and mechanical characteristics, will bear loads evenly and will last much longer.

Before unscrewing, thoroughly moisten the thread with WD 40 or kerosene. In extreme cases, brake fluid will do. If you don’t have a special puller at hand, you can unscrew it with a gas wrench. You need to pull smoothly, without jerking. If you can’t unscrew it right away, you should apply WD 40 again and wait 5-10 minutes.

After all connections have been unscrewed, they should be replaced with a new set. The threads can be lubricated with graphite lubricant - this will help you easily unscrew the parts if necessary. Next, you should install the cylinder head in place and begin tightening the nuts according to the diagram from the user manual.

- First, all nuts are tightened to light resistance.

- Using a wrench and a dynamometer, achieve the specified tightening force value.

- In the sequence described in the manual, all nuts are finally tightened.

The nuts can also be lubricated with graphite grease.

How to unscrew the remaining fragment

If the pin does break off, don’t despair. To unscrew the broken part, several techniques are used. Some require the use of industrial equipment, while for others, simple equipment available to a home craftsman is sufficient.

How to unscrew a broken hairpin

If a fragment remains sticking out, then use one of the following techniques:

- Put on a nut with a slightly larger diameter and weld it. Next, you can use a key to unscrew the broken pin.

- Weld a transverse rod (reinforcement) 30-40 cm long. Using it as a wrench, you can unscrew the fragment.

- Use a file to sharpen the top to a square. Now the fragment can be unscrewed with a tap wrench.

Unscrewing a broken pin

If the breakdown occurs flush with the surface of the cylinder head (or other unit), the fragment will have to be drilled out.

Drilling out the threads of a broken stud

Before drilling, cover the cylinder head with a thick cloth to prevent sparks and waste from entering the cylinders.

Next, you need to use an angle grinder with an abrasive disc to level the surface of the fragment. It should become strictly horizontal. A point is marked in the middle.

Next, take a drill with a diameter slightly smaller than the internal diameter of the thread. It is best to place the cylinder head on the workbench of a stationary drilling machine - this way there is less risk of the drill deviating from the vertical.

Drilling out the threads of a broken stud

After passing the hole to its full depth, you should unscrew the remains of the drilled fragment from it using pliers or needle-nose pliers. Next, you must go through the hole with a set of standard taps.

Replacing a stud with a repair part and cutting a larger thread

If all of the above measures fail, there is another replacement method. To do this, take a so-called repair pin of a larger diameter. In place of the old hole, a new, larger one is drilled. The thread is cut into it using appropriate taps, and the repair pin is screwed in. Of course, you will have to take the corresponding nut for it.

When installing the head, you need to be especially careful not to damage the threads on the new stud - it will fit into the hole on the cylinder head with less clearance than the standard ones.

How to unscrew the threads remaining in the block?

There are two options here, but each of them begins with drilling out the fragment. To do this, you should cover the engine block with a thick cloth to prevent sparks and dirt from entering the engine, then cut off the top part with a grinder and place it strictly in the middle.

Drilling out the threads of a broken stud

Using a drill of a slightly smaller diameter, we drill out the fragments on a drilling machine, or most often with an electric drill. Here it is very important to hold the instrument strictly vertically, without distortion. We reach the edge of the trim and try to unscrew the rest of the thread. To do this, before unscrewing, you can try to drive it with a tap or try to hammer the edge of the metal inward with a thin chisel, freeing the threads.

If you fail when unscrewing or drilling, you need to move on to the second option.

Flat head screwdriver and hammer

This method will give a positive result if the bolt breaks above the thread and there are irregularities on the surface. Then a handy set of tools for repair work of any complexity will come in handy.

On the cleaned surface of the fragment we find the largest protrusion. Take a flat-head screwdriver and place it at an angle, pressing it to the desired location.

Check it out here too!

- Replacing a pressure tap - a step-by-step description of how to change a pressure tap with your own hands (80 photos + video)

- What is an acoustic switch: device, operation, types and features of the device (100 photos)

- Low and high pass filter: making frequency filters and how to create high-end circuitry (95 photos + video)

For strong support, use a core, which makes the uneven surface deeper. Then, using gentle pushes, carefully turn the thread. If necessary, the emphasis on the surface can be increased.

Left-hand thread in stud

The second method is more complicated. It is used when it is impossible to unscrew a broken pin using any of the available methods. In this case, the measures taken will be even more drastic. This method will require an electric drill, a tap and a lot of time. First of all, a hole is drilled in the stud - right in the center. Then carefully cut the thread in the hole with a tap.

Let us note an important point: before unscrewing the broken pin from the head, make sure that the thread is “left-handed”. When a new bolt with the same thread is screwed into the newly cut part, the moment it reaches the end, the broken pin will begin to turn out.

How to unscrew a broken bolt without damaging the thread in the hole :: SYL.ru

Quite often, when using fasteners such as a bolt, situations arise when the head of the product breaks off, and the hardware itself remains inside. In this case, it becomes necessary to remove this residue without damaging the threads, so that the hole can continue to be used. Considering this, the topic of how to unscrew a broken bolt is very popular and requires more detailed consideration.

Types of fractures

Typically, such fasteners break at the end of the thread, although there may be exceptions. As a result, the hardware itself can be recessed into the hole, protrude above the surface, or be level with it

Based on this, you need to decide how to unscrew a broken bolt by paying attention to this very moment

Surface cliff

This type of failure includes the option when part of the hardware protrudes above the surface. We can assume that such a problem is easiest to solve without using radical measures. However, before any unscrewing of the broken bolt, it is worth treating the area with kerosene to remove carbon deposits and loosen the contact of the surfaces.

- If the protrusion is quite large, then the easiest way is to use tools such as pliers, pliers or a clamp, with which you can grab the part and unscrew it along the threads.

- Some experts, answering the question of what to do if a bolt that fits very tightly in the hole breaks, recommend using a welding machine. With its help, you can weld a lever to the hardware, which will result in a large arm for rotational movement.

- You can also use a drill with a diameter slightly smaller than the bolt itself. Using a drill, make a hole along the central axis of the bolt to the full depth. After this, the remaining fasteners are removed using a hook, trying to unscrew the thread from the very bottom.

Flush break

It is believed that this breakdown is the most difficult, since sometimes it is very difficult to determine the diameter of the hole, especially if the fastener has been cut off. Therefore, in order to determine how to drill out a broken bolt of this type, you should first clean the surface, determining the gaps.

Quite often, the break point has very uneven shapes, which, given this arrangement, are very difficult to straighten. It will not be possible to drill the product in this state. That is why a core is first used to prepare a place in the center for working with a drill.

Further steps describing how to drill out a broken bolt are described in the paragraph on surface breakage. After making the hole, the remaining threads are simply removed with a hook.

Cliff below the surface

Such damage is quite complex, especially if the part itself is made of soft metal. Therefore, you need to solve the problem of how to unscrew a broken bolt without damaging the threads in the hole.

First of all, using a core, mark the center of the hardware. In this case, it is best to use a thin tool made of durable metal so as not to accidentally damage the part.

The next step is to purchase a tap with reverse thread. Its diameter should be smaller than that of the bolt itself.

After this, a hole for the tap is drilled in the hardware itself, but not deepened too much. Next, it is enough to install the thread cutting tool and turn it as you go, which will lead to unscrewing. If this does not happen, then the tool is used as a regular bolt, but you should not apply too much force so as not to break it.

Extractor

The most correct answer to the question of how to unscrew a broken bolt is considered to be the one that suggests using a tool specially created for this purpose. It is called an extractor and is sold as a set of products of different diameters. Outwardly, it resembles a tap, but without longitudinal slots and with a conical notch for cutting.

To use the extractor, it is enough to drill a hole in the center with a diameter that allows the tool to go several turns. Then they begin to turn it all the way, and then until it is completely unscrewed.

Conclusion

There are several options for removing broken bolts from a hole that can be used for certain types of damage. However, it is best to purchase a set of extractors in advance, which can be considered the best tools for such tasks.

Effective ways to remove a broken bolt from an engine block

Not only will the bolts become loose, but they may also be over-tightened or mis-threaded. This may not have any effect on operation, but the next time you disassemble the connection, it will be difficult to unscrew the hardware. You have to put in a lot of effort. Because of this, the following consequences arise:

- the thread breaks;

- fasteners crack;

- the hat breaks off.

For one or more reasons, the fastener cannot be unscrewed from the seat in the usual way.

If we are talking about the cylinder head, then a large tightening torque is used here, which is why the above consequences arise. Before unscrewing a broken bolt, you need to perform preparatory measures:

Clean the hardware itself and the area around it from accumulated oil, rust, and dirt using a wire brush and solvent. The joint should then be further treated with a penetrating compound such as WD-40, brake fluid or clean engine oil. Thanks to this procedure, the bolts should loosen.

If the bolt breaks above the threaded surface

This case is considered easy, because the protruding pin means that the bolt has been unscrewed at least a little, and this also allows the use of clamping tools, as well as other manipulations to unscrew the fragment with a screwdriver or using a rod.

- To break up the rust and tear off the hardware, it is recommended to first tap the fastener with a hammer through the extension and heat it with an induction bolt heater or a blowtorch. The rotating pin is unscrewed using pliers, an adjustable wrench or another similar tool. When tapping, do not use much force, because you can break the threads in the hole or damage other parts.

- Using a hacksaw or grinder, slots are also cut into the fragment for a flat or Phillips screwdriver, and then unscrew it.

- If the fragment protrudes above the surface to a sufficient height, then a through transverse hole can be drilled in the body, into which a thick long nail, a metal rod or even a screwdriver is then inserted. The protruding parts of the tool at hand will not only allow you to influence the rest of the bolt, but will also play the role of a lever.

Method 1 - bolt shrinkage

Suitable for VAZ 2107 (other classic models), as well as cars where the cylinder head is secured with bolts to the outer edges. On models of the 2108 series and higher, this method is also acceptable, but at a certain stage of the work there you will have to resort to drilling.

Our goal is to seat the bolt using strong blows. As a result of vibrations and other complex physical processes, it will weaken.

But before you hit, try setting the head to 11 on the bolt with the licked edges and try to unscrew it that way.

If it doesn’t help, then take two hammers. We place the first one with the flat side on the problem bolt, and with the second hammer we hit the first one hard.

Next, the head is pressed onto the flattened head and the bolt is unscrewed using a large lever.

If the first attempt fails, then the second and third will definitely be successful. Typically this can take up to 20 minutes.

It is advisable that all other cylinder head bolts are tightened in order to press the head as much as possible. The method is described in more detail in the video.

Method 2 - drilling and unscrewing with a chisel

Suitable for cylinder head bolts with outer edges that have been torn off.

Algorithm of actions:

- Using a drill and a 10 mm drill bit, drill a hole in the center of the bolt, the depth of which should extend beyond the height of the edges of the head.

- Place the chisel at a right angle and, with strong blows, punch an edge in the bolt 2-3 mm deep.

- Place the chisel at a 45-degree angle to the surface of the head and begin to unscrew it with strong counterclockwise blows. Usually you have to beat for 4 to 5 minutes for the process to start.

Features of the work performed using the example of some cars

To prove the proposition that each power plant has its own characteristics of tightening the cylinder head, let’s consider the nuances of performing work on specific models.

VAZ-2112 16 valves

A number of modifications of the VAZ-2112 were equipped with two types of 16-valve power plants (factory indexes - 21120 and 21124). These two motors, despite some design features, have identical head tightening technology.

These units use 93mm long tension bolts. In this case, reuse of fasteners is allowed, but under one condition - if their length does not exceed 95 mm (if it is longer, they should be replaced). 10 bolts are used to secure the head.

Tightening is carried out in three approaches:

- The bolts are tightened according to the order with a force of 2 kg/m;

- Turning 90 degrees;

- Repeated tightening to 90 degrees.

The drawing diagram is shown below.

Between the 2nd and 3rd approaches you need to take a 20-minute break.

Since these engines use tensile bolts, additional tightening is not required during vehicle operation.

VAZ-2107

On the VAZ-2107, all installed modifications of power units are 8-valve.

The block head is attached to them with 11 bolts, 10 of which are main, and 1 is an auxiliary side bolt (installed in the side protrusion).

On this car, tightening fasteners is also performed in three approaches:

- 10 main bolts are tightened in order with a force of 3.5-4.0 kg/m;

- The same bolts reach with a torque of 11.5-12.0 kg/m;

- The auxiliary is tightened with a force of 3.5-4.0 kg/m.

Additional tightening of the cylinder head is not required when operating the VAZ-2107.

"Samara", 10th family, Priora

On models of the Samara family (2108-21099), as well as VAZ 2110-2112 with 8-valve units, tightening is already performed in 4 approaches:

- Tightening with a force of 2.0 kg/m;

- Reaching with a moment of 7.5-8.5 kg/m;

- Turn 90 degrees;

- Repeated rotation by 90 degrees.

The break between points 3 and 4 is 20 minutes.

As for the VAZ of the “tenth” family, which are equipped with 16-valve engines, their tightening technology is the same as that of the VAZ-2112 (described above).

The same applies to the Lada Priora; on 8-valve units, a method with 4 approaches is used (VAZ 2108-21099), and on 16-valve units, 3 approaches are used (VAZ 2112 with a 16-valve engine).

"Volga"

On ZMZ-406 engines installed on the Volga, according to the automaker’s technical documentation, tightening the engine block head bolts is carried out in two approaches:

- With a force of 4.0-6.0 kg/m;

- With a moment of 13.0-14.5 kg/m.

But many car owners of this car note that this technology does not allow the cylinder head to be properly tightened, so they use techniques with a large number of approaches.

A common method is the cross method, performed in 4 stages and with the following efforts:

- 4.0-4.3 kg/m;

- 7.5 kg/m;

- 11.0 kg/m;

- 14.3-14.5 kg/m.

Subsequent tightening of the bolts is not required when operating on this engine.

Method 6 - drill, use a hexagon and a lever

Suitable for VAZ 2108, 2199 and other cars with cylinder head bolts having internal edges. The essence of the method is to drill a hole in the bolt and unscrew it with a wrench. The hole is drilled so that the bolt loses its rigidity.

Take a drill with a power of at least 750 W (the more the better) and a drill with a diameter of 10 mm. The depth of the hole should be greater than the distance from the upper edge of the bolt to the washer, that is, go below the latter.

Next, we set the bolt using a hammer and a powerful spacer, which is inserted into the hole. The essence of the method is described above.

Next, we drive a four- or hexagon or a 25 Torx wrench into the hole.

Using a lever tube, unscrew the bolt. This method is described in more detail in the video.

What to do first

Before proceeding to the main actions, you can carry out preliminary “operations” - this will increase the chances of successfully removing the debris, and, perhaps, will help get rid of it immediately.

First of all, you can try to knock on the fragment, if possible, with a hammer. No need to hit hard. Such actions will loosen the bolt, making it easier to remove.

You can also try to warm up the part well in the place where the fragment remains. A gas burner is used for this. This will relieve internal tension

Remember: it is important to use the burner carefully if the part is made of aluminum - it can simply melt it

You must first warm up the part in the place where the fragment is located.

This must be done extremely carefully. It wouldn't hurt to pour a little liquid like W-40 into the hole.

If not, you can use a dirt and rust remover. Such lubricating fluids will help facilitate the “exit” of the bolt fragment

It wouldn't hurt to pour some W-40 type liquid into the hole. If not, you can use a dirt and rust remover. Such lubricating fluids will help facilitate the “exit” of the bolt fragment.

W-40

If during the preparatory process the fragment has not yet come out, it’s time to move on to a more radical method. Let's look at it in more detail below.

Method 5 – cylinder head bolt is broken

The method is suitable for cases where the bolt has burst and part of it in the form of a pin remains inside the cylinder block. We use welding, a tube, a nut.

Advantages of the method:

- there is no need to disassemble the engine;

- saves time.

Take a tube with the following diameters:

- The outer one is slightly smaller than the diameter of the cylinder head bolt.

- Internal – such that an electrode of 2–3 mm fits freely into the tube.

Weld a 17 - 19 nut onto one side of the tube.

- Insert the tube into the hole so that it touches the broken pin.

- Insert the electrode into the hole of the tube at a slight angle, so that its end is located where the edge of the tube touches the pin.

- Weld the tube to the stud.

- Use a wrench to unscrew the pin.

Another way if the cylinder head bolt breaks.

Suitable for cases where the broken pin is not deep, no more than 5 cm.

To unscrew the stud from the block, first use a drill and a long 10 mm drill bit. This will help you level and center its surface. Next, using a 4 mm drill, drill a hole in the stud with a depth of at least 1 cm.

Carefully drive a 25mm Torex key into the stud and use a lever tube to unscrew it. You need to unscrew without jerking, gradually increasing the force on the lever.

The reason for the breakdown of the edges of screws and bolts

There are several reasons. They usually occur in three cases:

- When choosing hardware for fastening certain parts of a mechanism, device or structure.

- In case of violation of technology when working with fastening tools.

- When using low-quality, faulty tools during installation or dismantling.

The choice of fastening elements (screws, bolts, studs, nuts, etc.) must be done carefully. Purchase only high-quality products, taking into account the scope of application and the influence of external factors

It is important to pay attention to the certificates of products and manufacturers, since now there are many handicraft workshops in gateways that produce hardware from ordinary wire and low-quality rods

As a result, the service life is short, the most vulnerable places of bolts and screws become corroded, and due to a violation of the technological process, the strength of the metal in critical areas of the product decreases (the transition from the body to the head, splines and edges on the head). When purchasing such fasteners, there is obviously a risk of damage to the hardware by the tool during operation.

When installing or dismantling any structure, you must use a serviceable tool to screw in and unscrew screws, screws and bolts. Make sure that screwdrivers and keys do not have “licked” or chipped working surfaces. Do not allow screwdrivers to slip through the edges of the head or keys around the bolt head.

Also, the causes of failure may be: “sticking” due to exposure to high temperatures, wear due to prolonged mechanical loads, corrosion due to long-term operation under aggressive environmental influences, use of the wrong tool for unscrewing, etc.