During the construction of private houses, the need arises to arrange roofing and fencing. For these purposes, profiled sheet metal is used. One of the varieties of this material is galvanized corrugated sheeting. Unlike painted sheets, galvanized sheets have advantages in price and wide range of applications.

Where is the material used?

It is advisable to use profiled galvanized sheets when carrying out the following types of construction work:

- to create a permanent formwork structure when the process of pouring the foundation is carried out;

- when constructing fences for temporary or permanent purposes;

- as a material for the construction of temporary structures and commercial facilities;

- during finishing work;

- as a roofing material;

- during the construction of tiled floor elements in frame-monolithic structures.

Hot rolled sheet - coating features

In addition to the quality of the hot-rolled sheet, it is necessary to pay attention to the quality of the coating applied to its surface. The coating can be made of zinc and various polymers. In both cases, the use of a coating significantly increases the sheet's resistance to corrosion.

Products related to thin sheets and coated with a polymer coating can be used in the construction of building structures and various equipment, for example, instrument housings. The coating can be done on one or both sides.

Material advantages

Galvanized sheets are popular among builders due to their many advantages:

- insignificant weight parameters depending on the thickness of the sheet and coating - on average the weight is 1 square meter. m is equal to 3-4.5 kg;

- low costs for purchasing the material - the average price of galvanized sheet PS-8 ranges from 140-320 rubles / sq. m. m depending on the thickness, and PS-20/PK-20 in the range of 120-350 rubles/sq. m;

- increased strength of the corrugated sheet, and thanks to the stiffening ribs, the resistance to deforming changes from loads increases;

- versatility in use - for roofing, fencing, as a load-bearing element;

- ease of installation and processing;

- the possibility of using work without lathing requirements;

- compliance with environmental and fire safety standards;

- economical in operation;

- ability to withstand temperature changes.

Which sheet should I choose?

When choosing sheet metal for the construction of any structure, you need to understand what problems it is intended to solve.

If there are no special requirements for the surface, then a hot-rolled sheet will come in handy. In addition, over time, sheets produced using hot technology do not change their strength parameters.

Meanwhile, there is a combined technology. That is, a hot-rolled sheet is subjected to cold rolling. After this treatment, the thickness of the sheet is stabilized, and the surface of the sheet becomes smooth. All this, of course, affects the quality of the products.

Sheet structure and coating application features

The zinc layer can be applied by electrolytic method and hot method. In the first case, the steel sheet is immersed in a container with a zinc solution. Then an electric current is applied, causing zinc particles to settle on the surface of the steel.

When the hot method is used, a container is filled with liquid molten zinc and a steel sheet is immersed. This option allows you to obtain corrugated sheeting with a durable coating.

Galvanized sheet steel varies in the structural characteristics of its surface. It can be smooth or profiled, as can be seen in the photo of a galvanized sheet.

If the profile is smooth, then it is usually used in the construction of roofs and other structural objects, as well as for arranging cornices, gutters, roof ridges, etc. Profiled material is actively used in the process of installing roofing and fencing.

Steel for sheet production

For the production of hot-rolled sheets, various types of steels are used - low-alloy and structural. They differ in chemical composition.

Low-alloy sheets are used in the production of non-critical structures in various industries. In addition, materials of this type are used in the production of seamed pipes and riveted bridge structures.

The scope of use of structural hot-rolled sheets is much wider. Alloy steels are used to produce this sheet.

Hot-rolled sheets are used for the manufacture of critical parts and assemblies installed in machines and mechanisms for various purposes, for example, in special construction equipment.

Galvanized wall products

This type is used in cladding and decorating vertical surfaces. A sheet with a wave of 8-21 mm is used.

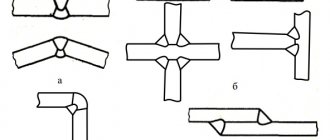

Low wave parameters provide a larger usable area, since for vertical installation of frame fastenings, rigidity is not particularly important. In this case, the stiffeners can be directed perpendicular to the foundation or parallel to it.

Production technology

Before starting to form the sheet, the surface of the workpiece is cleaned of dirt and the surface is leveled. This will result in a sheet with the most even surface possible.

Afterwards, the billet is heated to a certain temperature and sent to the rolling mill. On it, the workpiece is driven through rollers of different diameters; after passing through the next roll, the workpiece becomes thinner, wider and longer. Thus, a sheet of a given thickness is formed.

Throughout the passage of the workpiece, the temperature necessary to maintain the ductility of the metal is maintained. During the heating process, scale is formed on the surface of the sheet; in addition, the finished sheet cools unevenly and this leads to the formation of various types of irregularities.

After receiving the finished product, scale is removed using specialized equipment. Photos of hot-rolled sheets clearly show all these defects.

Roofing steel

Installation requires an inclined or horizontal surface. A product with a wavelength of more than 20 mm is used. As the installation angle increases, a material with a lower wave index is used.

On flat roofs, for example, the sheet should have a wave of 45 mm or more. The precipitation parameter and the probability of snow are also taken into account. The corrugated sheet is attached taking into account the direction of water movement.

Rolling

Compression of a metal ingot between the rolls of a rolling mill. 90% of all steels are rolled.

The range of rolled steel is extensive: sections, profiles, sheets, pipes. A significant volume of the rolled products market is occupied by rolled steel sheets.

Dimensional characteristics of the material

The weight of a galvanized sheet depends on its thickness and the zinc layer. The standard thickness of corrugated sheet is 0.3-1.7 mm, although the most commonly used material is 0.45-0.7 mm. Anti-corrosion resistance depends on the thickness of the zinc layer.

According to GOST, an indicator of 275 g/sq.m. is required. m, which ensures long-term operation of up to 20 years. If the layer is smaller, then along with the price reduction, the operating time will also decrease.

Over time, zinc can erode, and as a result of mechanical damage, integrity may be compromised. This becomes a factor in the appearance of rust.

The characteristics of the zinc coating will determine not only the overall thickness of the galvanized sheet, but also its appearance. Based on the crystallization pattern, the surface may be minimal, normal, or absent.

The width indicator is determined by the height of the wave. As it increases in height, the leaf becomes narrower. At the same time, different manufacturers produce material with different wave configurations. The length depends on the needs of customers. Typically this parameter varies between 200-12000 mm in increments of 50 mm.

Features of material manufacturing

Each corrugated metal sheet passes the GOST mark, as required by production. For example, a stainless steel corrugated sheet is produced using a technology that involves pressing the sheet into certain rollers, which creates a fancy pattern.

The metal passes through two rollers tightly adjacent to each other on a special machine under the influence of very high temperatures, which makes it possible to make the sheet corrugated.

Using additional coverage

For additional protection of the material, the technology of applying a special film is used. Galvanized coated sheet may include a layer of:

Polyester, when the polyester base is coated with paint, resulting in a glossy surface. With increased color stability and temperature resistance, such a sheet has low mechanical strength parameters. The price of corrugated sheets is low.

Purala. This is a polyurethane coating that gives the material anti-corrosion resistance, color stability and mechanical strength. Resistance to chemical components and heat resistance are quite high.

Plastisol film is a polymer film with a polyvinyl chloride base. Plasticizers are used. The sheet is strong, durable, but very expensive.

Galvanized corrugated sheeting is an affordable and durable material used for arranging various structures. If necessary, you can select a material with the parameters most suitable for the customer.

Advantages of hot rolled sheets

Hot rolled sheets have the following advantages:

- a large assortment;

- weldability without restrictions;

- high resistance to corrosion;

- ease of machining and many others.

Sheets of this type are suitable for welded metal structures that are installed outdoors. In addition, hot-rolled steel is used for the manufacture of safes and stoves, that is, products that must successfully withstand high temperatures.

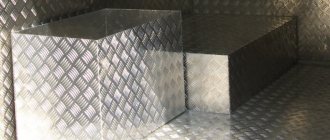

Photo of galvanized sheet

Types of corrugated sheets

Before we talk about the varieties, let's discuss what should not happen under any circumstances, namely obvious and visible cracks, metal delamination, bulges, and other defects.

In addition to the above factors, there are moments of fingerprints, corrosion, and small inaccuracies, but in this area of production they are just acceptable, since they do not affect the performance characteristics.

Varieties of corrugated metal sheet are becoming more and more popular every day, because this product has a lot of advantages, such as resistance to corrosion, a high degree of strength, resistance to any temperature, as well as to sudden changes, resistance to oxidation, as well as No matter how hard you try, it is almost impossible to damage it mechanically.

Even aluminum corrugated sheet shows amazing usage characteristics, let alone spring steel.

Metal building material

It is commercially available in various designs. For example, if you see a leaf with one convexity, that is, a corrugation, then it will be called a lentil, with two – a duet, and if there are as many as five of them, then it is just a corrugated leaf. In other words, riffles are another name for those very convexities that are observed on such material.

It is worth noting that each part of the drawing is worked out at a certain angle, which is required not only to add aesthetics, but also for use for various needs.

Each material may have its own standard corrugated sheet size. For example, a lentil pattern is made with a step of about 2.5 mm; if there is a riffle from 3 to 6 mm, the step is reduced to 1 mm. And this technology is repeated ad infinitum. The standard size of corrugated sheet is considered to be from 0.6 to 2.2 m.