Welding inverter Svarog ARC 205

Technical characteristics of the inverter Svarog ARC 205 (J96)

When welding, direct current electrodes UONII-13/55, UONI-13/55 and their modifications are used. Universal electrodes ANO-4S, MR-3, OZS-12 are applicable.

The best welding quality was observed when using electrodes with a diameter of 1.5–4.0 mm.

The welding machine is equipped with all cables, electrode holders and terminals necessary for operation, and is equipped with a welding helmet. It is quite compact, its dimensions are 336x120x198 mm, and its weight does not exceed 7.8 kg.

Technical characteristics of the welding machine Svarog TECH ARC 205 B (Z203)

The device is packed in a stylish case, allowing you to carry both the device itself and all the necessary accessories, as well as protective equipment. A set of additional functions ensures comfortable work for the welder on site. The outer shell with protection level IP 21 protects the device from foreign objects and drops of water falling vertically onto the housing.

The inverter is suitable for welding in private households, garages or small car repair shops. It is indispensable when carrying out construction and installation work of any volume associated with visiting the site, and is applicable in the housing and communal services sector.

The device is convenient to use as part of the equipment of mobile emergency services complexes, in small-scale production. Low weight and dimensions allow welding in hard-to-reach places when repairing metal structures.

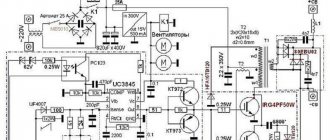

Operating principle of a welding inverter

Welding with the Svarog ARC 205 inverter is carried out with direct current (DC) using inverter technology. The device is powered from a conventional single-phase network 220 V, 50 Hz. In the absence of a stationary power source, it is possible to connect to a gasoline or diesel generator that provides voltage in the range of 185 V–260 V.

The AC supply voltage is converted into DC by the mains rectifier and inductor. The resulting direct current is supplied to the IGBT block of power bipolar transistors. It inverts direct current into RF alternating current with a frequency of 20–50 kHz.

The step-down transformer reduces the voltage to the operating level, after which it is rectified again and supplied to the operating connectors located on the front panel of the case.

Such preliminary conversion to high-frequency current allows the use of a transformer with very small dimensions. Compared to “classic” welding machines, the inverter weighs several times less, has better technical characteristics and efficiency.

The high quality of the welding process is ensured by a control unit with digital signal conversion (DSP).

Key features of the device:

- the presence of the Hot Start function (hot start) when igniting the electric arc;

- equipped with Antistick anti-stick option;

- adjusting the arc force (increasing power) guarantees deep penetration and a flat, even seam even at low current;

- 80% load duration when operating at a maximum current of 180 A;

- the ability to connect to a container with argon with subsequent welding of “non-ferrous metal” with non-consumable electrodes using the TIG method;

- equipped with a fan, protection against overheating and overvoltage of a single-phase 220 V network;

- the presence of a switchable idle voltage reduction system VRD.

inverter Svarog

Hello Everyone! I decided to buy an inverter this year, although I have an excellent welder, I wound it on a toroidal core made from the stator of a burnt-out 7 kW induction machine, everything would be fine, but carrying 45 kg plus cable in one mug is a little annoying. First of all, I decided surf the Internet to read what anyone has to say, so I wandered into the City of Masters. I haven’t come across a more detailed and long-lived forum on this topic. I read it, asked the price, and chose four models for myself: FORCAGE 161 (11800), NEON 160 (11800), Svarog ARC 165 (7700) and ELITECH AIS 160 SA (8410), (prices in Izhevsk companies). I was more inclined towards FORCING, just look at its official. characteristics according to Upit..But, firstly, the price, and secondly, FORCAGE and NEON are sold “naked”: no welding cables, no holder, no ground clamp - nothing! But it all “pulls” another one and a half two rubles. In addition, I read either here or in other forums that in Russian NEONs there is only a housing and a trans, and the boards come entirely from China, although I also read a diametrically opposite statement from a person who, according to him, had an internship at the factory in Nizhny, and personally saw how boards are produced and tested there. Included with ELITECH, as part of the promotion, is a “chameleon” mask, a funny thing, but in my experience the thing is very capricious and requires very careful handling, we have two at our enterprise masks made by USA, one died after six months (fell from about 4 meters), and the second, by itself, after 1.5 years. But “let’s go back to our sheep” On July 12 I walk along Krasnoarmeyskaya Street “I’m not touching anyone” and I hear someone yelling through a megaphone: “Promotion in the Elektrograd store! Discount on Svarog welding inverters! You can cook it yourself.” , couldn’t resist walking up, trying it, cooking it... In short, I bought a Svarog ARC 205 case for NINE pipes. The device was made by JASIK (China), which is written in black and glossy white on the cover of the passport, so there can be no illusions about the Russian spill. The kit includes: an inverter, a cable with a connector and an electrode holder, a cable with a connector and a ground clamp, a brush-hammer for metal (a small thing, of course, but, you see, it’s nice), a welding shield (glass about C3 or a little higher) and actually the case itself is where all this is packed. I immediately laid out the shield (with a mask it’s more common, but that’s what anyone cares about), and put an extension cord in the vacant space: SHVVP wire 2*4mm/sq 30m, with a twin socket for outdoor installation (so that you can connect an angle grinder ) I bought everything there. Now, FINALLY, about the operation of the device. I’ve used it three times so far, not counting the “test drive” in the store when purchasing. Twice in my garden (I made the proverbial fence) everything is OK because We have our own transformer substation on the array and there are no problems with the quality of the voltage. And they also invited me to tease him, I had to work almost outside the city, I don’t know what the voltage in the network is, naturally, I didn’t have a multimeter with me. I had to get power through an extension cord of unknown manufacture (it wasn’t long enough) the only thing I could figure out was: 50m 10A, how many volts reached the unit in the end I can’t say, but the current regulator had to be turned to maximum, the arc left much to be desired for the best, it seemed to go in jerks or jerks, but, nevertheless, I completed the work. (In all cases, approx. MP-3 electrodes, 3 mm in diameter) CONCLUSION: for a home for a family, the ARC 205, with normal power supply networks, is a good unit, and because In such cases, welding is usually done in threes, so there’s no need to “steam” - this model, with a light current of up to 140A, has a duty cycle of 100%, at least I burned 3 electrodes in a row at 26-28 degrees C and the thermal protection did not work .And if you have problems with the power supply, then I advise you to take a closer look at the Ryazan FORCAGE 161, for its price the device is simply amazing!! If it weren’t for the promotion, I would definitely buy it! But, as you know, history has no subjunctive moods. PS I couldn’t resist, I disassembled the holder and connectors (not for the sake of self-interest, but for order) everything was done very carefully, somehow not even in Chinese, thoroughly tightened. The only thing I touched was the fastening of the wire on the ground clamp. I wasn’t too lazy to calculate the cross-section of the electrical cable and here everything is as stated - 16mm/sq, even surprising. If everything inside the device is also well-made, then I think it will serve normally, and, by the way, the warranty on it is 2 years, just like FORSAZH.

sarc205 Welding inverter Svarog ARC 205 (J96)

Svarog ARC 205 (J96) does not overheat. Never. It works until the electrode burns out. And it doesn’t matter whether it’s summer or winter, whether the sun is shining outside or how thick the metal is. It is almost impossible to drive this machine - the PV according to the passport is 60%, and under test conditions in our laboratory it showed an even higher result (PV up to 80%). You will not wait until your device deigns to cool down, as happens with many other household inverters.

The power of this device (maximum welding current - 180A ) is sufficient to weld metal up to 6 mm thick (with an electrode up to 4 mm in diameter). is enough for household and installation work , and there will still be some left over. Moreover, with such a device you can not only weld , but also easily and simply cut metal.

Have you ever seen a household welding machine with a 5-year warranty (subject to annual paid maintenance starting from the 3rd year)? This is a unique guarantee. Apart from Svarog, no one gives such a guarantee. And having sold thousands of such devices, we understand that Svarog does not risk anything. They are indestructible.

Well, if suddenly (although unlikely) your device fails, more than 125 service centers in 85 cities of Russia are at your service.

Your device will be brought back to life quickly. Cooking in the country at low voltage is easy and simple! This device starts the arc at only 180 volts and is capable of maintaining it even at 160 volts.

Have questions? Call, our specialists sell such devices 8 hours a day for years and will be happy to answer any of your questions about welding equipment. We do not sell hammers and machines, but when it comes to welding, we try to know it inside and out.

We always have these devices in stock. We are ready to deliver them absolutely free of charge the next day in Moscow and St. Petersburg, or free of charge to any transport company of your choice if you need delivery to other cities of our Motherland.

Peculiarities

- HOT START

- Quick start (unregulated) - ANTISTICK

- Anti-stick (not switchable) - ARC FORCE

- Arc force (non-adjustable)

Contents of delivery

- Welding machine ARC 205 (J96)

- Ground terminal 200 A

- Electrode holder 200 A

- Tip OKS 35–50 (2 pcs.)

- Cable 1×16, 3 meters (2 pcs.)

Manuals and instructions

Specifications

| Characteristic | Meaning |

| Supply voltage, V | 220±15% |

| Power consumption, kW | 5,7 |

| Supply frequency, Hz | 50/60 |

| Open circuit voltage, V | 76 |

| Welding current control range, A | 10–180 |

| Rated voltage, V | 27,2 |

| PV, % | 60 |

| Consumption at idle, W | 40 |

| Efficiency, % | 85 |

| Power factor | 0,70 |

| Insulation class | B |

| Degree of protection | IP21S |

| Arc force, A | + |

| Electrode diameter, mm | 1,6–4 |

| Weight, kg | 5,8 |

| Overall dimensions, mm | 336×120×198 |

Reviews, questions and comments about the welding inverter Svarog ARC 205 (J96)

- Answer: Svarog ARC 205 is a newer model, the device is made on a more advanced element base, due to which the weight has been reduced. Great for home use.

- Question: Will a regular 6.5 kVA outlet be suitable for using this device?

- Answer: Basically, these are different elemental components, the first one operates on the basis of MOSFET transistors, ARC 205 (J96) on IGBT transistors. This may explain the difference in size and weight; therefore, the Z122 model consumes slightly less power, but the J96 has a argon arc welding function (a special valve TIG torch is required for its use).

- Question: Is it possible to order separately a branded Svarog case for the ARC 205 (J96) device?

- Question: What is the operating temperature range of the ARC 205 J96 inverter?

Answer: From -10°C to +40°C.

- Question: What kind of torch is required for this machine to perform TIG welding?

- Question: Does this model have a digital welding current indicator?

- Answer: In the Svarog ARC 205B (Z203) inverter, in addition to the presence of a digital current indicator, the welding current control range is increased to 200A, there is a VRD function (no-load voltage reduction) and the continuous operation time is increased - duty cycle 80%.

- Question: Is it possible to operate this inverter at a network voltage of 160A?

Answer: Possibly, but welding performance and available current range will be reduced.

- Question: What maximum diameter electrodes can be used for welding with this machine?

Answer: No more than 4mm.

- Question: Is it possible to cook this machine with AMG5M using special electrodes and which ones?

Answer: No, aluminum is welded using either semi-automatic welding (MIG) or alternating current argon arc welding (TIG AC/DC).

- Question: Will this device allow welding with a 3mm electrode at a network voltage of 160V?

Answer: Yes, it will.