Hot-rolled steel sheet does not lose its relevance for many branches of modern production. They are used for the production of household appliances, and are also used in the defense and chemical industries, automotive industry, mechanical engineering, and in the construction of ships and aircraft.

Hot-rolled steel is used in the manufacture of various structures by welding , for example, pipelines. Used for the production of riveted and bolted connections or parts. Despite the abundance of methods for producing metal products by rolling, hot and cold methods remain the most relevant. Hot rolled steel is popular due to its low cost.

Production technology

Sheet material is made from slabs, which are large slabs 75–600 mm thick and up to 2,500 mm wide. They are made from ordinary carbon and light alloy steel. Metallurgical enterprises can produce their own slabs, which are produced by continuous casting or rolling.

These billets can be supplied to the rolling mill from a third-party manufacturer, in which case they are preheated to a temperature of 1100 - 1300 °C, depending on the characteristics of the steel, giving the material plasticity.

Basic requirements for slabs:

- compliance with the declared composition;

- absence of foreign impurities;

- integrity of the structure without cracks and cavities.

Such blanks are suitable for further processing.

Production and assortment of steel metal sheets

As a result of applying pressure to a heated steel billet prepared in a continuous furnace, a hot-rolled steel sheet is obtained. The slab passes through flat rolls in a rolling mill, turning into a smooth sheet of the required dimensions.

Hot rolled sheets can be supplied in sheets or rolls. Its width is 500-1500 mm. The thickness of sheets is from 0.5 to 160 mm, and the thickness of rolls is from 1.2 to 12 mm. A product with a thickness of up to 4 mm is classified as thin-sheet, and above - thick-sheet.

Rolled products up to 8 mm thick are most in demand among enterprises in the construction and engineering industries.

In the production of steel sheet, a hot-rolled billet of low- or high-carbon steel is passed through a rolling mill, then the surface is treated with sulfuric acid or shot blasting. The finished product is wound into rolls and heated in bell-type ovens to relieve stress.

Cold rolled sheets have a thickness of 0.4-5 mm and are supplied in bundles or rolls. The product is used for construction and finishing work, in industry and as a blank for the production of corrugated sheets.

Rolling technology

When heated, the slabs are fed to a rolling mill - this is equipment equipped with sequentially arranged rolls that have different working gaps.

- Passing between the rolls, the workpiece decreases in thickness.

- Rolling can be carried out in several passes.

- At the last stage, when the required thickness of the sheet has been formed, it is marked and the edges are cut to size.

- The finished sheets are cut using guillotine shears.

- The sheets are cooled, after which the layer of scale that has formed is removed from them.

- Products enter the warehouse, are labeled and sent to the customer.

At the customer's request, additional heat treatment can be carried out, which relieves stress in the metal sheets that occurs after hot rolling.

offers sheet metal that complies with GOST 19903-2015.

Modern rolling production

Rolling mills are classified according to their purpose, number and location of working stands and rolls in the working stands. Depending on the purpose, i.e. Depending on the type of products manufactured, they can be divided into the following three groups:

- hot rolling mills (crimping, billet, rail and beam, section, wire, strip, sheet, broadband);

- cold rolling mills (sheet, sheet metal and thin and thin strip rolling mills);

- special-purpose mills (wheel rolling, bandage rolling, fork rolling, for rolling strips and profiles of variable cross-section, balls, gears, screws, bent profiles, etc.).

Rice. 1. Sheet rolling mill

Let us remember that crimping and billet mills are used for preliminary rolling of ingots poured into molds, and are not used when working with continuously cast billets.

The main parameter of crimping, billet and section mills is the diameter of the rolls or gears of the gear stand (in mm). If there are several working stands in the mill, the mill parameter is the diameter of the rolls of the finishing (last) stand. Thus, the name “small section mill 250” means that the diameter of the work rolls or gears of the finishing stand is 250 mm, and its purpose is the production of small sections.

The main parameter of sheet mills is the length of the barrel (working surface) of the roll (in mm), which determines the largest width of sheets or strips rolled on the mill. In this case, the name “thick sheet mill 3000” means that the length of the roll barrel is 3000 mm, while thick sheets up to 2700-2800 mm wide are rolled on the mill.

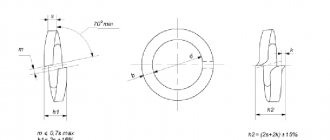

Rice. 2. Rolling rolls: with a smooth barrel (a) and calibrated (b): 1 – barrel; 2 – neck; 3 – driving or transfer ends

Based on the number and location of working stands, rolling mills are divided into the following five groups: single-stand, linear multi-stand, sequential, semi-continuous and continuous.

Single stand mills are the simplest type of rolling mill. The mill equipment includes one working stand and a work roll drive line, which consists of spindles, a gear stand, a gearbox, couplings and a main electric motor. The equipment included in the roll drive line is mainly repeated on rolling mills with a more complex arrangement of working stands.

The simplest are linear multi-stand rolling mills, in which the working stands are arranged in one or more lines. In this case, each line is driven by one electric motor. Single-stand mills can be reversible, when the work rolls can alternately rotate in one direction and the other, or non-reversible, when the work rolls rotate only in one direction. Linear multi-stand mills are used mainly as billet, section, rail and beam, wire and sheet mills.

A

b

V

Rice. 3. Calibration - the procedure for rolling a successive series of transition sections of rolled profiles

(a – rolling of rails; b – various options for rolling channel bars; c – various options for rolling angles)

Sequential mills are characterized by the arrangement of working stands, standing one after another in such a way that the rolled strip passes through each stand once. Therefore, the number of stands in such a mill should be equal to the maximum number of passes required to obtain the finished profile. On serial mills, the work stands are usually arranged in several parallel rows to reduce the length of the workshop and make better use of its space. Moreover, on such mills, the distance from stand to stand in the rolling direction increases due to an increase in the length of the rolled strip (since the cross-section decreases, the rolled metal is extended in length). Accordingly, the rotation speed of the rolls increases. Sequential mills are used mainly as varietal mills.

Rice. 4. Simple (a) and shaped (b) gauges

Semi-continuous mills consist of two groups of working stands: continuous and linear, or sequential. In a continuous group of stands, the rolled strip can be simultaneously in two, three or more stands, i.e. roll continuously. And in the second group, the strip is rolled either on a linear or sequential mill. Semi-continuous mills are used as section mills, wire mills and strip mills.

The most modern mills are continuous mills. Compared to other types of mills, continuous mills are characterized by higher rolling speeds (and therefore productivity). In this case, the drive of the rollers of the working stands can be either individual or group. These mills are used as billet mills, broadband mills, medium- and small-section mills, wire mills, etc.

Rolls are the main working tool of a rolling mill; they directly deform the metal. The costs associated with the operation of the rolls account for 5-15% of the total costs of a rolling mill.

{youtube}gb5ofEl__Sc&list=PLAEe6a6oMFf2oGqeIOgxBbyClQVKrhjau|100%|480|0{/youtube}

Rolling rolls are classified according to their purpose, the shape of the roll barrel, design, and material. According to their purpose, rolls can be sectioned and sheet, turning, split, leveling, etc., rolls for hot and cold rolling, crimping, roughing, pre-finishing and finishing rolls.

According to the shape of the barrel, the rolls can be smooth or cylindrical and with calibers. According to the design, rollers are distinguished between solid-cast, solid-forged and composite. According to the material, the rolls are made of steel, cast iron and hard alloys. The working diameter of the rolls is chosen so that they grip the metal without forced pushing, and also based on the conditions of strength and rigidity, especially for thin-sheet mills.

Fig.5. Options for arrangement of rolls in working stands:

a – two-roll stand; b – three-roll varietal and sheet; c – four-roll stand; d – six-roll stand; d – twelve-roll stand; e – twenty-roll stand; g – universal beam cage; h – universal slab stand

According to the location and number of rolls in the working stands and their design, rolling mills are divided into several groups: two-, three-, four- and multi-roll, universal with a special design (Fig. 5).

Double-roll stands (duo-) are the most common, and there are reversible and non-reversible. In reversible stands, the rolls have a variable direction of rotation. The rolled metal passes between the rollers forward and backward the required number of times, and the rollers accordingly change the direction of rotation and are reversed. Reversible twin-roll stands are used in crimping, plate, section and sheet mills.

In non-reversible twin-roll stands, the rolls have constant rotation in one direction. The rolled metal passes between the rolls of such a stand only once and in one direction. Irreversible stands are used in linear multi-stand, sequential, semi-continuous and continuous rolling mills for the production of billets, long products, wire rods, and sheets.

In three-roll stands, the roll axes are located in the same vertical plane and have a constant direction of rotation. Three-roll stands are widely used in the production of long products. The rolled metal moves in one direction between the lower and middle rolls and in the opposite direction - between the middle and upper. To lift the metal to the upper level and its task, lifting and swinging tables are installed between the upper and middle rolls in front of or behind the stand.

When producing sheets, three-roll stands are also used, but with a middle roll of smaller diameter than the lower and upper ones. The middle roll is non-driven and during the rolling process it is pressed either against the upper or the lower roll.

Just as in the production of long products, lifting and swinging tables are installed in front of and behind the stand. Since three-roll stands have low productivity and low rigidity of the roll system, they have practically not been used recently.

In four-roll stands, as in three-roll stands, the rolls are also located in the same vertical plane, one above the other. In these stands, two rolls are working, and the other two are supporting. The work rolls have a smaller diameter and are located in the middle of the stand, the support rolls have a larger diameter and are located at the top and bottom. Backup rolls are designed to reduce the deflection of the work rolls and to increase the rigidity of the roll system. The drive rolls in quarto (four-roll) stands are work rolls. Mills with four-roll stands are widely used for hot and cold rolling of thick and thin sheets, wide strips and strips.

Using four-roll stands, rolling is carried out on continuous multi-stand and single-stand mills. Four-roll non-reversing stands are used on continuous mills. Reversible four-roll stands are used in single-stand hot and cold rolling mills.

Multi-roll stands include six-, twelve- and twenty-roll stands.

Six-roll stands have two working drive rolls and four support rolls. These stands are characterized by increased rigidity of the stand itself and less deflection of the support rolls. Thanks to this, the stands are used for cold rolling of thin strips and narrow strips in coils with precise thickness tolerances. However, since the advantages of these stands compared to four-roll stands are small, and their design is more complex, they have not received significant distribution.

Twelve- and twenty-roll stands are widely used in rolling production. This complication of working stand designs is justified by a number of advantages, which are expressed in the rigid design of the roll system and the entire working stand. This allows them to be used for the production of thin and extremely thin tape. The diameters of the work rolls in such multi-roll stands range from 3 to 50 mm. They are non-driven and are supported by a series of large diameter drive rolls, which in turn are supported by a series of support rolls.

Universal stands have horizontal and vertical rolls located in the same vertical plane. The metal is compressed using horizontal and vertical rollers simultaneously.

Such stands are used in universal beam stands, where the vertical rolls are non-driven. These stands are used only for rolling wide-flange I-beams (beam height up to 1000 mm, flange width up to 400 mm), as well as for rolling other profiles (rails, universal sheets, etc.).

In addition, universal (conventional) stands are used as reversible two-roll (in slabs) or four-roll (in roughing broadband mills) stands. In these stands, the vertical planes in which either horizontal or vertical rolls are located are located at a certain close distance from each other.

In these stands, the rolled metal is compressed using both horizontal and vertical rolls. In this case, vertical rolls are located on the front or rear side of the working stand, the task of which is to obtain even and smooth side edges of the rolled metal.

The specially designed cages have a wide variety of roll arrangements. This group includes wheel-rolling, bandage-rolling, fork-rolling, ring-rolling, ball-rolling mills, as well as mills for rolling profiles of variable and periodic sections, gears and other products.

In addition to the rolling mill itself, the technological lines for rolling include a large amount of auxiliary equipment, which is divided into two main groups: transport, which performs operations of moving metal, feeding it to the working stands and turning it, and processing, the work of which is associated with finishing operations rental

The transport group of units and mechanisms includes roller tables, refrigerators, manipulators, tilters, rotating and lifting mechanisms. The processing group of units and mechanisms includes scissors, saws, straightening mechanisms and presses, winders, unwinders, etc.

An important role is played by roller tables - systems of rollers mounted on a frame. The rollers are driven by electric motors, and when they rotate, the metal laid on the roller table receives longitudinal movement due to friction forces. Roller conveyors provide metal supply to the rolling mill, its transfer into rolls, reception from rolls and movement to scissors, saws, levelers and other devices and mechanisms.

Refrigerators are the connecting link between the rolling mill and the units for finishing rolled products. The refrigerator receives the rolled metal, cools it, transfers it to the outfeed roller table, and transports the metal to the finishing units.

The most common rack-and-pinion coolers provide cooling of strips using movable gear racks that perform a rocking-forward motion. An important advantage of these refrigerators is the ability to straighten rolled metal during the cooling process. When moving through the refrigerator, the metal is cooled to 80-120 ° C and transferred to an outfeed roller conveyor leading to scissors for cold cutting to cut lengths.

Rolled products prepared in this way, as a rule, are supplied to units for heat treatment to improve its properties: hardening to impart hardness, or vice versa - to an annealing unit for softening (for example, for subsequent rolling of the sheet into a thin cold-rolled sheet), and then to units for surface finishing - mechanical or chemical (etching) method.

Fig.6. Rail Head Hardening Machine

In the future, thin-sheet rolled products can also be given special properties using special units. Mostly it is galvanized to protect against corrosion by passing it through a bath of molten zinc in continuous hot-dip galvanizing units (CAG), and it is also given additional protective and aesthetic properties by applying polymer coatings or by painting.

It is important to note that at all stages of production, quality control plays an important role, carried out both by cutting samples from metal for subsequent assessment of its properties using standard methods, and using non-destructive testing methods - ultrasonic, electrical inductive, X-ray and gamma flaw detection.

SHARE INTERESTING INFORMATION

Classification

Hot-rolled sheets are divided into categories, according to which they are marked.

Thickness:

- thin sheet 0.4 - 4 mm;

- thick sheet 4 - 160 mm.

Dimensional accuracy:

- increased – A;

- regular - B;

Edge processing:

- uncut edge - O;

- cut edge – BUT;

Accuracy of creating a sheet plane:

- especially high – PO;

- high – PV;

- improved - PU;

- normal - mon.

We sell not only standard rolled products, but also sheets with special properties and sizes. Deliveries are carried out both from the company’s warehouses and in transit from metallurgical enterprises.

Characteristics of rolled sheets

Rolled steel is produced in rolls or sheets. Product dimensions must comply with the standards established for hot-rolled and cold-rolled products (GOST 19903 and GOST 19904).

The regulations adopt four classes, formed according to the method of surface finishing: the first three (I, II and III) are for cold-rolled and correspond to the characteristics of “especially high finishing”, “high” and “increased”. The latter is divided into two subclasses (a and b). Hot-rolled sheets can be graded III – advanced finishing and IV – regular.

On the marking of cold-rolled steel you can also find the designations “G” and “N”. They characterize the drawing ability of a steel sheet/roll, where N is normal drawing, and G is deep drawing.

Using the symbols you can find out the maximum limit of tensile strength of the product. It is indicated when designating steel.

- So for steels of ordinary quality (OK), the designations of strength groups OK300V, OK370V, OK360V, OK400V are accepted, where the number is the lower limit.

- For quality steels (K) designations K260V, K310V, K270V, K330V, K390V, K350V, K490V.

To make it easier to navigate which steels the ordered products are made of, we have provided a list of grades included in each group.

Application area

Hot rolled sheets are widely used in industries where there is a need to form complex and inexpensive metal structures.

- Used for the production of seam pipes of various diameters.

- Widely used in shipbuilding to form ship hulls and structural strength systems.

- With light alloying, the sheets can be used for the production of tanks and containers.

- Hot-rolled material is a blank for the production of cold-rolled sheets, which, after additional processing, are used in construction and the production of consumer goods.

A sheet whose manufacturing technology is violated can retain internal stresses. They will prove themselves when creating welded structures and pressure vessels. To avoid this defect, you should contact trusted suppliers who have proven themselves in the market. Such a supplier is, which has been providing customers with high-quality rental products for 15 years.

Tags:

Hot rolled products, Sheets

Steel grades

For OK steels:

- OK300V are steel grades St1, St2 with all degrees of deoxidation.

- OK370V – steel St3ps, St3sp.

- OK360V – steel St3 (all degrees of deoxidation).

- OK400V – St5ps, St5sp, and also St4, also of all degrees of deoxidation.

For K-steels:

- K260V – brand 08kp;

- K310V – brands 15ps and 15kp;

- K270V – brands 10kp, 10ps, 10, 08ps, 08;

- K330V – brands 20kp and 15;

- K390V – grades 30 and 25;

- K350V – grades 20 and 20ps;

- K490V – 35, 40, 45 and 50.

The manufacturer himself chooses the grade of steel for the manufacture of steel sheets. The customer can, under certain conditions, choose other raw materials to fulfill his order, that is, the issue is resolved by agreement.

Important! At the same time, other conditions apply to rolled steel, which will be used in the manufacture of welded structures, as well as in structures for critical purposes. Here, the steel grade, as well as weldability, is determined directly by the order.

The mechanical properties of sheets of each strength group are given in the table in the attached document (tensile strength, relative elongation and bending until the sides are parallel).

Note: Another designation used in labeling is category. Since it is usually defined by a number from 1 to 6 without explanation, let’s look at what each of these numbers means.

Each category is characterized by one or more main parameters:

- Category 1 – the indicator is taken into account when testing for bending. It includes rental OK300V, OK370V, OK360V.

- Category 2 – the main characteristic is the draw of the spherical hole. This category includes only cold-rolled sheets of classes K260V, K310V, K270V, K330V, K350V.

- Category 3 – the two criteria described above are taken into account. The category includes rolled products of the same assortment as for category 2.

- Category 4 – mechanical properties are assessed. The group includes sheets manufactured by any method and of all strength classes presented.

- Category 5 – for hot and cold rolled sheets. Mechanical properties and bending test results are taken into account. All strength classes are included, except for K490V and OK400V.

- Category 6 – the results of all the above tests are taken into account (spherical dimple stretching, bending, and mechanical properties). Category only for cold-rolled steel, strength class K260V, K310V, K270V, K330V or K350V.

Acceptance and marking

Cold rolled sheets and hot rolled sheets with a pickled surface are lubricated on both sides with lubricant to avoid oxidation. The customer may request that the sheets not be lubricated, but in this case he must be prepared for the appearance of rust spots on the surface. Upon acceptance, this will not be considered a manufacturing or storage defect. In addition, since the sheets are supplied in bundles, without a protective lubricant, scratches may occur during transportation.

The bundles must be wrapped in sheets of soft metal.

When marking, the following characteristics are taken into account:

- sheet/roll,

- accuracy,

- flatness,

- character of the edge,

- dimensions

- and standard number.

For rolled products with specified weldability parameters, ensure weldability. Also indicate the steel grade, drawability, surface finishing group (I-IV), category (1-6) and strength group (K, OK).