Often in carpentry there is a need to measure angles other than 90 degrees. This need also arises in construction, for which a simple tool called a malka was invented. In construction, this tool is used mainly when installing window sills, but not every craftsman knows how to use the tool. The goniometer will also be an indispensable tool for those exceptional cases when it is necessary to level the baseboards on the floor or ceiling.

Do-it-yourself small goniometer

A goniometer is a fairly affordable tool that can be bought at almost any hardware store, but the master does not always have time for this, and the device may be needed urgently. In this case, you can do it yourself. To do this you will need:

- A block of wood from which the block will be made. A small piece of up to 30 mm will do.

- A piece of plywood, the thickness of which should be more than 3 mm. It is better not to take plywood thicker than 5 mm. The moving part of the device is made from this material.

- A bolt and nut can be used as fasteners.

- Using a drill, you need to drill a hole for the bolt.

You need to start assembling the goniometer from the block. To do this, measure 10 cm on the workpiece and saw off the required length. After this, you can proceed to making a slot for the feather, which will require cutting the block from the end.

The feather of the instrument is made of plywood, and if it is not available, then you can use a material of similar size - for example, a sheet of plastic. Marks of 20-40 mm are made on the sheet: these will be the dimensions of the pen itself. They can be changed at your discretion. If you did everything correctly, the feather and the cut in the block will form an acute angle when folded. The parts are bolted together at an angle of 90 degrees; the pen must be able to move. The excess needs to be cut off and cleaned.

Using powder for plastering

With this small tool you can easily and efficiently perform not only plaster, but also putty.

First of all, you need to form the same “dawn angle” for all slopes. We install the block on the edge of the window frame, for example, and use a pen to determine the angle along the edge of the slope adjacent to the wall. We secure the resulting result with a screw.

Now you need to check the entire slope around the perimeter of the small wall. The result should be the same everywhere. If there are deviations somewhere, then we remove the excess and check again. You may have to change the angle on the fry a little if there are large errors. The malka we made using a simplified scheme works in a similar way.

The next stage is preparatory work and plastering, puttying the slopes. The entire sequence is described in detail in the article plastering slopes. Here's a device for you - it seems like a very simple tool, but when used, the slopes are formed quickly and efficiently with a given opening angle, symmetrical and even.

I offer a short video where the small one is a very simple template made with your own hands.

How to use malka?

If we are talking about a pure transfer of an angle to a workpiece, then there is nothing to describe here: set the angle specified by a template or sample, or a drawing (possibly scaled), fix the relative position of the pen and the block and transfer it where necessary. In this case, it is absolutely indifferent to us what the magnitude of this angle is in degrees, radians or segments of any size. But, if you need to calculate the angle of conjugation of two connected elements, when it is different from a straight line, or a pair or three of others present on some miter box, then, perhaps, you cannot do without a small tool. Let's look at an advertising image of one of the digital cards.

The tool showed the wall bevel angle down to tenths, but did not bring us even 1/10 closer to a practical solution to the problem of accurately joining the plinth sections in such a strongly “wrong” angle. It is clear that by dividing 135.4° by 2, we get the angle at which the skirting boards should be cut, but marking them accurately and then cutting them is not an easy task. With the help of malka, these issues can be solved as easily as possible:

- Place the bait in the corner, pressing the block and feather tightly against both walls, and fix the turn of the corner.

- Transfer the resulting angle to a sheet of paper, drawing it with a pencil or pen.

- You cut out the resulting corner, although you can simply bend the sheet along the marked lines.

- Bend the resulting segment in half from the corner.

- You align the plinth by aligning its back part with one of the sides, and the end with the top of the corner.

- Combine the cutting tool with the second ray of the angle and make a cut. If you have doubts about the verticality of the cut, place a block with an exact right angle behind it and cut along its edge.

The video shows a slightly more complex way of transferring an angle taken from a scale drawing.

But its relative difficulty lies in maintaining extreme accuracy, because even minor deviations in the overall length of the structure can result in decent linear deviations in size. What can we say about such metal-plastic window systems, which are shown in the photo. If memory serves, their dimensions are: 5000 x 4000 x 3500 or so.

Can you imagine the consequences of an error in cutting the welding corners of the upper bevel of the structure? But everything was marked with impeccable accuracy using a small marker. A rectangle of 5000 ? was drawn on a flat floor in the workshop. 3500 with checking the diagonals, then one of the sides is extended to 4 meters and this point is connected to the second upper corner. Next - everything is as described in the example with the plinth, only the necessary values for welding are added to the nominal dimensions. For some types of work, special baits are created - double ones. They are used to transfer the angles of rotation of the bay window and similar tasks.

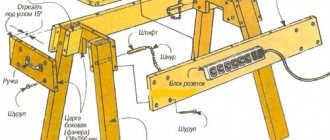

There is confidence that after what has been described above, there is no particular need to explain in detail how such a tool works. It is only necessary to emphasize that the grooves in the unit, which replaces the block common to both feathers, allow the fry to be moved apart in width, increasing its functionality. It is also obvious that this is a homemade small machine, and its design is significantly simplified, even in comparison with the simplest commercially produced one. But it does its job no worse than the factory one; you just need to be more careful when handling such not very durable structures. But making even a more structurally complex piece of work is not a problem for a person who knows how to use simple carpentry tools.

The main tasks of this tool

The main purpose of the grinder is to measure the existing angle and then transfer it to the workpiece or a more accurate measuring device. They are extremely popular when installing window sills. Using this tool, the angle of repose is measured, after which it is transferred directly to the workpiece, which allows you to cut the required size as accurately as possible.

The adjustable bevel is also used to determine the “dawn angle” during the installation of window slopes.

Malki are also called protractors, which today come in various types, shapes and sizes. Protractor meters with a size of 300 mm are popular, which allows you to measure different lengths of angles. Protractors are also made of wood, plastic or metal. You can measure angles using a protractor, but this is very inconvenient and time consuming. Recently, an electronic protractor has appeared that allows you to measure angle accuracy up to 1 mm.

Malka do-it-yourself protractor

Sometimes there is a need to use a protractor, but it is not at hand. It can and even needs to be purchased, but if a one-time job is being performed, then it is quite possible to make the tool in question yourself. For manufacturing you will need the following materials:

- A wooden block, which will serve as a block or a fixed ruler. If plywood or plastic is used, then use the thin part of the tool.

- A piece of plywood or plastic, but it is best to use old wood; their thickness should not exceed 3 mm. These materials will play the role of a moving element.

- To connect these two materials, you will need to drill holes in them, and then connect them together using a bolted connection with a “lamb.”

Marks of 20-40 mm are made on a sheet of plywood or plastic. If you use a ruler, then there are already markings on it. After this, you will need to combine the prepared materials, resulting in a homemade protractor. The video below shows how to make malka with your own hands in the simplest way.

How to use malka: step-by-step diagram

Not many craftsmen know that you can use malka in your work. In this context, there is not just a transfer of an indirect angle to the workpiece, but a direct calculation of the conjugation of the two elements being connected. Let's consider the features of using the tool in question using the example of window slopes.

Using a hammer, you can perform proper plastering based on standards. A step-by-step diagram of the correct use of the tool is as follows:

- The “dawn angle” is selected. We decide on the bevel under which the plastering will be carried out.

- A. To do this, we pick up a protractor, after which we proceed to measurements. The fixed part of the tool is applied to the edge of the window frame, and the movable part determines the angle from the edge of the window opening from the wall side. To fix the obtained value, you need to screw the “lamb” on the tool. From the wall side, we fix the result obtained directly at the top and bottom points.

- Slope leveling. To make the angles for the slopes ideal, you simply need to install a rail or strip to the wall around the perimeter of the window. The goniometer determines the location of the edge of the rail, after which we fix it with self-tapping screws. The rail must be checked using a building level, since it must be strictly vertical.

- Applying mortar and sealing slopes. The solution is applied to the slopes with a reserve, and the excess is removed using the rule. In order for the slope to receive the direction of the angle, you need to set the rule with the edge towards the window frame, and then draw it along the slope from bottom to top. The rule will remove excess mortar and also level the surface.

- Finishing is the addition of a final layer of plaster mortar (if needed) to complete the leveling of the slope. It is not advisable to seal slopes with large layers of plaster, since it will simply “float” without having time to dry. Finishing also involves the use of a protractor, with which the check is carried out.

Using the example of window slopes, the use of a protractor was considered

It doesn’t matter what kind of small tool you used to level the slope angles. The main thing is that the master uses a small tool to perform these actions, and also knows how to use it correctly

Protractor protractor

This is one of the popular DIY tool methods that can be found online. Even a child can do it. A minimum of materials will be required.

Necessary materials

For manufacturing you will need the following materials:

- Stationery protractor (in the shape of a semicircle, preferably made of transparent plastic);

- Laser pointer;

- Strong thread (can be replaced with thick fishing line);

- Fishing sinker with an eye (you can use a nut);

- Superglue and baking soda;

- Matches or lighter, needle.

The cost of such a protractor is literally 50 rubles. And this is taking into account the cost of the laser pointer and batteries required for operation.

Important! Matches and a needle are needed to make a small hole in the protractor. This can be done more accurately using a Dremel type grinder and a thin drill.

Manufacturing instructions

So, a protractor is made according to the following scheme:

- A small hole is made exactly in the center at the bottom of the protractor. The point will be on a line drawn perpendicular to the base from a mark of 90°. The hole can either be drilled or made using a hot needle. The latter is only needed for plastic devices - this is what it is advisable to use.

- A fishing sinker is tied to the thread. She will be like a pendulum. The recommended weight of the weight is 5 grams or more.

- The thread is threaded through the hole in the protractor. A knot is made at the threaded end so that the resulting thickening allows the thread not to slip out of the hole. You can fix the pendulum using superglue, but you don’t have to wait until it hardens - just add a pinch of baking soda and this mixture will instantly harden.

- A laser pointer is attached to the bottom edge of the protractor. You can also fix it with superglue and baking soda. If there are any irregularities on the pointer body, it is better to remove them or completely rub them with a file.

If possible, you should check the accuracy of the protractor using a building level (you need one that has a spirit level).

Usage

If everything is done strictly according to the instructions, then such a homemade protractor will have a maximum error of only 1-2 degrees, no more. To measure the angle you will need:

- Stand on a flat surface;

- Raise the structure to chest level, turn on the laser pointer;

- Point the laser point at the plane from which the angle is measured (preferably it should be a flat plane perpendicular to the ground);

- Fix the position of the protractor and thread;

- Look at the mark on the protractor that the pendulum thread points to.

Please note that you will need to subtract 90° from the indicated mark on the protractor. Naturally, such a homemade product will not replace a full-fledged building level, but in critical cases it will be enough to take measurements.

We make slopes without problems

Most often, a goniometer is used when constructing window and door slopes. Using this tool, you can achieve not only even corners, but also properly plaster the surface.

It is important that the corners have the correct angle of dawn and are symmetrical relative to each other. It is almost impossible to achieve this by eye: the difference between the slopes is immediately noticeable

How to get even slope angles? First of all, you need to prepare the walls for work. To do this, they are plastered, removing all visible irregularities. Areas of future slopes are cleaned of dirt and dust and primed. If there are traces of polyurethane foam on the window, its protruding parts are cut off.

Then you need to choose the right sunrise angle. To do this, you need to decide at what angle the plaster will be applied. This can be done using a goniometer. Its block must be placed on the edge of the window frame. The angle is determined using a pen; this is done from the side of the walls. After this, the result is recorded, and the remaining angles are checked with a small tool. If there is a discrepancy, another indicator is selected on the device, or excess plaster is knocked out.

In order for the slopes to become identical, their angles need to be aligned. Plasterers usually don't level the plaster near windows and it looks ragged. Before starting work, it is necessary to align these corners. To do this, you can install a leveled rail on the wall. Then the desired angle is set and the solution is applied at this angle.

Before plaster is applied to the slopes, it is necessary to secure the slats to the walls. This can be done using nails or self-tapping screws, depending on what material the walls are made of. After the slats are removed, the holes formed by the fastenings can be filled with putty.

The mixture must be applied in excess to the slope. To ensure that the plaster does not fall off and lies flat, it is applied at an angle; you need to act from the center to the corner. A goniometer will be needed to remove excess plaster from the slopes. Using the same tool, the corner is given the desired direction: to do this, the block must be moved to the window frame. You need to run the block along the frame, directing it from top to bottom. Using a pen, the goniometer leveles the surface and removes excess plaster from it. Sometimes pits appear during the work process. Getting rid of them is not difficult: just put more mixture on the recess. Excess amount can also be removed with malt.

The final stage of slope removal is finishing. For slopes, the normal thickness of the plaster layer is 5 mm. If an inexperienced master worked, the layer may be much thicker. In this situation, you usually want to immediately level the slope, but there is no need to rush into this, since the plaster solution has a large mass and falls off if handled carelessly. In order to avoid having to do all the work again and correct mistakes, it is better to give the plaster the opportunity to set a little in the form that it already exists.

You should wait about a day. After the plaster has set, you will need to use a special grater to clean it. This tool will allow you to remove all the crumbs and depressions that appeared on the slopes while working with them.

If desired, the surface can be made perfectly flat, but you need to work with caution: some craftsmen remove too much layer of plaster and make deep depressions that have to be repaired

The manual sanding method is quite dusty, so it is better to use a protective bandage. Using this method, the master will not have to resort to using additional tools or materials, and the angles of dawn will be the same.

Malka is a convenient carpentry tool. The small scale is used to measure and move any angles.

It is convenient to use when laying laminate, parquet, partially tiles, etc. The mould consists of two elements connected to each other with a bolt and nut. The bolt and nut are tightened a little so that the small can folds and unfolds while remaining in the desired position.

Sequence of work

Surface preparation

Before plastering the slopes on the windows, it is necessary to carry out a number of preparatory work.

Both the convenience of further work and the durability of the finished finish will depend on their quality.

It is advisable to install the window sill before starting plastering work. This will make it possible not to subsequently seal the gaps between it and the side slopes, as well as increase the strength of the installation.

It is recommended to reliably protect it from mechanical damage and possible ingress of solution by laying a thick layer of paper on top or laying unnecessary pieces of drywall of suitable size, if any are left over from the ceilings or walls.

- If there are remnants of old plaster, paint or other contaminants on the window opening, they should be removed. The solution should be placed on something solid and not on dirt or dust.

- It is also better to cover the window block with film. In a single production, you can get by with film by gluing it to the window with pieces of masking tape. You should also protect handles, heating radiators and other fittings by wrapping them in paper.

- After cleaning, cut off excess foam with a knife.

- To improve adhesion (increase the adhesion of the applied solution to the base), prime the surface with a deep penetration primer. Its choice depends on the building material from which the window opening is made.

- Then apply a vapor barrier. On the inside of the wall, the foam must be sealed with a special vapor barrier film or a layer of silicone frost-resistant sealant must be applied to it.

A few words about malka

Next, you should make a fry. Malka is a template according to which plaster is made. If you look closely at the slopes, they are not just straight, but expand slightly inward, forming a window opening.

It is usually made from a piece of plywood. It is a narrow piece of plywood, slightly longer than the slope by 5-10 cm, and about 15 cm wide. One side has a cutout; during operation, it is this side that will move along the slope. The second is based on the installed beacon.

Thanks to this device, after removing the applied mortar with a small tool, the slope will be smooth. It is also necessary to make another cutout through which the window hinges will pass.

It is advisable to slightly remove the “chamfer” (round it off with a file) so that the plywood does not chip during work.

Professionals use metal baits made of aluminum, which are made to order. In principle, you can do without it, but no one guarantees that the angle of repose will be the same everywhere.

The room temperature should not be lower than +5˚С for cement mortar or +10˚С for rotband.

Do not try to prepare a large volume of the mixture at once. This especially applies to, which requires a fairly fast operating technique.

Before plastering the slopes, it is necessary to calculate the amount of mortar. Its volume is determined based on the area of the slope and the thickness of the future plaster layer.

Plastering slopes is carried out according to the same rules as plastering a regular wall with an angle, only the opening of the window is done little by little.

This is done as follows:

The finishing is similar. Before starting, it is recommended to install a perforated corner on the corners to protect the edge from mechanical damage.

Tool structure

Most often, a goniometer is used in carpentry, but it can also be found in other areas of repair and interior decoration. Externally, the device is similar to, however, the small sample has a moving part, thanks to which you can conveniently take readings.

The tool in question has the following components:

- Block with slot. This is the main part of the protractor, which allows you to find out the inclination of the angle.

- Movable pen. It is threaded through a groove in the block: this saves space and makes the device more convenient to use.

- A wing that serves to secure the tool.

You can find both metal and wooden devices on sale. The wooden version is safer for surfaces and does not leave scratches.

Creating a Swenson Square

The author of such a useful device did not have time to properly file a patent for his brainchild, and numerous businessmen are actively using this.

The only thing they can't use is the special diamond cut hole, but some very resourceful competitors make a slightly different shaped slot. In the initial version, the Svenson square did not have a comb for special parallel markings and the hole itself. However, the comb is not an option that you cannot do without. It must be said that in almost a hundred years of history the device has not undergone significant changes.

Types of goniometers by method of application

Goniometers were invented quite a long time ago, but now this measuring tool continues to be popular. For different areas of use, appropriate measuring instruments are produced. Let’s find out in detail what they are and how they differ.

- Construction is the most common type of measuring tool that every craftsman must have. The device is intended for monitoring walls, foundations, ceilings, etc. The main feature of this meter is that its parts are at least 50 cm long, which ensures high accuracy of readings

- Carpenter's - used by carpenters in the manufacture of woodworking structures. A carpenter's goniometer is also called a small goniometer, and it is approximate, as it has low measurement accuracy. The main distinguishing feature of a small scale from a protractor is that one part has a graduated scale, and the second is a support leg

- Metalworking - compared to carpentry, it is distinguished by high measurement accuracy. In plumbing, high precision is important, so protractors have a sensitive adjustment mechanism that provides measurements down to the smallest fraction of degrees

- Mountain - in design it has little in common with previous options, but is also intended for measuring angles. It is used to visually determine vertical and horizontal angles in mountainous areas. Such instruments are used today only by amateurs, as they have been replaced by more accurate instruments

- Medical - few people know that medicine also uses a measuring device such as a protractor. The medical meter is used in medicine to determine the operating angles of large, medium and small joints. It looks like a circle with a graduated scale on which the amplitude of movements is analyzed

- Astronomical - has nothing in common in design with all the presented types of inclinometers. This type of instrument is the most accurate, and it is intended directly to calculate the trajectory of the stars in the sky, as well as their speed and size. Typically used in conjunction with telescopes

- Seaworthy - has an individual design, and is intended to identify the geographical coordinates of the vessel’s location. Today, such devices are not used by sailors, as they have been replaced by modern satellite devices. Only every ship must have such a device, which can be used in case of failure of electronic systems

- Artillery or military - serves to install an artillery gun, as well as adjust salvo fire. Today, devices are also practically not used

- Protractor for tightening bolts - a special device that allows you to ensure that bolts are screwed to the required angle of rotation

These are the main, but not the only types of protractors found on the planet. If construction work is being carried out around the house, then the craftsman will definitely need to buy a special protractor. What they are based on the method of measurement is described in detail below.

What is an analog micrometer and how does it measure?

An analog micrometer is also called a mechanical micrometer, as it has a simple operating principle and design. Based on the simplicity of the design, the device is durable, which is why even today you can often find devices produced back in Soviet times. A mechanical micrometer is resistant to physical impact, and to all the advantages, you can add a relatively low cost, which ranges from 400-500 rubles, depending on the model.

This is interesting!

On all types of micrometers, the clamps are different, and are presented in the form of a lever switch or a moving washer. Both clamping options are reliable, but the main disadvantage of washer devices is that they are not visible when the clamp is engaged.

Making malka yourself

We cut a blank from the board up to 20 cm in width, and calculate the length - a value equal to the depth of the slope plus up to 15 cm, so that it is comfortable for your hand to hold it.

Top view of the slope

To allow the tool to slide freely along the window or door frame, we make a cutout in the workpiece equal to the width corresponding to the dimensions of the door frame or window frame.

In order for the fry to move easily along this guide, you also need a hole through which the loops will “pass.” It is made round in the corner of a cutout made in a board or plywood. The diameter should be slightly larger than that of the loops so that the fry does not touch the loops when moving.

Many people simplify production - instead of all the cutouts, they drive a nail into the end part (then the workpiece should be a little thicker). To prevent it from scratching the surface on which it will move, bite off the cap and wrap it with electrical tape.

In both options, one end of the block with a cutout or nail moves along the window frame, and the opposite side moves along pre-nailed slats, like guides.

How to use malka - step-by-step diagram

Step 1: Preparing the walls and window opening

All walls of the room in which you plan to make slopes must be completely plastered. As a rule, the plaster ends at window openings. The slopes themselves must be prepared, cleaned of dust and treated with soil. Also, if the window was installed using polyurethane foam, the protruding excess must first be removed with a knife.

Step 2: Select the “dawn angle”

Now we need, first of all, to decide on the angle at which it will be carried out. To do this, we install the block along the edge of the window frame and, by moving the pen, determine the angle along the edge of the window opening from the wall side. We record the result obtained on the small scale and check the compliance along the perimeter of the window opening. If, when checking, the selected angle does not coincide with the selected value, it is necessary to cut the plaster from the side of the wall or change the angle on the grinder.

Step 3: Leveling the slope angle

Usually, on a window opening, the plaster ends up in a chaotic manner; even corners are created when working with slopes. In order to make ideal slope angles, you just need to install the rail on the wall along the edge of the slopes around the perimeter of the window. To do this, we use a small tool to determine where the edge of the slats will be located, and fasten it with self-tapping screws or ordinary nails to the wall. Don’t forget to check the rail vertically with a building level; it must be strictly level.

Step 4: Apply the solution, set the angle

When the slats are installed on the corners of the slopes, we begin to apply the plaster mixture. To do this, apply the solution to the slope with a trowel at an angle, preferably with a slight excess. After sanding, remove excess plaster mixture and set the slope to the direction of the angle. In this case, install the block on the window frame, exactly as we did during measurements, and slide the block along the frame from bottom to top. At the same time, the pen will remove excess and level the working surface. If after the work done there are holes on the slope, add mortar and again remove the excess with chalk.

Malka is a convenient carpentry tool. The small scale is used to measure and move any angles.

It is convenient to use when laying laminate, parquet, partially tiles, etc. The mould consists of two elements connected to each other with a bolt and nut. The bolt and nut are tightened a little so that the small can folds and unfolds while remaining in the desired position.

To take measurements

In order for the floor covering to be smooth and last a long time, you will need a tool to take measurements and markings. The master needs to have on hand:

- Roulette. This useful household device will be required often when laying laminate flooring. Even before work begins, you will need to take measurements of the rooms in order to know how much material you will need to buy.

- Meter ruler made of metal. If a tape measure is convenient for taking measurements of large-scale objects, then for measuring small parts and drawing straight lines you cannot do without a ruler.

- Metal square. Necessary for laying right angles.

- Protractor. This measuring tool is needed if you plan to lay the laminate flooring diagonally or shaped. In this case, it will be possible to cut the lamellas not only at a right angle, but also at an acute angle.

Advice! Instead of a protractor, you can use a device for a similar purpose - a protractor.

- Pencil. The purpose of this device does not need to be explained to anyone; it is necessary for applying marks.

Design and purpose of the fry

The usual, simplest malka consists of two elements:

- pads - a fairly wide block with a slot;

- feather - a thin strip, which, when assembled, hides in the slot of the block.

These elements are connected to each other by a screw pair. The design of the screw pair can be completely different, but there are two fundamental differences: the screw can be protruding, and then, most often, instead of a regular nut, a wing is used to conveniently fix the relative position of the block and the feather, or it can be recessed.

The latter option is more convenient for installing the bait in the right place, but is less practical for fixing given angles and, as a rule, is more technically complex.

Sometimes, but rarely, on the feather, and even less often, on the last, dimensional marks are applied. But the malka is not a measuring tool, but a marking tool. Its task is to fix the size and transfer it to the workpiece, or to workpieces, when replicating identical products. Although, the desire of many manufacturers for universal unification has led to the creation of digital cameras equipped with liquid crystal displays. With memory, zeroing the result in a given position and other attributes of modern digital instruments, but such devices only have a common design, and functionally they are, rather, protractors.

Digital fry

They try to build everything into the small machine - even a bubble of a level, which generally does not fit well with the list of basic work performed with the help of the small machine.

Malka-9

Malka-5

Malka digital

Mechanical improvements are also trying to catch up with digital sophistications, supposedly expanding the functionality of the tool.

Malka-2

Malka-3

Malka-7

Malka-8

In our opinion, of all this abundance of technical solutions, more or less useful is the device of a groove in the feather, which allows you to vary its length, which in rare cases, but still, can be useful. And we will confirm our, for many ambiguous, conclusions with examples of work where malka is truly irreplaceable.

Tool

For any task you need a tool. Plastering window slopes is no exception. The set of tools will depend on what materials you use.

In any case, you will need:

- good level;

- aluminum rule;

- pencil;

- fry;

- roulette;

- spatula 5 cm;

- plywood or metal block;

- Master OK;

- solution container;

- water container;

- hammer-pick.

A level that is too long will not work. It may simply not fit between the lintel and the window sill. At the same time, it is inconvenient to work short. Choose the golden mean, it will be a level 1 meter long. For auxiliary work, a gun with sealant and a knife will be useful.

You may also need a can of polyurethane foam to “blow out” the gaps between the window frame and the opening in which it is installed.

If you use cement-based, you need to get a grater and a grater. If using a rotband, a large and small trowel, as well as a 45 cm spatula and a sponge grater.

Overalls and work shoes should be comfortable and not interfere with movement. Since the plasterer's hands are in direct contact with the solution, it is best to get sealed nitrile gloves.

If you have seriously decided to master such a thing as the technology of plastering slopes, borrow or independently put together a normal plaster goat from boards. The work will be more fun, and it will be safer. Plastering from a stepladder or stool is a bad idea. It's very inconvenient and takes about twice as long.

Construction goat

How to choose plaster and prepare the right solution?

You can buy a mixture for plastering slopes. Facade plaster is better suited for exterior work. Following the instructions, the dry mixtures are diluted and applied to the surface. Despite the inconvenience and efficiency of preparing ready-made solutions, many people prefer to make their own mixtures. Their quality depends on maintaining proportions and choosing the right material.

Frost- and moisture-resistant ones are suitable for external finishing of slopes; the best option is a cement-sand mortar. Cement is the strongest among binding materials for external slopes. The component composition provides excellent adhesion to the base. The integrity of the coating is maintained much longer than when using other mixtures. Construction gypsum and clay are inferior in many respects. They are sensitive to moisture, which can lead to destruction of the coating.

Cement is diluted with water. Sand is most often used as a filler. The standard proportion is 1:3, the consistency of “liquid sour cream” is considered ideal. A mixture that is too thick can cause the surface to crack, and a weak, watery solution will spread.

The cement-sand mixture sets in 15 minutes and hardens in 11–12 hours. If you are plastering slopes with your own hands and have no experience in this matter, it is better to prepare the solution in small portions. The application process requires efficiency; you may simply not be able to cope with it, and as a result, the material will harden and be unsuitable for use.

Ideally, defects do not appear on a well-finished slope. The plaster should not peel off, crumble, crack, etc. If these phenomena are observed, additional costs will be required for restoration and sealing. To prevent defects in your work, we first advise you to study the instructions for using the material or consult with professionals.

How to make malka at home?

Of course, today all the necessary tools, in our case a small tool, can be bought at a hardware store. But sometimes situations arise when a device is needed now, and there is no time for it, or the necessary tool is simply not available for sale. Let's try to figure out how to make malka with your own hands from available materials. And here is what materials we need for these purposes:

- Wooden beam measuring 20 by 30 mm. We will make a block from it.

- Plywood with a thickness of 3 to 5 mm, it will be the moving part of the tool, the pen.

- Fastening element in the form of a nut and bolt.

- Electric drill and drill bit that matches the diameter of the fastener.

Having prepared all the components of the future instrument, you can begin assembling it. First of all, let's start making the pads. We measure 10 centimeters from the wooden block, more is possible, but you should not exceed the length of 15 centimeters. Use a hacksaw to cut the desired size of the future block. The next step in making the tool will be making a slot for the pen. To do this, make a cut on one side of the end base of the block, and for now put the block aside.

Now let's move on to making a feather, which can be cut from plywood or other suitable material. Let us mark on the plywood the future dimensions of the element, the width of the feather is 20-30 mm, the length can reach 300-400 mm. Advice! All dimensions given in this example can be changed at your own discretion. In the process of making a small tool, you can increase the length of the block and feather, the main thing is that it is convenient for you to work with the tool you have made. The feather is ready, and now it can be more accurately adjusted in the block.

Check the cut at the end of the block again; the feather should form an acute angle when you try to fold the tool, although, of course, this is not necessary in all cases. When everything is ready, you need to install the fasteners in place; to do this, align the parts at an angle of 90 degrees and drill a hole through with a drill. Then insert the bolt and clamp the parts together with a nut. Theoretically, our tool is ready, all that remains is to modify the pen a little. Move it in the block, and further process the protruding corners. The excess should be removed and the cut areas treated with sandpaper.

Uprooting of seedlings and weeds from a square for homemade people

Good afternoon My long absence from the channel was not in vain; during this time I managed to do a lot of household chores. And of course, I stocked up on a bunch of homemade products that I will show you, my dear subscribers and guests! There is no point in posting everything at once, because this also takes a lot of time, but if possible I will try to post at least one per day. Not only am I sitting at the computer, I can’t leave my workshop. Messing around in the garden is another hobby of mine; I spent a lot of time there in the summer. Caring for plants and weeding, although a pleasant activity, however, also requires a lot of effort. And how I would like to make a lot easier. Wanting alone is not enough, so you need to make useful things yourself that will make your work easier and make it a pleasure, rather than hard labor with a farmhand.

Today I’ll show you a device that I successfully used almost all spring and summer and will, God willing, last for more than one season. Do-it-yourself uprooter To make it, I took a square with walls 40 by 40 mm, 220 mm long. I didn’t cut this length on purpose; I had a lot of such scraps left over from other construction work.

I drew two oblique lines along the walls to the corner of the square. Having cut it out, it turned out to be such a spear. A pipe with a diameter of 25 mm was welded into the inner part of the angle. From the outside I welded a square right in the middle of the square. Instead of a square, you can weld a square, but it seemed to me that it would be more convenient.

A metal handle was installed in the pipe so that it would not break under load, because the force falls mainly on the handle. When working with a flat cutter, some types of weeds still germinate after a certain time, especially after rains. And having ripped it out by the roots, I eliminated this possibility and my garden became well-groomed and beautiful. Without damaging the root system, they can also remove seedlings for replanting, which is what I did at the beginning of the season with strawberries and other plants.

Source

Malka is a tool that will help you measure the desired angle

If this is your first time encountering a new device, you cannot avoid the question: what is it and how to use it? As already mentioned, this device helps to measure angles, and let's take an angle of forty-five degrees as an example. We take such numbers for a reason, but mean cutting wood at the most popular angle. You can also choose any other value that interests you. Technically, a malka is a tool that can measure an angle from zero to one hundred and eighty degrees. So, let's start taking measurements.

- To begin with, we can find the angle we need already in the finished version and take measurements. You can also use a special device to set the angle to the degree you need.

- Next, fix the result obtained with a fastening bolt, preferably as firmly as possible.

- Afterwards, we apply the resulting angle to the part and draw a line with a pencil.

- Using a wood hacksaw or electric jigsaw, cut the corner according to the markings.

Checked leaf

On a checkered piece of paper you can easily take measurements of the same standard angles as in the previous version.

- Determining 90 degrees will be easiest - you just need to draw a square.

- By drawing a diagonal in the square you can get an angle of 45 degrees.

- To determine 30, 60 degrees you need to draw a rectangle (5 cells in length, 3 in height). Drawing a diagonal in it, we get an angle of 30 and 60 degrees. If we divide an angle of 30 into 2 parts with a line, we get 15 degrees.

The resulting angles must be cut out and compared with the given angle. Usually, after applying the blanks, it is possible to visually determine the approximate indicators.