Equipment that allows cutting sheet metal is required at any machine-building and metalworking enterprise. Very often, the technical capabilities of the most common types of such equipment are not enough to ensure high quality cuts.

Fluid cutting process

Essence of the process

If ordinary water is compressed under a pressure of about 4000 atmospheres and then passed through a hole with a diameter of less than 1 mm, it will flow at a speed 3-4 times higher than the speed of sound. When directed at the workpiece, such a jet of water becomes a cutting tool. With the addition of abrasive particles, its cutting ability increases hundreds of times, and it is capable of cutting almost any material.

Waterjet cutting technology is based on the principle of the erosive (abrasive) effect of an abrasive and a water jet. Their high-speed solid-phase particles act as energy carriers and, hitting the particles of the product, tear off and remove the latter from the cut cavity. The rate of erosion depends on the kinetic energy of the impacting particles, their mass, hardness, shape and angle of impact, as well as on the mechanical properties of the material being processed.

How is cutting done?

In special devices, water pressure is pumped up to levels of several thousand atmospheres. Then, the liquid is fed through an ultra-thin nozzle, which increases the impact force of the jet. Such a thin stream can separate wood, leather, and plastic. This is called water cutting.

In combination with this technology, a longer nozzle is used, which has a mixing chamber inside and an additional inlet for supplying abrasive material. The pressurized liquid plays a secondary role here, acting as a carrier of solid particles. The latter, crashing at high speed into the base material, pierce it through and through, cutting the elements of the product at an angle specified by the nozzle. This is called waterjet cutting. The amount and weight of abrasive depends on the thickness and type of material being processed, and is adjusted individually for each job.

https://www.youtube.com/watch?v=prkxxpKhKsk

Cutting technology

Water, pumped by a pump to ultra-high pressure of the order of 1000–6000 atmospheres, is supplied to the cutting head. Erupting through a narrow nozzle (nozzle) usually with a diameter of 0.08-0.5 mm at near-sonic or supersonic speeds (up to 900-1200 m/s and above), a stream of water enters the mixing chamber, where it begins to mix with abrasive particles - garnet sand , grains of electrocorundum, silicon carbide or other highly hard material. A mixed jet emerges from a mixing (mixing) tube with an internal diameter of 0.5–1.5 mm and cuts the material. In some cutting head models, the abrasive is fed into a mixing tube. To dampen the residual energy of the jet, a layer of water usually 70–100 centimeters thick is used.

Drawing. Waterjet cutting diagram

Drawing. Abrasive particle mixing scheme

When water cutting (without abrasive), the scheme is simplified: water under pressure escapes through the nozzle and is directed towards the product being cut.

Table. Typical applications of water cutting technologies

| Water cutting | Waterjet cutting |

| Leather, textiles, felt (shoe, leather, textile industry) | Sheets of steel, metals |

| Plastics, rubber products (automotive industry) | Various metal parts (castings, gears, etc.) |

| Electronic boards | Alloys of aluminum, titanium, etc., composite materials, thick-walled plastics (aviation and space industries) |

| Laminated materials (aviation and space industry) | Concrete, reinforced concrete, gypsum blocks, hard paving stones and other building materials |

| Thermal insulation, sealing and noise reduction materials | Stone, granite, marble, etc. |

| Food – frozen foods, dense foods, chocolate, baked goods, etc. | Glass, armored glass, ceramics |

| Paper, cardboard | Combined materials, coated materials |

| Tree | Tree |

| Thermo- and duroplast | Reinforced plastics |

In waterjet cutting, the destructive power of the jet is created to a much greater extent by the abrasive, and water primarily performs a transport function. The size of abrasive particles is selected equal to 10–30% of the diameter of the cutting jet to ensure its effective impact and stable flow. Typically the grain size is 0.15–0.25 mm (150–250 µm), and in some cases it is on the order of 0.075–0.1 mm (75–100 µm) if a low roughness cutting surface is required. It is believed that the optimal abrasive size should be less than the value (dс.т. – dв.с.)/2, where dс.т. – internal diameter of the mixing tube, dv.s. – internal diameter of the water nozzle.

Various materials with a Mohs hardness of 6.5 or more are used as abrasives. Their choice depends on the type and hardness of the workpiece, and it should also be taken into account that a harder abrasive wears out the cutting head components faster.

Table. Typical cutting applications for some abrasives

| Name | Typical Applications |

| Garnet sand (consists of corundum Al2O3, quartz sand SiO2, iron oxide Fe2O3 and other components) | Widely used for cutting various materials, especially high-alloy steels and titanium alloys |

| Electrocorundum grains (consists mainly of Al2O3 corundum, as well as impurities) or its varieties | Man-made materials with very high Mohs hardness. Used for cutting steel, aluminum, titanium, reinforced concrete, granite and other materials |

| Silicon carbide (SiC) grains – green or black | |

| Quartz sand (SiO2) | Glass cutting |

| Silicate slag particles | Cutting plastic reinforced with glass or carbon fibers |

Nozzles are usually made of sapphire, ruby or diamond. The service life of sapphire and ruby nozzles is up to 100–200 hours, diamond nozzles – up to 1000–2000 hours. When water cutting, ruby nozzles are not used, and sapphire nozzles usually last 2 times longer.

Mixing tubes are made of ultra-strong alloys. Service life is usually up to 150–200 hours.

How to strengthen a concrete opening

After you have cut out the opening or expanded it, you need to reinforce the walls with additional metal structures.

Strengthening openings can be as follows:

- Single row. To construct this type of fortification, a channel is used. You need to make a U-shaped frame around the opening. In this design, various types of channels are used, and fastening to the walls can be done in various ways. Places where the channel does not adhere to the wall must be filled with mortar.

- Ugolkov. Edging is done with corners on both sides of the wall. To fasten the corners to each other, pins and metal plates are used. These are the most common designs.

- Combined. The openings are strengthened using channels and corners.

Technological parameters

The main technological parameters of the waterjet cutting process are:

- cutting speed;

- type, properties and thickness of the cut product;

- internal diameters of the water nozzle and mixing tube;

- type, size, flow rate and concentration of abrasive particles in the cutting mixture;

- pressure.

Cutting speed (the speed at which the cutting head moves along the surface of the workpiece) significantly affects the quality of the cut. At high speeds, the water-abrasive jet deviates (drifts) from straightness, and the jet weakens noticeably as the material is cut. As a result, the taper of the cut and its roughness increase.

Read also: Connection diagram for a starting capacitor to a 220V electric motor

Drawing. Typical cut shape depending on cutting conditions

Drawing. Jet drift when cutting at a speed higher than optimal

Separation cutting can be performed at 80-100% of maximum speed. High-quality cutting usually corresponds to a speed range of 33–65%, fine cutting – 25–33%, and precision cutting – 10–12.5% of the maximum speed.

Photo. Type of cut surface depending on the speed of water-abrasive cutting

Some cutting head models feature automatic taper compensation technology, such as Flow's Dynamic Waterjet. Taper compensation is achieved as a result of a software-controlled dynamic tilt of the cutting head by a certain degree. This allows you to increase cutting speed while maintaining cut quality and, accordingly, reduce production costs.

As the internal diameter of the mixing tube decreases (other things being equal), cutting productivity and accuracy increase, and the cutting width decreases (it is approximately 10% larger than the internal diameter of the tube). This also reduces the service life of the tube. During operation of the mixing tube, its internal diameter increases by approximately 0.01–0.02 mm for every eight hours of operation.

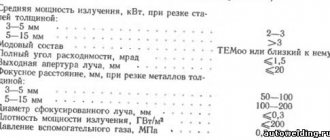

Table. Approximate abrasive sizes for various cutting modes

| Application | Particle size of garnet sand (Garnet) | Int. water nozzle diameter | Int. mixing tube diameter | |||

| mesh (USA) | micron | inches | mm | inches | mm | |

| Standard industrial configuration | 80 | 178 (300–150) | 0,013–0,014″ | 0,330–0,356 | 0,04″ | 1,02 |

| High speed cutting | 60 | 249 (400–200) | 0,014–0,018″ | 0,356–0,457 | 0,05″ | 1,27 |

| 50 | 297 (600–200) | |||||

| Precise cutting | 120 | 125 (200–100) | 0,012–0,013″ | 0,305–0,330 | 0,036″ | 0,91 |

| 80 | 178 (300–150) | |||||

| High precision cutting | 120 | 125 (200–100) | 0,010–0,011″ | 0,254–0,279 | 0,03″ | 0,76 |

The abrasive consumption depends on the diameters of the mixing tube and water nozzle, cutting conditions, etc. The approximate optimal values are given in the table below.

Table. Optimal consumption of abrasive material at certain ratios of the diameters of the mixing tube and nozzle

| Inner diameter of water nozzle (mm) | Mixing tube inner diameter (mm) | Abrasive consumption (g/min) |

| 0,25 | 0,76 | 270–360 |

| 0,36 | 1,02 | 500–640 |

| 0,46 | 1,27 | 800–1100 |

The maximum operating pressure is usually 3000–3200, 3800, 4150 or 6000 bar. The higher the pressure, the higher the cutting speed and efficiency. At the same time, more frequent replacement of gaskets in the pump is required.

Table. Dependence of straight separation (roughing) cutting speed on material thickness at pump pressure P = 4100 bar (approximately 4046 atm)

| Type of material | Cutting speed (m/h) * at thickness | ||||

| 5 mm | 10 mm | 20 mm | 50 mm | 100 mm | |

| Stainless steel | 52,62 | 28,56 | 13,02 | 3,84 | 1,44 |

| Titanium | 68,46 | 37,20 | 16,98 | 4,98 | 1,86 |

| Aluminum | 142,20 | 77,40 | 35,40 | 10,20 | 3,72 |

| Granite | 251,40 | 137,10 | 62,76 | 18,00 | 6,60 |

| Marble | 295,20 | 160,80 | 73,50 | 21,24 | 7,80 |

| Carbon fiber | 247,20 | 134,70 | 61,74 | 17,70 | 6,60 |

| Glass | 272,76 | 148,62 | 67,92 | 19,62 | 7,26 |

| * : pressure – 4100 bar; abrasive brand – Kerfjet #80; abrasive consumption – 250–450 g/min; internal diameter of the nozzle – 0.25 mm, 0.35 mm; internal diameter of the mixing tube - 0.76 mm, 1.01 mm / data from TechnoAllianceGroup LLC, Moscow, BarsJet GAR installations | |||||

Table. Dependence of the speed of straight dividing (roughing) cutting on the thickness of the material at pump pressure P = 6000 bar (about 5922 atm)

| Type of material | Cutting speed (m/h) * at thickness | ||||

| 5 mm | 10 mm | 20 mm | 50 mm | 100 mm | |

| Stainless steel | 86,64 | 47,16 | 21,48 | 6,12 | 2,40 |

| Titanium | 112,38 | 61,50 | 28,08 | 8,22 | 3,06 |

| Aluminum | 233,76 | 127,44 | 58,44 | 16,92 | 6,24 |

| Granite | 413,46 | 225,42 | 103,08 | 29,70 | 10,92 |

| Marble | 485,28 | 264,60 | 121,02 | 34,80 | 12,84 |

| Carbon fiber | 406,56 | 221,88 | 101,40 | 29,22 | 10,86 |

| Glass | 448,14 | 244,38 | 111,72 | 32,16 | 11,88 |

| * : pressure – 6000 bar; abrasive brand – Kerfjet #80; abrasive consumption – 250–450 g/min; internal diameter of the nozzle – 0.25 mm; internal diameter of the mixing tube - 0.76 mm, 1.01 mm / data from TechnoAllianceGroup LLC, Moscow, BarsJet GAR installations | |||||

Photo. Parts obtained by waterjet cutting: made of stainless steel 15 mm thick; made of aluminum alloy 6 mm thick; made of aluminum 30 mm thick; made of fibre-reinforced plastic, 20 mm thick; made of tool steel 60 mm thick

Story

WAZER began as a Kickstarter project with the help of several Penn State alumni.

It didn’t take long for recognition: the device is considered one of the most promising and was awarded, for example, the Make Magazine 2019 Editor’s Choice award.

Advantages, disadvantages and comparative characteristics

Using a water-abrasive or water jet, you can cut almost any material. In this case, neither mechanical deformation of the workpiece occurs (since the force of the jet is only 1–100 N), nor its thermal deformation, since the temperature in the cutting zone is about 60–90°C. Thus, compared to heat treatment technologies (oxygen, plasma, laser, etc.), waterjet cutting has the following distinctive advantages:

- higher quality of cut due to minimal thermal effect on the workpiece (no melting, melting or burning of edges);

- the ability to cut heat-sensitive materials (a number of fire and explosive materials, laminated, composite, etc.);

- environmentally friendly process, complete absence of harmful gas emissions;

- explosion and fire safety of the process.

The water-abrasive jet is capable of cutting materials up to 300 mm thick and more. Waterjet cutting can be performed along a complex contour with high accuracy (up to 0.025–0.1 mm), including for processing volumetric products. You can use it to make bevels. It is effective on aluminum alloys, copper and brass, due to their high thermal conductivity, thermal cutting methods require more powerful heating sources. Additionally, these metals are more difficult to cut with lasers due to their low ability to absorb laser light.

Read also: What is a cork gauge

The disadvantages of water-abrasive cutting include:

- significantly lower cutting speed of thin steel compared to plasma and laser cutting;

- high cost of equipment and high operating costs (typical for laser cutting) due to the consumption of abrasive, electricity, water, replacement of mixing tubes, water nozzles and seals that can withstand high pressure, as well as waste disposal costs;

- increased noise due to the flow of a jet at supersonic speed (typical for plasma cutting).

Table. Comparison of waterjet cutting with oxygen, plasma and laser cutting

Water cutting is a unique method for processing various materials. Today, there are 2 types of water cutting: using clean water and using a water jet with abrasive (water jet method). But the principle of operation in both cases is the same - liquid under very high pressure passes through a miniature hole in the cutting head, which is located above the material being processed. In this case, the waterjet mixture coming out of the cutting head has a speed exceeding the speed of sound three times.

The size of the head hole, as well as its diameter, depend on the density of the material. If the material is easily permeable, then heads with a diameter of 0.08 mm are taken; in the case of harder materials, the hole diameter can reach 0.8 mm.

As for the pressure of the multiplier itself, the maximum indicator is 420 MPa. According to practical research, the most productive and at the same time fastest cut is obtained at a pressure of 380 MPa. If the pressure is higher, then this only leads to more frequent intervals between replacement parts.

To ensure proper operation of the equipment, gaskets should be replaced promptly. Thus, with a regular constant operating pressure of 400 MPa, the gaskets are replaced after 400 – 1200 cutting hours.

Thanks to such conditions in which workpieces are processed, waterjet cutting becomes an alternative method of influencing materials in relation to thermal methods, and even outperforms the latter in some respects. Only cutting using a water jet with an abrasive leaves no traces of deformation on the metal, no traces of melting on plastic, fabric and other materials. Industrial and design work today is simply unthinkable without this method, because the most complex elements with excellent edge quality can be made from any blanks of varying thickness.

The use of rock destruction technology for extracting minerals under the influence of a water jet has been known since the 30s of the last century, but the industrial use of a high-pressure water jet for cutting various materials began only in the 80s of the same century. Today, waterjet cutting of metal is the most popular type of application of this technology in industrial production.

Scope of use

The main difference that water cutting of metal has from other processing methods is that there is no mechanical effect on the surface of the material. The absence of heat and friction of tools affects the possible areas of use and the quality of the cut.

The equipment is used for cutting materials such as:

- ceramics, glass;

- stone, granite, marble;

- rubber, paronite, ebonite and textolite plates, plastic;

- reinforced concrete;

- metals, including: steel, titanium.

What is waterjet cutting

Waterjet cutting is a process of abrasive action of a jet of hydraulic fluid with the addition of particularly hard particles on the material being processed to cut it to specified dimensions. From a mechanical point of view, this is the process of separation and entrainment of material by abrasive particles, which are fed at high speed in a stream of water under high pressure. Based on its physical properties, a thin stream of a mixture of water and abrasive at high speed is an ideal cutting tool.

The technology of using water flow and abrasive for cutting almost any materials is ensured by selecting the necessary conditions and parameters, such as:

- jet pressure,

- water consumption,

- the amount of abrasive in the jet,

- sizes of abrasive particles.

The technological capabilities of waterjet cutting are limited only by the thickness of the workpiece being processed and the physical properties of the substance from which it is made. What she can do is clearly shown in this video.

Where is water jet cutting used?

The technique has found active application in enterprises of various types. Waterjet cutting is used when working with ferrous and non-ferrous metals, alloy steels, composite materials, etc.

Main features of the method:

- Getting an accurate cut. The waterjet method is also used when edge warping is not acceptable (for example, in the production of machine parts). The edge roughness is less than Ra 1.25, which is several times less than other popular methods.

- Cutting thick parts. Using this cutting, you can cut elements up to 250-300 mm. It is difficult to do this in other ways, since the cut may melt. Thanks to the small jet diameter, material losses are minimal, and the high pressure avoids residual effects in the separation zone.

- Processing of dielectric materials. The technique is suitable for products made of non-ferrous metals and copper-based alloys. The electrical conductivity parameters of materials do not allow the use of lasers, so cutting with water and sand is the only suitable solution.

Waterjet cutting has become especially popular in the following industries:

- Building sector. Cutting with water and abrasives is indispensable in the production of finishing and decorative materials. Most often, the method is used for cutting marble, ceramics, stone and granite.

- Mechanical engineering. In this field, waterjet and waterjet cutting are typically used to produce sheet metal parts. The cut elements do not require mechanical processing, which saves time and reduces production time. In addition, high quality and precision cutting is ensured.

- Electrical industry. The machines have found their application in the production of printed circuit boards, mica, housings, cellulose, etc. Using this technique, it is possible to make small cuts without dust or uneven edges.

- Tool production. The use of waterjet cutting technology makes it possible to cut the hardest alloys (including tool steels and tungsten carbide). This process is indispensable for making tools.

- Aviation and aerospace industry. The technique is used for cutting heat-resistant alloys and titanium, which are used for the production of aircraft, helicopters and rocket engines.

Application area

Waterjet cutting is capable of working with all materials and structures that exist, with the exception of diamonds and tempered glass. One of the features of waterjet technology is the possibility of its use for processing materials capable of changing their physical and chemical properties when exposed to high temperatures and strong heating, as well as for structures with flammable and explosive substances.

The area of industrial use of these features was abrasive cutting of various metals with water under pressure, mainly such as:

- stainless steel,

- tool alloys,

- titanium,

- brass,

- aluminum.

It is also used to make artistic products from natural and artificial stone and use it in processing:

Water cutting is indispensable for:

- insulating,

- fireproof,

- multilayer,

- and other composite materials with special properties.

Types of GAR installations

- Industrial controlled CNC machine. It is used for processing materials on an industrial scale and is installed in factories.

- Tabletop CNC machine. Suitable for high-quality cutting of small materials and creating small parts.

- Portable machine. Such equipment is used in the gas and oil industries, as well as for handling hazardous cargo. Suitable for industries where installation of a stationary device is not possible.

Advantages and disadvantages

Today, there are four main industrial methods for cutting metals. If we arrange them according to the amount of equipment used and demand in production, we get the following sequence of methods, namely:

- mechanical,

- plasma,

- waterjet,

- laser

All of them differ significantly from each other in quality characteristics, while each has its own characteristics, advantages and disadvantages.

The main advantages of the waterjet processing method are:

- ability to work with any materials,

- no thermal effect on the workpiece,

- eliminating the release of dust, smoke and toxic fumes,

- Possibility to use for materials with explosive and fire hazardous properties.

But despite the undeniable advantages, there are significant disadvantages:

- high cost of replacing wear parts of equipment;

- more significant energy consumption compared to other cutting methods,

- requires constant adjustment and adjustment of equipment to meet the declared characteristics.

Read also: Lathe 1p611 for sale

How wall thickness affects concrete cutting

The size of the wall thickness is the main indicator by which it is determined which cutting method to use.

- The grinder can cope with a slot depth not exceeding 10 cm.

- With a concrete slab thickness of 8-10 cm, a machine with increased power is required for operation.

- When the thickness of the concrete slab is 15-16 cm, a circular saw is used, the diameter of the discs should be 350-400 mm. If you use a grinder, the work will have to be carried out in several stages, and the tool may overheat and break.

- If the concrete is 30 cm thick or more, use a special wall cutting tool - manual or machine.

- Concrete, the thickness of which reaches 60 mm, is cut using a tool such as a chain saw, a ring cutter.

- A concrete slab whose thickness exceeds 60 cm is cut with special equipment. A disc with a diameter of 100 mm or more is used. Rope cutting devices can also be used.

Industrial Application

The most widely used technology in industrial production and precision engineering is waterjet technology for cutting metal with water. Only it neutralizes the main characteristic consequences that arise when processed by other methods. So, for example:

- waterjet cutting of stainless steel makes it possible to take into account the features that arise when processing workpieces made of metal alloys, such as strength due to alloying additives and high viscosity under mechanical or temperature influences, leading to deformation of finished products;

- waterjet cutting of titanium makes it possible not to reach the critical temperature of 600 ° C, at which titanium is capable of burning in the open air and chemically combining with other substances;

- Waterjet cutting of aluminum reduces the loss of forging material to a minimum, despite the fact that the metal is relatively weak and has a low melting point of only 440 °C.

This treatment makes it possible to use a water cutter for metal with proper efficiency, providing the future product with good quality indicators:

- small seam width - only 0.7-1.4 mm,

- positioning accuracy up to 0.1 mm,

- with a workpiece thickness of even 300 mm,

- obtain a flawless cut edge that does not require additional processing.

The ability to start and carry out cutting in any direction allows you to minimize the overall loss of material when cutting metal blanks.

Advantages of a water jet machine

Now this is one of the most effective and popular methods, due to its advantages:

- this is the “coldest” method of metalworking, which allows you to work even with substances whose physical and chemical properties change due to heat;

- low material loss - there are virtually no chips, the cut is smooth and narrow;

- good for thin sheets, but it is also possible with denser ones - up to 3 cm;

- there is no need for final sanding, the edges are very smooth;

- highest accuracy – 0.5 mm;

- you can cut out any difficult parts;

- it is possible to cut in a “package”, that is, in several layers at once, if the workpieces are thin enough;

- very high cleanliness of work - no dust, noise, gases;

- fire safety is complete;

- the absence of a sharp cutting tool, that is, it does not need to be changed or sharpened.

Construction of waterjet cutting equipment

The range of production of waterjet cutting machines starts from small ones, representing conventional CNC metalworking machines and compact ones with a table design for processing sheet material with dimensions of 2 by 4 meters, to huge lines capable of working like rolling mills.

But according to the design principle, any machine for cutting metal with water has:

- body in the form of a water bath, which serves as a trap for the water jet, absorbing its energy,

- a system of settling tanks and filters necessary for water purification, as well as for sedimentation of spent abrasive particles,

- coordinate table with servomotors for moving the cutting head,

- high pressure pump unit with pipelines,

- operator control panel based on an industrial computer.

Modern CNC machines and drives for moving the cutting head allow processing of material using 2D, 2.5D and 3D technology, that is, with high precision, artistic cutting in several planes and processing the edge at any angle. The possibilities of making 3D parts using waterjet cutting are clearly shown in the video.

Possibilities of water-based metal cutting

Many methods are used only for direct sawing, while water cutting allows:

- make a curly cut;

- do not process edges;

- process sheets (metal blanks) up to 120 – 200 mm thick, depending on the type of steel;

- connect a difficult project to an automatic control panel and actually not participate in the process, only control it;

- cut circles, pipes.

Nowadays the technology is actively used in various fields:

- automotive and mechanical engineering in general;

- production of blanks and parts that cannot be stamped;

- water cutting of iron, insulation, fiberglass, insulators, marble;

- artistic processing.

Cutting tool

The main part of all waterjet machines is the cutting head. The principle of its operation is seemingly very simple, but technologically very complex. Thus, ultra-high water pressure is created by a plunger or piston pump, which delivers it through high-pressure pipelines to the cutting head. Here the water enters the chamber, where strictly dosed mixing with abrasive particles occurs. Next, the mixture of water and abrasive enters a calibrated nozzle (nozzle), which creates a cutting jet. The jet emerging from the nozzle reaches a speed approximately three times higher than the speed of sound.

The dimensions of the diameter of the nozzle and mixing chamber are determined based on the performance of the working pumping station and the material of the abrasive particles. Basically, garnet sand, also called almandine, is used for abrasive. It has a crystalline structure with extreme hardness and a heavy density of 4.1 - 4.3 g/cm, which allows it to provide high abrasive ability. It is well distributed in nature; its largest deposits are located in the southeast of India and Australia.

Water cutting equipment

They call it “dusty-free.” Indeed, there are virtually no chips, or rather, they are immediately washed away, resulting in a very even and clean cut, which, in most cases, does not even require grinding. The technological process is based on a natural phenomenon of water bodies - erosion, that is, the ability to erode the banks, while grinding away stones and tree roots. The essence remains the same, but in order to speed up the effect many times over, an abrasive is added to the liquid.

This mixture is released with a very high pressure jet. The pressure reaches 6 thousand atmospheres, and a speed develops that is three times higher than the propagation of a sound wave in the air - 800-1000 meters per second. Two main tasks of the equipment:

- separation and washing out of particles of workpiece material;

- instant cooling and cleansing.

The device of a machine that cuts with water

The classic device has many components:

- body - usually consists of metal, as the most wear-resistant and durable material, due to which it is quite massive;

- capacity – large, usually at least two cubic liters, but can be more;

- powerful pump - it performs an important function, pumps up high pressure and directs liquid from the reservoir to the junction of the two components;

- durable hoses - connect all components;

- compartment for storing and supplying abrasive particles;

- mixer;

- tool - it regulates the power of the jet, its width, direction;

- the plane on which the workpiece is located and the work will take place;

- Control block.

Most machines are equipped with CNC; the engineer only controls the process using a remote control, but does not do cutting manually. This is convenient - there is no negative impact on the person operating the machine and at the same time excellent accuracy is achieved. Another advantage of CNC is the ability to use computer-aided design programs, which can be used to create a project in a format compatible with the control unit.

Features of the main components

The uniqueness of the installation lies in many differences, starting with the desktop. Instead of the usual plane, a bathtub with shallow sides is presented here. It is equipped with ribs for gripping and fixing the workpiece; they can be quickly removed and applied. Also, the container is filled with liquid and then drained. The constant presence of metal in an aquatic environment makes it possible to eliminate noise and dust from production. The container, which contains abrasive particles, is easily removed, has a replenishment function even during operation, and is also equipped with sensors that control the amount of mixture.

The tool movement system is very important. It is mounted on belts that move the cutter along linear planes. Straps are used rather than chains, as they are more resistant to moisture, as well as to accidental ingress of abrasives. An additional advantage is that they are easy to replace when worn. Let's look at the video for more details about the device:

Consumables

The main consumable parts of waterjet cutting equipment are nozzles and focusing tubes, which are made from artificial diamonds, sapphires, rubies and corundum crystals.

Thus, the operating time of a focusing tube made of sapphire crystal does not exceed 60 hours. The same tube, made of the highest quality diamonds, lasts much longer, but at the same time costs 20 times more. Artificial ceramic carbide nozzles will last up to 120 hours, which is approximately 20% longer than the same parts made from other materials.

The average operating time of consumables and components is shown in the table:

These figures correspond to the operation of a waterjet machine with an average pressure of 400 MPa. When applying a cutting jet pressure of 600 MPa, the processing speed increases by 20-30%, and wear of the main consumables occurs twice as fast.

Tools for cutting concrete openings

Drilling is used to make technological holes, sockets, and furrows. If it is necessary to make openings in concrete walls or expand existing openings, diamond cutting elements, which are fixed in various tools, are often used.

If the thickness of the concrete slab is small, an angle grinder, popularly called a “grinder”, with wheels with a diameter of 105 to 125 mm is used for cutting.

Cutting concrete using a grinder.

Spraying water while working will reduce dust and at the same time help preserve the disc. If a situation arises in which contact with water is dangerous, you need to perform dry cutting.

However, even with dry cutting, in order to cool the segments, it is necessary to remove the disk from the cutting area at certain intervals so that the machine runs “idle” for 10-50 seconds.

To cut an opening in a concrete slab, the depth of which exceeds 10 cm, professional circular saws are used, which are hydraulic and electric cutters. This tool quickly cuts through concrete up to 15 cm deep on one side.

They work with disks with a diameter of 350-500 mm. When cutting openings in concrete, it is necessary to wear a respirator, since if concrete dust enters a person’s lungs, serious illnesses can develop. In addition, hands should be protected with gloves, and eyes with special glasses.

With your own hands

The use of waterjet cutting equipment in a home workshop is quite possible. For example: in the implementation of original works for artistic or decorative processing of small and medium-sized workpieces. But you can make such a machine with your own hands only for cutting wood, plastic, laminate or other not very durable materials.

It should be taken into account that the cost of equipment, plus the periodic replacement of consumables and the constant need for abrasive, makes the direct cost of one working hour of waterjet cutting at least 1,400 rubles. But this is a separate topic, and if you have your own experience in using a waterjet cutter at home, share it with others in the comments block.

Scissors, but not tailor's ones

As a rule, scissors in everyday perception are necessarily associated with cutting fabric, paper, leather and other materials that are not particularly durable. What do you think of the option called hydraulic shears for reinforced concrete? Believe me, there are such people.

With all its aggressive appearance and undisguised power, hydraulic shears are very reminiscent of a fossil lizard - a tyrannosaurus

Crusher and cruncher: brothers, but not twins

Hydraulic shears are one of the many tools that are equipped with excavators, usually crawler ones. The working mechanism is made in the form of a pair of cheeks made of high-alloy tool steel, which move according to a given algorithm using hydraulic cylinder rods powered by a standard high-pressure hydraulic system.

Hydraulic shears from serious manufacturers are mounted on a rotator head, which allows the working body to rotate around its axis.

A hydraulic rotator is an extremely useful thing that allows the scissors not only to rotate relative to the axis, but also to rotate around it

Hydraulic shears are a quick-release mechanism, and modern models are designed and made in such a way that they can be installed and removed by one person - the excavator operator, and he directly connects only the hydraulic system connectors with his own hands.

The operator's instructions are designed in such a way that they repeat the working algorithms for the movement of the boom and bucket of an excavator during basic and most common work and therefore can be easily mastered by even low-skilled excavator operators, who make up the bulk of the domestic labor market.

Protecting the cabin of an excavator equipped with hydraulic shears is absolutely necessary to protect not only the glazing, but also the operator himself from fragments of destructible concrete

The cost of such systems is high, primarily because effective mechanisms are manufactured exclusively by American, European and Japanese manufacturers. Chinese and domestic developments are extremely ineffective and short-lived, and, in essence, are low-quality copies of well-established brands.

For rough destruction of reinforced concrete structures, a crusher is used - its working body has more massive and larger teeth and larger gripping cavities.

The Swedes have released an excavator designed specifically for dismantling large structures, equipped not only with an extra-long boom, but also with a lifting cabin

A cruncher is used to crush dismantled concrete fragments. After processing pieces of concrete with its jaws, the resulting mass can be used as crushed concrete when organizing cushions, arranging temporary roads, filling sites and other activities.

The secondary crushed stone obtained in this way has a fraction of 40-70 mm convenient for clinching crushed stone cushions

You can learn more about the basics of waterjet cutting of concrete and examples of dismantling concrete structures using a hydraulic wedge and hydraulic shears by watching the video in this article.

Device classification

Waterjet machines are often divided into manual machines and computer numerical control (CNC) machines.

The design of abrasive metal cutting machines significantly affects their technical characteristics and production capacity.

Manual devices

Non-CNC machines are fully controlled by the operator, who sets all the parameters for future processing of parts. In addition, the operator will have to carry out certain stages of working with workpieces independently. But such devices also have a number of advantages:

- Relatively low price.

- Same quality of waterjet cutting of titanium, aluminum and other materials.

- Easy to care for and manage, which does not require the operator to have extensive knowledge and experience in the field of metalworking.

- A sufficient number of functions that allow you to create simple parts with correct geometric shapes.

CNC machines

Numerical software installed on waterjet machines significantly improves their functionality and production efficiency. CNC machines allow you to process all types of metal workpieces with high quality and do it with high precision. Automated devices have the following advantages:

- The software allows you to create holes of the required diameter in workpieces.

- After completing all established operations, the part does not require additional processing.

- The software allows you to select an individual processing mode for each workpiece. The device itself will select the necessary jet parameters and other parameters.

- CNC machines can control the quality of the cut and independently change it in accordance with the established program and sequence of machine actions.

At the same time, such a device also has a number of significant disadvantages. Firstly, the cost of a CNC waterjet machine is significantly higher than the price of its manual counterpart. Secondly, in order to correctly set the parameters of the work being performed, the operator must have certain knowledge in the field of metalworking and experience in creating parts on automated machines.

Operating principle and materials to be cut

Cutting metal products occurs with a water jet to which abrasive is added, after which it passes through a nozzle. Pressure of 200-600 atmospheres allows you to cut many materials. Work can be carried out at any angle; to do this, you just need to change the angle of the nozzle. In this case, you can effectively cut:

- metals (ferrous and non-ferrous) and their alloys;

- stone products from marble and granite;

- steel (stainless steel, heat-resistant, alloy);

- armored, ordinary and composite glass;

- ceramic products (concrete, tiles, ceramics, ceramic granite);

- composite;

- rubber;

- plastic;

- cardboard.

Cutting of particularly hard raw materials is carried out with water and special sand made from minerals. Soft materials (rubber, plastic, cardboard) are cut exclusively with water without any impurities.