Cutting metal with mechanical shears is a labor-intensive and time-consuming process.

Manual electric scissors significantly increase productivity and reduce labor intensity, ensure safety, convenience, accuracy and quality of work performed .

What to look for when choosing electric metal shears and which models are the best today, we will look at in this review.

Page navigation:

Design features

In appearance, electric scissors are similar to a regular grinder.

The design of electric scissors includes the following elements:

- Housing with an electric motor inside . It has an elongated shape, thanks to which it fits well in the palm. On models with a heavy, powerful motor, an additional handle is placed on the body for convenience. Regardless of the type and cost of the tool, the body is always made of impact-resistant plastic.

- Multi-stage gearbox . Responsible for transforming the rotational movement of the motor into the reciprocating movement of the cutting head. Made of metal.

- Work node . Contains the knives or die and punch needed to cut metal.

- Metal shield . Protects the operator's hand from contact with the sharp edge of the workpiece.

- Electrical cord for supplying power to the instrument.

The way of working with electric scissors is no different from working with conventional ones. The operator smoothly guides the cutting head along the intended cutting line from the starting point to the ending point. The main rule of work: the speed of hand movement must correspond to the speed of cutting metal.

Expert opinion

Kulikov Vladimir Sergeevich

The accuracy and precision of cutting on any electric scissors depends solely on the experience and skill of the operator.

Advantages of electric metal shears

Power tools provide the tinsmith with several advantages:

- Saving physical effort - no effort is required to cut metal, the process is automated.

- Possibility of cutting thick workpieces (up to 5 mm), as well as composite and polymer materials.

- High labor productivity – up to 3-5 meters per minute.

- Ease of working with profiled sheets - corrugated sheets, metal tiles, as well as ventilation ducts.

- Cut according to a template, radial cut, arbitrary cutting configuration.

- Minimal risk of injury.

The best metal scissors

Household and industrial metal scissors of all main varieties.

1

Stalex PBS-7

Universal tool

Multifunctional mechanical shears are suitable for processing sheets, corners, profiles, T-beams, etc. A good choice for installation in small production.

Find out the price

Reasons to buy:

- robust design;

- fastening to the base;

- fast cut;

- long service life;

- high quality sharpening.

A long handle with a soft grip and a gear transmission mechanism contribute to the comfortable use of the model, allowing you to apply less effort when working with metal. The special design of the main elements makes it possible to cut various parts.

The dimensions of the device are 970x370x700 millimeters, weight - 98 kilograms. The clamp height can be adjusted if necessary. The case is made of steel and is resistant to impacts and scratches. The presence of holes for fasteners ensures reliable fixation of the tool on the base.

READ ALSO

12 best pipe cutters

2

Bosch GSC 2.8 0.601.506.108

High performance

Electric scissors are recommended for intensive use, especially if the job requires careful cutting.

Find out the price

Reasons to buy:

- compactness;

- rotary knife;

- ease of holding;

- operational safety;

- rich equipment.

The model has a narrow body and a mushroom-shaped front handle, which contributes to a confident grip and ease of use of the tool from any position. A large safety slide switch makes the device easy to operate.

The motor power is 500 W. Other features include the ability to adjust the processing depth using a special screw. The rotating design of the knife allows you to cut at an angle, and the planetary gear mechanism does not interfere with the view of the surface.

3

Milwaukee M18 BMS20-0

Cordless scissors

The model is good for sheet metal processing. With these scissors you can accurately make both straight and curved cuts.

Find out the price

Reasons to buy:

- flexible setup;

- durability;

- compactness;

- self-discharge protection.

The model has a rubberized handle, which ensures a secure grip and ease of use. The small size and weight make the scissors easy to store and carry, and also reduce the likelihood of fatigue. The speed is easily adjusted with a special button.

The battery voltage is 18 V. The thickness of the metal available for processing is 3.2 millimeters. The keyless head of the tool can be rotated up to 360 degrees, which guarantees comfortable cutting in any position. To protect against overloads and extend battery life, the Redlink system is provided.

4

Encore Corvette 551

For sheet metal

Professional guillotine shears are designed for cutting sheet metal and are quite capable of withstanding intensive use over a long shift.

Find out the price

Reasons to buy:

- high strength;

- Ease of use;

- ergonomic handle;

- fastening to the surface;

- long knife.

The model has a manual drive, ensuring ease of use in any conditions. It does not require precise adjustment and has an extremely simple design, which allows you to start working with scissors immediately after purchase. Wide supports ensure the stability of the tool on the surface.

The length of the cutting element is 1000 millimeters, the permissible sheet thickness is 1.5 mm. If necessary, you can fix the housing to the base using standard fasteners. The use of a metal channel ensures the rigidity and durability of the scissors.

5

Stubai metal scissors 267701

Compact and lightweight

Surprisingly multifunctional scissors (as for hand tools) are suitable for radius, curved and round cuts, ensuring accurate processing of workpieces.

Find out the price

Reasons to buy:

- ease of holding;

- robust design;

- hardened blades;

- protective covering.

The curved design of the edges of the model allows for more accurate processing of non-standard shaped parts. The material of manufacture is carbon steel of increased hardness. A special coating is provided to protect against corrosion.

The weight of the scissors is 440 grams, length - 250 millimeters. Ergonomic handles with a non-slip surface provide additional comfort for the operator while working. Induction hardening of the blades guarantees resistance to high mechanical loads.

READ ALSO

10 Best Bolt Cutters

6

Kraftool Profi 2325-L

Reinforced hand scissors

They are used for both straight and shaped processing of sheet metal. A reliable solution for occasional use. The model is available in right- and left-hand orientation.

Find out the price

Reasons to buy:

- hardened blades;

- reliable grip;

- neat cut;

- light weight.

These scissors are made using tool and chrome-molybdenum steels. Therefore, they are characterized by high strength and resistance to deformation.

For additional reliability, the blades are induction hardened - their hardness is about 65 HRC. Notches on the edges prevent material jamming.

The length of the hand tool is 260 millimeters and weighs 580 grams. The double-lever hinge design improves cutting performance and makes the scissors easier to use. The two-component handles are resistant to sharp impacts and are covered with anti-slip material.

7

Hammer 601-013

Inexpensive straight scissors

This tool can be used for cutting steel sheets, wire, etc. An excellent solution for a home workshop.

Find out the price

Reasons to buy:

- reinforced design;

- smooth cut;

- comfortable grip;

- long service life;

- ease of storage.

The blades of the model are made of chrome vanadium steel, they are highly durable and resistant to high mechanical loads. For convenience and safety of storing scissors, a lock is provided.

The rubberized handles are ergonomically shaped for a comfortable and secure grip. The weight of the instrument is 400 grams, length - 250 millimeters.

Other features of the device include a special sharpening for a smooth cut without burrs. The instrument does not require complex maintenance and maintains quality for a long time.

Varieties

Based on the principle of the cutting mechanism, the following types of electric scissors are distinguished:

Leafy

The working unit of sheet metal shears is designed by analogy with the working unit of household shears: two knives, one of which is rigidly fixed to a support, and the other has free movement. The product falls into the gap and breaks under the pressure of the upper knife. The size of the gap can be adjusted by adjusting the scissors to work with workpieces of different thicknesses. Ideal for rough cutting of a dimensional product at its location (for example, for dismantling metal structures).

| pros | Minuses |

| No waste. | Crinkle the edge of the sheet. |

| High speed. | The cut can only be made from the edge of the workpiece. |

| Cutting products up to 5 mm thick. | |

| Durability of the working unit (if the cutting edge becomes dull, the upper and lower knives can be swapped and work continued). | Inconvenient for curved cuts. |

| Can be used as side cutters for cutting wire or nails. |

Splined

Just like sheet ones, they have two knives:

The top one is static, U-shaped with two chamfers.

The lower one is movable, fitting into the groove of the upper one.

As the lower knife moves, a strip 3-5 mm wide is extruded from the metal blank. In this case, the cut edge is perfectly smooth, without burrs. Slotted shears are most popular among ventilation workers, who use them for cutting pipes and ducts.

| pros | Minuses |

| Ability to cut sheets from anywhere. | The maximum thickness of the metal to be cut is 2 mm. |

| High quality cut. | |

| No sheet deformation. | The lower knife quickly fails. |

| Convenience when working with workpieces of complex configurations. | Maximum turning radius. |

Nibblers

Nibblers are similar in principle to a punching press, which is why they are also often called nibblers.

The main elements of their cutting head are:

- Matrix . A static part in the shape of a circle or square (a circle is used for thin-sheet workpieces up to 3 mm thick, a square for thicker ones).

- Punch . A movable punch made in the shape of a matrix. When the motor starts, the punch performs a back-and-forth motion, cutting out a continuous chain of holes in the workpiece, forming a cut line.

Nibblers are indispensable in car repair, roofing and ventilation work. They are perfect for cutting profile workpieces and making radial cuts.

| pros | Minuses |

| Perform cuts of any geometry. | Conventionally straight cut (difficult to maintain an even line). |

| Minimum turning radius. | |

| Lightness and mobility of the tool. | |

| Punch through a workpiece of maximum thickness. | |

| Possibility of cutting into the sheet from any point (from a pre-drilled hole). | A large amount of waste in the form of sharp shavings. |

| Good visibility of the working area. |

The best electric sheet shears

Electric sheet shears guarantee speed and reliability.

The tool provides perfect straight line cutting accuracy and ease of use.

CALIBER ENN-700/3.2M

Corded sheet metal shears CALIBR ENN-700/3.2M are a high-quality tool designed for straight and shaped cutting of sheet metal with a maximum thickness of 3.2 mm in domestic conditions.

The device provides an external minimum cutting radius of 50 mm.

The equipment is equipped with a 700 W electric motor, an ergonomic body with a convenient handle-holder for equipment, and a replaceable knife block with a special sharpening shape.

The device meets key safety requirements and is equipped with an instruction manual and a hex key.

Specifications:

- power supply - network, 220 V;

- power consumption - 0.7 kW;

- speed - 2000 strokes per minute;

- maximum cutting thickness - 3.2 mm;

- equipment weight - 3.6 kg.

Advantages

- ergonomic handle holder;

- convenient change of knives;

- high performance;

- good cutting thickness.

Flaws

- physical effort is required when cutting;

- impressive dimensions and weight;

- poor equipment.

BISON ZNL-500

Sheet network electric shears BISON ZNL-500 with four cutting edges on each knife will provide simple and shaped cutting of metal up to 2.5 mm thick.

When one edge becomes dull, the cutting element can be rotated and work continued using a sharp blade.

The model is equipped with a special canopy to protect the operator during operation, a ventilation system for engine cooling, and a convenient slide control switch.

The narrow body of the tool provides better grip.

To perform a more precise cut, the user can adjust the operating speed.

The minimum cutting radius is 40 mm. The device comes in an ergonomic, compact case.

Specifications:

- power supply - network, 220 V;

- power consumption - 0.5 kW;

- speed - 1800 strokes per minute;

- maximum cutting thickness - 2.5 mm;

- equipment weight - 2.5 kg.

Advantages

- equipment reliability;

- presence of a convenient case included;

- operating speed adjustment;

- soft and durable power cable.

Flaws

- difficult to find spare knives;

- large size and weight;

- low maximum speed.

Makita JS3201J

Makita JS3201J corded sheet shears, supplied in a stylish and convenient case, are a professional-class tool equipped with advanced equipment.

This is, first of all, a powerful and productive electric motor, control system, and ergonomic handle.

The device features a modern design.

The unit allows cutting aluminum up to 4 mm thick, steel – up to 3.2 mm.

The device is connected to the network with a 2.5-meter cable.

The electric scissors are equipped with an ultra-compact Mak Pac case, a hex wrench, and a set of knives and probes.

Specifications:

- power supply - network, 220 V;

- power consumption - 0.71 kW;

- speed - 1600 strokes per minute;

- maximum cutting thickness - 4 mm;

- equipment weight - 3.4 kg.

Advantages

- Ease of use;

- high-quality sharpening of knives;

- ergonomic case included;

- high power.

Flaws

- inflated price tag for spare parts;

- impressive weight of the device;

- low maximum speed.

Makita DJN161Z

Makita DJN161Z cordless sheet metal shears will become an indispensable assistant when working with steel, iron and non-ferrous metals in places where there is no possibility of connecting to an electrical outlet.

The tool provides cutting of sheet aluminum or copper up to 2.5 mm thick, steel - up to 1.6 mm.

The device is equipped with an indicator for monitoring the battery status during operation, and a start button with a locked pressed position.

The outer minimum cutting radius is 50 mm, the inner one is 45 mm.

The device is equipped with a punch, keys, and a matrix with a holder. The battery and charger for this equipment must be purchased separately.

Specifications:

- power supply - battery;

- speed - 1900 strokes per minute;

- maximum cutting thickness - 2.5 mm;

- battery parameters - Li-Ion, 18 V;

- equipment weight - 2.2 kg.

Advantages

- autonomy;

- handle ergonomics;

- relatively light weight;

- detailed user manual.

Flaws

- high price;

- lack of battery and charger included;

- high level of vibrations and noise.

Criterias of choice

When purchasing electric scissors, you need to pay attention to many different factors:

- Power. Varies in the range of 300-650 W. A powerful tool is always better, because... it allows you to make a deeper cut. But it must be taken into account that an increase in the power characteristics of the motor is accompanied by a loss of maneuverability.

- Knife stroke frequency. The higher this indicator, the more accurate the cut. However, with thick workpieces it is preferable to work at a low speed, so the best option would be a tool with a function for adjusting the speed of the knife.

- Maximum metal thickness. Varies from 0.3 to 16 mm. When assessing this parameter, you should also take into account what material the scissors are intended for: soft or hard steel, aluminum, composite, etc.

- Material of cutting elements. Most cutters are made from chrome-molybdenum and chrome-vanadium alloy, but the most durable blades are those made from chrome-nickel or high-carbon steel.

- Maneuverability. It is inversely proportional to the turning radius of the scissors: the smaller the radius, the higher the maneuverability.

- Ergonomics. The tool should be comfortable to hold with one hand. However, for processing thick metal, an additional removable handle will not be superfluous.

- Launch node. The operating mode lock button must be located in an accessible place so that it can be pressed by the finger of the operating hand.

- Power source: Built-in battery. The best option for working on the roof and in hard-to-reach places. In addition to ease of use, the advantage of such devices is that there is no risk of damage to the cord. The only but significant drawback of such devices is low power (maximum workpiece thickness is 1.5-2.0 mm, recharging is required every 50-70 meters).

- Mains powered. They allow you to operate with a workpiece on a workbench without thinking about charging and limiting productivity.

FAQ

What types of metal scissors are there?

+

A straight tool is usually used for working with profiles, sometimes for facing workpieces. Scissors with curved blades allow you to make roundings and are designed for shaped cutting. If it is necessary to obtain a complex contour, it is better to use finger models. Radius products have short edges and are optimal for forming circles of small diameter. Depending on the specifics of the design, one can also distinguish guillotine, lever, roller and other types of scissors, which, in general, are not very similar to scissors.

How to extend tool life?

+

With heavy use, blades can quickly become dull, so it is important to sharpen them regularly. In this case, it is necessary to pay attention to the initial angle of the chamfer. We also recommend that you adjust the stroke of the edges while using the tool. Too loose will lead to jamming of the material and a sloppy cut, too tight will quickly tire the master.

What affects comfort during work?

+

When using hand tools, we recommend taking into account the weight and ergonomics of the model. The presence of a return spring will help to spend less force during operation of the scissors. But for stationary installations, the ability to attach to the base is important. Also, in a small production or workshop, the function of adjusting the cutting depth will be useful.

Popular models

Experts identify several models of electric scissors that satisfy the maximum number of selection criteria:

Makita JN1601

Makita JN 1601 nibblers are equipped with a 550 W motor with an operating frequency of up to 2200 rpm. This is quite enough for high-quality cross-cutting of metal tiles or roofing corrugated sheets.

Advantages:

- The cartridge rotates 360*.

- Steel cutting depth up to 1.6 mm.

- Cuts easily and effortlessly.

Flaws:

- Leave a slightly rough cut.

Bosch GSC 75-16

Professional sheet shears with a power of 750 W. Copes with steel and aluminum up to 2 mm thick. Ideal for cutting smooth sheets and low-wave profiled sheets. They cut smoothly, without burrs or chips.

Advantages:

- Relatively light weight - 1.7 kg.

- Quiet sound of the engine.

- Convenient fastener.

Flaws:

- The quality of the cut greatly depends on the setting of the gap between the cutting edges.

- They don't like rusty steel.

Fein BLK 5.0

Professional nibblers from a German manufacturer. The 1200 W motor allows you to easily cut high-strength steel up to 2.5 mm thick and regular steel up to 5 mm thick. Speed – 750 rpm.

Advantages:

- Durable die and punch.

- Extra handle included.

- 5 meter cable.

Flaws:

- Weight – 3.8 kg.

- High price.

Bosch GSC 12V - 13

Bosch cordless sheet metal shears are designed for working with thin sheet steel (0.6-1.3 mm). Weighing 1.4 kg, they have excellent mobility. The brushed motor provides an idle speed of up to 3600 rpm.

Pros:

- Battery overload protection systems.

- System to protect the device from damage when dropped.

- Ease of use.

Minuses:

- They require physical strength and concentration from the operator; with a weak grip they slip out of the hand.

MAKITA DJN161

Makita cordless nibblers allow you to manipulate in hard-to-reach places when installing roofs and facades. The device has an 18 V lithium-ion battery and an electric motor that develops up to 1900 rpm. The maximum cutting depth is 2.5 mm.

Advantages:

- Quiet operation.

- Ergonomic handle.

- Compact sizes.

- Battery charge indicator on the case.

No deficiencies identified.

Makita JN 3200

Nibbler type scissors. Allows cutting steel up to 3.2 mm thick. The 660 W engine produces up to 1300 rpm.

Pros:

- Handle holder located above the main body.

- It is convenient to change the brushes (just unscrew the special nut).

- Perfect straight cut.

- Double insulated power cable.

Minuses:

- It makes a lot of noise when working.

- It is difficult to unfold when making a figured cut.

TITANIUM PPN55-16

The best cheap nibblers. Equipped with a 550 W motor that spins up to 2000 rpm. Capable of processing metal up to 2.5 mm thick.

Pros:

- Affordable price.

Minuses:

- Chinese assembly of low quality.

- Under high loads, the cutter quickly fails.

The best die-cut models

Electric nibblers have unsurpassed maneuverability and functionality.

These are powerful and efficient devices for a wide range of applications.

Rating of the best metal cutting shears in terms of price and quality ratio.

Makita JN1601

Makita JN1601 network electric shears are a professional-level tool and are suitable for performing shaped or straight cuts of metal with a maximum thickness of 2.5 mm.

The model is equipped with a reliable metal gearbox and a powerful electric motor, the performance of which is sufficient to solve problems of any complexity.

The scissors are characterized by a high speed of 2200 movements per minute at idle speed.

The outer minimum cutting radius of the device is 50 mm, the inner one is 45 mm.

The product is equipped with a hex key, punch, matrix with holder.

Specifications:

- power supply - network, 220 V;

- power consumption - 0.55 kW;

- speed - 2200 strokes per minute;

- maximum cutting thickness - 2.5 mm;

- equipment weight - 1.6 kg.

Advantages

- high build quality;

- light weight;

- compactness;

- Suitable for working with metal tiles.

Flaws

- high prices for components;

- small cutting thickness;

- low power.

DIOLD NER-0.65-2.5

Manual cutting electric shears DIOLD NER-0.65-2.5 are an affordable tool designed for straight and shaped cutting of sheet and profile metal in domestic conditions.

The device is equipped with a powerful 650 W motor, the number of strokes of the equipment reaches 2000 movements per minute.

The product is suitable for use at ambient temperatures of -15...+35 degrees.

The overall dimensions of the model are 345×77×166 mm.

The delivery set includes a set of brushes and tools for adjustment and routine maintenance of equipment.

Specifications:

- power supply - network, 220 V;

- power consumption - 0.65 kW;

- speed - 2000 strokes per minute;

- maximum cutting thickness - 2.5 mm;

- equipment weight - 1.8 kg.

Advantages

- affordable price tag;

- compact dimensions;

- relatively light weight;

- good performance.

Flaws

- the tools included are not of the best quality;

- lack of consumables for sale;

- small cutting thickness.

VERN 0.52-P

Manual cutting electric shears VERN 0.52-P are a convenient and effective tool that allows you to perform straight and shaped cutting of material of various thicknesses and shapes.

The cutting element of the product can be rotated 90 degrees; this wear-resistant unit is convenient to change and adjust.

The scissors receive energy from an alternating current network with a voltage of 220 volts and a frequency of 50 Hz.

The unit is made in accordance with protection class II.

Its overall dimensions are 271x160x67 mm. The product allows you to make cuts without deformation, according to markings or templates.

Specifications:

- power supply - network, 220 V;

- power consumption - 0.52 kW;

- speed - 1500 strokes per minute;

- maximum cutting thickness - 2.5 mm;

- equipment weight - 2.1 kg.

Advantages

- high-quality execution;

- Ease of use;

- long power cable;

- affordable price.

Flaws

- low power;

- low speed;

- heavy weight.

Safety precautions

The metal being processed has a thin edge that can easily cause injury. In addition, notching and slotting shears produce sharp shavings during operation, which can get into your eyes.

Therefore, in order to avoid injuries and injuries, when working with electric scissors, you should follow safety precautions:

- Before turning on, check the reliability of fastening of the cutters, inspect the working unit and power cable for cracks.

- Manipulate with protective gloves and goggles.

- During operation, do not touch the gearbox to avoid getting burned.

- It is forbidden to touch a cut of metal with bare hands, especially if it is formed with sheet-type scissors - in this case, the edges of the metal are flattened and become razor-sharp.

Safety precautions are an important aspect when working with electric scissors; do not neglect them under any circumstances!

Advice from professionals

Following the recommendations of professionals will help you get a beautiful and even cut:

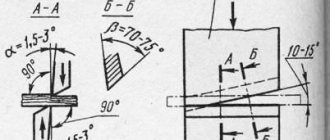

- The tool must be in a perpendicular position to the workpiece. Deflection of the cutter in any direction will lead to the appearance of nicks and herringbone.

- To speed up the work, the metal sheet can be lubricated with machine oil.

- The gap between the blades of the sheet shears must be adjusted correctly using special screws. The thicker the workpiece, the larger the gap should be.

A high-quality tool does not vibrate. The appearance of vibration may indicate either a breakdown or a discrepancy between the thickness of the workpiece and the capabilities of the machine.

Care instructions

In order for the scissors to last a long time and not cause trouble during operation, you need to devote time to their maintenance:

- Make sure that the cutter always remains sharp and replace the blades in a timely manner. This will protect the motor from overloads.

- Work intermittently. Ideally, for every 10-15 minutes of work there should be 5 minutes of rest.

- Do not work in damp and dusty conditions, so as not to cause a short circuit or clogging of the ventilation holes on the device body.

- Clean the cutting unit and ventilation grilles periodically.

What kind of electric scissors do you use?

SheetSlotted

conclusions

Electric scissors can save their owner a lot of effort and time.

Sheet shears are the simplest and most reliable, but limited in functionality.

Nibbler and spline tools are best suited for making radial cuts and working with profile workpieces.

For periodic use at home, a cheap tool like TITAN PPN55-16 will be sufficient.

For professional work with thick metal, the Fein BLK 5.0 nibblers are best suited

How to choose metal scissors

One of the main selection criteria is the maximum cutting thickness. The required value depends on the characteristics of the future use of the scissors. So, for working with thin sheet metal, an indicator of 0.3-0.8 mm will be sufficient; for corrugated sheets or steel tiles, you will need scissors that cut at least 1 millimeter.

Ease of use is greatly influenced by the design of the handles. Comfort for long-term work will be provided by indentations for fingers or anti-slip pads.

We recommend purchasing hand scissors equipped with impact-resistant two-component handles.

Compact scissors are more suitable for trimming, cutting, and shallow cutting. A larger tool (17.5 to 35 cm long) is purchased for working with thick sheets or hard metals.

Metal shears are subject to heavy mechanical load, so they must be durable. The optimal solution would be to purchase a model made of high-carbon steel and having hardened edges.

Metal shears can be right-handed or left-handed. As a rule, it is determined by the location of the lower blade. Most of the instruments on sale are intended for use by right-handers, and therefore are left-handed.