Chemical composition

| Standard | C | S | P | Mn | Cr | Si | Ni | Fe | Cu | V | Mo |

| GOST 398-96 | 0.57-0.65 | ≤0.04 | ≤0.035 | 0.6-0.9 | — | 0.22-0.45 | — | Remainder | — | ≤0.15 | — |

| GOST 5257-98 | 0.57-0.67 | ≤0.04 | ≤0.035 | 0.5-0.9 | — | 0.2-0.45 | — | Remainder | — | — | — |

| GOST 398-2010 | 0.57-0.67 | ≤0.02 | ≤0.03 | 0.6-0.9 | ≤0.2 | 0.22-0.45 | ≤0.25 | Remainder | ≤0.3 | ≤0.15 | ≤0.08 |

Fe is the basis. According to GOST 398-96, the allowed content of molybdenum is not more than 0.08%, nickel is not more than 0.25%, chromium is not more than 0.20%, copper is not more than 0.30%. The total content of sulfur and phosphorus should be no more than 0.065%. In finished bandages, maximum deviations in chemical composition are allowed in accordance with the requirements of GOST 380. According to GOST 5257-98, nickel content is allowed no more than 0.30%, chromium no more than 0.25%, copper no more than 0.30%. According to GOST 398-2010, the total proportion of sulfur and phosphorus in steel should not exceed 0.040%. In bandages, maximum deviations of the chemical composition are allowed: for carbon +0.030/-0.020, for manganese +0.050/-0.030, for silicon +0.030/-0.020, for chromium +0.020, for vanadium +0.010%, for phosphorus +0.0050% , for sulfur +0.0050%. The mass fraction of hydrogen in liquid steel should not exceed 0.00020%.

Advantages and disadvantages

D2 steel used for making knives has its pros and cons. Among the positive properties note:

- high level of hardness, allowing you to keep the blade sharp for a long time without sharpening;

- the composition of the alloy gives high anti-corrosion properties, although D2 steel for knives is classified as semi-stainless;

- excellent resistance to corrosion processes among all carbon steels;

- perfectly keeps the edge of a knife or blade sharpened;

- a cutting tool made of this alloy can withstand strong impacts and can be used by hunters to chop animal bones or by tourists to cut and process tree branches.

In addition, high-quality products have a low cost, which makes them even more attractive.

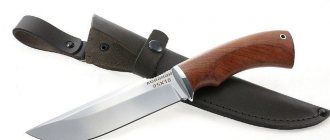

Basically, such knives are intended for hunters, fishermen, and tourists who appreciate the advantages of the D2 steel grade, but can be used in everyday life: D2 is used to produce high-quality kitchen knives. Handmade hunting knives, including those made by Kizlyar craftsmen from D2 steel, can be purchased in our online store.

Like any other, the alloy is not ideal, so D2 steel has its disadvantages and drawbacks; there are not many of them.

- Although not completely stainless, a knife made from this alloy requires at least minimal care to maintain the best qualities of the product.

- It is very difficult to sharpen it in field conditions, without the use of special materials and devices.

In addition, it is worth knowing that the surface of the alloy does not lend itself to final polishing of the blade, so it is almost impossible to find a sparkling, absolutely smooth blade made of D2 steel: its surface will be matte.

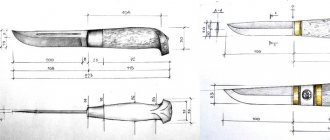

Variety of products from D2

A wide range of different knives are produced from D2 tool steel. Among them:

- folding - for universal purposes, including in gift wrapping;

- neck ones, with the help of which you can skin an animal killed during a hunt and carefully remove its skin;

- tourist, with a fixed blade and a wide range of applications;

- cutting machines, which will help cut the animal carcass into pieces and chop the bones.

High-quality knives made of D2 steel can be purchased in the online store KavkazSuveninr Ali Askerov, among them: hunting, tourist, folding. Our website also presents tactical survival knives made by the best Kizlyar craftsmen, including products made from D2 steel.

Also in our online store there are many handmade knives for various purposes. All of them are characterized by high accuracy and compliance with the required product parameters, aesthetics, and the use of natural materials for decoration.

Domestic knife manufacturers are increasingly using modern and high-quality alloys in the production of knives, and among them, D2 steel (D2), which has gained wide popularity.

Mechanical characteristics

| Section, mm | σB, MPa | d5, % | y, % | kJ/m2, kJ/m2 | Brinell hardness, MPa |

| Bandages according to GOST 398-96, GOST 398-2010. Quenching with separate heating + Tempering | |||||

| 930-1110 | ≥10 | ≥14 | ≥2450 | 269-321 | |

| Bandages according to GOST 5257-98. Quenching with separate heating + Tempering | |||||

| ≥900 | ≥10 | ≥14 | — | ≥250 | |

Review of Laoa pocket screwdriver made of S2 steel

It is useful to have a compact screwdriver made of good steel with you, since carrying a full-sized one is not very convenient, and screwdrivers in multitools and multi-item knives are rarely convenient for long-term work.

Personally, I bought a screwdriver as an addition to the good NexTool Flagship Pro 16 in 1 multitool. Testing showed that you can only use it to turn screws out of complete desperation.

Well, I’ll show you right away why the screwdriver is “pocket”. Here it is in comparison with a high-quality large Xiaomi Wiha and an ordinary old Soviet screwdriver.

Few people would think of keeping it as the only full-fledged screwdriver in the house, right? But to throw it in your bag just in case, it’s perfect for that.

This screwdriver costs $5.91 on Ali

This lot has an option with an additional longer bat with two PH2 tips for the same price. Why not choose it?

Link

This is what a screwdriver looks like. The handle is two-component - green rubber and black and yellow plastic.

There is some flash on the plastic.

Screwdriver length 90 mm. The diameter of the handle at its thickest part is 33 mm.

The main working tool is a standard double-sided extended bit

If necessary, it can be replaced with another option to work with the necessary splines.

One side is designed to accept PH2 Phillips splines.

The other side is for straight slot mounting. Here the size is difficult to determine by eye, but the dimensions of the working part are 6 x 1 mm.

The inside of the handle is metal. The bit is clamped into a recess with a spring-loaded steel ball.

The chubby handle is held quite confidently by your fingers.

Let's try to test the screwdriver a little using home methods. I bought it back in the summer, and it didn't inspire me. Handle with burr. Good s2 steel has a hardness above 60 HRC and should easily scratch glass, but it didn’t work out for me then (((.

Okay, let's try again.

He swiped it with force 4 times on the glass. It seemed to me that only dark stripes of smeared metal remained. But I tried them with my fingernail, they were real scratches.

This means that the screwdriver is softer than I have come across previously made from S2 steel, but the hardness is still decent.

Let's continue.

The screwdriver scratches the blade of a Soviet hacksaw for metal, but not very confidently. By the way, at this moment I noticed that the tip of the bit was magnetized.

The needle file, with difficulty, but grinds the steel off the bat. (I came across screwdrivers that the needle file hardly took).

Well, what’s a review of a tool without at least a little testing in operation.

He took out a frozen block from the balcony. I found several hardened wood screws and soft Soviet screws.

I tightened the screws without any problems. The screws got into the wood more poorly, but if you really need it, it’s quite possible to tighten it.

I twisted it back. The ergonomics of the handle pleasantly surprised me (I removed the flash beforehand). You can spin it for 20-30 minutes without any problems. Well, no one will work with such a screwdriver for hours on end anyway.

Let's look at the sting in macro.

The screwdriver came off several times during operation. So, a couple of jams after working with hardened screws is quite normal. I can say that the steel for such a tool is quite decent.

Based on the results of the mini-test, I was pleased with the screwdriver. The handle is comfortable and the bat can withstand loads. It is not for nothing that LAOA is considered a manufacturer of high-quality instruments by the standards of Chinese products.

That's all.

Thank you for your attention.

Thermo-mechanical treatment conditions

This type of steel requires hardening, which gives it greater strength. To harden an alloy not intended for making blades, an oxidizing atmosphere is used. Creating blades from D2 steel requires a different technology.

Heat treatment of steel D2.

For the production of cutting blades and parts designed for dynamic loads, different exposure times and temperatures are required. The most common treatment of steel for primary hardness, including low tempering and quenching in oil, under a stream of air or in hot environments.

To achieve uniformity in the structure of the blade, ensure uniform heating during hardening. The absence of oxidation during such processing prevents decarburization, which helps maintain strength and make the product more sharp.

Heating occurs at a temperature of +690…+850°C. After a few minutes or seconds, the alloy is cooled and alloyed with vanadium and molybdenum, which promotes hardening.

The production uses the electroslag remelting method. The molten metal is passed through a layer of slag, in the process being cleansed of harmful impurities, including sulfur and phosphorus.

After processing followed by heating, the steel is cooled and subjected to final mechanical processing in the form of grinding and sharpening the blade.

Technical features of D2 steel

There are five characteristics to evaluate an alloy:

- Hardness _ It has a high rating - up to 64 HRC according to Rockwell.

- Rigidity. It is durable, but is not rigid enough, which leads to inconvenience when sharpening products.

- Wear resistance to abrasive effects. Due to its hardness, this alloy has a high indicator.

- Corrosion resistance. This type of steel is not stainless because it does not contain enough chromium, but it resists rust. Corrosion resistance is rated as average.

- Protection of edges from rubble. During operation, the blade of a D2 product can maintain its sharpness for a long time.

Additional options

In addition to the central structural elements - the rod, tip and handle - screwdrivers from some manufacturers are equipped with additional features that make their everyday use a little more convenient or add new functions to the tool.

Hole in the handle.

Refers to options that increase the comfort of use. A screwdriver with it can be hung on a tool stand or simply on a nail in the wall.

Hole in the handle of a Dexell screwdriver.

Slot for power rotation.

Adds a new degree of freedom to the screwdriver. You can attach a wrench to the slot and multiply the force applied to the fastener. As a rule, power screwdrivers have a similar slot.

LUX screwdriver slot

Slot on a Dexter screwdriver

. Hammer head.

An additional steel platform on the back of the handle allows the use of a hammer. Of course, you shouldn’t drive screws using the “screwdriver-hammer” system, but driving the tip more tightly into the internal profile of a rusty screw is what you need.

Striker on a Jonnesway screwdriver

In some cases, when there is no particular concern for the tool, a screwdriver with a hammer striker can be used as a drift, punch, or even a chisel for stone.

History of the appearance of the alloy

Steel grade D2 plate 250x80x4 mm.

The alloy was developed in America in the 60s. for industrial purposes (production of knives and cutting tools). Nowadays such steel is produced not only in the USA. Alloys similar in composition to D2 have been developed in Japan, Germany and Sweden. The only difference is the amount of carbon. The alloy has the following designations:

- X155CrMo12 - produced in Germany;

- 1.2379 - this is how D2 is marked according to the European steel designation system;

- SLD - alloy in Japan;

- SKD-11 - D2 marking in Sweden.

In Russia there is also an analogue - X12MF.

The alloy is actively used in the metalworking industry, automotive industry, and in the production of razor blades. In addition, it is used to create edged weapon blades.

Screwdriver slot

The most common types of screwdrivers are available with the following slots:

- straight spline SL

- Phillips or Pozidriv

- hexagonal Torx slot

Splines are offered in a wide range of sizes, as they say, to fit any tricky screw.

Of course, the variety of splines is much wider. But other types of slots in the form factor of a classic screwdriver are critically rarer.

The choice of slot depends on what tasks you plan to solve with a screwdriver.