A drill is a special cutting tool for forming holes in solid materials.

The drilling process involves reaming - increasing the diameter of an existing hole and drilling - making recesses or blind holes. For these purposes, various equipment is used (drill, hammer drill, machine tool), which puts the drill into operation: through translational and rotational movements, cutting edges of different configurations and with different sharpening angles remove chips from the material being processed (metal, wood, glass, plastic, etc. ). When working with concrete, brick, stone, tile, the drill not only cuts the material, but also crushes it.

Varieties of drills according to the configuration of the working (cutting) area

This type of classification is considered the main one, since for high-quality drilling a tool should be used, taking into account the specifics of the source material, the size of the hole, etc. A drill of the correctly chosen shape of the working surface will allow you to make exactly the hole that is necessary, avoiding defects in work, which will be very difficult to correct. Let's consider the main types of tools according to this classification.

Screw or spiral

This type of drill is the most in demand, so every craftsman will probably have one.

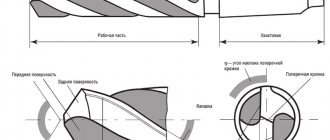

The design consists of a shank - a rod, thanks to which the drill is attached to the drill chuck, neck and directly the working (cutting) area.

The elements of the working area ensure the desired position of the drill in the hole and cut the material. This zone has a cylindrical shape with helical grooves diametrically opposite to each other, which serve to remove chips. An additional cutting element necessary for precise movement of the drill is a ribbon. There are two of them on a typical screw drill. The width of the bands is proportional to the diameter of the drill, but if they are too wide, the friction of the tool against the walls of the hole will increase. Cutting edges are the main functional element of a twist drill. They cut the material, forming a conical cutting surface.

Lewis spiral or screw

This is a type of screw drill that has one groove and a cutting part equipped with a sharp centering end with a thread that allows the drill to easily, without pressure, go deep into loose material, for example, wood. Lewis spirals are recommended for the formation of through holes with a smooth inner surface, large depth, but medium diameter. The main disadvantage of this tool is its high price, tendency to become off-center and jam. In addition, they are quite fragile.

Feather (feather) or flat

This type of drill is used when it is necessary to make deep holes with a diameter of 8-50 mm. The double-edged cutting zone is shaped like a shovel with the tip protruding from the center. It serves to center the hole. The blade (feather) can be solid cast with a shank or attached to it with a holder or a boring bar.

Feather drills are easy to manufacture and inexpensive, but the absence of spirals does not ensure normal removal of chips from the surface being machined. Another disadvantage of using a flat pen drill is that the resulting hole will have a very rough surface.

Single-sided cutting

This type of tool is used for drilling holes of particular precision. The working area of the drill consists of a reference plane and two cutting edges located on one side of the center.

Crown (ring) or crown

This drill is a hollow cylinder (glass) with a serrated edge at the ends. A crown is necessary for preparing holes with a diameter of more than 100 mm. A set of drills of this type includes a mandrel, a centering drill with a shank and several attachments of different diameters.

Subtypes of core drills

Craftsmen use a variety of crown designs, which is due to the requirements for the hole diameter.

- Double-cutting core drill. The body of this tool has 3 guide plates and 2 cutters. This allows you to drill holes 110-180 mm in diameter.

- Three-incisor crown. The design differs from the previous one in the size of the drill and the number of cutters. Suitable for forming holes with a diameter of 180-250 mm.

- Multi-cutter drill. Cutters are installed in a body with a centering drill, grooves for removing chips and ball bearings for adjusting the direction of the drill. With a tool of this configuration, you can drill holes with a diameter of 50-100 mm to a depth of up to 400 mm.

Centering

This type of drill is suitable for drilling the center. Tools with a safety cone are available for sale.

Stepped

A drill of this configuration began to be used relatively recently and is now often indispensable for producing large-diameter holes (from 35 mm) when working with sheet material with a thickness of 1 to 8 mm. The design of the drill consists of cutting parts of different diameters mounted on one rod, which allows you to work without changing drills if you need a smooth hole of large or medium diameter. The main advantages of a step drill include precise centering and very smooth hole edges. The disadvantages are the high price of the product and the limited thickness of the processed material by the height of the cutting zone step. Step drills can be used to make a new hole or widen an old one.

Forstner drill

This tool has become indispensable when working with wood, laminate, chipboard and other loose materials. Thanks to the special design (the presence of a centering tip with a scoring tool), the exact dimensions of the hole are maintained and a neat cut is ensured. This is achieved by a clear fit of the cutting zones of the drill to the surface being processed. The result is a round blind hole with a flat bottom, smooth, even edges and walls. These capabilities of Forstner drills are widely used in furniture production.

Ruzheinoye

This tool allows you to make holes with a depth that is several times greater than the diameter of the drill. The main design feature is that the tip of the drill and the main cutting edges are located asymmetrically relative to the axis by 0.2-0.25 mm in diameter. A typical gun drill design includes two screw channels located either in soldered tubes or inside the cutting area. Through these channels, coolant (coolant) enters the cutting zone.

TEST METHODS

3.1. Tests of drills for performance, average and 95% durability periods are carried out on drilling, milling, lathes with mechanized feed using auxiliary tools, which must meet the standards of accuracy and rigidity established for them.

3.2. Drills must be tested on samples made of steel grade 45 according to GOST 1050, hardness 187 ... 207 HB by drilling blind holes with a depth equal to three diameters, but not more than 85 mm.

The roughness parameter of the sample surfaces should not be more than, µm:

| for drills up to 2.95 mm diameter Ra 0,8 for drills with a diameter of St. 2.95 mm Rz 40 |

3.3. A 5% by weight solution of emulsol in water with a flow rate of at least 5 l/min or oil coolants should be used as a cutting fluid.

3.4. When drilling holes with a diameter of up to 1 mm, the surface of the workpiece can be pre-cored.

3.5. Tests of drills must be carried out in the modes specified in table. 8.

3.6. After performance testing, the cutting edges of the drills should be free of chips and chips, and the drills should be suitable for further work.

3.7. Acceptance values for the average and 95% durability periods must be no less than those indicated in the table. 9.

3.8. The hardness of drills is controlled using devices in accordance with GOST 23677.

Table 8

| Drill diameter, mm | Cutting speed for series drills, m/min | Feed for drills, mm/rev | Number of holes in performance tests | ||

| short and normal | long and elongated | short and normal | long and elongated | ||

| From 0.26 to 0.5 | 12 | — | 0,004 | — | 30 |

| St. 0.6 to 0.7 | 14 | 0,006 | |||

| St. 0.7 to 0.9 | 15 | 0,008 | |||

| St. 0.9 to 1.1 | 20 | 16 | 0,010 | 0,008 | |

| St. 1.1 to 1.4 | 21 | 0,015 | 0,012 | 25 | |

| St. 1.4 to 1.8 | 18 | 0,020 | 0,015 | ||

| St. 1.8 to 2.2 | 0,025 | 0,020 | |||

| St. 2.2 to 2.8 | 23 | 20 | 0,030 | 0,025 | 22 |

| St. 2.8 to 3.0 | 25 | 0,040 | 0,030 | ||

| St. 3.0 to 5.0 | 29 | 23 | 0,100 | 0,070 | 20 |

| St. 5.0 to 7.0 | 0,140 | 0,100 | 18 | ||

| St. 7.0 to 9.0 | 0,170 | 0,140 | |||

| St. 9.0 to 11.0 | 28 | 22 | 0,200 | 0,170 | 15 |

| St. 11.0 to 14.0 | 0,220 | 0,170 | |||

| St. 14.0 to 18.0 | 0,250 | 0,200 | 12 | ||

| St. 18.0 to 23.0 | 0,280 | 0,220 | 10 | ||

| St. 23.0 to 30.0 | 0,320 | 0,250 | 6 | ||

| St. 30.0 to 35.0 | 27 | 21 | 0,400 | 0,280 | 4 |

| St. 35.0 to 45.0 | — | 0,430 | — | 4 | |

| St. 45.0 to 60.0 | 0,560 | 3 | |||

| St. 60.0 to 80.0 | 25 | 0,800 | 3 | ||

Notes:

1. For drills made of 9ХС steel, the correction factor for cutting speed and feed is 0.5.

2. If the machine does not have the required feed S (mm/rev), rotation n (min-1), it is allowed to select the nearest S and n, provided that the minute feed Smin = n ∙ Sob differed by no more than 10% from that calculated according to the data specified in table .

Table 9

| Drill diameter, mm | Acceptance durability periods, min | |||

| average | installed | |||

| A1 | B1, B | A1 | B1, B | |

| From 0.25 to 0.5 | 8 | — | 2,3 | — |

| St. 0.5 to 0.7 | 9 | 2,8 | ||

| St. 0.7 to 0.9 | 12 | 3,5 | ||

| St. 0.9 to 1.1 | 16 | 11 | 4,5 | 2,8 |

| » 1,1 » 1,4 | 20 | 14 | 6,0 | 3,5 |

| » 1,4 » 1,8 | 23 | 16 | 7,0 | 4,0 |

| » 1,8 » 2,2 | 26 | 18 | 8,0 | 4,5 |

| » 2,2 » 2,8 | 29 | 21 | 9 | 5,0 |

| » 2,8 » 3,0 | 33 | 23 | 10 | 6,0 |

| » 3,0 » 5,0 | 34 | 24 | 15 | 8 |

| » 5,0 » 7,0 | 36 | 25 | 16 | 9 |

| » 7,0 » 9,0 | 41 | 28 | 18 | 10 |

| » 9,0 » 11,0 | 49 | 34 | 22 | 12 |

| » 11,0 » 14,0 | 58 | 40 | 26 | 14 |

| » 14,0 » 18,0 | 64 | 45 | 29 | 16 |

| » 18,0 » 23,0 | 76 | 51 | 35 | 18 |

| » 23,0 » 30,0 | 82 | 56 | 37 | 20 |

| St. 30.0 to 35.0 | — | 62 | — | 22 |

| » 35,0 » 45,0 | 68 | 24 | ||

| » 45,0 » 60,0 | 74 | 25 | ||

| » 60,0 » 80,0 | 85 | 30 | ||

3.9. The appearance of drills is checked visually.

3.10. The surface roughness parameters of drills are checked by comparison with roughness samples in accordance with GOST 9378 or with standard tools having values of surface roughness parameters not exceeding those specified in clause 1.11 using a magnifying glass LP-1 - 2´ in accordance with GOST 25706.

3.11. When monitoring drill parameters, control methods and means must be used, the error of which should not be more than: when measuring linear dimensions - the values specified in GOST 8.051; when measuring angles - 35% of the tolerance value for the angle being tested; when monitoring the shape and location of surfaces - 25% of the tolerance value for the parameter being tested.

3.12. For drills with a diameter of 3 mm or more, accelerated tests for the average durability period are allowed.

When carrying out accelerated tests of five drills at the modes specified in paragraph 3.11, wear on the flank surface is measured after operating time t.

The time values t and permissible average wear h should be no more than those indicated in the table. .

Table 10

| Drill diameter, mm | Test time for drills of accuracy classes, min | Average wear, mm | |

| A1 | B1, B | ||

| From 3 to 5 | 17 | 12 | 0,18 |

| St. 5 » 7 | 18 | 12,5 | 0,24 |

| » 7 » 9 | 20,5 | 14 | 0,30 |

| » 9 » 11 | 24,5 | 17 | 0,33 |

| » 11 » 14 | 29 | 20 | 0,36 |

| » 14 » 18 | 32 | 22,5 | 0,48 |

| » 18 » 23 | 38 | 25,5 | 0,54 |

| » 23 » 30 | 41 | 28 | 0,60 |

| » 30 » 35 | — | 25 | 0,40 |

| » 35 » 45 | — | 27 | 0,50 |

| » 45 » 60 | — | 30 | 0,60 |

| » 60 » 80 | — | 34 | 0,80 |

(Introduced

additionally, Amendment No. 3 ).

Varieties of drills by types of shanks

The shank, the so-called “drive” of the drill, is a mandatory fastening element of the drill, which is clamped in the chuck of a hammer drill, drill or spindle head of the machine. All types of drills are produced with shanks of the following shapes:

- conical (cone-shaped);

- cylindrical (cylindrical);

- faceted;

- SDS type.

Conical (Morse taper)

This drill shank is shaped like a cone and is intended for drills used on machine tools. The cone-shaped head allows for quick tool changes in automatic mode. The variety of designs of tapered shanks is due to the methods of fixing drills for machine tools. They are:

- with claws - fasteners in the spindle head are carried out by wedging. Thanks to this fixation, light materials are prevented from turning during drilling.

- with thread - fastened by means of a rod. This type of fixation is the most reliable. It prevents the tool from falling out.

- without threads and paws - designed for working with light materials.

Types of tapered shanks

There are several modifications of tapered shanks:

- Instrumental. The product parameters are regulated by GOST. The most common type, since they are specially designed for quickly replacing drills on machine tools.

- Shortened. Used to form shallow holes. The tail part is reduced due to thickening.

- Elongated. Necessary for deep drilling.

- Metric. The ratio of the length of the shank to the working area of the drill is one to twenty.

The main advantage of the tapered shank is the ease of centering without the use of additional tools.

Cylindrical

Drills with a drive of this shape are the most popular among home craftsmen, since the cylindrical shank is suitable for a regular drill. As a rule, the diameters of the cutting part of the drill and the shank are identical, but it happens that for more reliable fixation in the chuck, a shank of a larger diameter is used. But if you need to clamp a thick drill in a standard drill chuck, select shanks with a smaller diameter. The main disadvantage of working with a cylindrical drive of drills is their slippage during rotation.

Faceted

Such shanks are rods with three, four or six edges.

tetrahedral

The use of these shanks has been practiced since the mid-19th century. Initially, they were simply inserted into the spindle or secured with a screw. Over time, clamping chucks appeared, but most modern drills are not equipped with devices that can securely hold drills with a square shank. In addition, the centering of the drill is not ensured. The advantages of the design include ease of manufacture and resistance to rotation. Drills with similar shanks are used for working with a brace.

Hexagonal (hexagonal, hex)

The six sides of the shank provide excellent resistance to twisting of the drill and transmit high torque to it. Therefore, for thin drills that require high torque, a shank of this configuration is made. With this type of drive, there are various types of drills: pen drills, twist drills, Forstner drills.

Triangular

The convenience of using these shanks lies in the possibility of clamping in standard three-jaw chucks, transmitting high torques, and also being resistant to rotation.

Type SDS

This design was developed and patented by Bosch for the rapid replacement of used drill bits in rotary hammers. A design feature is the presence of grooves on the tail rod of the drill, due to which the drill is fixed in the chuck. There are several types of SDS shanks used in different models of rotary hammers or jackhammers.

Drill markings

All industrial drills (with the exception of drills with a diameter of up to 3 mm) must be marked. The thicker the tool, the more information the consumer needs to know. This is a kind of calling card of the instrument. Therefore, the lack of information about the accuracy class, steel grade, and manufacturer may indicate a falsified product. At best, the drill will quickly fail; at worst, it will ruin the material being processed. By alphanumeric designations you can determine which drill is foreign or domestic.

Products from domestic manufacturers

On Russian drills you can most often find the “P” sign, which indicates that high-speed steel was used in production. The number following “P” corresponds to the percentage of tungsten in the alloy. For tungsten-free high-speed grades, codes EK-41 and EK-42 are used. Next, the presence of alloying elements is indicated: molybdenum (M), cobalt (K), vanadium (F), nitrogen (A), electroslag remelting (SH). The values of elements such as carbon and chromium are not marked, since the amount of the first usually corresponds to the vanadium content, and the second is always equal to 4%. Sometimes the marking contains a value indicating the size of the drill.

Imported drills

Foreign manufacturers mark products differently - HSS and DIN:

- H.S.S. This is a general designation for all grades of high-speed steels. The following letters indicate the material that this drill can handle. “G” – for alloy and carbon steels, cast iron, copper and aluminum alloys. Drills with the letter “E” are suitable for both the listed materials and acid-resistant and stainless metals.

- DIN. This marking marks drills that can cope with different tasks: both for standard work and for deep drilling.

ACCEPTANCE RULES

2.1. Acceptance rules - according to GOST 23726.

2.2. Testing of drills for the average durability period is carried out once every three years, for the 95% durability period once a year, on at least 5 drills.

2.3. Drills of accuracy classes A1 and B (or B1) of the same standard size from each range of diameters, mm: from 0.25 to 3.0 must be tested; St. 3.0 to 11.0; St. 11.0 to 18.0; St. 18.0 to 23.0; St. 23.0 to 80.0.

2.2; 2.3. (Changed edition, Amendment No. 3).

Types of coating

Additional processing of the external surface of the drill performs several important functions: it protects the tool from corrosion, strengthens the surface, improves heat transfer, and reduces friction. Let's look at the most well-known drill coating operations.

- Oxidation is the application of a black oxide film to the drill, protecting it from extreme heat and corrosion. This type of coating is the most common and inexpensive.

- TiN – drill treatment with titanium nitride. This technology increases the service life of the drill by more than 3 times, allows you to work with fairly hard materials, and reduces friction. But a drill coated with titanium nitrite cannot be sharpened, so as not to remove this hardening layer from the working surface.

- TiCN – titanium carbonitride coating. In terms of performance characteristics, it is close to TiN treatment.

- TiAlN – titanium-aluminum nitride coating. Increases the service life of the tool by five times or more.

- Diamond coating is the most durable coating available today. It makes it possible to drill holes in particularly hard materials.

Drill color

By the color of the drill, with some degree of probability, you can determine what kind of processing the tool was subjected to and what characteristics it has. Approximate correspondence between drill color and coating method is given in the table:

| Color | Image | Coating |

| Steel | No additional processing | |

| Black | Oxidation (treatment with superheated steam) | |

| Light gilding | After the vacation procedure | |

| Bright gilding | TiN, TiCN |

When purchasing drills, you need to pay attention to the uniformity of the tool’s coating and the absence of cracks, chips, or burrs.

GOST 10902-77 Group G23

INTERSTATE STANDARD

Twist drills with straight shank

Average series. Main Dimensions

Twist drills with straight shank. Middle series. Basic dimensions

MKS 25.100.30 OKP 39 1213; 39 1214

Date of introduction 1979-01-01

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Machine Tool and Tool Industry of the USSR

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated October 14, 1977 N 2443

3. The standard fully complies with ST SEV 273-87

4. The standard fully complies with the international standard ISO 235-1-75

5. INSTEAD GOST 10902-64, MN 5807-65

6. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 2034-80 | 6 |

| GOST 4010-77 | 8 |

| GOST 14034-74 | 4 |

| ST SEV 198-75 | 5 |

| ST SEV 273-87 | 1 |

7. The validity period was removed by Decree of the State Standard of July 22, 1982 N 2776

8. EDITION with Amendments No. 1, 2, approved in July 1982, April 1988 (IUS 11-82, 7-88)

1. This standard applies to right-hand and left-hand twist drills with a cylindrical shank with a diameter of 0.25 to 20 mm. The standard complies with the international standard ISO 235-1-75 in terms of diameter sizes. The standard fully complies with ST SEV 273.

2. The main dimensions of the drills must correspond to those indicated in the drawing and table.

Drawing. Basic drill sizes

Dimensions in mm

| High precision drills class A1 | Drills of normal accuracy of classes B1 and B | |||||||||

| Version 1 | Version 2 | Version 1 | Version 2 | |||||||

| Rights | Left | Rights | Left | Rights | Left | Rights | Left | |||

| Designation | Designation | Designation | Designation | Designation | Designation | Designation | Designation | |||

| 2300-8169 | — | — | — | 2300-8171 | — | — | — | 0,25 | 19 | 3 |

| 2300-8001 | — | — | — | 2300-0112 | — | — | — | 0,30 | ||

| 2300-8003 | — | — | — | 2300-5038 | — | — | — | 0,32 | 4 | |

| 2300-8005 | — | — | — | 2300-0113 | — | — | — | 0,35 | ||

| 2300-8007 | — | — | — | 2300-5039 | — | — | — | 0,38 | ||

| 2300-8011 | — | — | — | 2300-0114 | — | — | — | 0,40 | 20 | 5 |

| 2300-8013 | — | — | — | 2300-5041 | — | — | — | 0,42 | ||

| 2300-8015 | — | — | — | 2300-0115 | — | — | — | 0,45 | ||

| 2300-8017 | — | — | — | 2300-5042 | — | — | — | 0,48 | ||

| 2300-8021 | — | — | — | 2300-0116 | — | — | — | 0,50 | 22 | 6 |

| 2300-8023 | — | — | — | 2300-5043 | — | — | — | 0,52 | ||

| 2300-8025 | — | — | — | 2300-0117 | — | — | — | 0,55 | 24 | 7 |

| 2300-8027 | — | — | — | 2300-5044 | — | — | — | 0,58 | ||

| 2300-8031 | — | — | — | 2300-0118 | — | — | — | 0,60 | ||

| 2300-8033 | — | — | — | 2300-5045 | — | — | — | 0,62 | 26 | 8 |

| 2300-8035 | — | — | — | 2300-0119 | — | — | — | 0,65 | ||

| 2300-8037 | — | — | — | 2300-5046 | — | — | — | 0,68 | 28 | 9 |

| 2300-8041 | — | — | — | 2300-0120 | — | — | — | 0,70 | ||

| 2300-8043 | — | — | — | 2300-5047 | — | — | — | 0,72 | ||

| 2300-8045 | — | — | — | 2300-0121 | — | — | — | 0,75 | ||

| 2300-8047 | — | — | — | 2300-5048 | — | — | — | 0,78 | 30 | 10 |

| 2300-8051 | — | — | — | 2300-0122 | — | — | — | 0,80 | ||

| 2300-8053 | — | — | — | 2300-0287 | — | — | — | 0,82 | ||

| 2300-8055 | — | — | — | 2300-0123 | — | — | — | 0,85 | ||

| 2300-8057 | — | — | — | 2300-5049 | — | — | — | 0,88 | 32 | 11 |

| 2300-8061 | — | — | — | 2300-0124 | — | — | — | 0,90 | ||

| 2300-8063 | — | — | — | 2300-0288 | — | — | — | 0,92 | ||

| 2300-8065 | — | — | — | 2300-0125 | — | — | — | 0,95 | ||

| 2300-8067 | — | — | — | 2300-5051 | — | — | — | 0,98 | 34 | 12 |

| 2300-8071 | 2300-8072 | — | — | 2300-0126 | 2300-0542 | — | — | 1,00 | ||

| 2300-8073 | 2300-8074 | — | — | 2300-0289 | 2300-0543 | — | — | 1,05 | ||

| 2300-8075 | 2300-8075* | — | — | 2300-0127 | 2300-0401 | — | — | 1,10 | 36 | 14 |

| 2300-8077 | 2300-8078 | — | — | 2300-0290 | 2300-0544 | — | — | 1,15 | ||

| 2300-8081 | 2300-8082 | — | — | 2300-0128 | 2300-0402 | — | — | 1,20 | 38 | 16 |

| 2300-8083 | 2300-8084 | — | — | 2300-0129 | 2300-0403 | — | — | 1,25 | ||

| 2300-8085 | 2300-8086 | — | — | 2300-0130 | 2300-0404 | — | — | 1,30 | ||

| 2300-8087 | 2300-8088 | — | — | 2300-0131 | 2300-0405 | — | — | 1,35 | 40 | 18 |

| 2300-8091 | 2300-8092 | — | — | 2300-0132 | 2300-0406 | — | — | 1,40 | ||

| 2300-8093 | 2300-8094 | — | — | 2300-0133 | 2300-0407 | — | — | 1,45 | ||

| 2300-8095 | 2300-8096 | — | — | 2300-0134 | 2300-0408 | — | — | 1,50 | ||

| 2300-8097 | 2300-8098 | — | — | 2300-0291 | 2300-0545 | — | — | 1,55 | 43 | 20 |

| 2300-8101 | 2300-8102 | — | — | 2300-0135 | 2300-0409 | — | — | 1,60 | ||

| 2300-8103 | 2300-8104 | — | — | 2300-0292 | 2300-0546 | — | — | 1,65 | ||

| 2300-8105 | 2300-8106 | — | — | 2300-0136 | 2300-0410 | — | — | 1,70 | ||

| 2300-8107 | 2300-8108 | — | — | 2300-0137 | 2300-0411 | — | — | 1,75 | 46 | 22 |

| 2300-8111 | 2300-8112 | — | — | 2300-0138 | 2300-0412 | — | — | 1,80 | ||

| 2300-8113 | 2300-8114 | — | — | 2300-0293 | 2300-0547 | — | — | 1,85 | ||

| 2300-8115 | 2300-8116 | — | — | 2300-0139 | 2300-0413 | — | — | 1,90 | ||

| 2300-8117 | 2300-8118 | — | — | 2300-0140 | 2300-0414 | — | — | 1,95 | 49 | 24 |

| 2300-8121 | 2300-8122 | — | — | 2300-0141 | 2300-0415 | — | — | 2,00 | ||

| 2300-8123 | 2300-8124 | — | — | 2300-0142 | 2300-0416 | — | — | 2,05 | ||

| 2300-8125 | 2300-8126 | — | — | 2300-0143 | 2300-0417 | — | — | 2,10 | ||

| 2300-8127 | 2300-8128 | — | — | 2300-0144 | 2300-0418 | — | — | 2,15 | 53 | 27 |

| 2300-8131 | 2300-8132 | — | — | 2300-0145 | 2300-0419 | — | — | 2,20 | ||

| 2300-8133 | 2300-8134 | — | — | 2300-0294 | 2300-0548 | — | — | 2,25 | ||

| 2300-8135 | 2300-8136 | — | — | 2300-0146 | 2300-0420 | — | — | 2,30 | ||

| 2300-8137 | 2300-8138 | — | — | 2300-0295 | 2300-0549 | — | — | 2,35 | ||

| 2300-8141 | 2300-8142 | — | — | 2300-0147 | 2300-0421 | — | — | 2,40 | 57 | 30 |

| 2300-8143 | 2300-8144 | — | — | 2300-0296 | 2300-0550 | — | — | 2,45 | ||

| 2300-8145 | 2300-8146 | — | — | 2300-0148 | 2300-0422 | — | — | 2,50 | ||

| 2300-8147 | 2300-8148 | — | — | 2300-0149 | 2300-0423 | — | — | 2,55 | ||

| 2300-8151 | 2300-8152 | — | — | 2300-0150 | 2300-0424 | — | — | 2,60 | ||

| 2300-8153 | 2300-8154 | — | — | 2300-0151 | 2300-0425 | — | — | 2,65 | ||

| 2300-8155 | 2300-8156 | — | — | 2300-0152 | 2300-0426 | — | — | 2,70 | 61 | 33 |

| 2300-8157 | 2300-8158 | — | — | 2300-0297 | 2300-0551 | — | — | 2,75 | ||

| 2300-8161 | 2300-8162 | — | — | 2300-0153 | 2300-0427 | — | — | 2,80 | ||

| 2300-8163 | 2300-8164 | — | — | 2300-0298 | 2300-0552 | — | — | 2,85 | ||

| 2300-8165 | 2300-8166 | — | — | 2300-0154 | 2300-0428 | — | — | 2,90 | ||

| 2300-8167 | 2300-8168 | — | — | 2300-0299 | 2300-0553 | — | — | 2,95 | ||

| 2300-0155 | 2300-7516 | 2300-2721 | — | 2300-7515 | 2300-0429 | — | — | 3,00 | ||

| 2300-0156 | 2300-7518 | 2300-2401 | 2300-6518 | 2300-7517 | 2300-0430 | 2300-6501 | 2300-2551 | 3,10 | 65 | 36 |

| 2300-0157 | 2300-7522 | 2300-2402 | 2300-6522 | 2300-7521 | 2300-0431 | 2300-6521 | 2300-2552 | 3,15 | ||

| 2300-0158 | 2300-7524 | 2300-2403 | 2300-6524 | 2300-7523 | 2300-0432 | 2300-6523 | 2300-2553 | 3,20 | ||

| 2300-0159 | 2300-7526 | 2300-2404 | 2300-6526 | 2300-7525 | 2300-0433 | 2300-6525 | 2300-2554 | 3,30 | ||

| 2300-0160 | 2300-7528 | 2300-2405 | 2300-6528 | 2300-7527 | 2300-0434 | 2300-6527 | 2300-2555 | 3,35 | ||

| 2300-0161 | 2300-7532 | 2300-2406 | 2300-6532 | 2300-7531 | 2300-0435 | 2300-6531 | 2300-2556 | 3,40 | 70 | 39 |

| 2300-0162 | 2300-7534 | 2300-2407 | 2300-6534 | 2300-7533 | 2300-0436 | 2300-6533 | 2300-2557 | 3,50 | ||

| 2300-0163 | 2300-7536 | 2300-2408 | 2300-6536 | 2300-7535 | 2300-0437 | 2300-6535 | 2300-2558 | 3,60 | ||

| 2300-0164 | 2300-0438 | 2300-2409 | 2300-2559 | 2300-7537 | 2300-7538 | 2300-6537 | 2300-6538 | 3,70 | ||

| 2300-0165 | 2300-0439 | 2300-2410 | 2300-2560 | 2300-7541 | 2300-7542 | 2300-6541 | 2300-6542 | 3,80 | 75 | 43 |

| 2300-0166 | 2300-0440 | 2300-2411 | 2300-2561 | 2300-7543 | 2300-7544 | 2300-6543 | 2300-6544 | 3,90 | ||

| 2300-0167 | 2300-0441 | 2300-2412 | 2300-2562 | 2300-7545 | 2300-7546 | 2300-6545 | 2300-6546 | 4,00 | ||

| 2300-0168 | 2300-0442 | 2300-2413 | 2300-2563 | 2300-7547 | 2300-7548 | 2300-6547 | 2300-6548 | 4,10 | ||

| 2300-0169 | 2300-0443 | 2300-2414 | 2300-2564 | 2300-7551 | 2300-7552 | 2300-6551 | 2300-6552 | 4,20 | ||

| 2300-0170 | 2300-0444 | 2300-2415 | 2300-2565 | 2300-7553 | 2300-7554 | 2300-6553 | 2300-6554 | 4,25 | ||

| 2300-0300 | 2300-0554 | 2300-2416 | 2300-2566 | 2300-7555 | 2300-7556 | 2300-6555 | 2300-6556 | 4,30 | 80 | 47 |

| 2300-0301 | 2300-0555 | 2300-2417 | 2300-2567 | 2300-7557 | 2300-7558 | 2300-6557 | 2300-6558 | 4,40 | ||

| 2300-0171 | 2300-0445 | 2300-2418 | 2300-2568 | 2300-7561 | 2300-7562 | 2300-6561 | 2300-6562 | 4,50 | ||

| 2300-0172 | 2300-0446 | 2300-2419 | 2300-2569 | 2300-7563 | 2300-7564 | 2300-6563 | 2300-6564 | 4,60 | ||

| 2300-0302 | 2300-0556 | 2300-2420 | 2300-2570 | 2300-7565 | 2300-7566 | 2300-6565 | 2300-6566 | 4,70 | ||

| 2300-0173 | 2300-0447 | 2300-2421 | 2300-2571 | 2300-7567 | 2300-7568 | 2300-6567 | 2300-6568 | 4,80 | 86 | 52 |

| 2300-0303 | 2300-0557 | 2300-2422 | 2300-2572 | 2300-7571 | 2300-7572 | 2300-6571 | 2300-6572 | 4,90 | ||

| 2300-0174 | 2300-0448 | 2300-2423 | 2300-2573 | 2300-6173 | 2300-6174 | 2300-6573 | 2300-6574 | 5,00 | ||

| 2300-0175 | 2300-0449 | 2300-2424 | 2300-2574 | 2300-6175 | 2300-6176 | 2300-6575 | 2300-6576 | 5,10 | ||

| 2300-0176 | 2300-0450 | 2300-2425 | 2300-2575 | 2300-6177 | 2300-6178 | 2300-6577 | 2300-6578 | 5,20 | ||

| 2300-0304 | 2300-0558 | 2300-2426 | 2300-2576 | 2300-6181 | 2300-6182 | 2300-6581 | 2300-6582 | 5,30 | ||

| 2300-0305 | 2300-0559 | 2300-2427 | 2300-2577 | 2300-6183 | 2300-6184 | 2300-6583 | 2300-6584 | 5,40 | 93 | 57 |

| 2300-0177 | 2300-0451 | 2300-2428 | 2300-2578 | 2300-6185 | 2300-6186 | 2300-6585 | 2300-6586 | 5,50 | ||

| 2300-0178 | 2300-0452 | 2300-2429 | 2300-2579 | 2300-6187 | 2300-6188 | 2300-6587 | 2300-6588 | 5,60 | ||

| 2300-0179 | 2300-0453 | 2300-2430 | 2300-2580 | 2300-6191 | 2300-6192 | 2300-6591 | 2300-6592 | 5,70 | ||

| 2300-0180 | 2300-0454 | 2300-2431 | 2300-2581 | 2300-6193 | 2300-6194 | 2300-6593 | 2300-6594 | 5,80 | ||

| 2300-0306 | 2300-0560 | 2300-2432 | 2300-2582 | 2300-6195 | 2300-6196 | 2300-6595 | 2300-6596 | 5,90 | ||

| 2300-3401 | 2300-8169 | 2300-3402 | 2300-6598 | 2300-0181 | 2300-0455 | 2300-2433 | 2300-2583 | 6,00 | ||

| 2300-3403 | 2300-6202 | 2300-3404 | 2300-6602 | 2300-0182 | 2300-0456 | 2300-2434 | 2300-2584 | 6,10 | 101 | 63 |

| 2300-3405 | 2300-6204 | 2300-3406 | 2300-6604 | 2300-0183 | 2300-0457 | 2300-2435 | 2300-2585 | 6,20 | ||

| 2300-3407 | 2300-6206 | 2300-3408 | 2300-6606 | 2300-0184 | 2300-0458 | 2300-2436 | 2300-2586 | 6,30 | ||

| 2300-3409 | 2300-6208 | 2300-3410 | 2300-6608 | 2300-0307 | 2300-0561 | 2300-2437 | 2300-2587 | 6,40 | ||

| 2300-3411 | 2300-6212 | 2300-3412 | 2300-6612 | 2300-0185 | 2300-0459 | 2300-2438 | 2300-2588 | 6,50 | ||

| 2300-3413 | 2300-6214 | 2300-3414 | 2300-6614 | 2300-0308 | 2300-0562 | 2300-2439 | 2300-2589 | 6,60 | ||

| 2300-3415 | 2300-6216 | 2300-3416 | 2300-6616 | 2300-0186 | 2300-0460 | 2300-2440 | 2300-2590 | 6,70 | ||

| 2300-3417 | 2300-6218 | 2300-3418 | 2300-6618 | 2300-0309 | 2300-0563 | 2300-2441 | 2300-2591 | 6,80 | 109 | 69 |

| 2300-3419 | 2300-6222 | 2300-3420 | 2300-6622 | 2300-0310 | 2300-0564 | 2300-2442 | 2300-2592 | 6,90 | ||

| 2300-3421 | 2300-6224 | 2300-3422 | 2300-6624 | 2300-0187 | 2300-0461 | 2300-2443 | 2300-2593 | 7,00 | ||

| 2300-3423 | 2300-6226 | 2300-3424 | 2300-6626 | 2300-0188 | 2300-0462 | 2300-2444 | 2300-2594 | 7,10 | ||

| 2300-3425 | 2300-6228 | 2300-3426 | 2300-6628 | 2300-0189 | 2300-0463 | 2300-2445 | 2300-2595 | 7,20 | ||

| 2300-3427 | 2300-6232 | 2300-3428 | 2300-6632 | 2300-0190 | 2300-0464 | 2300-2446 | 2300-2596 | 7,30 | ||

| 2300-6233 | 2300-6234 | 2300-6633 | 2300-6634 | 2300-5052 | 2300-5053 | 2300-5054 | 2300-5055 | 7,40 | ||

| 2300-3429 | 2300-6236 | 2300-3430 | 2300-6636 | 2300-0191 | 2300-0465 | 2300-2447 | 2300-2597 | 7,50 | ||

| 2300-3431 | 2300-6238 | 2300-3432 | 2300-6638 | 2300-0192 | 2300-0466 | 2300-2448 | 2300-2598 | 7,60 | 117 | 75 |

| 2300-3433 | 2300-6242 | 2300-3434 | 2300-6642 | 2300-0193 | 2300-0467 | 2300-2449 | 2300-2599 | 7,70 | ||

| 2300-3435 | 2300-6244 | 2300-3436 | 2300-6644 | 2300-0194 | 2300-0468 | 2300-2450 | 2300-2600 | 7,80 | ||

| 2300-3437 | 2300-6246 | 2300-3438 | 2300-6646 | 2300-0311 | 2300-0565 | 2300-2451 | 2300-2601 | 7,90 | ||

| 2300-3439 | 2300-6248 | 2300-3440 | 2300-6648 | 2300-0195 | 2300-0469 | 2300-2452 | 2300-2602 | 8,00 | ||

| 2300-3441 | 2300-6252 | 2300-3442 | 2300-6652 | 2300-0196 | 2300-0470 | 2300-2453 | 2300-2603 | 8,10 | ||

| 2300-3443 | 2300-6254 | 2300-3444 | 2300-6654 | 2300-0197 | 2300-0471 | 2300-2454 | 2300-2604 | 8,20 | ||

| 2300-3445 | 2300-6256 | 2300-3446 | 2300-6656 | 2300-0198 | 2300-0472 | 2300-2455 | 2300-2605 | 8,30 | ||

| 2300-3447 | 2300-6258 | 2300-3448 | 2300-6658 | 2300-0199 | 2300-0473 | 2300-2456 | 2300-2606 | 8,40 | ||

| 2300-3449 | 2300-6262 | 2300-3450 | 2300-6662 | 2300-0200 | 2300-0474 | 2300-2457 | 2300-2607 | 8,50 | ||

| 2300-3451 | 2300-6264 | 2300-3452 | 2300-6664 | 2300-0312 | 2300-0566 | 2300-2458 | 2300-2608 | 8,60 | 125 | 81 |

| 2300-3453 | 2300-6266 | 2300-3454 | 2300-6666 | 2300-0201 | 2300-0475 | 2300-2459 | 2300-2609 | 8,70 | ||

| 2300-3455 | 2300-6268 | 2300-3456 | 2300-6668 | 2300-0313 | 2300-0567 | 2300-2460 | 2300-2610 | 8,80 | ||

| 2300-3457 | 2300-6272 | 2300-3458 | 2300-6672 | 2300-0202 | 2300-0476 | 2300-2461 | 2300-2611 | 8,90 | ||

| 2300-3459 | 2300-6274 | 2300-3460 | 2300-6674 | 2300-0203 | 2300-0477 | 2300-2462 | 2300-2612 | 9,00 | ||

| 2300-3461 | 2300-6276 | 2300-3462 | 2300-6676 | 2300-0314 | 2300-0568 | 2300-2463 | 2300-2613 | 9,10 | ||

| 2300-3463 | 2300-6278 | 2300-3464 | 2300-6678 | 2300-0204 | 2300-0478 | 2300-2464 | 2300-2614 | 9,20 | ||

| 2300-3465 | 2300-6282 | 2300-3466 | 2300-6682 | 2300-0315 | 2300-0569 | 2300-2465 | 2300-2615 | 9,30 | ||

| 2300-3467 | 2300-6284 | 2300-3468 | 2300-6684 | 2300-0316 | 2300-0570 | 2300-2466 | 2300-2616 | 9,40 | ||

| 2300-3469 | 2300-6286 | 2300-3470 | 2300-6686 | 2300-0205 | 2300-0479 | 2300-2467 | 2300-2617 | 9,50 | ||

| 2300-3471 | 2300-6288 | 2300-3472 | 2300-6688 | 2300-0206 | 2300-0480 | 2300-2468 | 2300-2618 | 9,60 | 133 | 87 |

| 2300-3473 | 2300-6292 | 2300-3474 | 2300-6692 | 2300-0207 | 2300-0481 | 2300-2469 | 2300-2619 | 9,70 | ||

| 2300-3475 | 2300-6294 | 2300-3476 | 2300-6694 | 2300-0317 | 2300-0571 | 2300-2470 | 2300-2620 | 9,80 | ||

| 2300-3477 | 2300-6296 | 2300-3478 | 2300-6696 | 2300-0318 | 2300-0572 | 2300-2471 | 2300-2621 | 9,90 | ||

| 2300-3479 | 2300-6298 | 2300-3480 | 2300-6698 | 2300-0208 | 2300-0482 | 2300-2472 | 2300-2622 | 10,00 | ||

| 2300-3481 | 2300-6302 | 2300-3482 | 2300-6702 | 2300-0209 | 2300-0483 | 2300-2473 | 2300-2623 | 10,10 | ||

| 2300-3483 | 2300-6304 | 2300-3484 | 2300-6704 | 2300-0210 | 2300-0484 | 2300-2474 | 2300-2624 | 10,20 | ||

| 2300-3485 | 2300-6306 | 2300-3486 | 2300-6706 | 2300-0319 | 2300-0573 | 2300-2475 | 2300-2625 | 10,30 | ||

| 2300-3487 | 2300-6308 | 2300-3488 | 2300-6708 | 2300-0211 | 2300-0485 | 2300-2476 | 2300-2626 | 10,40 | ||

| 2300-3489 | 2300-6312 | 2300-3490 | 2300-6712 | 2300-0212 | 2300-0486 | 2300-2477 | 2300-2627 | 10,50 | ||

| 2300-3491 | 2300-6314 | 2300-3492 | 2300-6714 | 2300-0320 | 2300-0574 | 2300-2478 | 2300-2628 | 10,60 | ||

| 2300-3493 | 2300-6316 | 2300-3494 | 2300-6716 | 2300-0213 | 2300-0487 | 2300-2479 | 2300-2629 | 10,70 | 142 | 94 |

| 2300-3495 | 2300-6318 | 2300-3496 | 2300-6718 | 2300-0321 | 2300-0575 | 2300-2480 | 2300-2630 | 10,80 | ||

| 2300-3497 | 2300-6322 | 2300-3498 | 2300-6722 | 2300-0322 | 2300-0576 | 2300-2481 | 2300-2631 | 10,90 | ||

| 2300-3499 | 2300-6324 | 2300-3500 | 2300-6724 | 2300-0214 | 2300-0488 | 2300-2482 | 2300-2632 | 11,00 | ||

| 2300-3501 | 2300-6326 | 2300-3502 | 2300-6726 | 2300-0323 | 2300-0577 | 2300-2483 | 2300-2633 | 11,10 | ||

| 2300-3503 | 2300-6328 | 2300-3504 | 2300-6728 | 2300-0215 | 2300-0489 | 2300-2484 | 2300-2634 | 11,20 | ||

| 2300-3505 | 2300-6332 | 2300-3506 | 2300-6732 | 2300-0324 | 2300-0578 | 2300-2485 | 2300-2635 | 11,30 | ||

| 2300-3507 | 2300-6334 | 2300-3508 | 2300-6734 | 2300-0325 | 2300-0579 | 2300-2486 | 2300-2636 | 11,40 | ||

| 2300-3509 | 2300-6336 | 2300-3510 | 2300-6736 | 2300-0216 | 2300-0490 | 2300-2487 | 2300-2637 | 11,50 | ||

| 2300-6337 | 2300-6338 | 2300-6737 | 2300-6738 | 2300-5056 | 2300-5057 | 2300-5058 | 2300-5059 | 11,60 | ||

| 2300-3511 | 2300-6342 | 2300-3512 | 2300-6742 | 2300-0217 | 2300-0491 | 2300-2488 | 2300-2638 | 11,70 | ||

| 2300-3513 | 2300-6344 | 2300-3514 | 2300-6744 | 2300-0326 | 2300-0580 | 2300-2489 | 2300-2639 | 11,80 | ||

| 2300-3515 | 2300-6346 | 2300-3516 | 2300-6746 | 2300-0218 | 2300-0492 | 2300-2490 | 2300-2640 | 11,90 | 151 | 101 |

| 2300-3517 | 2300-6348 | 2300-3518 | 2300-6748 | 2300-0219 | 2300-0493 | 2300-2491 | 2300-2641 | 12,00 | ||

| 2300-6351 | 2300-6352 | 2300-6751 | 2300-6752 | 2300-0327 | 2300-0581 | 2300-2492 | 2300-2642 | 12,10 | ||

| 2300-6353 | 2300-6354 | 2300-6753 | 2300-6754 | 2300-0328 | 2300-0582 | 2300-2493 | 2300-2643 | 12,20 | ||

| 2300-6355 | 2300-6356 | 2300-6755 | 2300-6756 | 2300-0329 | 2300-0583 | 2300-2494 | 2300-2644 | 12,30 | ||

| 2300-6357 | 2300-6358 | 2300-6757 | 2300-6758 | 2300-0330 | 2300-0584 | 2300-2495 | 2300-2645 | 12,40 | ||

| 2300-6361 | 2300-6362 | 2300-6761 | 2300-6762 | 2300-0220 | 2300-0494 | 2300-2496 | 2300-2646 | 12,50 | ||

| 2300-6363 | 2300-6364 | 2300-6763 | 2300-6764 | 2300-0331 | 2300-0585 | 2300-2497 | 2300-2647 | 12,60 | ||

| 2300-6365 | 2300-6366 | 2300-6765 | 2300-6766 | 2300-0221 | 2300-0495 | 2300-2498 | 2300-2648 | 12,70 | ||

| 2300-6367 | 2300-6368 | 2300-6767 | 2300-6768 | 2300-0332 | 2300-0586 | 2300-2499 | 2300-2649 | 12,80 | ||

| 2300-6371 | 2300-6372 | 2300-6771 | 2300-6772 | 2300-5061 | 2300-5062 | 2300-5063 | 2300-5064 | 12,90 | ||

| 2300-6373 | 2300-6374 | 2300-6773 | 2300-6774 | 2300-0222 | 2300-0496 | 2300-2500 | 2300-2650 | 13,00 | ||

| 2300-6375 | 2300-6376 | 2300-6775 | 2300-6776 | 2300-0333 | 2300-0587 | 2300-2501 | 2300-2651 | 13,10 | ||

| 2300-6377 | 2300-6378 | 2300-6777 | 2300-6778 | 2300-0223 | 2300-0497 | 2300-2502 | 2300-2652 | 13,20 | ||

| 2300-6381 | 2300-6382 | 2300-6781 | 2300-6782 | 2300-0334 | 2300-0588 | 2300-2503 | 2300-2653 | 13,30 | 160 | 108 |

| 2300-6383 | 2300-6384 | 2300-6783 | 2300-6784 | 2300-5065 | 2300-5066 | 2300-5067 | 2300-5068 | 13,40 | ||

| 2300-6385 | 2300-6386 | 2300-6785 | 2300-6786 | 2300-0224 | 2300-0498 | 2300-2504 | 2300-2654 | 13,50 | ||

| 2300-6387 | 2300-6388 | 2300-6787 | 2300-6788 | 2300-5069 | 2300-5071 | 2300-5072 | 2300-5073 | 13,60 | ||

| 2300-6391 | 2300-6392 | 2300-6791 | 2300-6792 | 2300-0225 | 2300-0499 | 2300-2505 | 2300-2655 | 13,70 | ||

| 2300-6393 | 2300-6394 | 2300-6793 | 2300-6794 | 2300-5074 | 2300-5075 | 2300-5076 | 2300-5077 | 13,75 | ||

| 2300-6395 | 2300-6396 | 2300-6795 | 2300-6796 | 2300-0335 | 2300-0589 | 2300-2506 | 2300-2656 | 13,80 | ||

| 2300-6397 | 2300-6398 | 2300-6797 | 2300-6798 | 2300-5078 | 2300-5079 | 2300-5081 | 2300-5082 | 13,90 | ||

| 2300-6401 | 2300-6402 | 2300-6801 | 2300-6802 | 2300-0226 | 2300-0500 | 2300-2507 | 2300-2657 | 14,00 | ||

| 2300-6403 | 2300-6404 | 2300-6803 | 2300-6804 | 2300-0227 | 2300-0501 | 2300-2508 | 2300-2658 | 14,25 | 169 | 114 |

| 2300-6405 | 2300-6406 | 2300-6805 | 2300-6806 | 2300-0228 | 2300-0502 | 2300-2509 | 2300-2659 | 14,50 | ||

| 2300-6407 | 2300-6408 | 2300-6807 | 2300-6808 | 2300-0336 | 2300-0590 | 2300-2510 | 2300-2660 | 14,75 | ||

| 2300-6411 | 2300-6412 | 2300-6811 | 2300-6812 | 2300-0230 | 2300-0504 | 2300-2511 | 2300-2661 | 15,00 | ||

| 2300-6413 | 2300-6414 | 2300-6813 | 2300-6814 | 2300-0231 | 2300-0505 | 2300-2512 | 2300-2662 | 15,25 | 178 | 120 |

| 2300-6415 | 2300-6416 | 2300-6815 | 2300-6816 | 2300-0232 | 2300-0506 | 2300-2513 | 2300-2663 | 15,40 | ||

| 2300-6417 | 2300-6418 | 2300-6817 | 2300-6818 | 2300-0233 | 2300-0507 | 2300-2514 | 2300-2664 | 15,50 | ||

| 2300-6421 | 2300-6422 | 2300-6821 | 2300-6822 | 2300-0337 | 2300-0591 | 2300-2515 | 2300-2665 | 15,75 | ||

| 2300-6423 | 2300-6424 | 2300-6823 | 2300-6824 | 2300-0234 | 2300-0508 | 2300-2516 | 2300-2666 | 16,00 | ||

| 2300-6425 | 2300-6426 | 2300-6825 | 2300-6826 | 2300-0235 | 2300-0509 | 2300-2517 | 2300-2667 | 16,25 | 184 | 125 |

| 2300-6427 | 2300-6428 | 2300-6827 | 2300-6828 | 2300-0236 | 2300-0510 | 2300-2518 | 2300-2668 | 16,50 | ||

| 2300-6431 | 2300-6432 | 2300-6831 | 2300-6832 | 2300-0338 | 2300-0592 | 2300-2519 | 2300-2669 | 16,75 | ||

| 2300-6433 | 2300-6434 | 2300-6833 | 2300-6834 | 2300-0237 | 2300-0511 | 2300-2520 | 2300-2670 | 17,00 | ||

| 2300-6435 | 2300-6436 | 2300-6835 | 2300-6836 | 2300-0238 | 2300-0512 | 2300-2521 | 2300-2671 | 17,25 | 191 | 130 |

| 2300-6437 | 2300-6438 | 2300-6837 | 2300-6838 | 2300-0239 | 2300-0513 | 2300-2522 | 2300-2672 | 17,40 | ||

| 2300-6441 | 2300-6442 | 2300-6841 | 2300-6842 | 2300-0240 | 2300-0514 | 2300-2523 | 2300-2673 | 17,50 | ||

| 2300-6443 | 2300-6444 | 2300-6843 | 2300-6844 | 2300-0339 | 2300-0593 | 2300-2524 | 2300-2674 | 17,75 | ||

| 2300-6445 | 2300-6446 | 2300-6845 | 2300-6846 | 2300-0241 | 2300-0515 | 2300-2525 | 2300-2675 | 18,00 | ||

| 2300-6447 | 2300-6448 | 2300-6847 | 2300-6848 | 2300-0242 | 2300-0516 | 2300-2526 | 2300-2676 | 18,25 | 198 | 135 |

| 2300-6451 | 2300-6452 | 2300-6851 | 2300-6852 | 2300-0243 | 2300-0517 | 2300-2527 | 2300-2677 | 18,50 | ||

| 2300-6453 | 2300-6454 | 2300-6853 | 2300-6854 | 2300-0244 | 2300-0518 | 2300-2528 | 2300-2678 | 18,75 | ||

| 2300-6455 | 2300-6456 | 2300-6855 | 2300-6856 | 2300-0245 | 2300-0519 | 2300-2529 | 2300-2679 | 19,00 | ||

| 2300-6457 | 2300-6458 | 2300-6857 | 2300-6858 | 2300-0246 | 2300-0520 | 2300-2530 | 2300-2680 | 19,25 | 205 | 140 |

| 2300-6461 | 2300-6462 | 2300-6861 | 2300-6862 | 2300-0247 | 2300-0521 | 2300-2531 | 2300-2681 | 19,40 | ||

| 2300-6463 | 2300-6464 | 2300-6863 | 2300-6864 | 2300-0248 | 2300-0522 | 2300-2532 | 2300-2682 | 19,50 | ||

| 2300-6465 | 2300-6466 | 2300-6865 | 2300-6866 | 2300-0340 | 2300-0594 | 2300-2533 | 2300-2683 | 19,75 | ||

| 2300-6467 | 2300-6468 | 2300-6867 | 2300-6868 | 2300-0249 | 2300-0523 | 2300-2534 | 2300-2684 | 20,00 | ||

| ________________ * Corresponds to the original. — Note "CODE". | ||||||||||

An example of a symbol for a high-precision drill with a diameter of = 15 mm, right-hand, version 1, accuracy class A1:

Drill 2300-6411-A1 GOST 10902-77

An example of a symbol for a normal precision drill with a diameter = 15 mm, right-hand, version 1, accuracy class B:

Drill 2300-0230 GOST 10902-77

The same, accuracy class B1:

Drill 2300-0230-B1 GOST 10902-77

1, 2. (Changed edition, Amendment No. 1, 2).

3. The main dimensions of drills with intermediate diameters that differ from those regulated in the standard are indicated in the appendix. (Introduced additionally, Amendment No. 1).

4. Center holes - according to GOST 14034. It is allowed to manufacture drills without center holes.

5. Dimensions of drill drivers - according to ST SEV 198.

6. Technical requirements - according to GOST 2034.

7. Drills can be made with or without a neck. Neck sizes are not regulated.

8. Structural elements and geometric parameters of drill cutting elements - in accordance with GOST 4010.

APPENDIX Reference

MAIN DIMENSIONS OF DRILLS WITH INTERMEDIATE DIAMETERS

The main dimensions of drills with intermediate diameters that differ from those regulated in the standard must correspond to those indicated in the table below.

mm

| over | before | ||

| 0,24 | 0,30 | 3 | 19 |

| 0,30 | 0,38 | 4 | 19 |

| 0,38 | 0,48 | 5 | 20 |

| 0,48 | 0,53 | 6 | 22 |

| 0,53 | 0,60 | 7 | 24 |

| 0,60 | 0,67 | 8 | 26 |

| 0,67 | 0,75 | 9 | 28 |

| 0,75 | 0,85 | 10 | 30 |

| 0,85 | 0,95 | 11 | 32 |

| 0,95 | 1,06 | 12 | 34 |

| 1,06 | 1,18 | 14 | 36 |

| 1,18 | 1,32 | 16 | 38 |

| 1,32 | 1,50 | 18 | 40 |

| 1,50 | 1,70 | 20 | 43 |

| 1,70 | 1,90 | 22 | 46 |

| 1,90 | 2,12 | 24 | 49 |

| 2,12 | 2,36 | 27 | 53 |

| 2,36 | 2,65 | 30 | 57 |

| 2,65 | 3,00 | 33 | 61 |

| 3,00 | 3,35 | 36 | 65 |

| 3,35 | 3,75 | 39 | 70 |

| 3,75 | 4,25 | 43 | 75 |

| 4,25 | 4,75 | 47 | 80 |

| 4,75 | 5,30 | 52 | 86 |

| 5,30 | 6,00 | 57 | 93 |

| 6,00 | 6,70 | 63 | 101 |

| 6,70 | 7,50 | 69 | 109 |

| 7,50 | 8,50 | 75 | 117 |

| 8,50 | 9,50 | 81 | 125 |

| 9,50 | 10,60 | 87 | 133 |

| 10,60 | 11,80 | 94 | 142 |

| 11,80 | 13,20 | 101 | 151 |

| 13,20 | 14,00 | 108 | 160 |

| 14,00 | 15,00 | 114 | 169 |

| 15,00 | 16,00 | 120 | 178 |

| 16,00 | 17,00 | 125 | 185 |

| 17,00 | 18,00 | 130 | 195 |

| 18,00 | 19,00 | 135 | 200 |

| 19,00 | 20,00 | 140 | 205 |

| 20,00 | 21,20 | 145 | 210 |

The lengths and can vary within one diameter interval between the minimum and maximum values corresponding to those given in the table for the nearest lower and upper limit of the interval. For example, for a diameter of 4.1 mm, the length can vary from 39 to 47 mm with a nominal value of 43 mm, and the length can vary from 70 to 80 mm with a nominal value of 75 mm. Note. The drill diameter values specified in the appendix are not recommended for use. APPLICATION. (Introduced additionally, Amendment No. 1). The text of the document is verified according to: official publication Twist drills. Part 1: Sat. GOST. - M.: IPK Publishing House of Standards, 2003

Classification of drills by purpose

It is recommended to use a specific type of drill for each material. Illiterate use of cutting tools often leads to damage to equipment, fittings and, of course, the source material. To avoid such mistakes, you need to know which type of drill will do the best job for a particular job.

Drills for working with metal

Drilling in metal is usually carried out with a milling, twist or step drill. The material used to make such drills is usually high-speed steel. This should be indicated by appropriate markings. If it is missing, the product should be treated with caution - there are many low-quality fakes on the construction market. The table below contains information about which grade of drill bit is suitable for a specific type of metal.

| Markings on Russian products | Marking on foreign products | Characteristics, scope |

| M1 | HSS-R, HSS | Basic metal drills with average wear resistance, not very resistant to overheating and impact, but are inexpensive. You can drill shallow holes. |

| R6M5, M2 | HSS-G | They have a wide range of applications. High levels of wear resistance, strength, and impact resistance. Suitable for forming holes of any depth in sheets of carbon and alloy steel, in alloys of cast iron and non-ferrous metals. |

| R6M5K5, M35 | HSS Co, HSS-E | Recommended for processing stainless steels. |

| — | HSS-G TiAlN, HSS-G TiN | Metal drills of maximum hardness and heat resistance. The cost of the tool is high, but you can drill particularly strong metals and titanium alloys. Sharpening of drills of this type is not allowed. |

In addition to the marking, the sharpening angle may indicate the purpose of the tool. The sharper it is, the softer the alloy should be. For such cases, the optimal angle is 80-90º, for drilling cast iron and steel alloys - 100-120º, for harder metals - 130-140º.

Wood drills

The following types of drills are used for working with wood:

- spiral;

- feathers;

- Lewis spiral;

- Forstner;

- milling, etc.

A twist drill for wood is visually not much different from a drill for metal, but it requires special sharpening with a centering spike. Therefore, to make holes with increased accuracy and a smooth, clean surface, you need to use a wood drill with an appropriate working surface, made of carbon or tool steel.

Drill bits for concrete/brick

To work with brick, concrete, stone and similar materials, you need a special concrete drill tipped with a high-hardness alloy, for example, Pobedit, on the tip of the working surface. The operation of drilling concrete itself is somewhat different: the drill or drill, together with rotational movements, must perform shock-translational movements. In this case, the stone will not be cut, but crushed. It will be difficult to make a hole in concrete more than 6 mm deep with a drill, even an impact drill. Therefore, to work on concrete, brick or stone, you need a hammer drill and high-strength drills.

To make large-diameter holes in concrete, brick or stone, a core drill with diamond coating or carbide teeth will help.

Drill bit for tiles/glass

Working with tiles/glass requires special care and, accordingly, special tools. For these purposes, tubular diamond drills (crown), as well as feather (spear-shaped) drills soldered with tungsten carbide or Pobedit, are used. The effectiveness of tools of these configurations is the same, however, for drilling large holes in tiles, it is better to use a crown, and for glass - a feather. To make large holes in the tiles, use a “ballerina” device. At minimum speed, drilling is performed from the back of the tile.

Universal drills

In addition to drills for narrow purposes, there are universal ones. They can be sold individually or as a set. Thanks to the special sharpening, such drills can process almost any material from wood to steel and ceramics. Most often this is a pobedite soldered tool. The packaging with a set of drills usually indicates what materials they are suitable for.

Drill sharpening

Any drill wears out during use. You can work with wood without thinking about sharpening the drill for months. But for drilling metal, the sharpness of the tool is extremely important. Only a well-sharpened drill can handle this material. Let's look at the signs that indicate a drill requires immediate sharpening.

- slow and uneven immersion into the material being processed;

- strong heating during operation;

- “chewing” the material instead of cutting;

- drilling is accompanied by a creaking-squealing sound;

- finished products have jagged edges and a rough interior surface.

Most often, such drills are thrown away or used for soft materials - many craftsmen do not consider it necessary to give the tool a second life. However, at home, you can build a device for sharpening drills from the tools available in almost every workshop.