The metal bit is designed for drilling large-diameter through holes in sheet and profile metal products. This is one of the few cutting tools that has several parallel names not only in everyday life, but also in professional literature. In GOST 17013-71 it is called a ring drill. But since it has a tubular design of the working part, it is often referred to as a hollow or tubular drill in metalworking textbooks and catalogs of Russian manufacturers. When drilling with such a tool, the cutting process is carried out by teeth located evenly around the circumference of its working end. In appearance, this configuration of the cutting part resembles a crown, so another name for a metal crown is a core drill. And since in its appearance and operating principle it is more similar to a milling tool, you can also find another name - annular cutter.

Types of crowns for metal

The classification of core drills for metal is made according to the following main characteristics:

- material of the cutting teeth of the crown;

- type of shank;

- working part designs;

- geometric size (including maximum drilling depth).

There are two basic types of cutting parts for metal bits: with teeth made of high-speed steel and teeth made of carbide materials. The former are cheaper and less productive, but nevertheless much more efficient than conventional drilling tools. The latter operate at higher cutting speeds and, as a rule, are used when drilling high-chromium steels and hard alloys. The cheapest are bimetallic crowns for metal, in which the cutting part is made of high-speed cutters, and the main body is made of ordinary structural steel.

For core drills, the most common type of shank is Weldon. In addition, tools are produced with Nitto shanks, which are compatible with Weldon, as well as according to the standard of the German company Fein, whose shanks are suitable only for power tools from this company. The working part of metal crowns is characterized by the number of cutting teeth and, accordingly, the number of spiral grooves and ribbons, which can be from four to sixteen or more.

Many manufacturers include a separate group of tools with an extended working part, designed for deep drilling, as well as bits for drilling railway rails.

Carbide bits for metal

In carbide bits for metal, cutting teeth made of carbide are attached to the body by soldering, since all three surfaces are working surfaces. This is a higher performance tool, capable of working at high speeds on alloy metals, stainless steel and aluminum alloys with a high silicon content. Compared to monolithic metal crowns made from quick cutters, it is less resistant to vibrations and variable loads. One of its main disadvantages is the difficulty of replacing or regrinding the cutting teeth if they become dull or broken. There are also core drills with a diamond cutting part, but they are not intended for metal work.

Design and characteristics of core drills

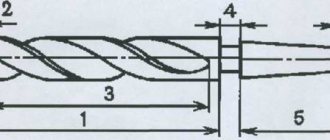

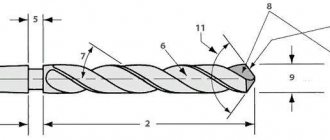

Despite the features of individual models, the basic designs of all metal crowns are approximately the same. All of them consist of a shank, a guide part with spiral grooves and a cutting crown consisting of an even number of teeth (see figure below).

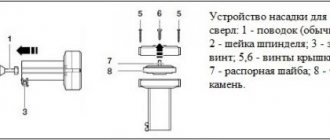

The guide part of such a tool is hollow. When drilling, a metal core is advanced into its internal space, which is knocked out with a special pusher at the end of the operation. The central channel runs through the entire body. A pusher pointed at the end (often spring-loaded) is inserted into it, which, in addition to pushing out the metal core, serves to center the bit on the metal before drilling begins. Also, a centering drill can be attached along the axis of the central channel. In addition, on some models, coolant is supplied to the central channel through a side valve. Due to the large number of cutting teeth, a core drill requires significant cutting force to operate. Therefore, such tools, as a rule, have shanks with flats or grooves for reliable fixation in the chuck. Metal bits designed for conventional drills have a small diameter and cylindrical shanks.

Cutting part

The cutting part of the metal bits consists of an even number of teeth, evenly distributed along the working end of the body. Since this tool is designed for making an annular groove, all its teeth have three cutting edges: one frontal and two lateral (see photo below). For this feature, metal crowns are sometimes called annular cutters, since this cutting method is characteristic not of a drilling tool, but of a milling tool. The number of cutting teeth directly depends on the diameter of the core drill. Small and medium-sized instruments most often have four to six.

Types of shanks

To date, three types of shanks have become the de facto standard for crowns intended for drilling metal (see figure below):

- WELDON. The most common type of shank. It is a short cylinder with a diameter of 19 or 32 mm with three flats. Chucks with WELDON standard sockets can only accept this type of shank.

- UNIVERSAL (other names ONE-TOUCH and NITTO). In accordance with its name, it is a universal shank and can be mounted both in WELDON chucks and in a number of chucks from other manufacturers, except for QUICK –IN standard equipment.

- QUICK –IN. Fit standard of the well-known power tool manufacturer FEIN. Compatible only with devices from this company.

In addition, many manufacturers offer a wide selection of adapters and extensions to accommodate different standards, as well as adapter mandrels for different spindle tapers.

Advantages and overview of drill attachments for cutting wood and metal

Devices for cutting metal or wood are used in cases where it is not possible to perform this procedure in any other way. In addition, they will be useful if heating the sheet material during cutting is undesirable.

Advantages of attachments over an angle grinder:

Attachments for cutting wood and metal are capable of performing their functions quickly and efficiently

- High quality cut.

- Possibility to make holes of any shape in the material.

- There is no need to purchase consumables (discs for an angle grinder).

- Simple system of use.

- Some attachments can cut sheet plastic of a certain thickness.

- If a cordless drill is used for work, the tool becomes mobile. It does not depend on the power grid and can be used in field conditions.

- Light weight.

Review of drill attachments for cutting sheet metal

Three types of attachments are used for cutting metal sheets: “Cricket”, “Scissors” and “Beaver”. Each of them has its own characteristics, structure and is designed for cutting material of a certain thickness.

When using the “Scissors” attachment on a drill, the rotation of the chuck on the tool is converted into reciprocating movements. As a result of this, a special matrix knocks out a strip in the metal and separates the material. The thickness of this line is 3.1 mm. With this method of cutting sheets, the cut is high-quality and even. The “Scissors” attachment allows you to completely avoid finishing the edges on the metal or reduce it to a minimum.

The Cricket attachment is capable of cutting not only sheet metal, but is also suitable for plastic

The Beaver attachment works in a similar way, only it can be used to make both straight and curved cuts, the minimum radius of which is 12 mm.

The “Cricket” drill attachment can be considered a universal device, since it can be used to cut not only metal, but also plastic sheets. In some cases, it can be used for cutting profile products. The device is equipped with two cutting heads that ensure a perfectly even cut.

Table showing restrictions on material processing by thickness:

| Material type | Recommended thickness, mm |

| "Nibblers" | |

| Stainless steel | up to 0.8 |

| Brass and copper | up to 1.5 |

| Aluminum | up to 2 |

| "Cricket" | |

| Stainless steel | up to 1.2 |

| Steel | up to 1.5 |

| Aluminum | up to 2 |

| Plastic | up to 2 |

| "Beaver" | |

| Stainless steel | up to 1.3 |

| Steel | up to 1.8 |

| Aluminum | up to 2 |

The main types of drill attachments for cutting wood

The nozzle designed for cutting wood has a rather complex structure. This mechanism is similar in principle to a jigsaw. Using this device, you can cut wood whose thickness does not exceed 2 cm, as well as cut plywood sheets and chipboards.

In addition, the saw attachment on the drill can be used not only for wood, but also for cutting plastic and thin sheets of steel. For this reason, this device will be a very useful addition to the tool kit in a home workshop. It is worth noting that the cost of such an attachment is very high, this is due to the complex structure of its mechanism.

You can find entire sets on sale that include:

- the nozzle itself (mechanism);

- three reciprocating files of different configurations;

- hex wrench for chuck.

The saw-style drill attachment is suitable for wood, plastic and even thin sheets of steel

Reciprocating files are made of durable plastic. The removable devices included in the kit vary in the length and shape of the teeth. The scope of their application depends on the configuration of these products. There are these types of files:

- for cutting wood;

- for quick cutting on wood;

- for cutting metal (the file is short and has small teeth).

Removable plastic files are lightweight and therefore very convenient to use. The attachments are secured in the lock with a special screw.

Metal crown markings

A twist drill and a metal crown are marked almost identically. The shanks of both products are marked with the manufacturer's trademark, material grade, coating type and tool diameter. For core drills, the length of the working part is additionally indicated (see photo below). All other technological characteristics are contained in catalogs, and some of them are applied to the packaging. Moreover, each manufacturer uses its own system for designating product characteristics, which primarily includes the types of processed materials with maximum drilling parameters.

About the benefits

If we compare metal crowns with other types of drills, we can highlight several of the most important advantages.

These include:

- thanks to the special design, the hole can be made along the contours;

- for work you do not have to use devices with reinforced wires;

- with the help of such nozzles it is possible to obtain holes with a rough inner surface - other types of nozzles do not allow this to be achieved;

- attachments are suitable for use with any drilling equipment - drills, machines, milling machines and lathes;

- metal crowns allow for multi-tool processing;

- the area of contact between the drill and the surface being processed is quite noticeable;

- Several metal layers can be processed at once in one pass.

The drilling process itself using metal crowns is characterized by increased productivity. The entire work process is performed not only quickly, but also with maximum accuracy. No drilling attachment can guarantee such qualities. In addition, the work is not accompanied by a lot of noise. At the same time, the metal crowns themselves are economical and ergonomic. One revolution of the crown bit can remove a fairly large amount of metal.

Pros of core drills

Ring bits for metal have no equal when drilling through holes of large diameter in rolled metal several tens of millimeters thick. When using conventional tools, this operation usually involves drilling followed by incremental reaming or boring. In this case, the entire mass of metal located at the site of the hole is cut off. During the drilling process with a crown, metal is sampled only in a groove located along the perimeter of the future hole, and the main part of it remains intact. This technology has a number of undeniable advantages over traditional drilling. The most significant among them:

- the ability to produce holes with a diameter of up to 200 mm in one installation of the tool;

- high productivity and, as a result, a significant reduction in cutting time;

- energy saving;

- less wear of cutting edges due to their larger number;

- work at high feeds and low speeds;

- effective cooling of the working area.

Perhaps the only drawback of metal crowns is their inability to drill blind holes. Sometimes it is pointed out that these products are much more expensive than conventional twist drills. But here it is necessary to take into account the fact that the total cost (tool consumption, labor costs, energy intensity, etc.) of producing a large-diameter hole with a traditional tool is much higher than with an annular drill with a cutting crown. In addition, due to the presence of a large number of cutting edges, the service life of such a tool is much greater than the service life of twist drills.

Preparatory operations for work

It must be taken into account that to prevent rotation, manufacturers create an irregularly shaped socket for fitting the tool. More experienced specialists remind you that for high-quality fixation it is necessary to tighten the thrust nut or bolt well. This will allow the cutting tool to be securely held in the grooves and not to become loose, deforming and bending the hole.

Example of the resulting hole

It is necessary to install the tool into the drill chuck only after all threads have been tightened. Then you can start drilling at the selected point. The process is practically no different from working with a classic drill.

It is important during the operation to maintain maximum perpendicularity to the axis of rotation of the plane being treated. This factor is maintained in the first millimeters, then everything follows the initially formed cylinder

The number of revolutions for rotating the crown is also set in advance. It is worth considering that an increase in the diameter of a tool is combined with an increase in its vibration. This forces the use of more powerful drills if you take wood drills for large holes and large diameters. If possible, attach an additional handle to support and maintain perpendicularity.

When setting the rotation speed on a drill, you need to follow these rules:

- soft wood can be processed at speeds from 1000 (diameter 3.0-5.0 cm) to 2400 rpm (diameter 10-55 mm);

- for hard wood, it is advisable to increase the speed to 250 rpm (3.0-5.0 cm) to 600 rpm (1.0-1.5 cm);

- When using bits with carbide tips, you cannot lower the speed below 400-500 rpm, as the cutting edge will crumble.

VIDEO: How to drill a large diameter hole

Tips for choosing a tool

Compared to twist drills, metal core bits are expensive and quite difficult to use tools, so they are produced by a fairly limited number of manufacturers. Core drills from Karnasch, as well as from such well-known brands as Kornor, RUKO, Rotabroach, Bosch, TIZ and Enkor, have a high reputation on the Russian market. When choosing a crown for metal, first of all, you need to focus on the production tasks for which it is purchased. It is important to understand in advance what metal or alloy you will be working on, what the diameter and depth of the drilling will be, as well as the capabilities of your power tool in terms of power and type of socket. All manufacturers in their catalogs provide not only the geometric parameters and types of metal bit shanks, but also indicate what materials it is intended for drilling. In addition, they can find recommended cutting conditions and coolant flow rates. The figure below shows a description of the HARD-LINE series core drill with carbide tips and Weldon shank from the Karnasch catalog.

Sharpening core drills

The cutting tooth of a metal crown is sharpened on three sides with precise control of both the angular positioning of the abrasive wheel and the inclination of the drill relative to its surface.

Therefore, machines for sharpening core drills are quite complex mechanical devices, and sharpening itself requires professional skills. This machine can sharpen core drills of various diameters and with different numbers of teeth. In addition, its clamping device is designed for all types of modern shanks found in various metal bits (Weldon, Nitto, Fein, etc.). This is quite expensive and complex equipment and it makes sense to purchase it only if you intend to provide tool sharpening services. And in order to return the cutting edges of a metal crown to their original sharpness, it is enough to contact a service company with the appropriate competence. The price of such a service is not very high. For example, sharpening a Karnasch GOLD-LINE series core drill with a diameter of up to 25 mm will cost 500–600 rubles. Sharpening work for Anchor metal crowns and Hilti and Makita bimetallic annular drills will cost slightly less.

When sharpening a crown for metal, the protective coating of the cutting edges is completely removed. The price of sharpening work for such a tool is openly published on the websites of specialized enterprises. But we couldn’t find out how much a new titanium nitride coating would cost. If anyone has such information, please share it in the comments.