“Standard” electrodes are very popular because they have high quality and excellent performance parameters. Their distinctive feature is fast ignition, as well as the absence of the need for lengthy preparation for work. Because of these properties, this type of electrode is perfect for beginners. For professionals, they allow them to increase the quality and speed of their work.

Advantages of electrodes

“Standard” is a worthy competitor to the leaders of the welding products market. This applies not only to electrodes, but also to other equipment necessary for this type of work. “Standard” is mainly aimed at simplifying work. This means that those who are just learning to weld should use these rods.

These electrodes are manufactured according to an improved design. They provide the highest technological properties when working with household transformers. Among other things, it is worth noting the easy and quick ignition of the arc. This is useful when learning welding skills. A scaly joint is formed at the seam. The slag is removed independently.

“Standard” is used for tack welds, root and small seams. Work can be carried out in the presence of low voltage. Often these rods are used when working with elements and parts affected by corrosion. These electrodes can also be used to cook products with galvanic coating.

Electrodes Standard RC - analogue of ANO-21

Type of coating – rutile cellulose

| AWS A 5.1:E 6013 | ISO 2560-A - E 38 0 RC 11 | GOST 9466 | E 46 – Standard RC-Ø - UD E 432 (3) RC 11 |

TU U 25.9-34142621-008:2012

Purpose and scope

Standard RC electrodes are intended for manual arc welding of ordinary and critical structures made of carbon steel grades according to DSTU 2651-2005/GOST 380-2005 (St 0, St 1, St 2, St 3) of all degrees of deoxidation - “KP”, “PS” , "SP" and GOST 1050-88 (05kp, 08kp, 08ps, 08, 10kp, 10ps, 10, 15kp, 15ps, 15, 20kp, 20ps, 20).

Directions for use

Designed for welding corner, butt, and overlap joints of metal with a thickness of 3 to 20 mm. Electrodes with a diameter of 2.0 to 4 mm are suitable for welding in all spatial positions; with a diameter of 5 mm - for welding in the lower, horizontal on the vertical plane and vertical “bottom-up” positions.

Welding using the “top-down” method is carried out with a short arc or support, while the electrode should be in a bisector plane at an angle of 40-70° to the welding direction.

Deposition rate – 8.5-9.5 g/Ah. Electrode consumption per 1 kg of deposited metal is 1.7 kg.

Chemical composition of deposited metal, %

| Mn | C | Si | P | S |

| 0,40-0,75 | no more | |||

| 0,11 | 0,15-0,35 | 0,035 | 0,035 | |

Mechanical properties of

weld

| Tensile strength, N/mm2 | Relative extension, % | Impact strength, J /cm2 |

| ≥450 | ≥22 | ≥78 |

Special properties

Standard RC electrodes are made according to an improved recipe, which allows for good welding and technological properties when welding from small-sized (household) transformers: easy ignition of the arc, fine-scale formation of the weld metal, easy or spontaneous separation of the slag crust. Can be used for tack welds, short and root welds at low mains voltage.

Welding data

| Welding current strength, A, for electrode diameter, mm | |||||

| 2,0 | 2,5 | 3,0 | 3,2 | 4,0 | 5,0 |

| 40-80 | 50-90 | 70-110 | 80-120 | 120-170 | 160-220 |

Packaging details

| Diameter, mm | Length, mm | Electrode weight, g | Number of electrodes in a pack, pcs. | Pack weight, kg |

| 2,0 | 300 | 9-10 | 100-111 | 1 |

| 2,50 | 350 | 17-18 | 55-58; 138-147 | 1; 2,5 |

| 3,00 | 350 | 25-26 | 38-40; 96-100 | 1; 2,5 |

| 3,20 | 350 | 30-31 | 32-33; 80-83 | 1; 2,5 |

| 4,00 | 450 | 58-59 | 17; 42;85 | 1; 2,5;5 |

| 5,00 | 450 | 91-92 | 27; 55 | 2,5; 5 |

Analogs

| Manufacturer | Electrode brand |

| ESAB | OK 46.00 |

| LEZ | 46.00 |

| SpecialElectrode | SE OK-46 |

| Oerlikon | Overcord U |

Calcination before welding

Under normal storage conditions, no calcination is required before welding; in case of moistening, drying before welding: 110±10°C 40-60 minutes.

Welding

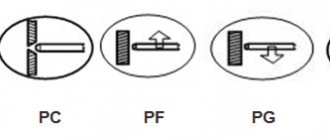

position PA PB PC PF

PG PE PD EN 287

Certification

Certificate of compliance with the UkrSEPRO certification system

Certificate of compliance with state standards of the Republic of Belarus (StB)

State standard of the Russian Federation (GOST R)

Electrode characteristics

The electrodes have a rutile coating. Their parameters comply with all necessary technical standards, including GOST, TU, ISO, DIN. The rods are produced in several diameters: 2.5, 3, 4 mm, etc.

The electrodes are supplied in special packaging, which ensures optimal storage conditions and does not require calcination. If the conditions have been violated and the humidity level has exceeded 0.9%, they should be calcined in a special oven for 40 minutes at 120°C.

Welding electrodes Standard (welder review)

ADVANTAGES:

Rutile cellulose electrodes Standard are an excellent choice for those who are just learning to weld. Why? Everything is very simple. The electrodes are not too demanding on storage conditions and are unpretentious in welding; they operate at subzero temperatures. They are very easy to ignite, have a low level of hygroscopicity, that is, they do not absorb moisture well - this is good for welders! This means that you don’t need to spend time drying in an electric oven, electric pencil case, or use old-fashioned methods passed down from generation to generation, such as drying on a heating radiator in an apartment in winter or calcining a gas stove in a regular oven in the kitchen! Another advantage of electrodes: they are quite common, you don’t need to search for them on the Internet, pay for postal services, they are sold in almost any hardware store. The cost of the pack is reasonable, as is the famous price-quality ratio. The main purpose is welding of metal structures made of low-carbon steel. Electrodes are especially good for setting tacks, when applying short beads and passing the root of a seam. The weld metal is formed by small scales. There are no difficulties with repeated ignitions. The slag is separated very simply by lightly tapping the slag hammer, sometimes the crust separates itself, without additional manipulations by the welder. All these indicators were achieved thanks to the use of a new recipe, which, however, the manufacturer keeps secret. Visually, the electrode coating is distinguished by a red color; each electrode has its own number. On sale you can find the most common diameters for welding: 2.5 mm; 3 mm; 3.2 mm. The electrodes are packed in a thick plastic bag. They can be stored in such a bag even in a damp room, provided that the bag is tightly closed. Unused electrodes should also be wrapped in a bag. However, the electrodes will show better performance characteristics if they are stored in a dry, heated room.

welding equipment

The electrodes are suitable for both an AC welding transformer with an AC voltage of at least 50V, and for a modern DC inverter-type device. The polarity when welding with a DC inverter is any (but it is believed that it is better to weld in reverse). They work great with popular household inverters Resanta, Svarog, Aurora.

Welding modes

Welding steel 1.5-3 mm is carried out at a current of 40-80A; If the steel thickness is more than 3.5 mm, the current is set above 80A. Metal cutting is carried out at a current of over 170A.

FLAWS:

We come across a Standard of very low quality, in which the only advantages that can be highlighted are the use of good cardboard for packaging or the ability to make good-quality hooks for hangers from electrodes. They smoke heavily, ignite and burn poorly, do not ignite again, and the weld pool is practically absent. It's hard to say what could be causing such low quality. Perhaps the reason is counterfeit. The electrode manufacturer itself can produce low-quality goods, since the raw materials are partially imported and the quality of these raw materials may vary from delivery to delivery.

So be careful and have great welds!

Purpose of electrodes

This type of rod is used for manual welding of materials containing carbon compounds. During manufacturing, a minimal amount of harmful impurities is added to them, which reduces the level of toxicity of the emitted aerosol. It is possible to use rods when working with gas and water pipes.

Using these electrodes, corner and butt connections can be made. It is also possible to make an “overlapping” connection, which is necessary when repairing pipes and other metal structures. No preliminary cleaning of surfaces is required. You can work in the presence of rusty areas and residues of different coatings. When cooked, the seam will be dense and uniform and will not lose its properties over time.

“Standard” electrodes allow you to work in various positions. At the same time, the seam will remain high quality and reliable. For welding, direct or alternating current can be used. The mode is selected depending on the direction of the seam and the diameter of the electrodes used.

general information

Standart electrodes are manufactured by the Ukrainian company PlasmaTec. The company produces welding electrodes under various brands. And the “Standard” brand is one of them. Electrodes are sold not only in Ukraine. They can be found in many stores in Russia, Belarus, Poland, Latvia, Moldova and even the Czech Republic.

The “Standard” brand includes electrodes Standard RC (in some stores Standard ANO-21), Standard MR-3, Standard UONI 13/55 and Standard TMU-21U. In short, the most popular brands of electrodes. Most welding electrode manufacturers have them. Their technical characteristics differ slightly from competitors, so welders, first of all, pay attention to the price.

Advantages of ANO-21 electrodes (ANO-21 STANDARD)

So, what are the advantages of welding electrodes ANO-21 (ANO-21STANDARD) with rutile coating? First and most importantly: the same high efficiency and productivity as products with a basic coating, but at the same time - environmental friendliness. Rutile coating concentrate is titanium dioxide, a natural mineral that does not emit substances hazardous to health during the work process. Therefore, welding with such electrodes can be performed in closed, poorly ventilated areas.

Due to the composition of the coating, the weld metal has an increased coefficient of surface tension of the melt. It does not spread even when working in the ceiling and vertical position from top to bottom. This is the second important advantage. Among other advantages:

- thanks to the good electrical conductivity of TiO2, easy instant ignition of the arc is ensured;

- the weld pool is reliably protected from slag particles entering it;

- when the length changes, the arc does not lose combustion stability;

- the volume of sprayed metal is very small;

- the resulting weld is smooth, with a fine-scale pattern, and has high impact strength and tensile strength.

Finally, another advantage that is inherent in all electrodes with rutile coating is that they allow you to weld on wet surfaces, as well as on metal with traces of rust or scale. The risks of pores and cracks in the weld metal are minimized.

Electrodes for welding ANO-21 (ANO-21 STANDARD) - technical characteristics

- The metal composition of the rod is low-carbon steel (Sv-08 or Sv-08A).

- Temporary tensile strength – not less than 450 MPa.

- The proportion of splashed metal does not exceed 4%.

- The rod metal consumption coefficient per 1 kg of deposited metal is 1.65 kg.

- The typical value of the yield strength is 350 MPa.

- Relative elongation – no less than 18%.

- Electrode impact strength ≥80 J/cm².

- Productivity – 1.2 kg/h (for rod d 4 mm).

- Electrode length – from 250 to 450 mm.

Decoding the marking of electrodes for welding

Like many other welding electrodes, ANO-21 (ANO-21 STANDARD) is a product developed by specialists from the Institute of Electric Welding named after. E.O. Paton, who belonged and now belongs to the Academy of Sciences of Ukraine. Hence the simple decoding of the abbreviation and number:

- AN – Academy of Sciences;

- O – general purpose;

- 21 – brand number.

The development of new welding electrodes in the 70s of the last century was caused by an important need. Before this, products with a basic coating were widely used - during the work, the coating released very toxic fluoride compounds, which limited the conditions for their use (welding - only in the open air or in a very well-ventilated area). Scientists have proposed a fundamentally new solution - welding electrodes with rutile coating.