Often there is a need to weld materials that cannot be joined with conventional types of welding, for example, aluminum, copper, titanium, and so on. Therefore, in order to create a durable one-piece structure from these metals, argon welding is used. What is argon welding and how does it work? These and other questions are answered in this article.

What is argon arc welding

Often there is a need to weld plastic materials that do not join with conventional types of welding. For example, copper, aluminum, titanium, etc. To create a durable and permanent structure from these metals, argon welding can be used.

Argon arc welding takes place in an inert gas environment - argon. That is why this welding process is called so.

The use of a gas such as argon in the process of joining parts is due to the need to protect against oxidation due to contact with oxygen. Argon is 38% heavier and denser than air; it covers the welding zone and does not allow oxygen into the area with mating surfaces.

When exposed to oxygen, the quality of welds is seriously affected, and aluminum can ignite. This is why argon is used.

In addition to argon, arc welding uses other gases that create an insulating environment. These are helium, active nitrogen, hydrogen, carbon dioxide.

Criteria for choosing an argon-arc welder

When choosing an inverter for argon arc welding, you should focus on the tasks that are supposed to be solved with its help. First of all, you need to pay attention to the technical characteristics of the selected device.

Maximum value of welding current. The choice should be started with this parameter, since it largely determines the capabilities of the inverter. The thickness and composition of the alloy with which a given specimen can work depends on the magnitude of the welding current.

GOST standards

When using this method, the following legal regulations and standards must be taken into account:

- GOST 5.917-71. Manual torches for argon arc welding;

- GOST 14771-76. Gas shielded arc welding. Welded connections;

- GOST 18130-79. Semi-automatic machines for consumable electrode arc welding;

- GOST 14806-80. Arc welding of aluminum and aluminum alloys in inert gases. Welded connections. Main types, structural elements and dimensions;

- GOST 2246-70. Steel welding wire. THAT;

- GOST 23949-80. Tungsten welding electrodes, non-consumable;

- GOST 10157-79. Argon gaseous and liquid. THAT;

- GOST 7871-75. Welding wire made of aluminum and aluminum alloys;

- GOST 13821-77. Single-station rectifiers with falling external characteristics for arc welding.

Literature

Technical literature

- GOST R ISO 17659-2009 // Welding. Multilingual terms for welded joints. - M.: FSUE “Standardinform”, 2009.

- Cheban V.A.

Welding work / Executive editor: Oksana Morozova, Technical editor Galina Logvinova. — 5th ed. — Rostov-on-Don: “Phoenix”, 2008. — 412 p. — (Primary vocational education). — 3000 copies. — ISBN 978-5-222-13621-8. - Nikolaev G. A. Welding in mechanical engineering: A reference book in 4 volumes - M.: Mechanical Engineering, 1978 (1-4 volumes).

Types of argon welding

There are several types of argon welding. It can be carried out in the following ways:

- Manual.

- Semi-automatic.

- Automatic.

The classification, in addition to the degree of automation of the process, is based on the types of electrodes used.

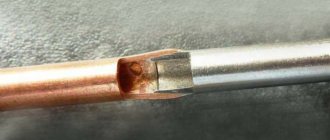

Electrodes are either consumable or non-consumable. An example of the latter electrode is refractory tungsten wire, which allows for reliable connection of parts, even if they are of dissimilar materials in type. Graphite is used less frequently.

Electrodes are produced in different diameters and materials for different metals being welded.

Thus, there are such types of argon welding as:

- Manual - using a non-consumable electrode (this type is labeled as RAD).

- Automatic - using non-consumable electrodes (marked as AMA).

- Automatic - using consumable electrodes (marking - AADP).

The two most common welding methods today are AMA and RAD.

The use of consumable electrodes is only possible in automatic mode. For this purpose, special installations and devices are used, which are welded with a special torch equipped with an electric motor that transfers the wire from the spool. The consumable electrode is simultaneously used for ignition and acts as soldering material. During the ignition process, the conductor melts and provides mass for the seam.

Argon arc welding diagram

Automatic argon arc welding is mainly used only at various industrial enterprises (in particular, for the production of metal structures, for welding copper busbars in stationary and installation conditions), which is associated with the high cost of automatic installations and the complexity of their setup. It is much easier to weld several parts manually, but if high productivity is required, then you cannot do without equipment.

Types of equipment

For argon arc welding, 4 types of equipment can be used:

- Manual welding requires the welder to hold the torch and filler wire with his own hands.

- Mechanized version , in which the welder holds the torch and the wire is fed mechanically.

- Automatic argon arc welding - with this method of implementing the process, a welder is not needed, he is replaced by an operator who monitors the process, because the supply of the torch and filler wire is carried out automatically.

- Robotic welding process - in this case, neither a welder nor an operator is needed, the entire procedure is carried out within the framework of a program that is fully responsible for the production process.

Technology

Let's consider the technology of argon welding based on manual welding with a non-consumable electrode.

Necessary equipment

Welding equipment includes:

- Welding machine of any type for arc welding with a voltage of 60-70 volts.

- Power contactor , which supplies voltage from the welding material to the torch.

- An oscillator is a device that converts a mains voltage of 220 volts and an oscillation frequency of 50 Hz into a voltage of 2000-6000 volts. The specified current parameters make it easy to form an arc.

- Ceramic burner.

- Device for blowing the welded area with argon.

- Argon cylinder.

- Electrode and filler wire.

Approximate cost of welding machines on Yandex.market

Additional options may include a time regulator for argon blowing, hoses and fittings, etc.

If you want to calculate the economic efficiency of gas-shielded arc welding, then, in addition to the cost of the welding machine itself, you need to take into account the price of consumables: filler rods, wire, argon in cylinders, hoses of different sizes, etc.

Filler wire is made from various materials: aluminum, cast iron, stainless steel, copper, etc.

Approximate cost of welding wire on Yandex.market

Argon is supplied from special cylinders with a standard operating pressure of 150 AM. Cylinders come in different sizes: 5, 10, 20, 40 liters, etc. It is gas that is the main and most expensive consumable for this welding.

Approximate cost of argon cylinders of different volumes on Yandex.market

Hoses, fittings and other work parts wear out frequently and must be replaced periodically.

We also must not forget that personal protective equipment is needed to carry out the work: gloves, mask, overalls.

Execution steps

When performing manual argon arc welding, you must adhere to the following algorithm of actions:

- Set welding mode.

- Clean metals to be joined.

- Turn on the button on the torch handle to supply shielding gas to the welded area (take the torch in your right hand). This should be done approximately 20 seconds before welding begins. The filler wire should be in your left hand.

- The burner is lowered so that there is a distance of up to 2 mm between the electrode and the surfaces . The electrode from the burner must be inserted into the burner so that a rod no longer than 5 mm remains on the surface.

- Turn on the welding machine and transfer voltage to the electrode . An arc appears between it and the metal, and argon is supplied from the torch to the welding zone. The filler wire melts under the action of an electric arc and covers the gap.

- Move slowly along the seam.

It is advisable not to ignite the electrode by contact with the metals being welded, as in conventional welding; an oscillator is used for this (it supplies high-voltage pulses to ignite the arc). Without it, the tungsten electrode becomes dirty.

What affects the quality and size of the weld

For proper welding, four basic principles must be observed:

- Correct settings : to hold the desired arc, you need to adjust the supply of gas, current, rod, etc.

- The skill of the welder , which guarantees the continuous creation of a high-quality seam.

- A properly organized workplace . In this case, it is important to have a heat-resistant table, the ability to fix the part, good ventilation, etc.

- Correctly setting up equipment for work.

Knowing certain rules when welding with argon allows you to achieve high quality welds:

- To create a narrow and deep seam, you should adhere only to the longitudinal movement of the electrode and the torch . Any lateral movements and deviations will reduce the quality of the connection. Therefore, during the welding process, the welder needs to be careful and attentive.

- The longer the welding arc, the wider the seam and the shallower its depth . Ultimately, this reduces the quality of the connection. Therefore, during the process it is recommended to keep the non-consumable electrode as close to the joint as possible.

- The filler wire must be fed as evenly and smoothly as possible ; abrupt feeding is unacceptable.

- It is better to supply gas from the opposite side of the welding track . This, of course, will increase its consumption, but will significantly increase the quality.

- The filler wire together with the electrode must be in the welding zone , covered with argon, to prevent nitrogen and oxygen from entering there.

- The wire is fed in front of the torch with the electrode at an angle , which ensures the evenness of the seam and its small width.

- It is important to achieve good penetration values . In argon arc welding, it is determined by visual inspection of the seam: if it is round and convex, then this is evidence of insufficient surface penetration.

- Welding under argon should not start and end abruptly, otherwise the access of oxygen and nitrogen to the welded zone will be open . It is recommended to start welding 15-20 seconds after supplying inert gas, and finish 7-10 seconds before turning off the burner. This is required so that the material has time to crystallize in an argon environment without exposure to oxygen.

- Before welding large products, you need to make test seams on small workpieces or in an unimportant area.

Before starting work, metal products must be cleaned and degreased.

To reduce the financial costs of welding, you can use not only pure argon, but also its mixture with other gases.

How to cook?

Do-it-yourself argon welding involves following a certain technological process. It consists of several stages:

- Prepare your work surfaces. Remove any layer of dirt, plaque, or rust from them.

- Degrease the parts.

- Set up the welding machine.

- Turn on the gas supply. After 20 seconds, strike the arc.

- Towards the end of the seam, reduce the current. After the arc dies out, leave the gas open for another 10 seconds.

It is important to make uniform movements and maintain a short arc length.

Argon welding is a technological process of joining metal parts, which occurs under the protection of inert gas. In this way, you can work with various metals and alloys, avoiding the formation of an oxide film.

Modes

Welding under argon will be of the highest quality if the optimal mode is correctly selected. The choice of mode is based on the following components:

- properties of welded metals . They determine the choice of current supply direction and polarity. For example, for welding steel structures, direct current of direct polarity is used, for welding aluminum and beryllium - direct current with reverse polarity;

- current strength . It is selected based on the diameter of the electrode that the welder uses; based on the type of metal to be welded, the thickness of the metals and the polarity. For example, for welding titanium, the operating mode is determined by the following parameters, from which it follows that the thicker the metal being joined, the larger the diameter of the tungsten electrodes should be:

| Material thickness | Electrode diameter, mm | Current strength, A |

| from 0.3 to 0.7 | 1,6 | 40 |

| from 0.8 to 1.2 | 1,6 | from 60 to 80 |

| from 1.5 to 2.0 | 2 | from 80 to 120 |

| from 2.5 to 3.5 | 3 | from 150 to 200 |

- welding arc length . The tension depends on it (as noted, the length of the arc directly affects the quality of the seam);

- gas consumption depends on the strength and uniformity of its supply by the burner . Experts recommend avoiding pulsations.

Advantages and disadvantages

Argon arc welding has its advantages and disadvantages. Its key advantages are:

- The process provides a low heating temperature . This preserves the shape and size of the workpieces.

- The inertness of argon provides high protection of the welded area.

- The welding process is extremely simple and easy to learn (although it is not possible to start welding without training).

- The process uses a high-power arc , which ensures fast welding.

- The technology allows you to connect different types of metals that cannot be bonded in other ways.

- Requires rare electrode replacement.

The high quality of weld seams obtained by argon arc welding allows the method to be used in industries in which there is a high need for high-quality metal welding. In particular, the method can be used and has found distribution in the aviation, nuclear, food industries, medicine, and mechanical engineering.

Additional advantages of automatic welding are efficiency in joining several parts , as well as the elimination of human error. To maintain such an installation, a minimum number of personnel is required.

The disadvantages of the process are the complex welding equipment, in which it is difficult to adjust the modes . This limits the use of the method by beginners: the welder requires experience and dexterity. When a high-ampere arc is needed during the joining process, the welder needs to consider additional cooling of the joints.

also necessary to provide good protection from wind and draft so as not to lose argon protection, which complicates the practical application of the method. Therefore, it is recommended to perform such work indoors. With the manual method, the limitation of the method is the low cost of performing the work.

Limitations in the use of an automatic installation are the inability to weld any non-standard seams, the high cost of equipment, limitations on setting parameters; if the machine malfunctions, the entire batch of products may become defective.

Another disadvantage of this method is the high cost of argon . In practice, welders sometimes replace it with helium and carbon dioxide, but such a replacement is not always possible: it all depends on the type of metal to be welded.

Welding safety

Almost all safety rules for welding in argon relate to preliminary preparation for the process. The likelihood of a hazardous situation occurring is minimal with proper preparation. Here are the basic principles for ensuring safety when welding using the argon method:

- The specialist has no right to carry out adjustment and repair procedures while the device is running..

- There must be at least 10 meters from the gas source to the fire source.

- During automatic welding, no manipulations are allowed . This can not only disrupt technology, but also harm health.

- Before starting work, you need to check the grounding of the welding machine, the reliability of the hose for supplying argon and water (if the torch is supposed to be cooled with water), check the seals on the pressure gauges, the threads on the union nuts, and the insulation of the holder handle.

- On automatic welding machines, a folding shield with a light filter is installed on the welder's side . Electrical wiring and tubes are contained in a common rubber hose. Burners must not have exposed live parts.

- The burner handles are covered with material and a shield that protects the welder’s hands from burns.

- During the welding process of some metals (in particular, copper and aluminum), toxic gases are released , so the room must be provided with good ventilation or an air supply.

- In exceptional situations, work should be carried out wearing a gas mask . In order to avoid burns from hot aluminum, molding spacers are used on horizontal seams, and movable curtains are used on vertical seams.

- Cleaning of aluminum additives in caustic soda solution should be carried out using rubber gloves and goggles for protection.

Thus, argon arc welding allows high-quality welding of special types of metals that cannot be joined by other methods. These are aluminum, copper and non-ferrous metals. With standard welding, it is not possible to obtain a high-quality and reliable seam for joining refractory workpieces. A special feature of welding is that it is carried out in a shielding gas environment. Argon provides reliable protection of the welding zone from the influence of external adverse factors.

Device

To work in an argon environment, various welding devices are used.

The choice may fall on a manual control method, in which case the specialist himself holds the torch and supplies a metal wire to the welding area, or an improved portable method, when a metal wire is fed into the device.

There are also devices powered by electronics and cooked under the influence of argon. The torch and metal wire are supplied to the welding area automatically; sometimes the master does not need to control what is happening; a master is provided for this.

In mass production, robotic devices are used that independently control the process. They are directly programmed to perform argon welding tasks.

Let's get to work. We will explain the use of a welding machine when working in an argon environment, so that the result will satisfy you and serve you for many years.