Instead of various fasteners, dowels and corners made of wood were previously used. Today there are many more options; in addition to confirmatories and eccentric ties, furniture bolts are common on the market. They are similar to the usual construction hardware, but at the same time they have their own characteristics. The appearance of the furniture does not deteriorate due to its design features. Before buying bolts, you need to decide on their size, material and other technical parameters so that the assembly is of high quality.

Overview of species

Depending on how the furniture structure will be used, there are also types of bolts with a semicircular head. Furniture hardware is divided according to design and size. In addition, models may differ in color - it can be black or silver, yellowish or copper.

By design

In addition to bolts with a round head, furniture makers also have other types of hardware that differ from each other in their design.

Confirmat (euroscrew) - this hardware has the shape of a working rod in the form of a long cylinder with a countersunk head located at one end. On the surface of the head there are slots designed for a Phillips or hex screwdriver. The size of the cylindrical working rod depends on what the Euroscrew will be used for. For example, to connect a particle board whose thickness according to standards is 16 mm, you will need a confirmat 16 mm long. Sometimes longer hardware is used to connect two elements, the length of which can reach 50 or 60 mm.

The most common parameters of a Euroscrew are 7x50 mm, and the configuration of their splines is most often in demand for an internal hexagon. You can screw such a confirmation using a screwdriver or a screwdriver into which a bit with six edges is inserted.

Euroscrew is used in the manufacture of furniture to create rigid and durable fastening of parts to each other. Such fastening would not have been possible if it were not for the metric threads on the working body of the Euroscrew. The disadvantages of the confirmat are that fastening using it is quite difficult, since this procedure requires great precision. In addition, the design of the fastener is visible on the furniture product; special decorative plugs help to hide it, but this cannot be done completely.

Using a conical tie is quite difficult, so creating such a fastener requires a high degree of skill and experience in performing the work. An additional disadvantage is that the hardware has a small resource for repeated cycles of disassembling and assembling a furniture product.

This type of hardware is also difficult to install and requires highly qualified craftsmen. In order to accurately join furniture elements, you will need not only to perform the correct markings, but also drilling and milling. These manipulations are performed only with the use of special equipment.

This type of fastening is quite easy to use. This is a reliable option for hardware for furniture assembly and can be used repeatedly.

As for the semicircular head, such a smooth shape provides the consumer with comfortable and safe use without the threat of injury from the protrusions of the hardware. This type of bolt is not only reliable and safe, but also does not spoil the overall appearance of the furniture. You can see similar hardware in almost every design of a bed, chair or sofa.

By shape

Furniture hardware can differ from each other not only in structural features, but also in appearance. For a certain type of assembly, different types of fasteners are used.

Flange type - hardware with a flat round washer, which is located under a semicircular head.

Confirmat

The most common type of fastener is confirmat.

At the same time the easiest to use. With its help, assembling furniture is easier and faster than using other types of furniture screed. Especially if during assembly you have to drill holes for fasteners yourself. Using a confirmat, two parts are connected at an angle of 90 degrees. Fig.1.

Confirmat - used to connect parts at an angle of 90 degrees. The two parts are connected with 2 confirmed screws. The confirmat is installed at a distance of 3-7 cm from the end of the parts to be connected. To install 1 confirmation screw, you must first drill 2 holes in the parts to be joined: in the end of the first part for threads (drill diameter 5 mm), in the second part for the head (drill diameter 6 mm).

In order to tighten the two parts, you need to drill two holes. One in one part, with a diameter equal to the diameter of the confirmator head, the other, at the end of the second part, with a smaller diameter equal to the diameter of the threaded part.

As a rule, drills with a diameter of 6 and 5 mm are used for this, respectively.

However, there is a combination drill available for drilling holes at the same time. It is very comfortable. There is no need to constantly rearrange drill bits or use two drills at the same time. Fig.2.

Drill for confirmation. Allows you to make a hole for 1 confirmat screw in two parts at once, and also forms a recess for the confirmat head. Increases the speed of furniture assembly by at least 50%.

Confirmat is a universal fastener, but it has some disadvantages and application features.

Confirmat should be used simultaneously with the use of dowels.

A dowel is a wooden rod with a diameter of 6-8 mm and a length of 20-30 mm (in the photo below, next to the confirmation). The dowel acts as a guide and does not allow parts to move during tightening. Fig.3.

Connecting the parts using a dowel with a diameter of 6-8 mm and a confirmat. This joining method is used in factory furniture, for example furniture from IKEA. Provides high accuracy of joining parts.

Despite the fact that furniture assembled using confiramate can be assembled or disassembled, furniture made from laminated chipboard does not tolerate this very well. As a rule, after one disassembly, the furniture screed no longer holds well.

Dimensions

Modern manufacturers produce furniture hardware in a varied size range. The bolt parameters are indicated using a code, for example, M8x30, M4 6x40 or M5 6x50 A4, where:

- M5 is a metric thread and its pitch on the hardware rod, there are markings M4, M6, M8, M10, M12;

- number 6 – diameter of the bolt stud excluding thread, in mm;

- number 50 is the length of the hardware, in mm;

- A4 – grade of stainless steel.

The minimum size for the length of furniture hardware is 40 mm, and the maximum can reach 120 and even 150 mm (in products with a square headrest). The diameter of a furniture bolt ranges from 5 to 7 mm.

Installation Tips

When purchasing cabinet furniture, it also includes a set of hardware for assembly. If you are assembling furniture yourself, you will need to stock up on a certain type of tools:

- hexagon and Phillips screwdriver;

- screwdriver;

- electric drill and drill;

- wrench.

To assemble upholstered or cabinet furniture, you must first mark out future holes - this stage of work must be approached responsibly, since this moment is the key to successful and accurate assembly. After marking, you need to make holes according to the markings using a drill and a drill. Sometimes such holes are already made in furniture production.

Following the instructions, you need to fasten all the elements of the furniture product using the hardware included in the kit. To make the fastener reliable, you need to tighten the hardware all the way, but excessive efforts are unnecessary here - you can break the threads of the bolt. You need to tighten furniture bolts and ties using a hexagon or screwdriver.

Furniture joints are described in the following video.

general description

Until metal fasteners appeared, furniture parts were assembled using wooden dowels or corners. Modern furniture bolts are manufactured according to GOST standards; they have one of the main positions in the furniture industry. A bolt intended for assembling cabinets or chairs is different from construction hardware, also called a bolt. Furniture-type hardware provides not only strong fastenings, but also does not spoil the aesthetic appearance of the finished product.

The cylindrical shaft has a metric thread that allows the nut to be attached to the bolt shaft. The most popular are bolts with a hemispherical head.

The reliability of the hardware is explained by the fact that it is made from durable alloys. Most often, the bolts have a galvanized coating that protects the fastener from corrosion. Sometimes you can find furniture hardware made from aluminum alloy or polymer plastics. If we compare the strength of construction bolts, then furniture hardware, of course, is inferior to them, since they do not need to support excessively large weight loads. For this reason, furniture hardware costs less than construction bolts.

Advantages

Furniture bolts with a mustache have a number of advantages. Let's highlight only the main ones.

- The absence of even the slightest protrusions and sharp edges on the semicircular head that could cut a person who touched them. Therefore, such fasteners ensure maximum safety for furniture owners during its operation.

- The appearance of the furniture set does not deteriorate. After assembly, only the smooth hemispherical head rises above their parts. Such bolts are found in the design of every type of modern furniture: beds, sofas, armchairs, etc.

- The seat is protected from small cracks and from the occurrence of faults. This is ensured by the presence of a larger clamping area due to the increased diameter of the bolt head. This parameter is of paramount importance when working with laminate and structures made of chipboard, plywood, and natural wood.

- Reasonable cost. The price of the products in question is several times lower than those used in mechanical engineering. Of course, the strength of the latter is higher. But this does not mean at all that this indicator for furniture bolts is uncritical. Before purchasing a batch of such fasteners, a furniture manufacturer should require that the selling company present a certificate of product quality compliance with GOST requirements.

GOST 7802 regarding bolts

The protocol standardizes the diameter of fasteners for furniture with headrests in the form of squares and enlarged heads made in the shape of semicircles. Nominal thread sections should be 5−24 mm with cross-sections of the heads themselves 11−52 mm

Attention is also drawn to:

- head length;

- headrest height;

- dimensions of the side of the headrest;

- head section;

- thread length.

https://youtube.com/watch?v=WOMQCF2Fm9w

GOST 7802 contains a number of references to other important standards governing the production process. I remember, in particular:

- 24705 - description of the thread with detailed descriptions;

- 27148 - regulation of permissible thread undercuts and maximum run-outs;

- 24670 — dimensions of the radii under the heads;

- 1759.0 - list of technical requirements for bolts;

- 12414 - sizes and shapes of ends.

The testing procedure for elements with square headers is set out in Gosstandart 1759.1.

It should be noted that furniture bolts are different from furniture screws. The second ones have a countersunk head (hexagon) and are produced according to DIN912. They are easy to tighten; the screws actually seem to “sink” into objects made of wood. Thus, the fasteners have an additional decorative function, because the head will not rise on the surface. Screws with internal hexagons in our country are made in accordance with the requirements of State Standard 11738.

with an enlarged semicircular head and a square headrest; accuracy class C

Screw classification

Let us now consider the screws available in the TsKI assortment. The largest group of them are general purpose screws. We meet them every day in everyday life and at work. They all have a fully threaded shaft (although there are exceptions) and different shaped heads. The heads have slots or recesses for different types of keys.

Another large group of screws are set screws. The name comes from their purpose. For the most part, they are designed for precise installation and fixation of parts in mechanisms. To do this, they have various protrusions or recesses at their ends.

According to GOST 12414-94 (ISO 4753:1999): “Ends of bolts, screws and studs. Dimensions" the following setscrew ends are provided:

The torque is driven by the following elements:

The summary table shows the actual, most common combinations of setscrew heads and ends, indicating the DIN standard.

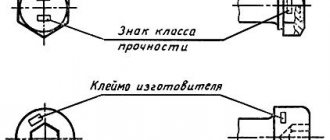

Strength classes

The grade of steel from which furniture hardware is made determines its strength class. In the furniture industry, fasteners are used whose strength varies from 4.6 to 12.9. The decoding of these numbers is as follows:

5.6 is 5x100 = 500 N/mm2, while the material flow ratio is 60%.

The most in demand in the furniture industry are hardware, the class of which is from 4.6 to 6.6 and 6.8 as well. If it is necessary to connect the heavy and most critical parts of a furniture structure, hardware is used whose strength is 8.8 - they are called high-strength. The higher the strength of the hardware, the more expensive its cost.

Related Posts via Categories

- Strength class of bolts - how well do hardware resist destruction?

- Anchor bolt with nut - proven fastening option

- Dowel-nail – which fasteners are of the highest quality?

- Anchor bolts - a special type of fastener for complex structures

- Designation of bolts according to GOST - navigating the world of hardware

- How to set a rivet - automatic and manual methods for different materials

- Making bolts is a clear technological process

- Needle spring cotter pin – eared fastener for mechanical engineering

- High Strength Bolts - Complete Information on Fasteners

- Blind rivet sizes – what should you think about when calculating?

Installation features

Fastening wooden furniture parts using such fasteners involves 3 stages.

First, holes are drilled in the mating elements.

The bolt is inserted into the holes. With a light blow of a hammer, this fastener is fixed in place.

A flat washer according to GOST 11371-78 is put on the threaded part of the bolt. Then a hex nut with similar thread characteristics is screwed on.

This is what the connection of wooden furniture parts will look like in cross-section.