An anchor bolt with a nut is a relatively new type of fastener, the design of which is specially designed to ensure reliable fixation of objects of significant size and weight. When choosing such a bolt as a fastener, you should have a good understanding not only of its technical capabilities, but also of the installation rules, operation and areas of application of this product.

Anchor bolt with nut is used for fastening in concrete, stone and solid brick

Parameters and requirements of the regulatory document

When choosing anchor fasteners to solve a specific problem, you should focus on the relevant regulatory documentation (GOST), the provisions of which indicate all the parameters of such products. GOST requirements stipulate not only the dimensions and weight of the anchor bolt with a nut, but other technical characteristics (in particular, the level of maximum load that it is able to withstand).

The smallest fastener of this type, according to the provisions of GOST, is an anchor, the dimensions of which are 5x6.5x18 mm. If it is made from high-quality material, it can withstand a load of up to 800 kgf (for tearing). In other words, with the help of such a small anchor, you can fasten an object whose weight is 800 kg. In practice, anchors are usually chosen whose maximum permissible load, specified in the regulatory documentation, significantly exceeds the mass of the fixed product.

In accordance with the main parameters (diameter, length, permissible load level), all anchor fasteners are divided into several classes, which is also specified in the regulatory document for such products.

Installation parameters of anchor bolts with nut

Technical characteristics of anchors

Important parameters of anchor-type bolts are their dimensions. When choosing a fastener by size, you should focus primarily on the weight of the object being fixed with it: the higher this indicator, the longer and thicker the bolt should be. Naturally, the thickness of the structure in which the anchor will be installed should also be taken into account. Otherwise (if the length of the bolt is chosen incorrectly), you can pierce the wall or floor with it.

The minimum length of the anchor bolt studs produced by modern industry starts at 18 mm. This parameter can reach a value of 400 mm. If we talk about the diameter of anchor bolts with a nut, which is calculated by the diameter of the spacer sleeve, then the standard stipulates a minimum value of 6.5 mm. As the length of the stud increases, the diameter of the anchor also increases and can reach 20 mm.

Bolts with the maximum diameter of the spacer naturally have the maximum load-bearing capacity, but when choosing such fasteners, you should take into account the condition and dimensions of the structure in which they are supposed to be installed.

Types of fasteners

Spacer and double-spacer elements inside structures operate due to friction. The forces that the anchor takes are transferred to the base when the rod rubs against the walls of the hole. This requires expansion force due to the steel collet.

All anchor bolts according to GOST, regardless of purpose and type, have structural parts :

- lower anchor - concreted to the maximum depth for reliable fastening;

- threaded rod - the main organ for absorbing forces;

- The top part is different for all bolts.

Valera

The voice of the construction guru

Ask a Question

To distribute the load, the thrust force that the bolt receives and compensates for due to the strength of the material from which it is made is also important. Foundation studs are sold separately or as a set with anchor plates, pressed washers, nuts, collets and couplings.

Curved

They are installed to fix iron elements and structures to concrete and reinforced concrete bases . The bolts are secured with nuts and washers. The latter are needed to distribute the load on the surface so that the anchor does not fall into the body of the base.

The products have the shape of a curved rod and are available in two versions:

- a fastener bent at a right angle on a straight pin at the lower section;

- curved into a hook or Z shape below the center of the stud.

For different parts and methods of fastening, there is a metric thread of the selected size and pitch at the top of the barrel. It should not be less than 100 mm. Screw two nuts onto it, and place a washer between them. The length of such rods can be up to 2.5 meters, and the outer section is 16-48 mm.

With anchor plate

The length of anchor rods of this design can be up to 5 m . The fastening point is protected by a plate; the steel part is pulled through it with a nut and washer. In appearance, this structure is presented in the form of four rods, onto which a metal plate is welded on top. The thickness of the slab (16 - 50 mm), studs, plates depends on the calculation of the loads that act on the base.

Features of the anchor panel:

- made of low-alloy structural metals, the type of material is indicated in the marking of the foundation bolts;

- must be connected to the bolts motionlessly and securely;

- protected from destruction and rust;

- Made to order, taking into account the parameters of the bolts.

The shape of the slab can be round, but rectangular and square versions are more often made. Plates marked M30 and M46 are installed to increase the rigidity of the joint, and M42 and M48 are used on foundation blocks.

Composite

This type is used for fastening structural parts . It consists of two or three rods with threaded ends, which are connected to each other using a coupling or bushing with a thread inside.

Features of composite foundation anchors:

- external diameter is 24 – 64 mm;

- for joining individual rods, hex nuts and flat pressed washers are used;

- There are options with a top anchor plate;

- produced from carbon and heat-resistant metal;

- Some models are protected from rust by a zinc layer.

The lower pin of the composite stud is placed in the formwork before concreting, the upper one is then screwed into the coupling and welded after installation of the equipment.

Removable

Presented in the form of a metal rod, which includes a special anchor system in the structure. Such models are designed for installation in stone walls, brick fences, and reinforced concrete.

Removable models are available in three versions :

- composed of several parts;

- solid cast;

- The parts of the rod are connected by welding.

The length ranges from 20 to 180 cm, diameter 24 – 125 mm. Removable bolts are used to install engineering products for various purposes. They are used for electrical, forging, and pressing equipment, when machines and units must be replaced over time.

Direct

Standard iron rods up to 140 cm long with screw threads. They are installed in ready-made reinforced concrete without preliminary concreting of the lower part, and the finished structures are pulled together . During the anchoring process, the hole intended for the pins is filled with a cement mixture or special glue.

Distinctive features of the products:

- external thread diameter 12 – 48 mm;

- the material is heat-resistant, alloyed and carbon metal;

- Designed for use in cold and temperate climates;

- has a zinc coating.

The kit includes a stud, two hex nuts, and a flat washer.

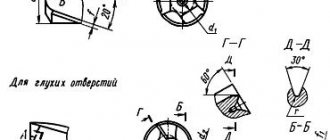

With tapered end

A separate type of foundation rods, characterized by a spacer anchor at the bottom of the shank . After installation, this fastener cannot be removed without dismantling the concrete base.

Feature of Conical Type Foundation Bolt:

- the thickening in the lower part is unclenched by placing a special collet and a conical bushing in the hollow rod;

- they can be installed in the base after the concrete mixture has hardened;

- there are models made from different types of steel, so designs are selected according to their load-bearing capacity for different applications;

- durability is imparted by galvanizing and heat treatment.

The special shape of the rod works effectively if effective tightening is applied and full threads are applied across the entire surface.

Anchor stud expansion galvanized GOST 28778-90 GOST 24379.1-80 for installation in concrete.

Thus, depending on the specific task, you can choose one of the installation depths: - The maximum anchoring depth is designed for maximum loads on the chemical anchor. — As a result of reducing the anchoring depth, the working length increases, which makes it possible to install a part of greater thickness. Thanks to shallower anchoring depths, the required minimum thickness of the building base for installing a chemical anchor is reduced.

Foundation bolts with anchor plate type 2.1 GOST 24379.1-80

Foundation bolts with anchor plate type 2.2 GOST 24379.1-80

Foundation bolts with anchor plate type 2.3 GOST 24379.1-80

Composite foundation bolts type 3.1 GOST 24379.1-80

Composite foundation bolts type 3.2 GOST 24379.1-80

Removable foundation bolts type 4.1 GOST 24379.1-80

Removable foundation bolts type 4.2 GOST 24379.1-80

Removable foundation bolts type 4.3 GOST 24379.1-80

Straight foundation bolts type 5.1 GOST 24379.1-80

Foundation anchor bolts with conical end type 6.1 GOST 24379.1-80

Foundation anchor bolts with conical end type 6.2 GOST 24379.1-80

Foundation anchor bolts with conical end type 6.3 GOST 24379.1-80

Foundation studs position 5 GOST 24379.1-80

Foundation studs position 9 GOST 24379.1-80

Foundation anchor plates GOST 24379.1-80

Foundation anchor coupling

Anchor fittings version 1 GOST 24379.1-80

Anchor fittings version 2 GOST 24379.1-80

Anchor fittings version 3 GOST 24379.1-80

Composite anchor plate GOST 24379.1-80

Welded anchor plate GOST 24379.1-80

Foundation anchor collet GOST 24379.1-80

Foundation washers GOST 24379.1-80

Installation recommendations

Tighten the nuts on the threads of the anchors so that the friction force inside is greater than the force in the bolt due to the load. In this case, favorable conditions are created, the pin only works to break. Sometimes custom-made fasteners are better if you cannot choose from standard ones.

Installation procedure:

- markings are carried out on the site of the future foundation;

- After pouring, the lower part of the anchor is immersed in fresh concrete to the required depth;

- tie the element to the walls of the formwork with wire so that it does not go into the concrete;

- a through hole is drilled in the mounted structure, and the upper pin is passed through it;

- After the concrete has set, the upper part of the bolt is screwed into the lower sleeve.

The immersion depth is maintained in order to maintain the strength and load-bearing characteristics of the fastening element.

Anchor stud expansion galvanized GOST 28778-90 GOST 24379.1-80 for installation in concrete.

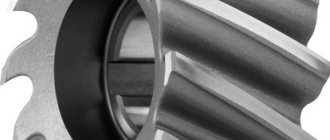

Double spacer anchor bolts equipped with a nut

The most effective fastener for fixing objects of significant weight on various surfaces is an anchor bolt with a double-expansion nut. Even from the photos of such fasteners, we can conclude that they have a higher load-bearing capacity compared to conventional anchor bolts.

A design feature of this type of bolt is the use of two bushings at once, mounted on a threaded rod. One of these bushings has a cone-shaped shape and, when the nut is tightened, it enters into the second element, pushing it apart. Thus, inside the mounting hole there are two loosened bushings at once, which significantly increases the load-bearing capacity of the bolt.

Double-expansion anchor is intended for solid materials; use in hollow-core structures is not recommended

The ability of a double-spacer anchor product to withstand significant loads not only of a static but also of a dynamic nature allows it to be successfully used not only in construction and repair, but also in production. In particular, it is with the help of such fasteners that heavy industrial equipment is installed, which during operation creates significant vibration loads.